设计简介

摘要

剪板机是机械生产中关键的辅助设备之一,运用电液结合对其进行自动化控制实现了剪板机的高效率、低噪声、操作简单、维护方便等诸多优点。液压技术作为实现现代传动与控制的关键基础技术之一,已成为工业机械、工程建设机械及国防尖端产品等不可缺少的基础,是它们向自动化、高精度、高效率、高速度方向发展的关键技术。PLC是近几年发展起来的一种新型工业控制器,由于它把计算机的编程灵活、功能齐全、应用面广泛等优点与控制器系统的控制简单、使用方便、抗干扰能力强、价格便宜等优点结合起来,而其本身又具有体积小、重量轻、能耗低等特点,在工业过程控制中的应用越来越广泛。加之PLC以其在硬件设计中采用了屏蔽、滤波、光电隔离等技术,在软件设计中采用了故障检测、信息保护与恢复等措施,进一步提高了PLC的可靠性。

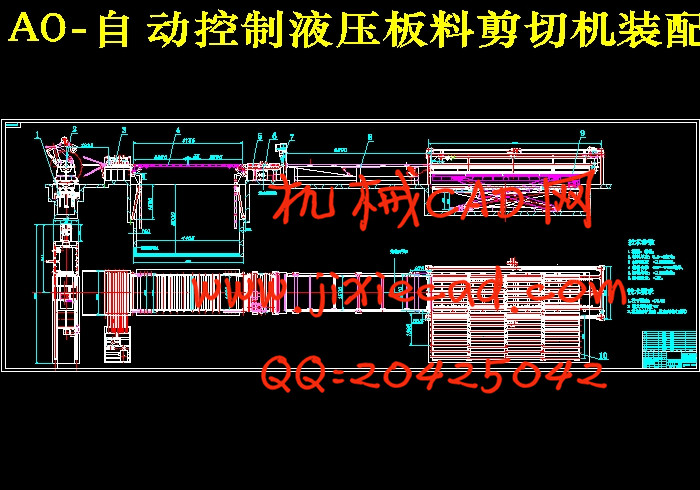

本课题中我主要进行液压控制系统和泵站设计、PLC控制系统设计,该部分的完成是为了实现剪板机的自动化加工,减少劳动强度,提高加工效率。本文详细介绍了设计的整个过程。

关键词:液压系统;集成油路;泵站;可编程控制器;全自动剪板机

剪板机是机械生产中关键的辅助设备之一,运用电液结合对其进行自动化控制实现了剪板机的高效率、低噪声、操作简单、维护方便等诸多优点。液压技术作为实现现代传动与控制的关键基础技术之一,已成为工业机械、工程建设机械及国防尖端产品等不可缺少的基础,是它们向自动化、高精度、高效率、高速度方向发展的关键技术。PLC是近几年发展起来的一种新型工业控制器,由于它把计算机的编程灵活、功能齐全、应用面广泛等优点与控制器系统的控制简单、使用方便、抗干扰能力强、价格便宜等优点结合起来,而其本身又具有体积小、重量轻、能耗低等特点,在工业过程控制中的应用越来越广泛。加之PLC以其在硬件设计中采用了屏蔽、滤波、光电隔离等技术,在软件设计中采用了故障检测、信息保护与恢复等措施,进一步提高了PLC的可靠性。

本课题中我主要进行液压控制系统和泵站设计、PLC控制系统设计,该部分的完成是为了实现剪板机的自动化加工,减少劳动强度,提高加工效率。本文详细介绍了设计的整个过程。

关键词:液压系统;集成油路;泵站;可编程控制器;全自动剪板机

Abstract

The shearing machine is one of the most important accessory machinery in manufacturing. Controlled by electric and hydraulic make the shearing machine has high efficiency,low noise,simple operating and service freely. The hydraulic technology as one of the essential foundation technologies of the realization modern transmission and controlling, has become the essential foundation of the industry machinery, the engineering construction machinery and the national defense state-of-the-art product and so on, It is their essential technology to the automation,high accuracy,high efficiency and high speed . PLC is the controller of a kind of infant industry developed in recent years. Because the programming of a pair of computer of its is flexible , and controller control of system simple easy to use, anti-interference ability strong, price getting cheap advantage combined together, and it has characteristics such as small , light , power consumptive provinces ,etc, the application in the industrial process is controlled is more and more extensive. In addition PLC adopt , shield , strain wave , photoelectricity person who isolate technology in hardware design with their, have adopted measures such as detection of trouble , information protection and resuming ,etc. in software design, have further improved the dependability of PLC.

I mainly solve the shearing machine’s hydraulic system design,its pumping station design and the take-up parts’ PLC control in this topic, in order to realizes the machinery automatic processing, reduce worker's labor intensity, and enhance the mechanical efficiency.

Key words: Hydraulic system; Integrated hydraulic system; Pumping station; Programmable logic controller ; Full-automatic board cutting machine

The shearing machine is one of the most important accessory machinery in manufacturing. Controlled by electric and hydraulic make the shearing machine has high efficiency,low noise,simple operating and service freely. The hydraulic technology as one of the essential foundation technologies of the realization modern transmission and controlling, has become the essential foundation of the industry machinery, the engineering construction machinery and the national defense state-of-the-art product and so on, It is their essential technology to the automation,high accuracy,high efficiency and high speed . PLC is the controller of a kind of infant industry developed in recent years. Because the programming of a pair of computer of its is flexible , and controller control of system simple easy to use, anti-interference ability strong, price getting cheap advantage combined together, and it has characteristics such as small , light , power consumptive provinces ,etc, the application in the industrial process is controlled is more and more extensive. In addition PLC adopt , shield , strain wave , photoelectricity person who isolate technology in hardware design with their, have adopted measures such as detection of trouble , information protection and resuming ,etc. in software design, have further improved the dependability of PLC.

I mainly solve the shearing machine’s hydraulic system design,its pumping station design and the take-up parts’ PLC control in this topic, in order to realizes the machinery automatic processing, reduce worker's labor intensity, and enhance the mechanical efficiency.

Key words: Hydraulic system; Integrated hydraulic system; Pumping station; Programmable logic controller ; Full-automatic board cutting machine

目 录

引言 1

1概述 2

2设计构思及方案论证 3

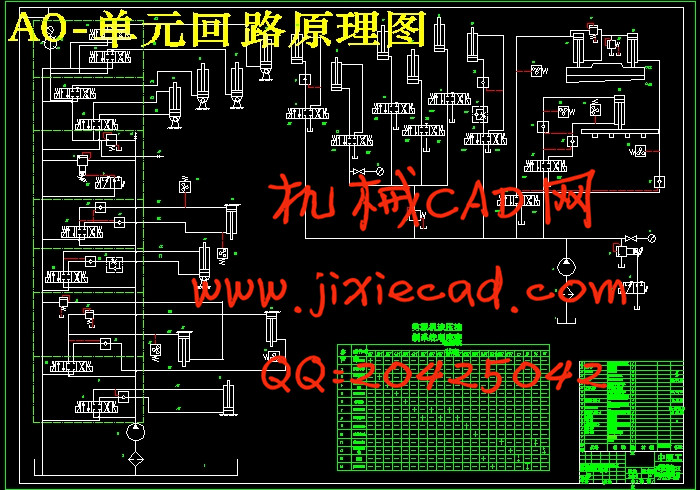

3液压系统设计 5

3.1液压同步回路的分析论证 5

3.2液压回路确定 8

3.3液压元件的选择 10

3.3.1 系统参数 10

3.3.2 阀类零件的选择 10

3.3.3 管道的选择 11

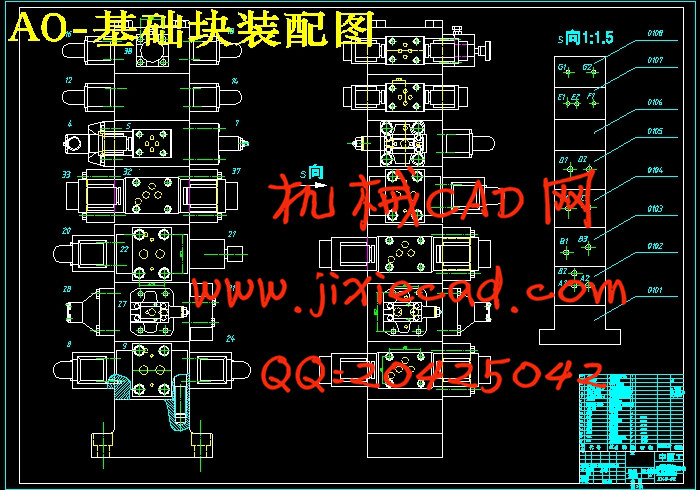

3.4液压系统连接装置的结构设计 12

3.4.1 集成块连接装置的设计步骤 13

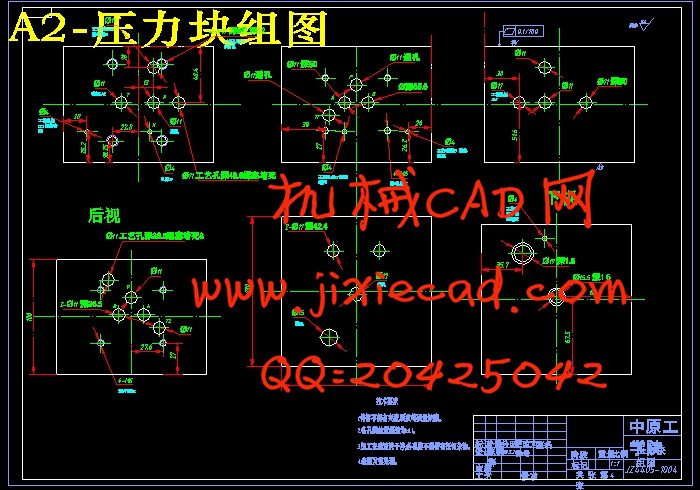

3.4.2 集成块设计 14

3.4.3 集成三维图 15

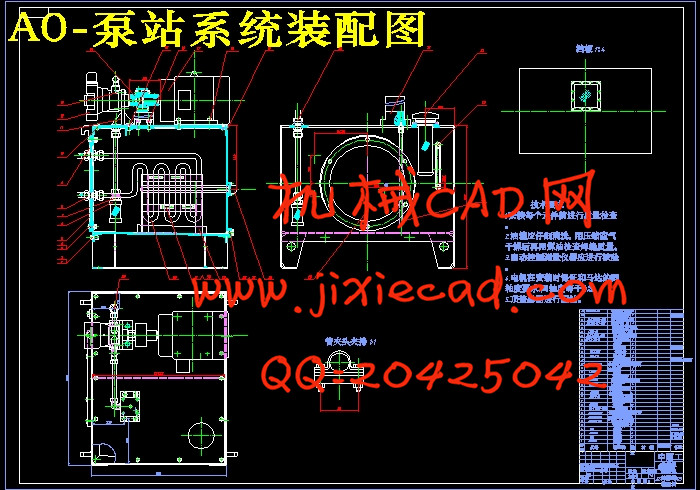

4油箱及液压泵装置的设计 18

4.1油箱容积的计算 18

4.2 油箱的结构设计 18

4.2.1 油箱的结构设计要点 18

4.2.2 油箱设计参数 19

4.3液压泵装置 20

4.3.1液压泵放置 21

4.3.2 液压泵与电机的连接 21

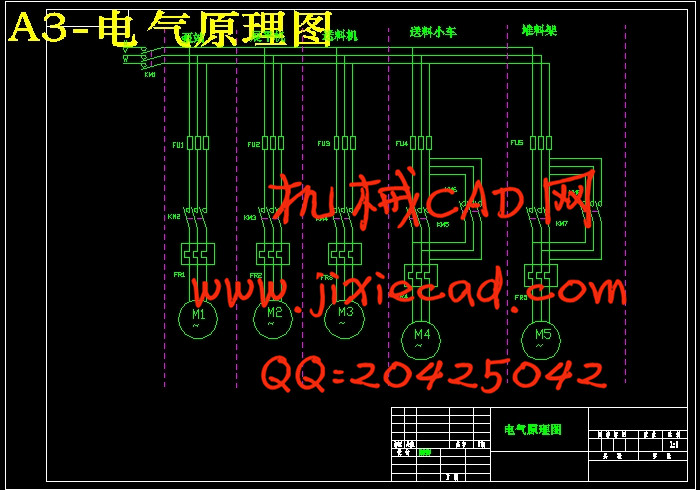

5控制系统设计 22

5.1控制系统动作流程图 24

5.2控制系统PLC梯形程序图 25

5.3控制系统PLC SEL型程序图 30

5.4程序界面及操作面板 35

5.5控制系统有关图纸及操作说明 36

6技术经济分析 38

7结语 39

8致谢 40

参考文献 41