设计简介

摘要

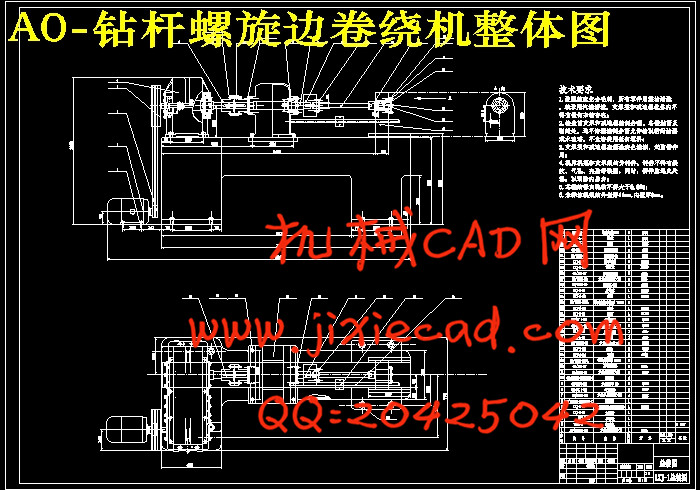

本设计主要对钻杆螺旋边卷绕机进行了较全面论述,了解了缠绕机的类型、发展现状。阐明了卷绕机的工作原理、组成及其特性。并根据螺卷绕机的工作原理、工作条件、工作要求等设计一卷绕机。在此过程中,经过对比结合,初步确定了合适的卷绕机结构形式。 在计算中,首先确芯轴的尺寸,然后通过对该尺寸计算校核,选择出其他部件的外形尺寸,再对其进行校核,确定是否能达到设计要求。 由于芯轴在卷绕过程中受力较复杂。本设计从这个问题出发,通过芯轴的动力学模型对其受力过程进行分析.同时,利用分析问题的结果再综合其他因素,最终选取合适的电动机、减速器和联轴器。接下来的设计包括对主轴组件的设计校核,对送料压轮的设计校核,对连接接键及转盘的强度校核,对支承轴的命、前后支架轴承端盖及套杯的设计和优化。

最后对钻杆螺旋边卷绕机的安装和平时保养做了总结,整个设计对今后的设计工作将有实际指导意义和价值。

关键词:螺旋边卷绕机 芯轴 校核 原理

Abstract

This design on the drill pipe spiral side winding machine, discussed in a more comprehensive understanding of a winding machine type, development status. Clarifies the working principle of the winding machine, the composition and characteristics. And in accordance with the working principle of the spiral winding machine, working conditions, job requirements and the design of a winding machine. In this process, after the contrast combination, initially identified a suitable winding machine structure. In the calculation, first determine the mandrel size, then by the size calculation checking, select the other components Dimensions, and then its check to determine whether it can meet the design requirements. Force due to the mandrel in the winding process is more complex. This design, starting from this issue, and analyzed by the dynamic model of the mandrel force. The same time, the results of the analysis of the problem and then combined with other factors, and ultimately select a suitable motor, speed reducer and coupling. Next, the design includes the spindle component design verification, the design of the feed pressure round of design checking, checking the strength to connect the access key and dial the life of the supporting shaft, front and rear bracket bearing cover and cup set and optimization.

Finally, the installation and normal maintenance of the drill pipe spiral edge of the winding machine to do the entire design for the future design work will have practical guidance on the meaning and value.

Key words: Spiral side winding machine Mandrel Check principle

目 录

前 言………………………………………………………………1

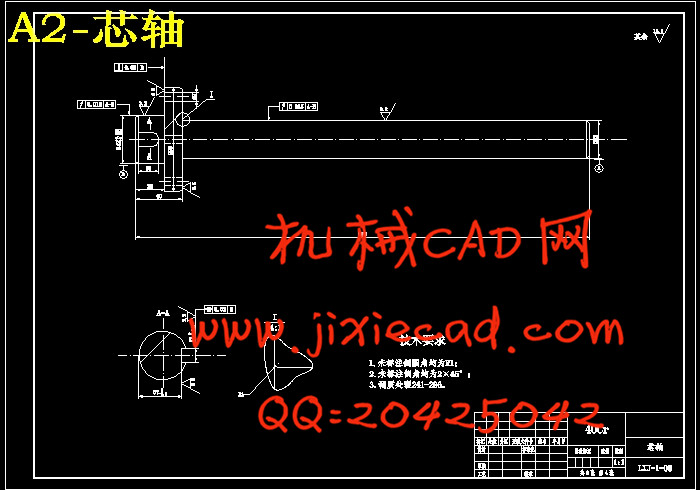

1 芯轴参数设计……………………………………………………2

1.1芯轴直径及螺旋边弧长计算......................2

1.2 芯轴的其他尺寸参数设计........................3

2 芯轴力学模型及电机选用..............................4

2.1 芯轴装置力学模型..............................4

2.2 扁钢塑性变形分析..............................5

2.3 芯轴和卷制的扁钢转动惯量分析..................5

2.4 电动机功率计算及选用..........................8

3 芯轴尺寸校核和确定.................................10

3.1按扭转强度条件强度校核并确定轴的直径..........11

3.2 按弯扭合成强度校核轴.........................12

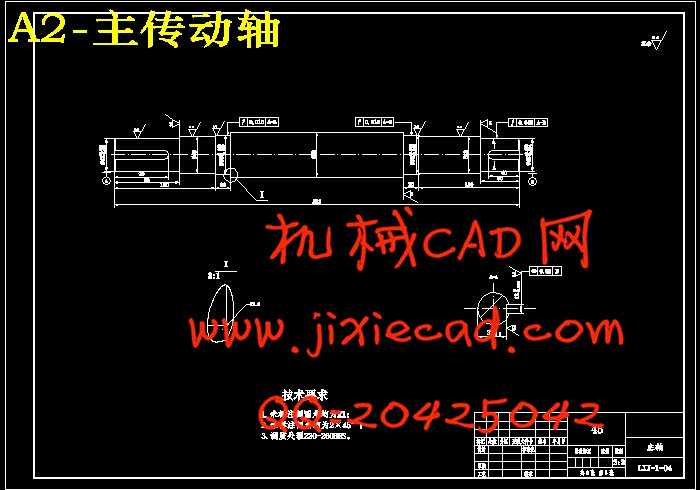

4 主轴组件设计.......................................29

4.1主轴组件的基本要求............................29

4.2滚动轴承的刚度确定............................31

4.3主轴组件设计计算..............................31

4.4 主轴组件的刚度校核...........................39

5 连接接键的强度校核计算及转盘的设计.................40

5.1键的连接强度计算..............................40

6 支承轴承的寿命校核.................................43

6.1 力作用于I处时对轴承的寿命校核...............44

6.2 力作用于II处时对轴承的寿命校核..............50

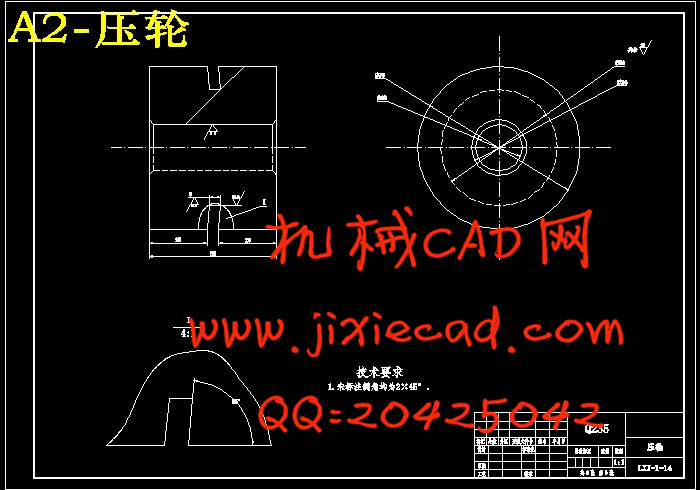

7 送料压轮设计.......................................55

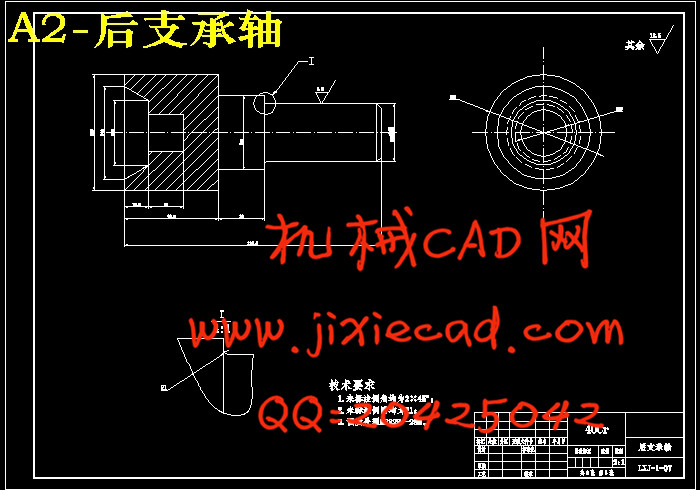

8 前、后支承设计......................................57

8.1 前后支承的作用和设计基本要求.................57

8.2 前支承的具体设计参数.........................57

8.3 后支承的具体设计参数.........................60

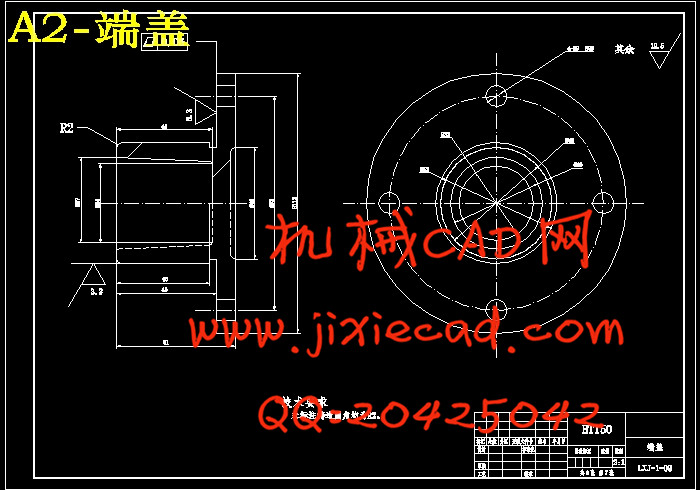

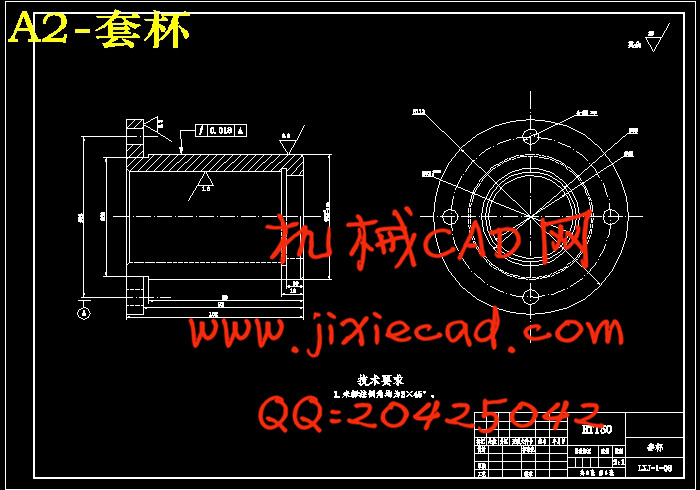

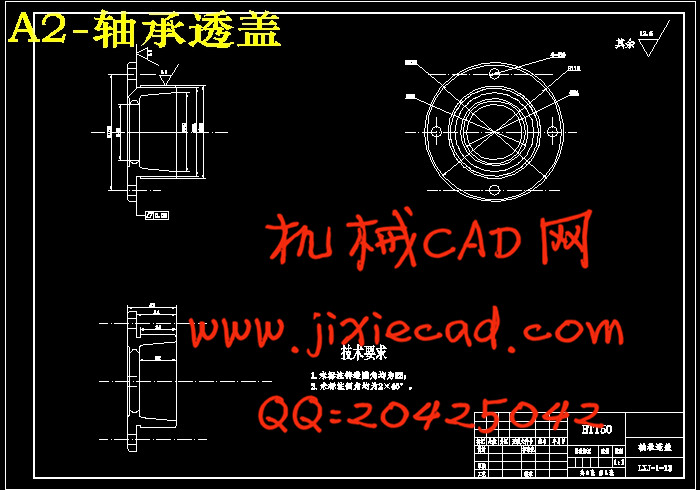

9 前后支架轴承端盖及套杯设计..........................60

9.1 前支架轴承端盖设计...........................60

9.2 后支架轴承端盖及套杯设计.....................62

10 导轨和机架设计.....................................64

10.1 导轨设计....................................63

10.2 机架设计....................................63

致 谢.................................................66

参考文献..............................................69

本设计主要对钻杆螺旋边卷绕机进行了较全面论述,了解了缠绕机的类型、发展现状。阐明了卷绕机的工作原理、组成及其特性。并根据螺卷绕机的工作原理、工作条件、工作要求等设计一卷绕机。在此过程中,经过对比结合,初步确定了合适的卷绕机结构形式。 在计算中,首先确芯轴的尺寸,然后通过对该尺寸计算校核,选择出其他部件的外形尺寸,再对其进行校核,确定是否能达到设计要求。 由于芯轴在卷绕过程中受力较复杂。本设计从这个问题出发,通过芯轴的动力学模型对其受力过程进行分析.同时,利用分析问题的结果再综合其他因素,最终选取合适的电动机、减速器和联轴器。接下来的设计包括对主轴组件的设计校核,对送料压轮的设计校核,对连接接键及转盘的强度校核,对支承轴的命、前后支架轴承端盖及套杯的设计和优化。

最后对钻杆螺旋边卷绕机的安装和平时保养做了总结,整个设计对今后的设计工作将有实际指导意义和价值。

关键词:螺旋边卷绕机 芯轴 校核 原理

Abstract

This design on the drill pipe spiral side winding machine, discussed in a more comprehensive understanding of a winding machine type, development status. Clarifies the working principle of the winding machine, the composition and characteristics. And in accordance with the working principle of the spiral winding machine, working conditions, job requirements and the design of a winding machine. In this process, after the contrast combination, initially identified a suitable winding machine structure. In the calculation, first determine the mandrel size, then by the size calculation checking, select the other components Dimensions, and then its check to determine whether it can meet the design requirements. Force due to the mandrel in the winding process is more complex. This design, starting from this issue, and analyzed by the dynamic model of the mandrel force. The same time, the results of the analysis of the problem and then combined with other factors, and ultimately select a suitable motor, speed reducer and coupling. Next, the design includes the spindle component design verification, the design of the feed pressure round of design checking, checking the strength to connect the access key and dial the life of the supporting shaft, front and rear bracket bearing cover and cup set and optimization.

Finally, the installation and normal maintenance of the drill pipe spiral edge of the winding machine to do the entire design for the future design work will have practical guidance on the meaning and value.

Key words: Spiral side winding machine Mandrel Check principle

目 录

前 言………………………………………………………………1

1 芯轴参数设计……………………………………………………2

1.1芯轴直径及螺旋边弧长计算......................2

1.2 芯轴的其他尺寸参数设计........................3

2 芯轴力学模型及电机选用..............................4

2.1 芯轴装置力学模型..............................4

2.2 扁钢塑性变形分析..............................5

2.3 芯轴和卷制的扁钢转动惯量分析..................5

2.4 电动机功率计算及选用..........................8

3 芯轴尺寸校核和确定.................................10

3.1按扭转强度条件强度校核并确定轴的直径..........11

3.2 按弯扭合成强度校核轴.........................12

4 主轴组件设计.......................................29

4.1主轴组件的基本要求............................29

4.2滚动轴承的刚度确定............................31

4.3主轴组件设计计算..............................31

4.4 主轴组件的刚度校核...........................39

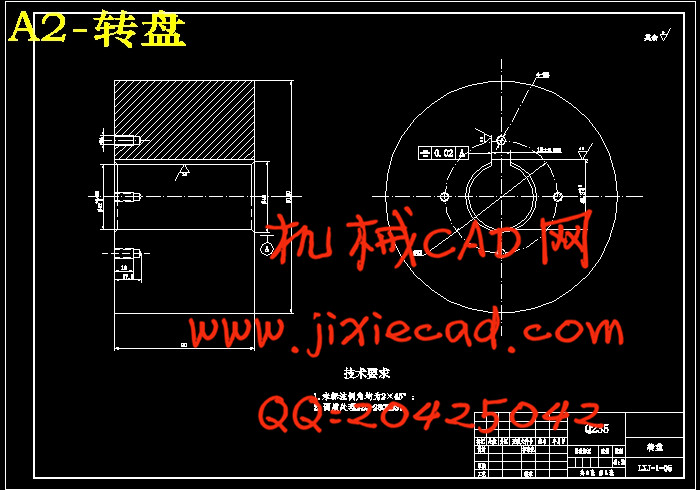

5 连接接键的强度校核计算及转盘的设计.................40

5.1键的连接强度计算..............................40

6 支承轴承的寿命校核.................................43

6.1 力作用于I处时对轴承的寿命校核...............44

6.2 力作用于II处时对轴承的寿命校核..............50

7 送料压轮设计.......................................55

8 前、后支承设计......................................57

8.1 前后支承的作用和设计基本要求.................57

8.2 前支承的具体设计参数.........................57

8.3 后支承的具体设计参数.........................60

9 前后支架轴承端盖及套杯设计..........................60

9.1 前支架轴承端盖设计...........................60

9.2 后支架轴承端盖及套杯设计.....................62

10 导轨和机架设计.....................................64

10.1 导轨设计....................................63

10.2 机架设计....................................63

致 谢.................................................66

参考文献..............................................69