设计简介

摘 要

加工中心是指在一次装卡中,能够实现自动铣削、钻孔、镗孔、铰孔、攻丝等多工序的数控机床。更为明确的说法是:加工中心就是自动换刀数控镗铣床。这就把加工中心和自动换刀数控车床和车削中心区别开来。加工中心区别于别的数控镗铣床的主要特点就在于它具有根据工艺要求自动更换所需刀具的功能,机自动换刀(ATC)机能。

加工中心的自动换刀系统,通常是由刀库和机械手组成,它是加工中心的象征,又是加工中心成败的关键环节。因此各加工中心制造厂家都在下大力研制动作迅速、可靠性高的自动换刀装置,以求在激烈的竞争中取得好的效益。正因为自动换刀装置是加工中心的核心内容,各厂家都在保密,极少公开有关资料,尤其机械手部分更始如此。

加重中心的自动换刀形式,可分为有机械手换刀方式和无机械手换刀方式。加工中心的ATC,大都采用有机械手的换刀方式,因为更节省时间。

由于液压驱动的机械手需要采用严格的密封,还需较复杂的缓冲机构,控制机械手动作的电磁阀都有一定的时间常数,因为换刀速度较慢。近年来国内、外先后研制出凸轮联动式单臂双抓机械手。这种机械手的优点是由电机驱动,不需要较复杂的液压系统及其密封、缓冲机构,没有漏油现象,结构简单,工作可靠。同时,机械手手臂的回转和插刀、拔刀的分解动作是联动的,部分时间可重叠,从而大大缩短了换刀时间。

关键词:机械手;加工中心;自动换刀

Abstract

Machining Center is installed in a card, to achieve automatic milling, drilling, boring, Reaming, Tapping and other processes of CNC machine tools. A more explicit statement of Machining Center is the automatic tool change CNC milling machines. This brings the processing center and automatic tool change CNC lathe and turning centers to distinguish.

Machining Center is different from other CNC milling machines to the main features is that it has under the technological requirements for automatic tool change function, Automatic Tool Change (ATC) function.

Machining Center, ATC system is usually a knife and the composition manipulator, it is a symbol of the processing center. Machining Center is the key to success. Therefore the processing center manufacturers are vigorously developing the next moves quickly, high reliability, ATC, to the fierce competition to achieve good results。It is precisely because of automatic tool change is the core processing center, the manufacturers are confidential, rarely disclose the information In particular, some manipulator so start anew.

Add to the automatic tool change form, it can be divided into a manipulator tool change and free manipulator ATC way. ATC machining centers, most using a manipulator tool change, because it is more time-saving.

Due to hydraulic-driven manipulators need strict sealed need more complex buffer, manipulator control of the solenoid valve moves have a certain amount of time constants, because slower speed up the pace. In recent years, domestic and foreign has developed a cam linkage arm-grasping manipulator. This manipulator from the advantages of motor-driven, not more complex hydraulic system and its sealed buffer, no leakage, simple, reliable. Meanwhile, the manipulator arm and rotary knife inserted, the decomposition Everyone moves are linked, and some may overlap time, thus greatly reducing the time ATC。

KeyWords:Manipulator; Machining Center; Automatic tool change

目 录Machining Center is different from other CNC milling machines to the main features is that it has under the technological requirements for automatic tool change function, Automatic Tool Change (ATC) function.

Machining Center, ATC system is usually a knife and the composition manipulator, it is a symbol of the processing center. Machining Center is the key to success. Therefore the processing center manufacturers are vigorously developing the next moves quickly, high reliability, ATC, to the fierce competition to achieve good results。It is precisely because of automatic tool change is the core processing center, the manufacturers are confidential, rarely disclose the information In particular, some manipulator so start anew.

Add to the automatic tool change form, it can be divided into a manipulator tool change and free manipulator ATC way. ATC machining centers, most using a manipulator tool change, because it is more time-saving.

Due to hydraulic-driven manipulators need strict sealed need more complex buffer, manipulator control of the solenoid valve moves have a certain amount of time constants, because slower speed up the pace. In recent years, domestic and foreign has developed a cam linkage arm-grasping manipulator. This manipulator from the advantages of motor-driven, not more complex hydraulic system and its sealed buffer, no leakage, simple, reliable. Meanwhile, the manipulator arm and rotary knife inserted, the decomposition Everyone moves are linked, and some may overlap time, thus greatly reducing the time ATC。

KeyWords:Manipulator; Machining Center; Automatic tool change

摘 要 I

Abstract II

1 绪 论 1

1.1国内外数控机床的的发展情况 1

1.1.1 加工中心发展简史 1

1.1.2 加工中心的主要优点 2

1.1.3 加工中心的发展趋势 3

1.2可编程控制器的特点 5

2换刀机械手的相关介绍 7

2.1 数控技术的发展历程 7

2.2数控加工中心的基本功能 7

2.3加工中心的组成部分 8

2.3.1 刀库 8

2.3.2 刀具交换装置(机械手) 8

2.3.3 运刀装置 9

2.3.4 刀具编码装置 9

2.3.5刀具识别装置 10

2.4刀库的驱动及定位 10

2.5我国数控系统的发展概况 11

2.6数控系统的发展趋势 11

2.7 ATC装置的分类 11

2.8 ATC装置的换刀速度比较 13

2.9 分步双爪式ATC装置 14

2.10自动换刀系统产品化的前景 15

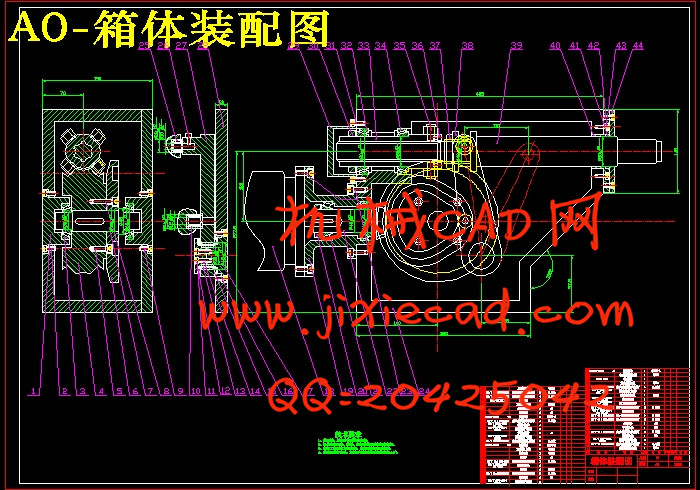

3 换刀机械手的总体方案设计 16

3.1 设计任务 16

3.2机械手的平稳性 16

3.2.1、影响平稳性以定位精度的因素 16

3.2.2 机械手的运动特性 17

3.3机械手运动特性的分类 18

3.4开关型机械手的速度及位置控制 18

3.5机械传动型机械手速度及位置控制 19

3.6 机械手类型确定 19

3.7 驱动系统和电控系统的选择 19

3.7.1驱动系统的选择 19

3.7.2电控系统的选择 20

4 总体结构设计 23

4.1 手爪部分设计 23

4.2 机械手手臂的设计 24

4.2.1臂部要防止偏重 24

4.2.2加强臂部刚度 25

4.2.3改进缓冲装置和提高配合精度 25

4.2.4采取的措施: 25

4.3机械手传动结构的设计 27

5 换刀机械手的参数和计算 30

5.1 手臂的弯曲变形 30

5.2 连杆的强度计算 32

5.3 驱动电动机的选择 32

6 换刀过程 35

结 论 39

参考文献 40

致 谢 42