设计简介

摘 要

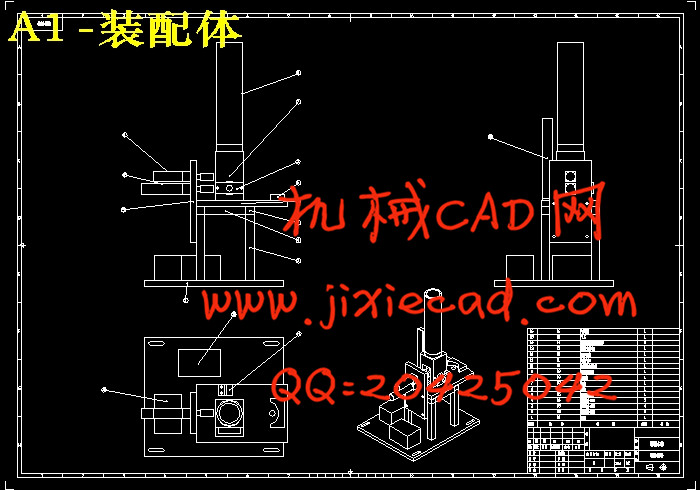

亚龙YL-335B 型自动生产线实训考核装备由安装在铝合金导轨式实训台上的送料单元、加工单元、装配单元、输送单元和分拣单元5个单元组,供料单元是YL-335B 中的起始单元,在整个系统中,起着向系统中的其他单元提供原料的作用。具体的功能是:工件垂直叠放在料仓中,推料缸处于料仓的底层并且其活塞杆可从料仓的底部通过。当活塞杆在退回位置时,它与最下层工件处于同一水平位置,而顶料气缸则与次下层工件处于同一水平位置。在需要将工件推出到物料台上时,首先使夹紧气缸的活塞杆推出,压住次下层工件;然后使推料气缸活塞杆推出,从而把最下层工件推到物料台上。在推料气缸返回并从料仓底部抽出后,再使夹紧气缸返回,松开次下层工件。这样,料仓中的工件在重力的作用下,就自动向下移动一个工件,为下一次推出工件做好准备。

关键词:自动,PLC,供料

Abstract

Automatic production line training and testing equipment by the installation in the aluminum alloy guide training and send feeding unit, processing unit, assembly unit, conveying and sorting unit 5 unit group of Yalong YL-335B type, feeding unit is the starting unit YL-335B. In the whole system and play a role to other units in the system to provide raw materials. Specific functions: workpiece vertically stacked in silo, pushing cylinder is at the bottom of the silo and the piston rod can be passed from the bottom of the silo. When the piston rod is retracted, it is at the same level as the lower part of the piston rod, while the top cylinder is in the same horizontal position with the sub layer. When the workpiece to the launch of the material on the stage, first of all, make the clamping cylinder piston rod out of, time press and hold the underlying workpiece; then the pushing cylinder piston rod out, to the bottom of the workpiece is pushed to the material. The pushing cylinder return and withdrawn from the bottom of the bin, then the clamping cylinder return time, loosen the lower workpiece. So bin in the workpiece under the action of gravity automatically move downwards a workpiece, as a introduction of the workpiece to prepare.

Keywords: automatic feeding, PLC,feeder.

目录

摘 要 1

Abstract 2

目录 3

第1章 了解现代化自动生产线 4

1.1 自动生产线的概念 4

1.2 认知YL-335B型自动化生产线 5

第2章 供料单元的结构设计 15

2.1 供料单元的结构设计方案 15

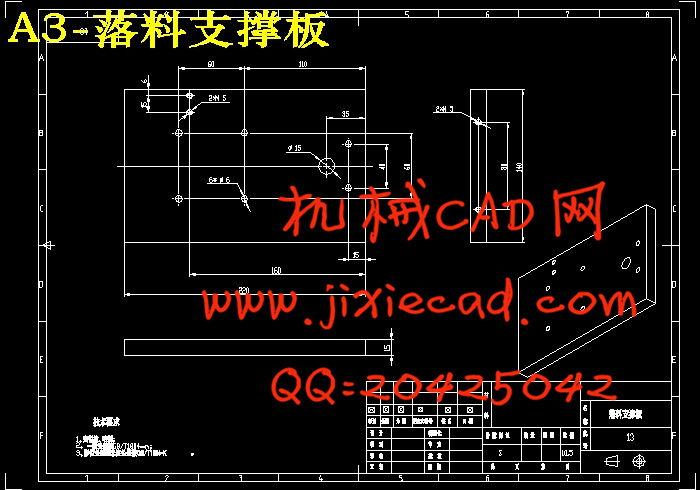

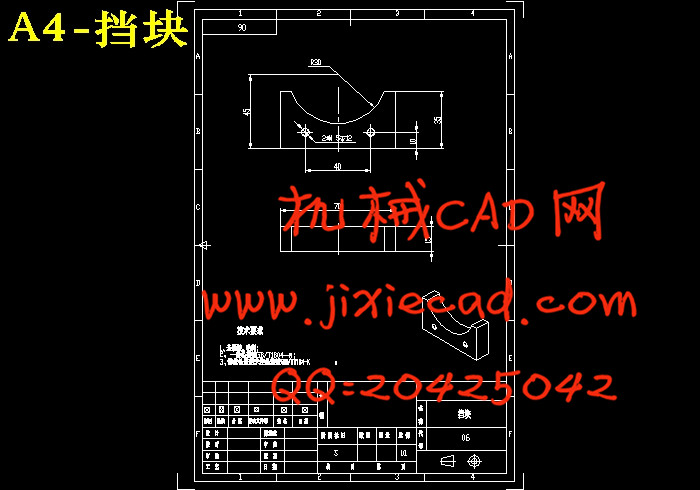

2.1.1工件推出与支撑及漏斗部分设计 15

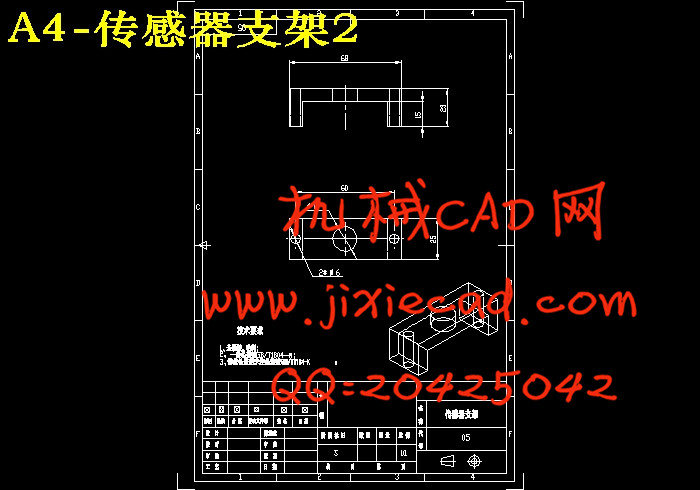

2.1.2 支撑架设计 16

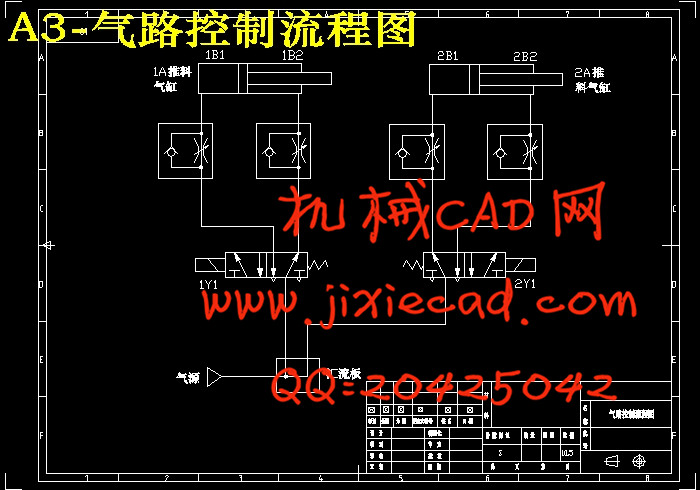

2.2 气路设计与选型 17

2.2.1 气动回路设计 17

2.2.2 供料单元的气动元件选择 17

2.2.2.1 标准双作用直线气缸 17

2.2.2.2 单电控电磁换向阀、电磁阀组 18

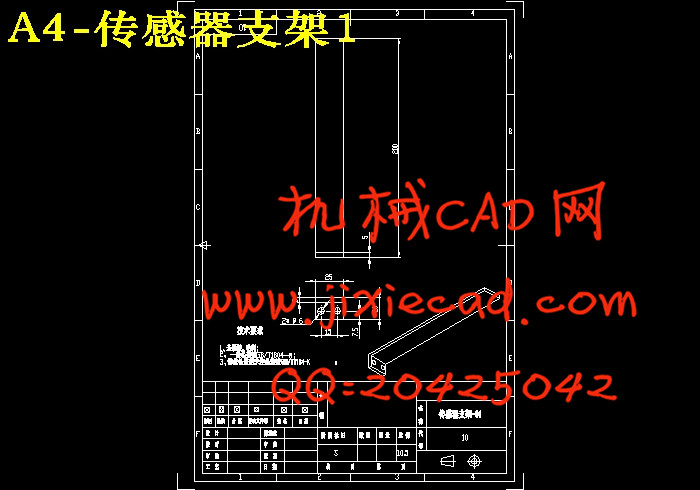

2.2.2.3 传感器的选择 20

第3章 供料单元控制系统设计 26

3.1 工作任务 26

3.2 PLC的I/O 接线 26

3.3 供料单元单站控制的编程思路 27

3.4 调试与运行 35

第4章 结论 37

参考文献 38

亚龙YL-335B 型自动生产线实训考核装备由安装在铝合金导轨式实训台上的送料单元、加工单元、装配单元、输送单元和分拣单元5个单元组,供料单元是YL-335B 中的起始单元,在整个系统中,起着向系统中的其他单元提供原料的作用。具体的功能是:工件垂直叠放在料仓中,推料缸处于料仓的底层并且其活塞杆可从料仓的底部通过。当活塞杆在退回位置时,它与最下层工件处于同一水平位置,而顶料气缸则与次下层工件处于同一水平位置。在需要将工件推出到物料台上时,首先使夹紧气缸的活塞杆推出,压住次下层工件;然后使推料气缸活塞杆推出,从而把最下层工件推到物料台上。在推料气缸返回并从料仓底部抽出后,再使夹紧气缸返回,松开次下层工件。这样,料仓中的工件在重力的作用下,就自动向下移动一个工件,为下一次推出工件做好准备。

关键词:自动,PLC,供料

Abstract

Automatic production line training and testing equipment by the installation in the aluminum alloy guide training and send feeding unit, processing unit, assembly unit, conveying and sorting unit 5 unit group of Yalong YL-335B type, feeding unit is the starting unit YL-335B. In the whole system and play a role to other units in the system to provide raw materials. Specific functions: workpiece vertically stacked in silo, pushing cylinder is at the bottom of the silo and the piston rod can be passed from the bottom of the silo. When the piston rod is retracted, it is at the same level as the lower part of the piston rod, while the top cylinder is in the same horizontal position with the sub layer. When the workpiece to the launch of the material on the stage, first of all, make the clamping cylinder piston rod out of, time press and hold the underlying workpiece; then the pushing cylinder piston rod out, to the bottom of the workpiece is pushed to the material. The pushing cylinder return and withdrawn from the bottom of the bin, then the clamping cylinder return time, loosen the lower workpiece. So bin in the workpiece under the action of gravity automatically move downwards a workpiece, as a introduction of the workpiece to prepare.

Keywords: automatic feeding, PLC,feeder.

目录

摘 要 1

Abstract 2

目录 3

第1章 了解现代化自动生产线 4

1.1 自动生产线的概念 4

1.2 认知YL-335B型自动化生产线 5

第2章 供料单元的结构设计 15

2.1 供料单元的结构设计方案 15

2.1.1工件推出与支撑及漏斗部分设计 15

2.1.2 支撑架设计 16

2.2 气路设计与选型 17

2.2.1 气动回路设计 17

2.2.2 供料单元的气动元件选择 17

2.2.2.1 标准双作用直线气缸 17

2.2.2.2 单电控电磁换向阀、电磁阀组 18

2.2.2.3 传感器的选择 20

第3章 供料单元控制系统设计 26

3.1 工作任务 26

3.2 PLC的I/O 接线 26

3.3 供料单元单站控制的编程思路 27

3.4 调试与运行 35

第4章 结论 37

参考文献 38