设计简介

摘要

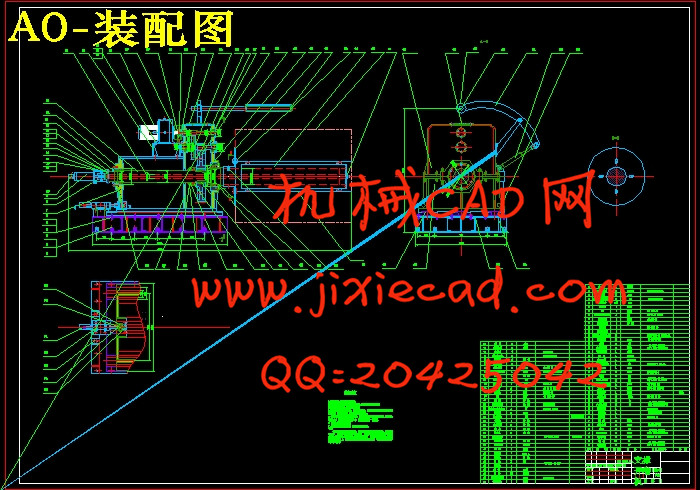

液压剪板机自动生产线中第一道工序就是开卷。这就用到了开卷机,开卷机是用来支撑钢卷、回转钢卷的。随着对开卷机速度和板面质量的要求,开卷机的型式已由箱式开卷机,无胀缩卷筒开卷机等类型,逐步发展过渡到胀缩卷筒式开卷机。目前市场上开卷机的型式有很多种,如单卷筒悬臂式.双卷筒回转式.双柱头开卷机。它们共同特点都是涨缩卷筒式开卷机。采用胀缩卷筒式开卷机的优点是:其设备配置较为简单,主要由传动系统及胀缩卷筒、压紧辊和支撑等装置组成。

根据现场调研,原开卷机的张力较小,现增加了带钢的张力,进行了主要零件的强度计算。该开卷机保证开卷时恒定张力,保证开卷线速度恒定,从而提高了带钢的表面质量。而且具有对中调节功能,即在上卷和工作过程中,始终保证带材中心线与下道机组中心线重合,减少带钢的翘曲现象,从而保证剪板的正常进行,提高了带钢产品质量。

关键词:开卷机,表面质量,恒定张力

Abstract

The first step of hydraulic plate shears automatic production line is open- book. This will use the uncoiler, uncoiler is used to support steel coil, rotary steel coil. As the uncoiler speed and surface quality request, uncoiler type already developed from box uncoiler, without swell-shrink reel of decoiler type etc, and gradually developed transition to swell-shrink prefabricated uncoiler. Now on the market of decoiler type has a lot of kinds, such as single reel cantilever. Double drum rotary. Double the stigma of decoiler. Their common characteristic is all decoiler prefabricated rose shrinkage. The advantage of adopting swell-shrink prefabricated uncoiler in equipment configuration is simple, and mainly by the transmission system and swell-shrink drum, pressure roller and supports device component.

According to the field investigation, the tension of original fetching machines is relatively small, increase the tension with steel now,the intensity of carrying on the major part is calculated.The uncoiler guarantee open-book invariableness tensile, guarantee the open-book rotational speed, thereby improving the strip surface quality. And it has regulating function , be in namely roll-up and working process, always guarantee strip with road centerline centerline coincidence, reduce strip unit to ensure the warp phenomenon, the normal shear, improved the surface quality with steel.

Keyword:uncoiler,surface quality,invariable tension

目录

引言 1

1 开卷机的概念和发展趋势 2

1.1选题的背景和目的 2

1.2开卷机的概述 2

1.3开卷机的结构 3

1.3.1 单筒可胀缩开卷机 3

1.3.2双锥头无胀缩开卷机 4

1.3.3双圆柱头可胀缩开卷机 5

1.4开卷机的发展趋势 6

2 开卷机筒结构设计 8

2.1 开卷机筒结构 8

2.2开卷机筒结构设计 9

3 开卷机电机功率与减速箱速比的合理选择 11

3.1开卷机电机功率与减速箱速比合理选择重要性 11

3.2开卷机张力和速度的确定 11

3.3开卷电机的选择及功率计算 11

3.3.1电磁调速电动机的选用及工作原理 11

3.3.2按卷筒上的静张力计算的电机功率 12

3.3.3减速箱速比的设计 12

4 减速箱各齿轮设计计算 14

4.1齿轮模数的估算和验算 14

4.1.1齿轮模数的估算(以高速级小齿轮为例) 14

4.1.2齿轮模数的验算(以高速级小齿轮为例) 14

4.2齿轮强度校核 15

4.2.1选定的齿轮材料及精度等级及齿数(以低速级啮合齿轮为例) 15

4.2.2按齿面接触疲劳强度设计 15

4.3齿轮齿数及结构设计 17

5 减速箱实际传动比及主轴的设计计算 19

5.1所设计的减速器实际传动比及各轴动力参数计算 19

5.2 主轴的设计计算 19

5.2.1选择轴的材料 19

5.2.2 初步估算轴的最小直径 19

5.2.3 轴上受力分析 20

5.2.4 轴的强度校核 21

6 轴承寿命计算 23

7 开卷机对中调节功能 24

8 开卷机压辊压紧力计算 25

9 开卷机各液压缸压力流量的确定 27

9.1 开卷机卷筒胀缩缸推力及压力流量的确定 27

9.1.1卷筒胀缩功能的介绍 27

9.1.2胀缩缸推力的计算 27

9.2 开卷机上其他液压缸流量的确定 28

9.2.1压辊装置中液压缸流量的计算 28

9.2.2横移液压缸流量的计算 29

致谢 31

参考文献 32

液压剪板机自动生产线中第一道工序就是开卷。这就用到了开卷机,开卷机是用来支撑钢卷、回转钢卷的。随着对开卷机速度和板面质量的要求,开卷机的型式已由箱式开卷机,无胀缩卷筒开卷机等类型,逐步发展过渡到胀缩卷筒式开卷机。目前市场上开卷机的型式有很多种,如单卷筒悬臂式.双卷筒回转式.双柱头开卷机。它们共同特点都是涨缩卷筒式开卷机。采用胀缩卷筒式开卷机的优点是:其设备配置较为简单,主要由传动系统及胀缩卷筒、压紧辊和支撑等装置组成。

根据现场调研,原开卷机的张力较小,现增加了带钢的张力,进行了主要零件的强度计算。该开卷机保证开卷时恒定张力,保证开卷线速度恒定,从而提高了带钢的表面质量。而且具有对中调节功能,即在上卷和工作过程中,始终保证带材中心线与下道机组中心线重合,减少带钢的翘曲现象,从而保证剪板的正常进行,提高了带钢产品质量。

关键词:开卷机,表面质量,恒定张力

Abstract

The first step of hydraulic plate shears automatic production line is open- book. This will use the uncoiler, uncoiler is used to support steel coil, rotary steel coil. As the uncoiler speed and surface quality request, uncoiler type already developed from box uncoiler, without swell-shrink reel of decoiler type etc, and gradually developed transition to swell-shrink prefabricated uncoiler. Now on the market of decoiler type has a lot of kinds, such as single reel cantilever. Double drum rotary. Double the stigma of decoiler. Their common characteristic is all decoiler prefabricated rose shrinkage. The advantage of adopting swell-shrink prefabricated uncoiler in equipment configuration is simple, and mainly by the transmission system and swell-shrink drum, pressure roller and supports device component.

According to the field investigation, the tension of original fetching machines is relatively small, increase the tension with steel now,the intensity of carrying on the major part is calculated.The uncoiler guarantee open-book invariableness tensile, guarantee the open-book rotational speed, thereby improving the strip surface quality. And it has regulating function , be in namely roll-up and working process, always guarantee strip with road centerline centerline coincidence, reduce strip unit to ensure the warp phenomenon, the normal shear, improved the surface quality with steel.

Keyword:uncoiler,surface quality,invariable tension

目录

引言 1

1 开卷机的概念和发展趋势 2

1.1选题的背景和目的 2

1.2开卷机的概述 2

1.3开卷机的结构 3

1.3.1 单筒可胀缩开卷机 3

1.3.2双锥头无胀缩开卷机 4

1.3.3双圆柱头可胀缩开卷机 5

1.4开卷机的发展趋势 6

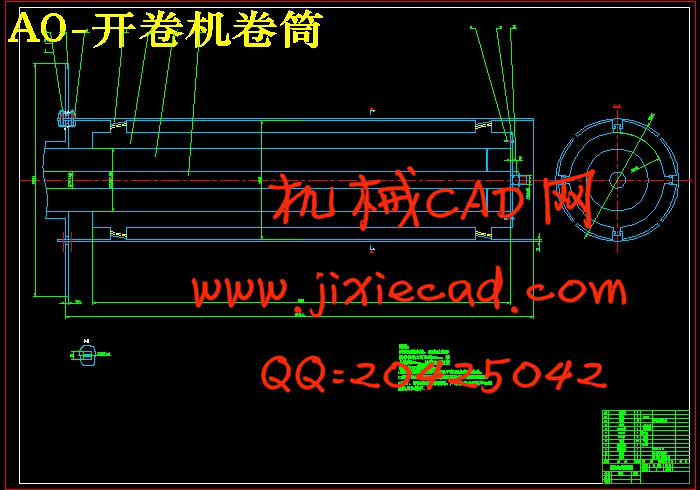

2 开卷机筒结构设计 8

2.1 开卷机筒结构 8

2.2开卷机筒结构设计 9

3 开卷机电机功率与减速箱速比的合理选择 11

3.1开卷机电机功率与减速箱速比合理选择重要性 11

3.2开卷机张力和速度的确定 11

3.3开卷电机的选择及功率计算 11

3.3.1电磁调速电动机的选用及工作原理 11

3.3.2按卷筒上的静张力计算的电机功率 12

3.3.3减速箱速比的设计 12

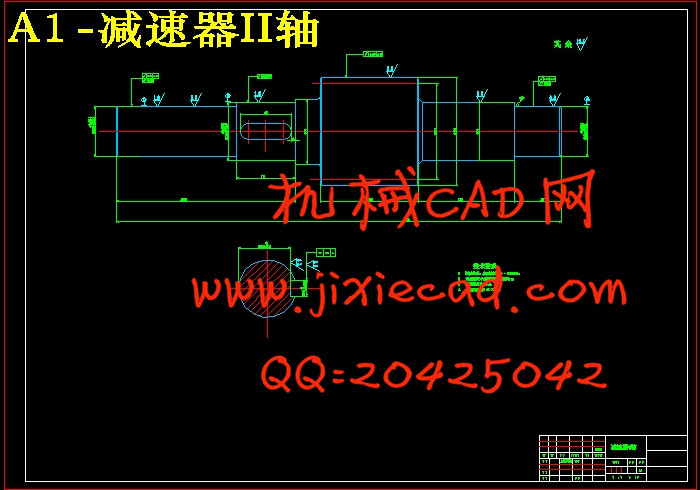

4 减速箱各齿轮设计计算 14

4.1齿轮模数的估算和验算 14

4.1.1齿轮模数的估算(以高速级小齿轮为例) 14

4.1.2齿轮模数的验算(以高速级小齿轮为例) 14

4.2齿轮强度校核 15

4.2.1选定的齿轮材料及精度等级及齿数(以低速级啮合齿轮为例) 15

4.2.2按齿面接触疲劳强度设计 15

4.3齿轮齿数及结构设计 17

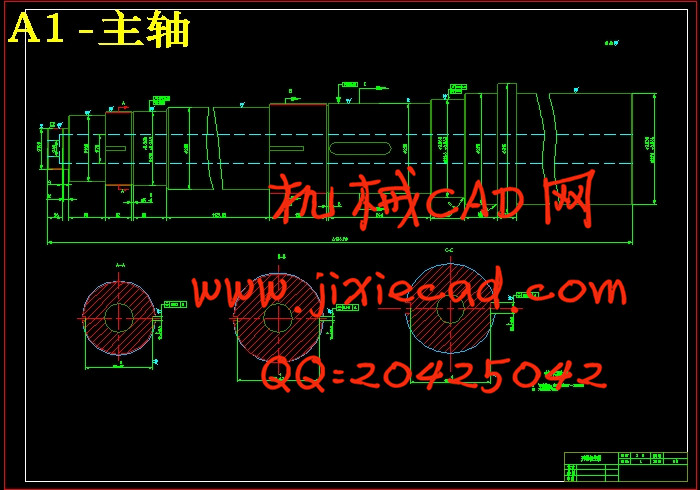

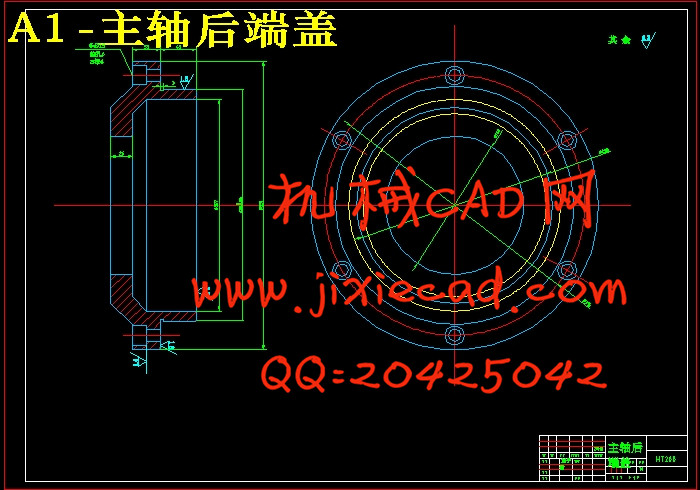

5 减速箱实际传动比及主轴的设计计算 19

5.1所设计的减速器实际传动比及各轴动力参数计算 19

5.2 主轴的设计计算 19

5.2.1选择轴的材料 19

5.2.2 初步估算轴的最小直径 19

5.2.3 轴上受力分析 20

5.2.4 轴的强度校核 21

6 轴承寿命计算 23

7 开卷机对中调节功能 24

8 开卷机压辊压紧力计算 25

9 开卷机各液压缸压力流量的确定 27

9.1 开卷机卷筒胀缩缸推力及压力流量的确定 27

9.1.1卷筒胀缩功能的介绍 27

9.1.2胀缩缸推力的计算 27

9.2 开卷机上其他液压缸流量的确定 28

9.2.1压辊装置中液压缸流量的计算 28

9.2.2横移液压缸流量的计算 29

致谢 31

参考文献 32