设计简介

摘 要

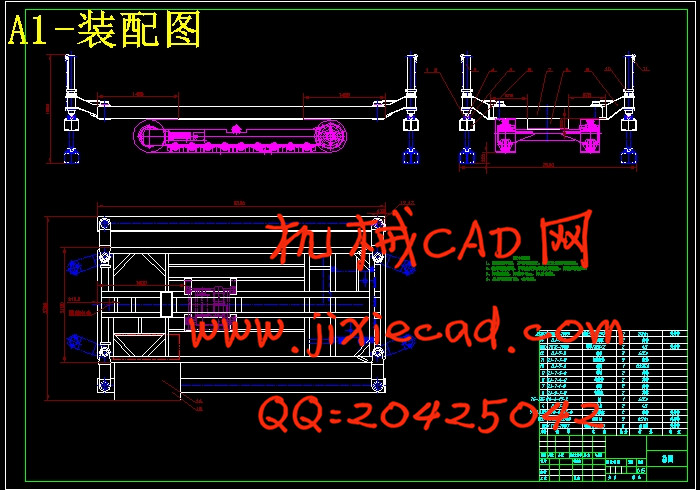

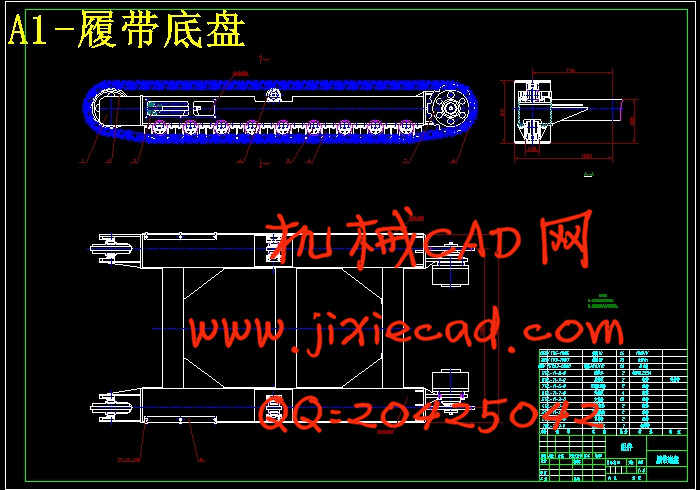

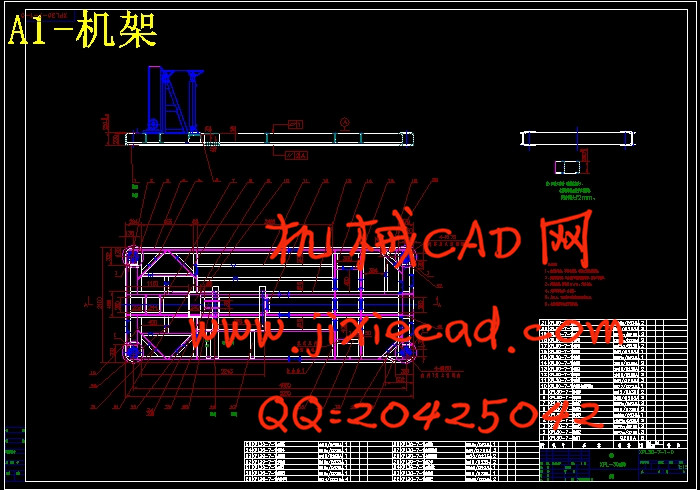

钻机主要是适应旋喷工法的逐步推广而研制而成的。采用履带底盘行走装置,通过不同模块的组合,可以适合定喷、摆喷、旋喷等施工工艺;单重、双重、三重旋喷等各种施工要求。可用于各类软地基加固、高层建筑地下室的防渗处理、大江大河堤坝的整治、铁路公路桥墩的加固等。钻机的底架组件的主要作用是:支撑组件、存放物品和负责整机的行走。钻机的行走包括直行和转向。本文主要是在一组已知参数的基础上,参考大量成熟产品的设计方案,进行履带底盘及底架的结构和参数设计,设计各个零件,并对整个组件的结构进行合理的布置。最后,在理解设计要求的基础上,编制了主要零部件的工艺。

关键词:钻机;底架组件;工艺;履带底盘

Abstract

Drilling Rig is produced for the sake of the work method-revolve with spray. they are joined by the track fleeting. Pass the combination of the different mold piece, it can suit the craft of construction to settle to spray, put to spray, the revolve to spray the etc.; it can suit the every kind of construction request of, such as single, double, three times etc. It can be used to reinforce the various soft foundations, to handle the leakage of ground floor of high layer building, to renovate the embankment of the big river, to reinforce the railroad, highway, abutment etc. The frame is made of top frame, inside frame, descend frame and flank frame. The function of the frame is to prop up whole machine, deposit the goods and move whole machine. It can go straight and turn around.On base of a set of given parameters and reference of mature products , this paper mainly design the structure and parameters of pretrial and Frame module, design necessary parts and arrange the whole discreteness propel . In the end , workout the craftwork of producing technical of typical parts after totally understanding of its design desire .

Keywords: Drilling Rig; Frame module; craftwork; pretrial

目 录

摘 要 IV

Abstract V

目录 V

1 概述 1

1.1 钻机主要用途: 1

1.2 主要特点: 1

1.3 钻机主要性能: 2

1.4 钻机的工作原理 2

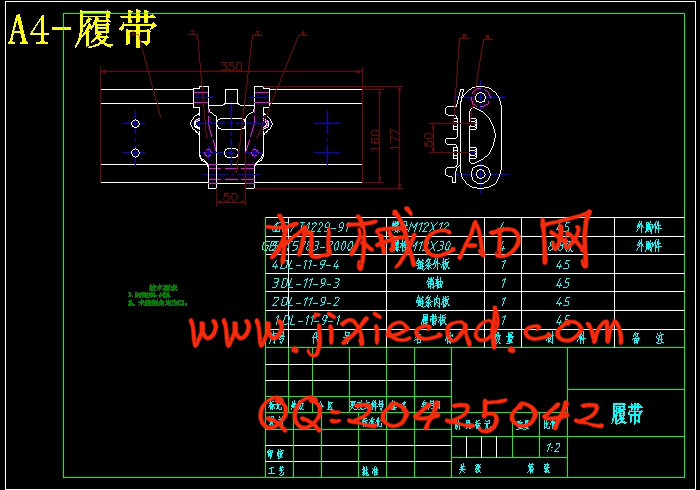

2 履带底盘设计 4

2.1 方案论证 4

2.2 履带底盘的介绍 4

2.3 设计要求 4

2.4 履带行走装置的设计因素 5

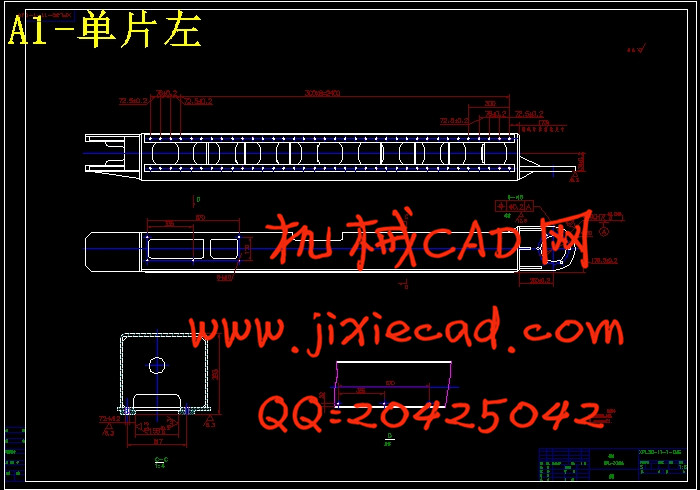

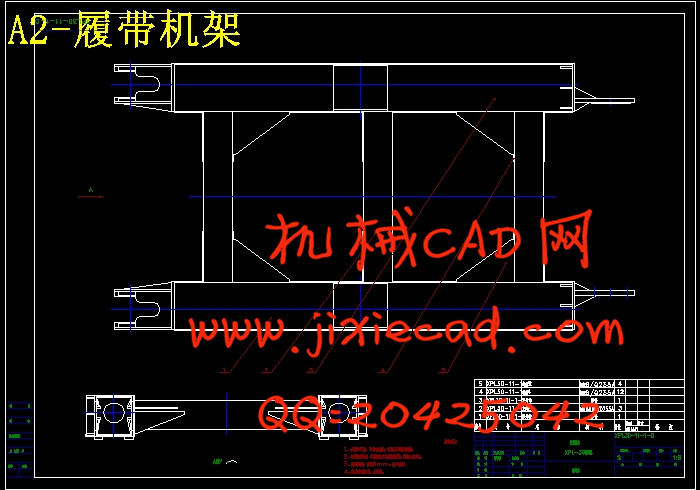

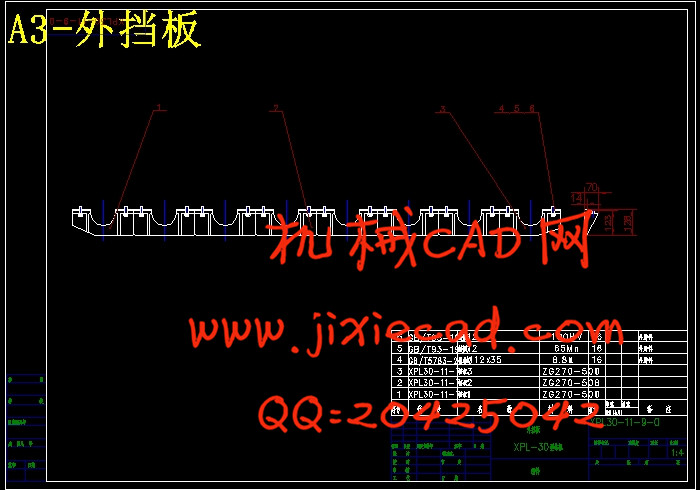

2.5 结构设计 6

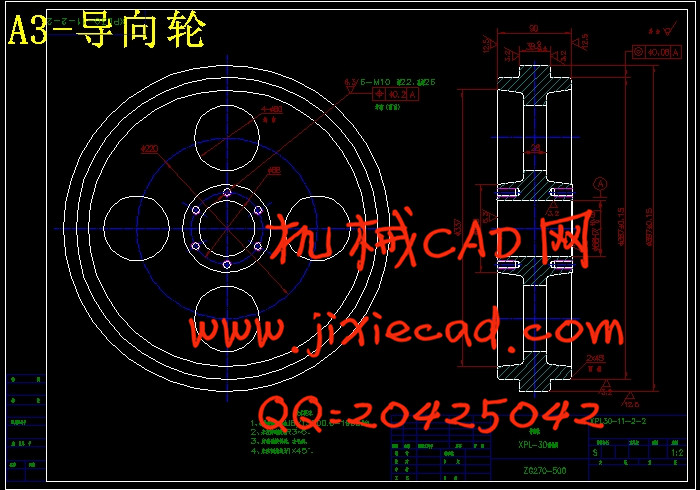

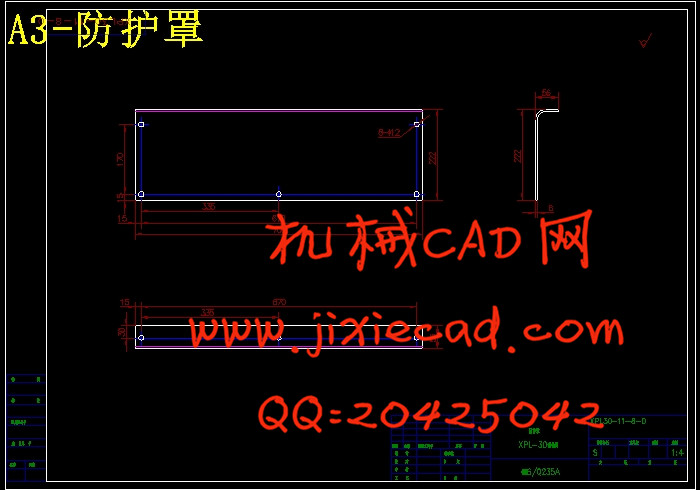

2.5.1 整体结构设计 6

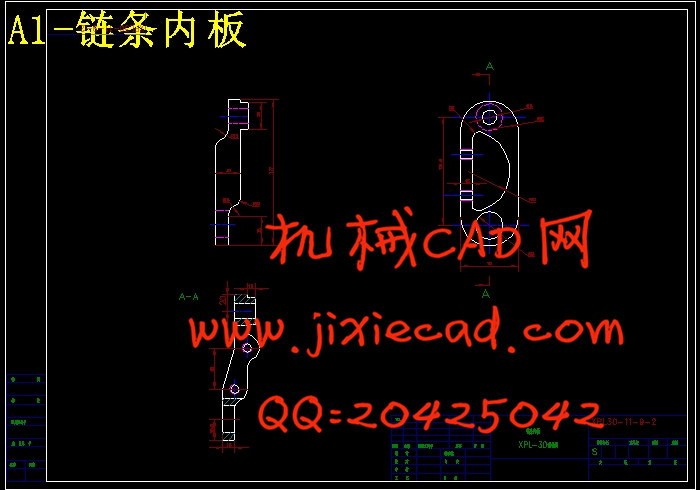

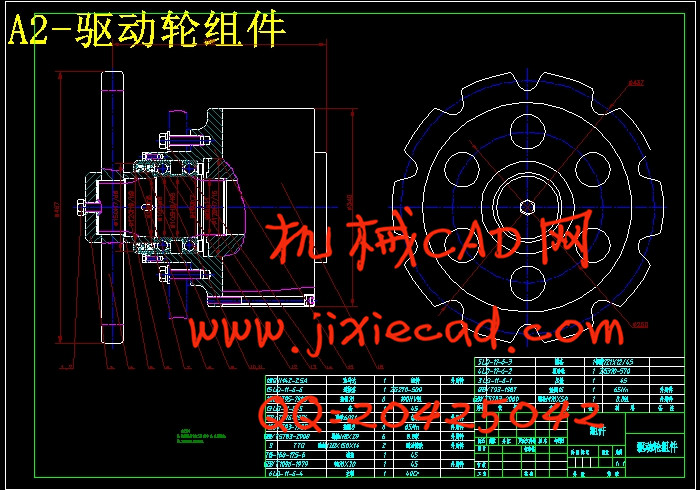

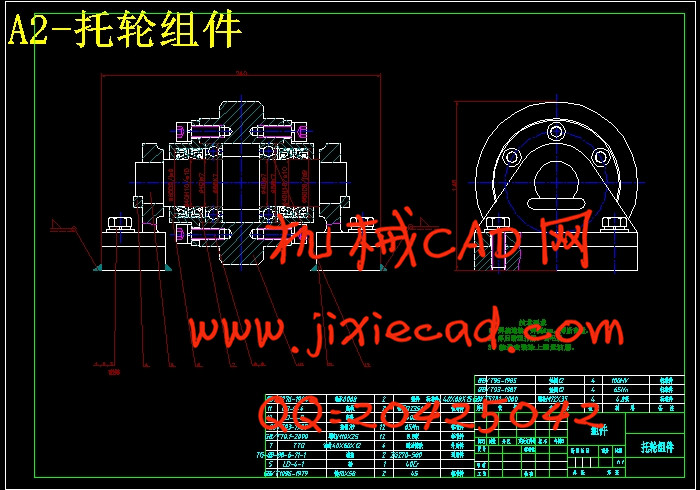

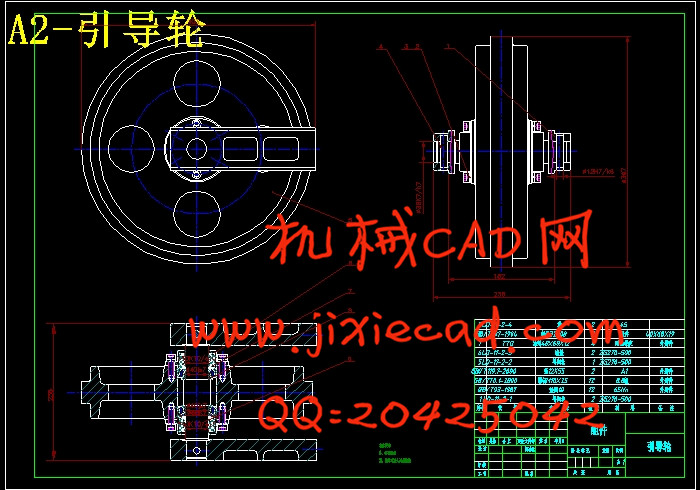

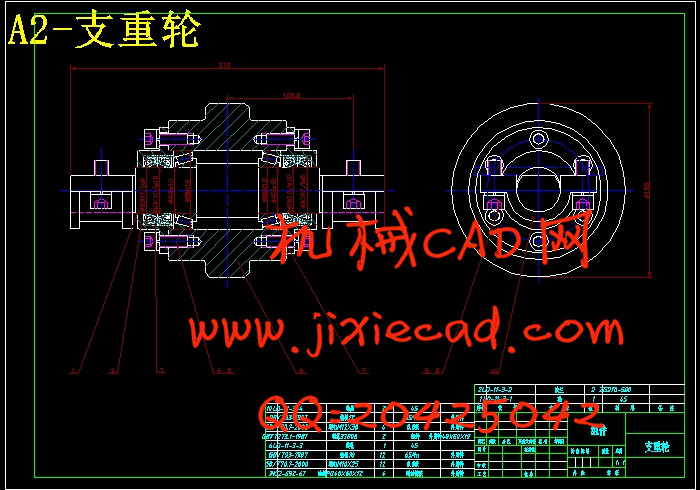

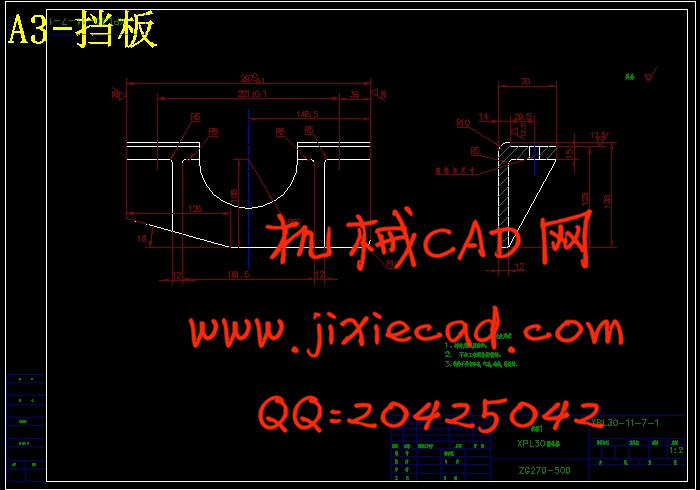

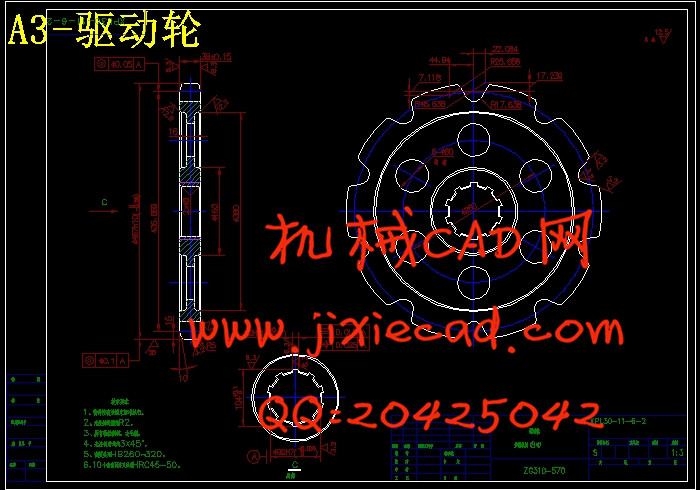

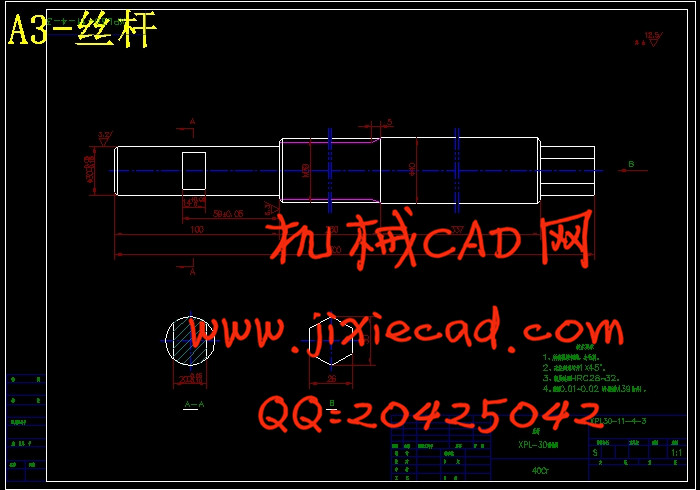

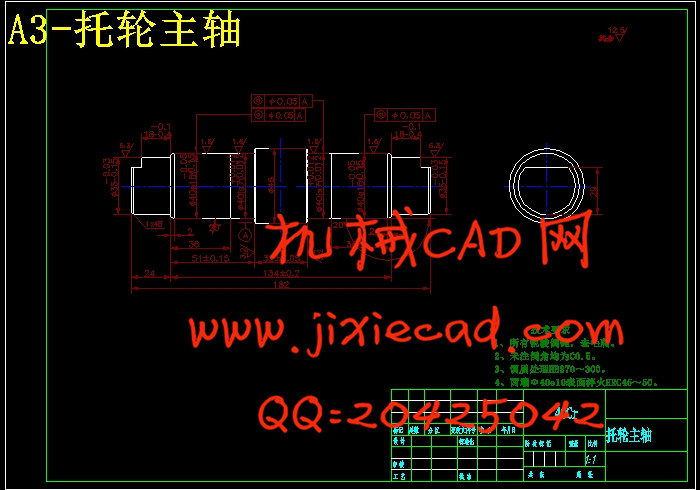

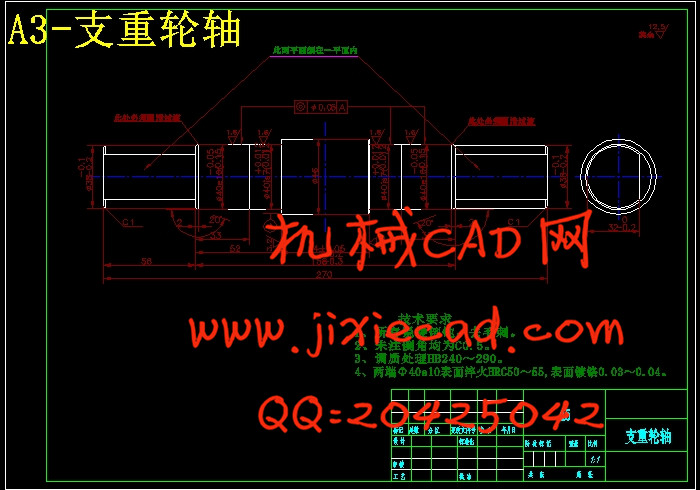

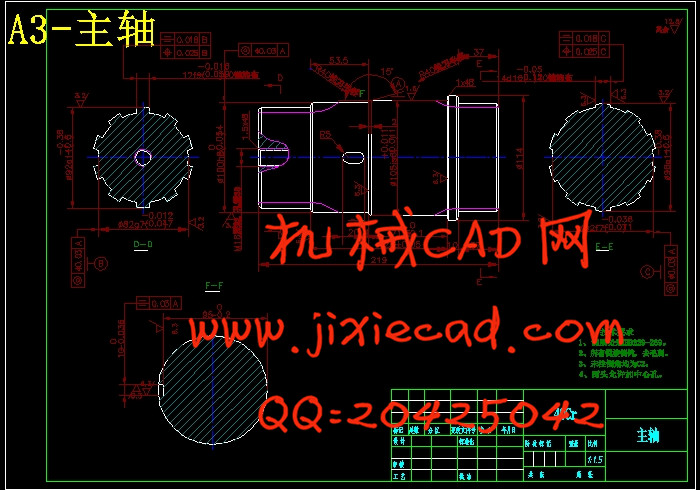

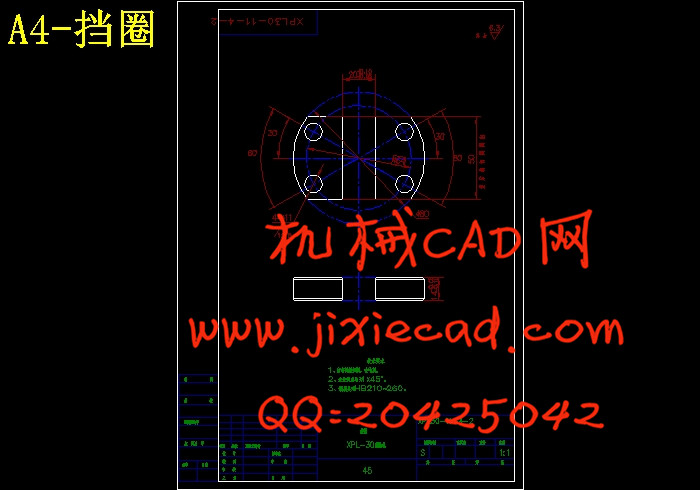

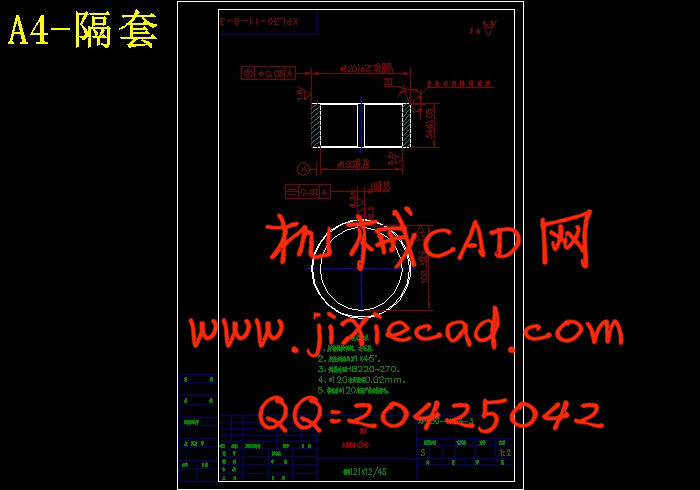

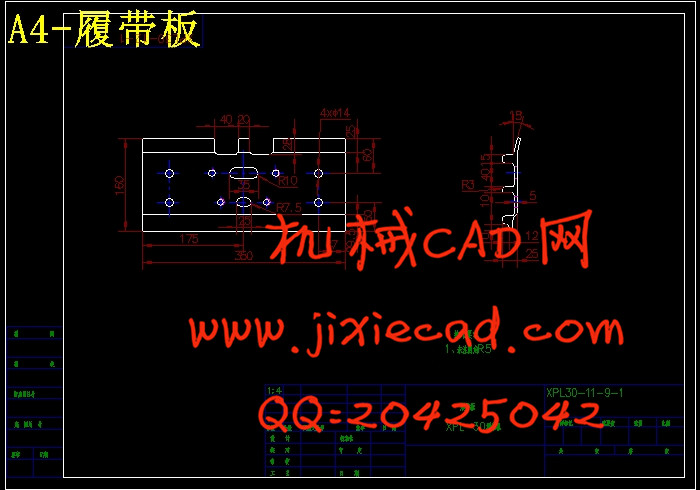

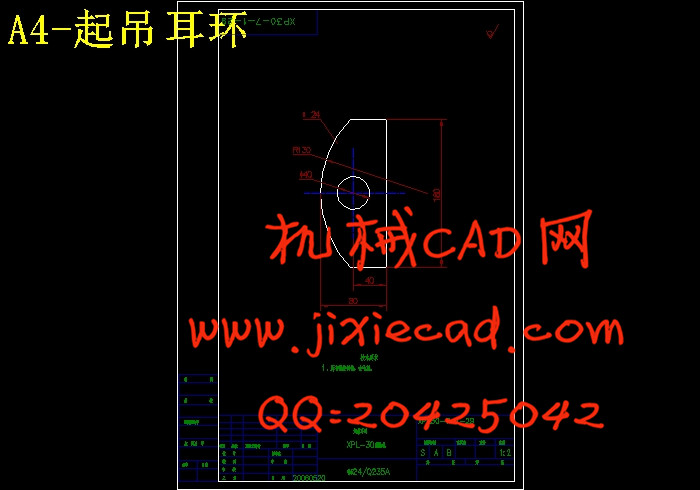

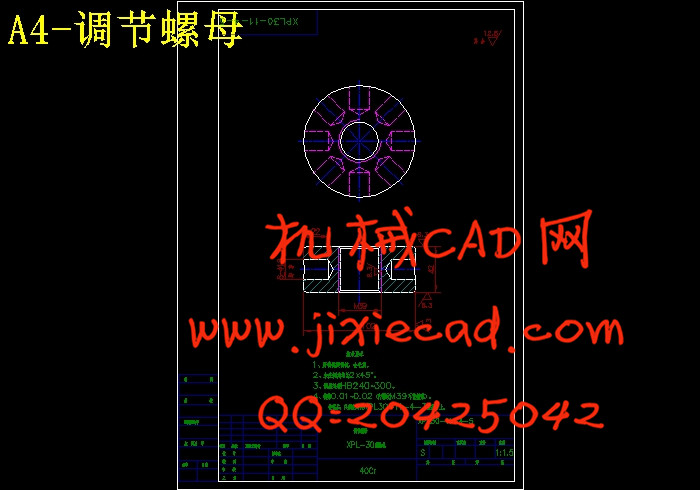

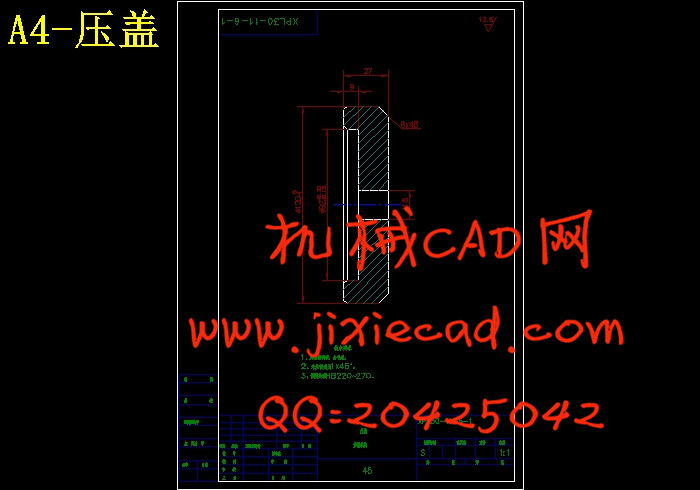

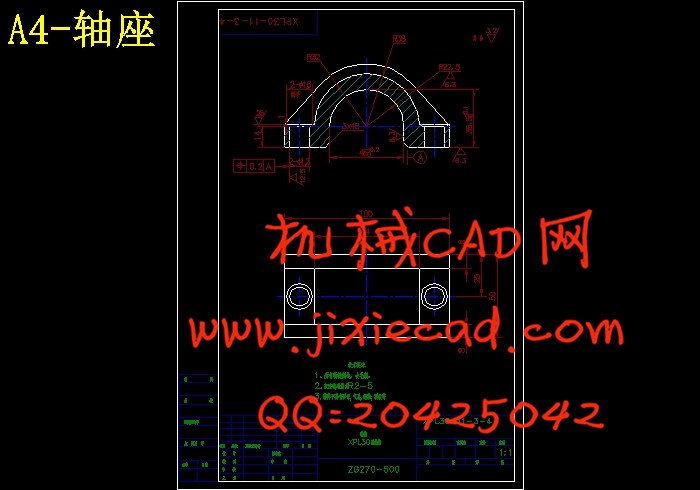

2.5.2 零部件的设计 7

2.6 设计计算 11

2.6.1 主机行走装置计算 11

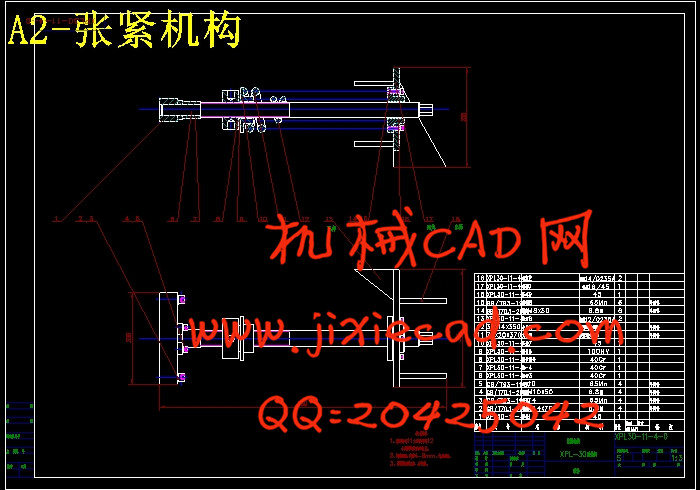

2.6.2 履带张紧机构有关计算 16

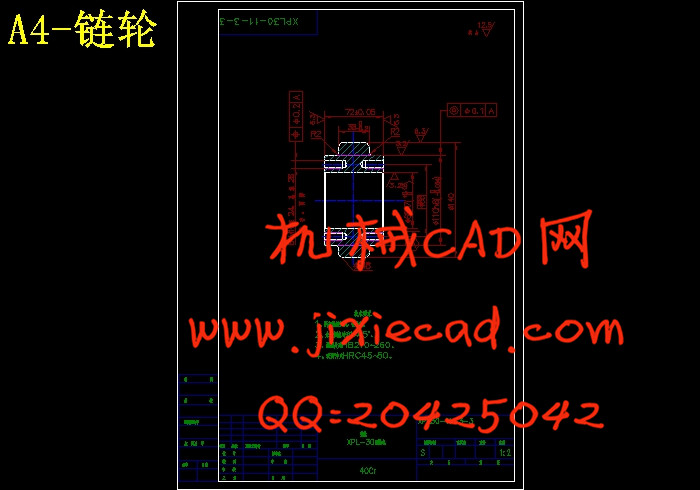

2.6.3 驱动轮组件的设计 17

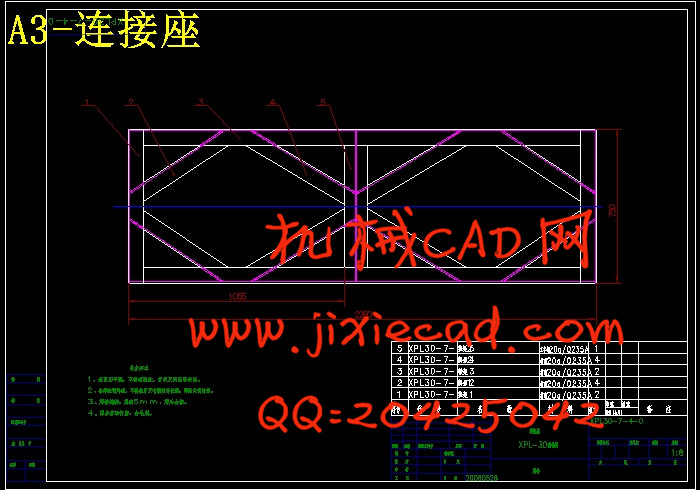

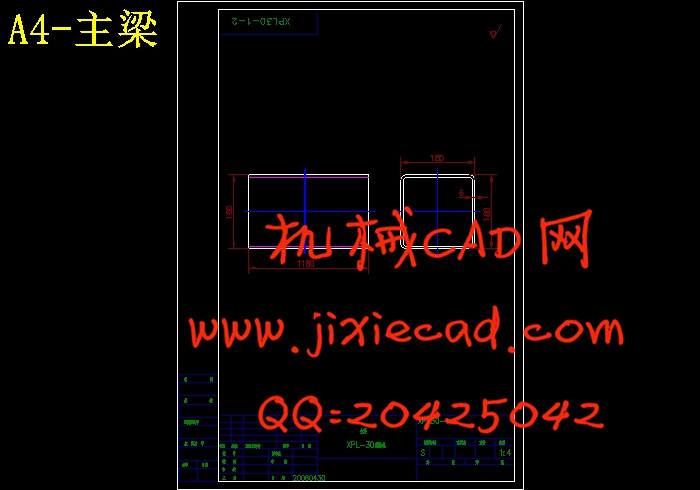

3 底架设计 26

3.1 底架的介绍 26

3.2 设计要求及步骤 26

3.3 底架架的设计 26

3.3.1 底架设计准则 26

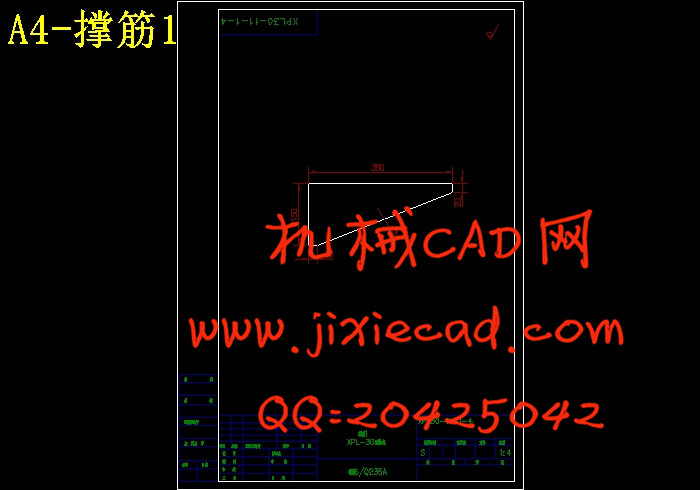

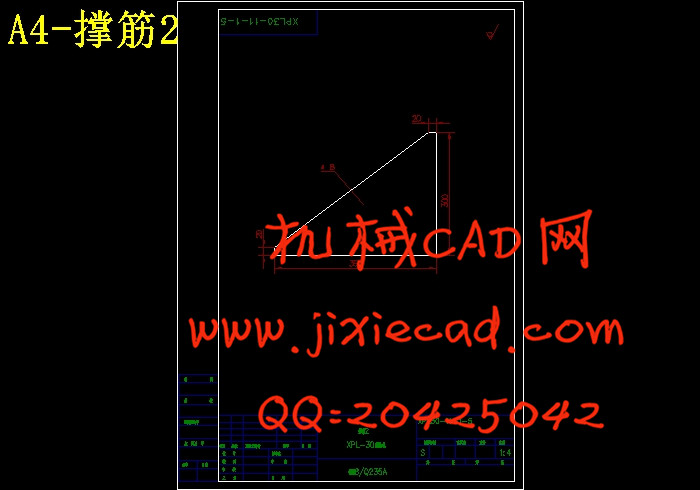

3.3.2 焊接工艺的说明 27

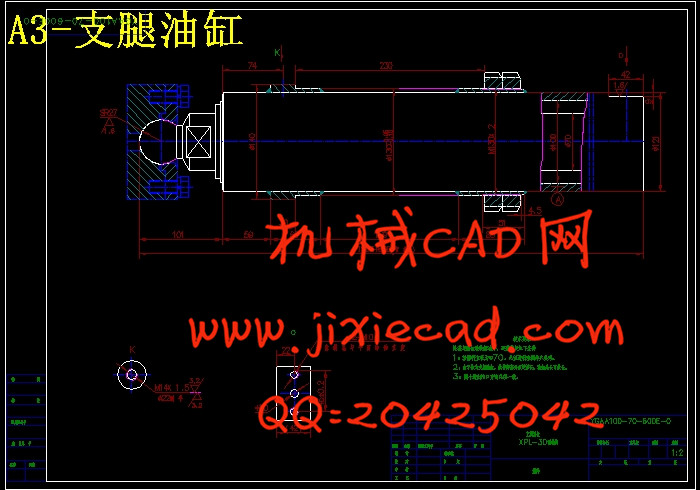

3.4 支腿机构的设计 28

3.4.1 支腿机构的介绍 28

3.4.2 设计要求 28

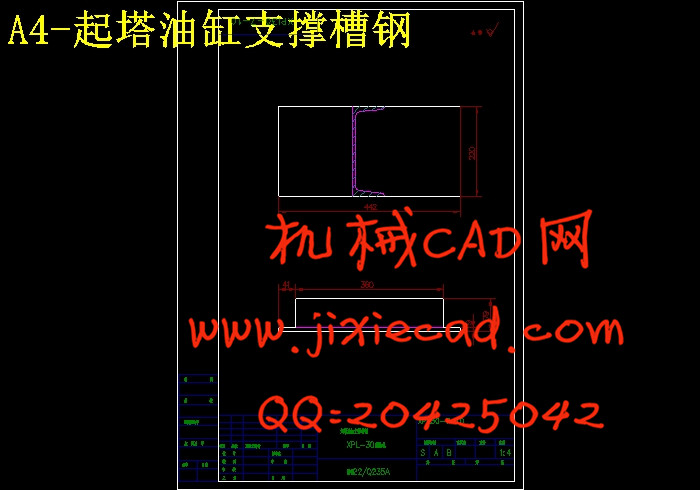

3.4.3 支腿油缸的相关计算 29

4 典型零件工艺编制 32

5 设计心得 35

致谢 36

参考文献 37