设计简介

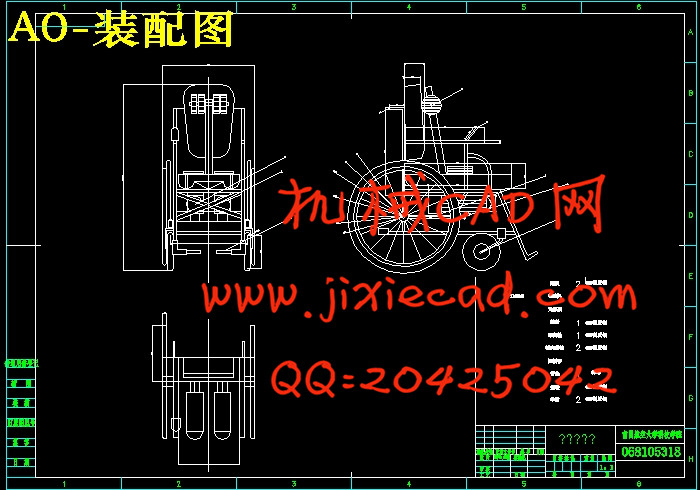

摘要:为实现高性能和低成本的自行走轮椅, 开发了全数字自行走轮椅控制器; 采用先进的无速度传感器测速技术, 设计了带电流补偿的电压负反馈加负载不平衡补偿的双电机协调控制方案。驱动部分采用有刷幅条电机的后轮驱动。幅条电机传动具有转矩大、噪音低、效率高、耗电少、寿命长、绿色环保等优点,克服了链传动噪声大、冲击大、传动不平稳等缺点,且外观新颖,控制部分采用采用平等四边形连杆机构,结构简单,并实现了大角度的转向控制和两轮同步运动,同时增加轮椅在行进中的稳定性,而且起到防倒的功能,遇上下坡也能自主掌控,安全性高;制动部分采用特制的涨刹机构,达到前后手柄都可以制动,安全性高。

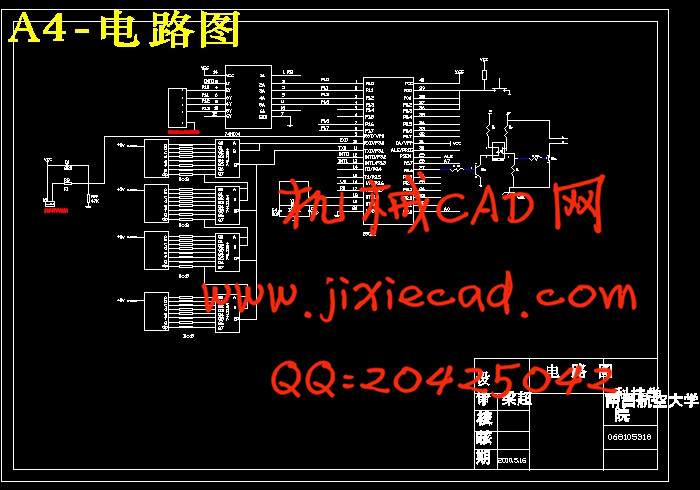

给出了软硬件结构和单元电路的设计及参数选择方法; 分析了操纵杆工作原理; 给出了轮椅速度和运动方向信息合成计算公式和提高运行舒适度的S曲线生成策略。

关键词: 自行走轮椅; 控制器; 双电机; 协调控制; S曲线; 误差检测;幅条电机;连杆机构;涨刹机构;电动控制;辅助装置

Abstract: To achieve high performance and low cost to walk the wheelchair, developed by digital controller; walk wheelchairs, Using advanced speed sensorless speed technology, design with the current compensation voltage feedback and compensation of unbalanced load motor coordination control scheme. Driving part adopts a brush painting of the rear wheel drive motor. The picture has great torque motor drive, low noise, high efficiency, energy saving.longlife, green environmental protection etc, and overcome the impact noise, large chain drive not smooth, novel appearance and defects, and control part adopts USES equal quadrilateral linkage mechanism, simple structure, and realize the large Angle of steering control and two wheels, adding wheelchairs synchronous movement in the stability and travel, prevent fall function, meets the downhill can independently control, high security, Braking part adopts special rose, and brake to handle all can apply the brake, high safety.

The hardware and software structure and given the unit circuit design and parameter selection method, The lever principle analysis, Given the speed and direction of movement wheelchair synthetic formulas and improve information generated the comfort of the S curve operation strategy.

Key Words: EPW; Controller; Two2motor; Coordinated control; S curve; Fault detection;electromotive wheelchair;hand control;electric control;auxiliary unit

目 录

1 绪论 ............................................................................................................................ 2

1.1 国内外发展情况 ............................................................................................................. 4

1.2 设计内容 ........................................................................................................................5

1.3 设计思路 ........................................................................................................................5

2 系统方案 .......................................................................................................................7

2.1 机械系统方案 ....................................................................................................................7

2.2 控制方案 ........................................................................................................................9

2.3 总体方案 .......................................................................................................................10

3 机械结构计 .................................................................................................................11

3.1 链条的传动设计 ............................................................................................................11

3.2 电动机的选用 ..............................................................................................................11

3.3 驱动电路设计 ................................................................................................................12

4 控制系统设计 ...............................................................................................................13

4.1 控制系统软件设计 ...........................................................................................................14

5 总 结 ..........................................................................................................................14

5.1 设计总结 ....................................................................................................................... 14

5.2 展望 ........................................................................................................................... 14

参考文献 ........................................................................................................................... 15

给出了软硬件结构和单元电路的设计及参数选择方法; 分析了操纵杆工作原理; 给出了轮椅速度和运动方向信息合成计算公式和提高运行舒适度的S曲线生成策略。

关键词: 自行走轮椅; 控制器; 双电机; 协调控制; S曲线; 误差检测;幅条电机;连杆机构;涨刹机构;电动控制;辅助装置

Abstract: To achieve high performance and low cost to walk the wheelchair, developed by digital controller; walk wheelchairs, Using advanced speed sensorless speed technology, design with the current compensation voltage feedback and compensation of unbalanced load motor coordination control scheme. Driving part adopts a brush painting of the rear wheel drive motor. The picture has great torque motor drive, low noise, high efficiency, energy saving.longlife, green environmental protection etc, and overcome the impact noise, large chain drive not smooth, novel appearance and defects, and control part adopts USES equal quadrilateral linkage mechanism, simple structure, and realize the large Angle of steering control and two wheels, adding wheelchairs synchronous movement in the stability and travel, prevent fall function, meets the downhill can independently control, high security, Braking part adopts special rose, and brake to handle all can apply the brake, high safety.

The hardware and software structure and given the unit circuit design and parameter selection method, The lever principle analysis, Given the speed and direction of movement wheelchair synthetic formulas and improve information generated the comfort of the S curve operation strategy.

Key Words: EPW; Controller; Two2motor; Coordinated control; S curve; Fault detection;electromotive wheelchair;hand control;electric control;auxiliary unit

目 录

1 绪论 ............................................................................................................................ 2

1.1 国内外发展情况 ............................................................................................................. 4

1.2 设计内容 ........................................................................................................................5

1.3 设计思路 ........................................................................................................................5

2 系统方案 .......................................................................................................................7

2.1 机械系统方案 ....................................................................................................................7

2.2 控制方案 ........................................................................................................................9

2.3 总体方案 .......................................................................................................................10

3 机械结构计 .................................................................................................................11

3.1 链条的传动设计 ............................................................................................................11

3.2 电动机的选用 ..............................................................................................................11

3.3 驱动电路设计 ................................................................................................................12

4 控制系统设计 ...............................................................................................................13

4.1 控制系统软件设计 ...........................................................................................................14

5 总 结 ..........................................................................................................................14

5.1 设计总结 ....................................................................................................................... 14

5.2 展望 ........................................................................................................................... 14

参考文献 ........................................................................................................................... 15