设计简介

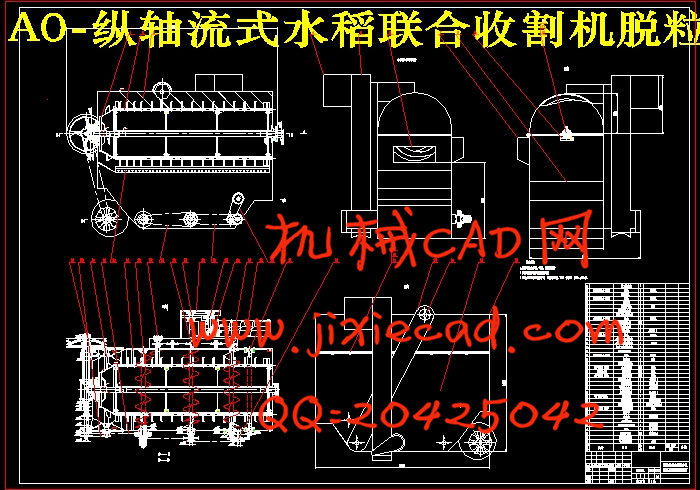

纵轴流式水稻联合收割机脱粒系统结构设计

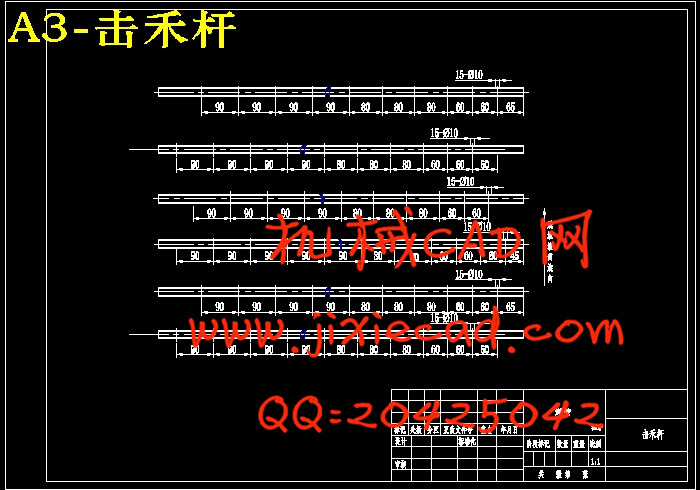

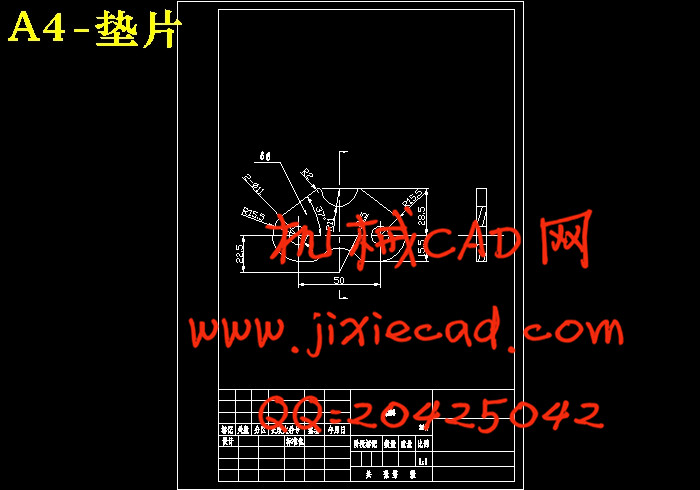

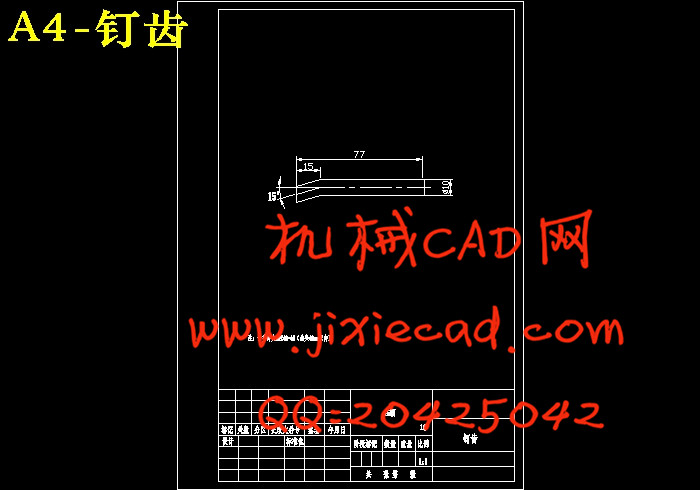

摘 要:本文简述了国内、外联合收割机的研究现状和典型脱粒分离装置的工作原理。通过查阅资料了解水稻的农艺、形态参数。通过对比方式选择出钉齿-栅格凹板-顶盖导向板脱粒分离的方式的效果最佳。并且采用纵置脱离滚筒,在不改变机体体积的条件下能够加长滚筒长度,增加脱粒和分离时间。这种纵置式轴流脱粒与分离装置工作时谷物留作空间螺旋运动,脱粒柔和且工作时间长,脱粒和分离比较充分,在脱净率、破碎率、分离率等都优于切流。为了减少脱粒损失,此脱粒系统还增加了复脱机构,能够将未脱粒完全的穗头通过它再次输送到脱粒滚筒再次脱粒,大大提高了脱粒效率。

本课题的研究为知道实际生产,提高轴流脱粒分离装置的性能以及降低成本提供了理论依据。

关键词:水稻 ; 纵置式轴流脱粒; 复脱; 理论依据

The Structure Design of Vertical Type Axial Flow Rice Combine Harvester Threshing System

Abstract: This article describes the research status at home and aboard of combine-harvester and working principle of typical threshing separating device.Through looking up materials about agronomy and morphological parameters of rice, I think the most effective way is the spike tooth-grid concave-header guiding plate threshing separation by comparison.The device is equipped with longitudinal separating drum which can lengthen the drum and increasing the threshing and separation time. When the vertical axial flow threshing and separating installation are working, grain is in a spiral movement. It separates softly , works in long hours and threshes and separates fully. So it is better than shear flow in the threshing rate, broken rate and separating rate. In order to reduce the loss of threshing, the threshing system adopt the re-threshing mechanism which greatly improves the efficiency of threshing. This mechanism can convey the incomplete threshing ear to the threshing drum again.

The purpose of this research is to guide the actual production process, improve the performance of axial flow threshing and separating device and provide a theoretical basis on reducing the cost.

Key words: Rice ; Vertical type axial flow threshing ; Re-threshing ; Theoretical basis

目 录

摘要 1

关键词 1

1绪论 2

1.1课题研究的意义 2

1.2国内外的联合收割机脱粒系统研究状况 2

1.3研究内容 4

1.4研究方法 5

1.5本章小结 6

2脱粒装置整体方案的确定 6

2.1脱粒装置简介 6

2.1.1脱粒装置的基本脱离原理 6

2.2本章小结 9

3主要零部件选择 9

3.1零部件的设计 9

3.1.1脱粒装置的选择 9

3.2本章小结 14

4主要零部件设计与计算 14

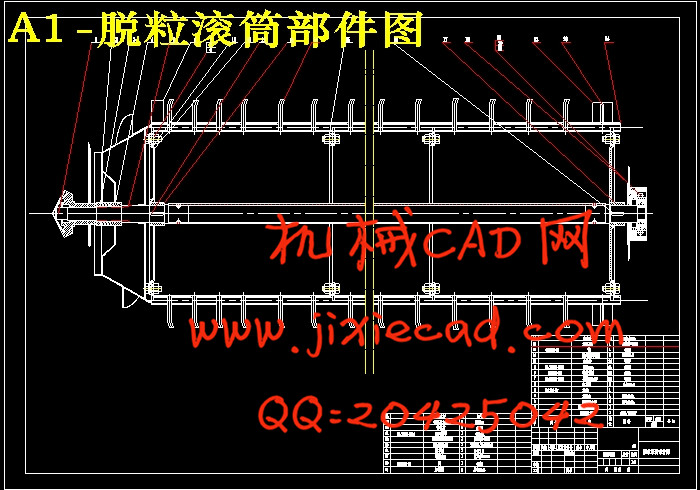

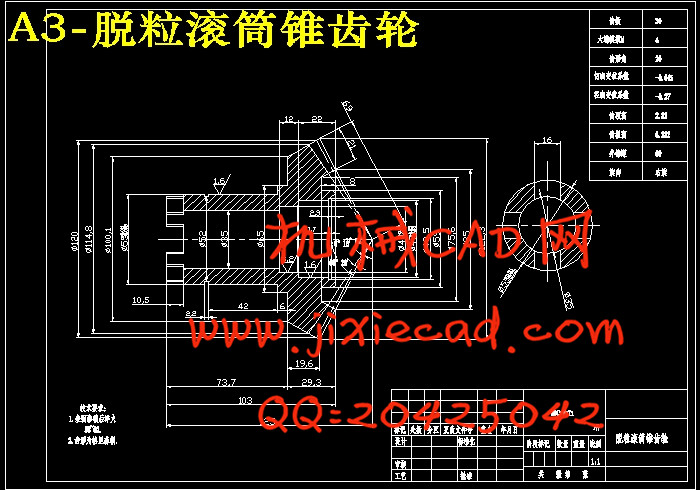

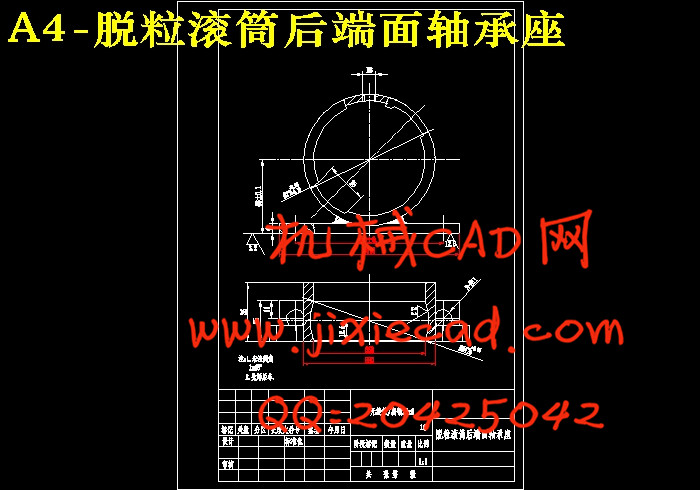

4.1脱粒滚筒的设计 14

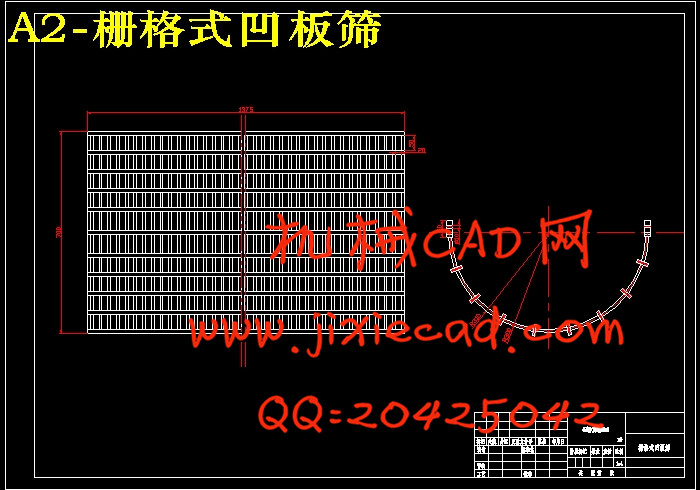

4.2凹板的设计 15

4.3脱粒间隙的设计 16

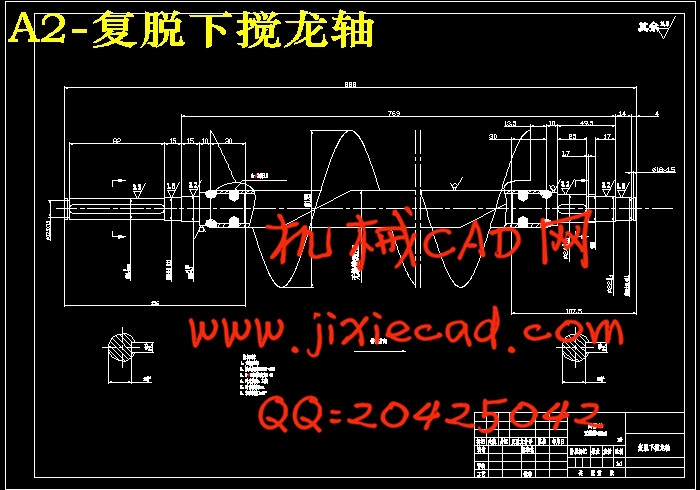

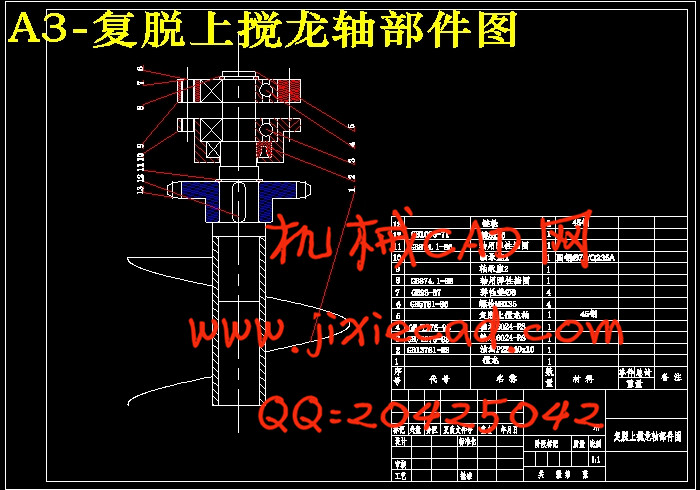

4.4复脱机构的设计 17

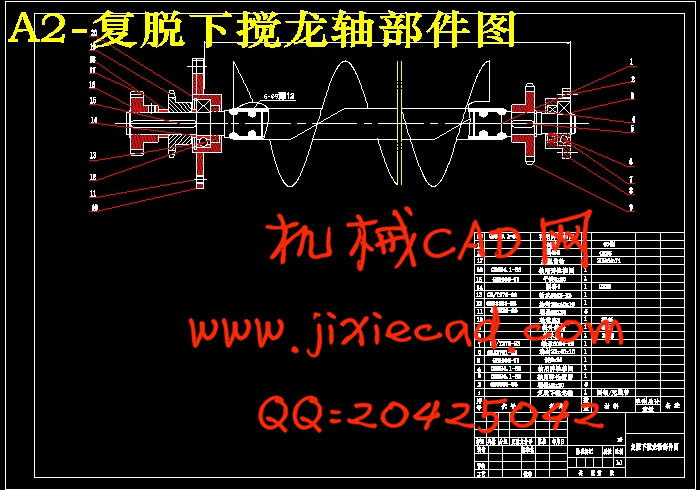

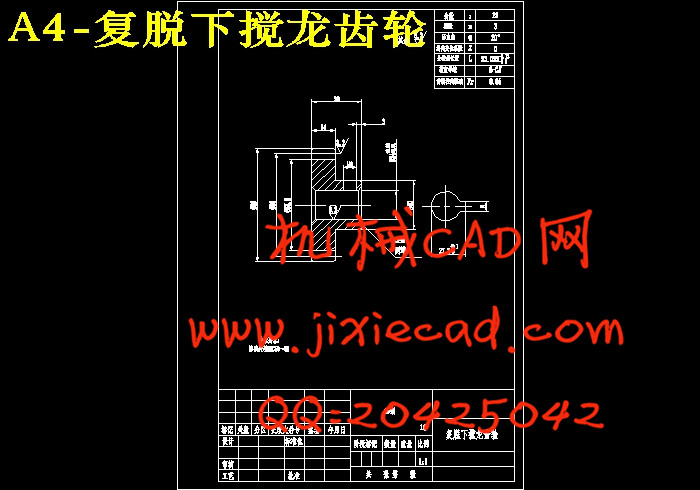

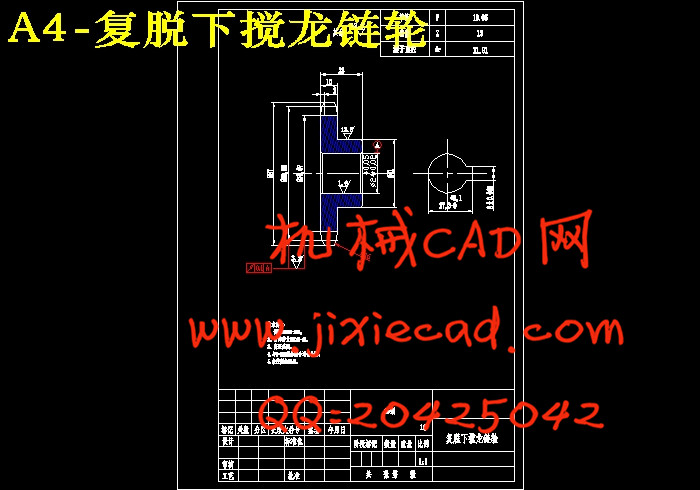

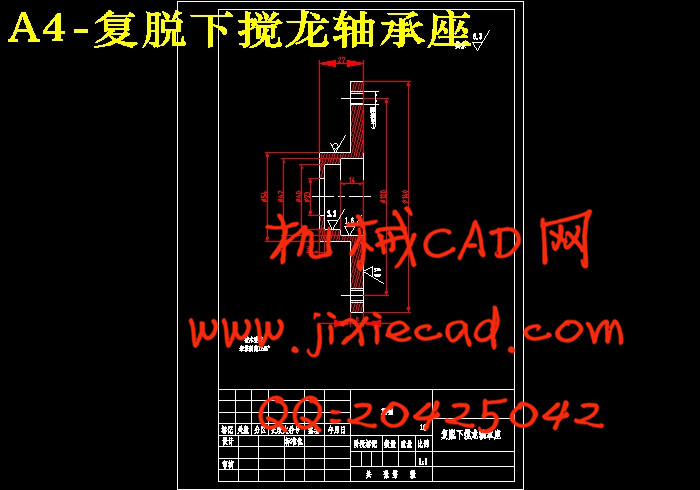

4.4.1复脱下搅龙的设计 17

4.5本章小结 19

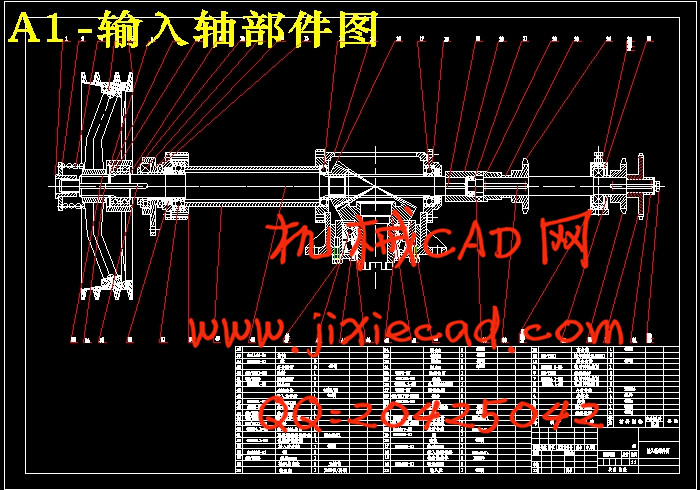

5传动设计及其校核 20

5.1传动装置总体设计 20

5.2确定传动装置的传动比和链条长度 20

5.3轴的设计与校核 24

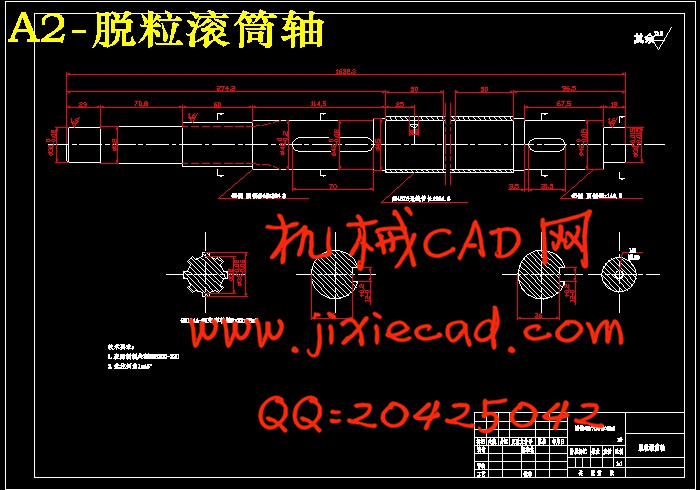

5.3.1脱粒滚筒轴设计与校核 24

5.4本章小结 29

6结论 29

参考文献 30

致谢 31

摘 要:本文简述了国内、外联合收割机的研究现状和典型脱粒分离装置的工作原理。通过查阅资料了解水稻的农艺、形态参数。通过对比方式选择出钉齿-栅格凹板-顶盖导向板脱粒分离的方式的效果最佳。并且采用纵置脱离滚筒,在不改变机体体积的条件下能够加长滚筒长度,增加脱粒和分离时间。这种纵置式轴流脱粒与分离装置工作时谷物留作空间螺旋运动,脱粒柔和且工作时间长,脱粒和分离比较充分,在脱净率、破碎率、分离率等都优于切流。为了减少脱粒损失,此脱粒系统还增加了复脱机构,能够将未脱粒完全的穗头通过它再次输送到脱粒滚筒再次脱粒,大大提高了脱粒效率。

本课题的研究为知道实际生产,提高轴流脱粒分离装置的性能以及降低成本提供了理论依据。

关键词:水稻 ; 纵置式轴流脱粒; 复脱; 理论依据

The Structure Design of Vertical Type Axial Flow Rice Combine Harvester Threshing System

Abstract: This article describes the research status at home and aboard of combine-harvester and working principle of typical threshing separating device.Through looking up materials about agronomy and morphological parameters of rice, I think the most effective way is the spike tooth-grid concave-header guiding plate threshing separation by comparison.The device is equipped with longitudinal separating drum which can lengthen the drum and increasing the threshing and separation time. When the vertical axial flow threshing and separating installation are working, grain is in a spiral movement. It separates softly , works in long hours and threshes and separates fully. So it is better than shear flow in the threshing rate, broken rate and separating rate. In order to reduce the loss of threshing, the threshing system adopt the re-threshing mechanism which greatly improves the efficiency of threshing. This mechanism can convey the incomplete threshing ear to the threshing drum again.

The purpose of this research is to guide the actual production process, improve the performance of axial flow threshing and separating device and provide a theoretical basis on reducing the cost.

Key words: Rice ; Vertical type axial flow threshing ; Re-threshing ; Theoretical basis

目 录

摘要 1

关键词 1

1绪论 2

1.1课题研究的意义 2

1.2国内外的联合收割机脱粒系统研究状况 2

1.3研究内容 4

1.4研究方法 5

1.5本章小结 6

2脱粒装置整体方案的确定 6

2.1脱粒装置简介 6

2.1.1脱粒装置的基本脱离原理 6

2.2本章小结 9

3主要零部件选择 9

3.1零部件的设计 9

3.1.1脱粒装置的选择 9

3.2本章小结 14

4主要零部件设计与计算 14

4.1脱粒滚筒的设计 14

4.2凹板的设计 15

4.3脱粒间隙的设计 16

4.4复脱机构的设计 17

4.4.1复脱下搅龙的设计 17

4.5本章小结 19

5传动设计及其校核 20

5.1传动装置总体设计 20

5.2确定传动装置的传动比和链条长度 20

5.3轴的设计与校核 24

5.3.1脱粒滚筒轴设计与校核 24

5.4本章小结 29

6结论 29

参考文献 30

致谢 31