设计简介

摘 要

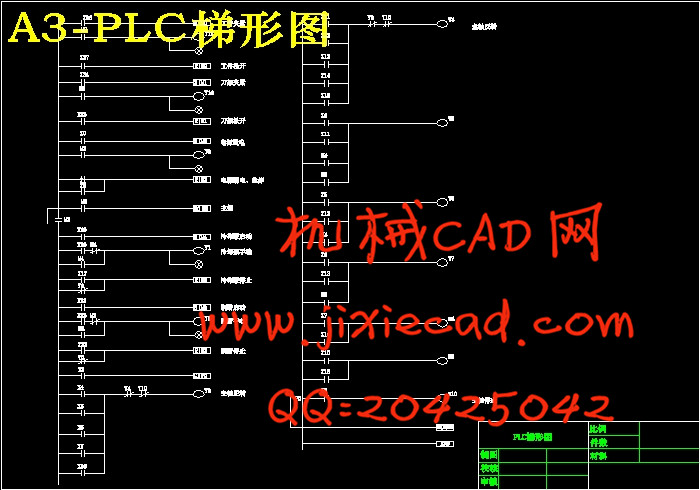

本文是研究可编程控制器(plc)在XA6132万能铣床数控化改造中的技术应用问题,利用plc的自身特性解决传统继电器—接触器电气控制系统存在的线路复杂、可靠性稳定性差、故障诊断和排除困难等难题。由于PLC电气控制系统与继电器—接触器电气控制系统相比,具有结构简单,编程方便,调试周期短,可靠性高,抗干扰能力强,故障率低,对工作环境要求低等一系列优点。因此,本论文对XA6132万能铣床的数控改造,将把PLC控制技术应用到改造方案中去,从而大大提高铣床的工作性能。论文分析了铣床的控制原理,制定了可编程控制器改造XA6132万能铣床电气控制系统的设计方案,完成了电气控制系统硬件和软件的设计,其中包括PLC机型的选择、I/O端口的分配、I/O硬件接线图的绘制、PLC梯形图程序的设计。对PLC控制铣床的工作过程作了详细阐述,论述了采用PLC取代传统继电器—接触器电气控制系统从而提高机床工作性能的方法,给出了相应的控制原理图。

关键词:可编程控制器,铣床,数控改造,电气控制系统

Abstract :This paper is to examine programmable controller (plc) XA6132 Universal Milling Machine transformation of technology should be with problems, plc's own characteristics resolve traditional relay - contactor electrical control system of complex circuits, Stability poor reliability, fault diagnosis and rule out other problems difficult. As the PLC control system and electrical relay - contactor electrical control systems, is simple in structure, programming convenience, Debugging a short cycle, high reliability and anti-jamming capability and a low failure rate, the work environment requires a series of low strengths. Thus, the thesis of the XA6132 Universal Milling Machine CNC transformation, PLC control technology will be applied to the transformation of the program, and thus greatly enhance the performance of Miller. Analysis of the paper machine control theory, developed a programmable controller XA6132 Universal Milling Machine electrical control system design, completed the electrical control system hardware and software design, including the choice of PLC Systems, I/O port allocation, I/O hardware wiring the drawing, PLC ladder logic program design. PLC control of the milling process were discussed in detail, This paper discusses the PLC to replace traditional relay - contactor electrical control system so as to enhance the performance of the machine, the corresponding control diagram.

Keywords : PLC, milling, NC transformation, electrical control system目 录

1 绪论..........................................................

1.1 机床数控化改造是工艺设备更新的途径..........................

1.2机床数控化改造的条件.........................................

1.3 国内外旧机床数控改造的实例..................................

1.4 plc(可编程控制器)技术应用发展历程..........................

2.XA6132型卧式万能铣床的基本结构和控制要求........................

3.数控化改造的一般途径...........................................

3.1主传动的数控化改造..........................................

3.2进给传动的数控化改造........................................

4.基于PLC的XA6132万能铣床电气控制系统硬件部分的设计............

4.1 PLC型号的选择..............................................

4.2 PLC的I/O端口分配表..........................................

4.3 PLC的I/O电气接线图的设计....................................

5. XA6132万能铣床电气控制系统软件部分的设计........................

5.1 系统电源开启控制............................................

5.2主轴变频器调速控制...........................................

5.3 冷却泵程序控制设计..........................................

5.4润滑油泵程序控制设计........................................

5.5 刀架松紧设计................................................

5.6 工件松紧设计................................................

5.7 PLC外部紧急停车控制设计......................................

6.FX系列PLC外部接线问题...........................................

7.PLC在控制柜中的接线问题.........................................

8.控制柜与现场设备之间电缆接线问题................................

9.XA6132铣床控制梯形图设计........................................

10.结论...........................................................

10.1 研究成果.....................................................

10.2 不足之处.....................................................

设计感想..........................................................

参考文献.........................................................