设计简介

摘 要

空气压缩机(简称空压机)是一种用来压缩气体提高气体压力或输送气体的机械。空压机的用途很广,几乎遍及工农业、国防、科技、民用等各个领域。空气压缩机的安全生产保护对于煤矿企业的生产是十分重要的。可编程控制器(PLC)将传统的继电器控制技术、计算机控制技术和通信技术融为一体,专为工业控制而设计。

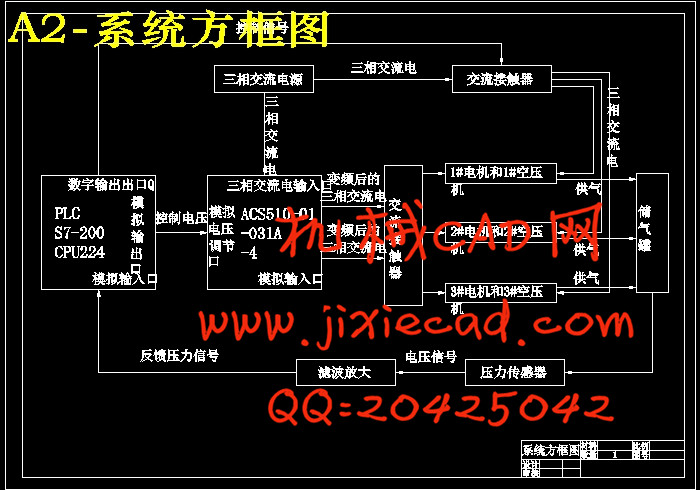

本设计以煤矿井下储气罐为控制对象,系统主要由3台空压机、1台变频器、PLC以及线性远传压力传感器等组成。其中PLC、变频器、空压机组和压力传感器组成闭环反馈控制系统。使供气压力保持恒定。PLC根据控制各台空压机的运行状态(如工频运行、变频运行、停止),从而控制空压机的运行台数,在大范围上控制供气气压; 变频器内部PID调节器控制变频器对变频电机进行速度调节,在小范围上控制供气气压。空压机电机的速度调节采用变频调速技术,利用变频器对空压机进行速度控制。

关键词:空气压缩机;可编程控制器(PLC)控制系统;变频器;PID调节器;压力传感器

ABSTRACT

Air compressor ( referred to as the compressor) is a method used to increase the gas pressure of compressed gas or gas transportation machinery. Air compressor is widely used, almost throughout the industry and agriculture, national defence, science and technology, civil and other fields. Air compressor safety protection for coal mine enterprise's production is very important. Programmable controller ( PLC ) will be the traditional relay control technology, computer control technology and communication technology com., designed specifically for industrial control and design.

The design of coal mine gas storage tank as the control object, the system is mainly composed of 3 air compressors,1 frequency converters, PLC and linear remote pressure sensor and so on.PLC and linear remote pressure sensor and so on. PLC and linear remote pressure sensor and so on. The PLC, inverter, air compressor and pressure sensor composed of closed-loop feedback control system. The supply pressure constant. PLC according to the control of the air compressors operating state ( such as frequency operation, frequency operation, stop ), thereby controlling the compressor running numbers, in a wide range of control of gas pressure regulator control; inverter internal PID converter for variable frequency motor speed regulation, on a smaller scale control of gas pressure. Air compressor motor speed regulation with frequency conversion technology, the use of frequency converter speed control for air compressor.

Key words: Air compressor; Programmable Logic Controller ( PLC ) control system; Frequency converter; PID regulator; Pressure sensor

目录

摘要 Ⅰ

Abstract Ⅱ

第1章 绪论 1

1.1 空气压缩机的发展与现状 1

1.2本课题研究的目的与意义 1

1.3设计内容 2

第2章 变频恒压供气系统方案的设计 4

2.1变频恒压供气方法的设计 4

2.2控制系统的工作原理 4

2.2.1空压机变频调速要求 6

2.2.2空压机切换工作过程 6

2.3本章小结 7

第3章 控制系统的硬件设计 8

3.1 控制系统的要求及分析 8

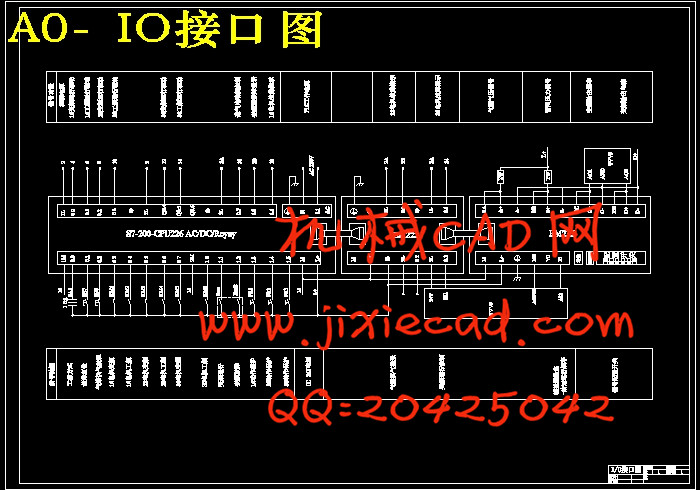

3.2控制系统I/O配置 8

3.3 PLC系统的硬件选型设计 9

3.3.1 PLC的产生和发展 9

3.3.2 PLC的基本结构 10

3.3.3 PLC的基本工作原理 10

3.3.4 PLC的主要特点 12

3.3.5 PLC的选型 13

3.3.6 变频器的选择 13

3.3.7 传感器的选择 14

3.4 PLC电气控制系统原理图 14

3.4.1 主电气原理图 14

3.4.2 控制电气原理图 14

3.4.3 PLC外围控制电气接线图 16

3.5 本章小结 18

第4章 控制系统软件设计 19

4.1软件设计分析 19

4.2 梯形图程序设计 19

4.3 系统流程图 19

4.4 本章小结 19

结论 24

参考文献 25

致谢 27

空气压缩机(简称空压机)是一种用来压缩气体提高气体压力或输送气体的机械。空压机的用途很广,几乎遍及工农业、国防、科技、民用等各个领域。空气压缩机的安全生产保护对于煤矿企业的生产是十分重要的。可编程控制器(PLC)将传统的继电器控制技术、计算机控制技术和通信技术融为一体,专为工业控制而设计。

本设计以煤矿井下储气罐为控制对象,系统主要由3台空压机、1台变频器、PLC以及线性远传压力传感器等组成。其中PLC、变频器、空压机组和压力传感器组成闭环反馈控制系统。使供气压力保持恒定。PLC根据控制各台空压机的运行状态(如工频运行、变频运行、停止),从而控制空压机的运行台数,在大范围上控制供气气压; 变频器内部PID调节器控制变频器对变频电机进行速度调节,在小范围上控制供气气压。空压机电机的速度调节采用变频调速技术,利用变频器对空压机进行速度控制。

关键词:空气压缩机;可编程控制器(PLC)控制系统;变频器;PID调节器;压力传感器

ABSTRACT

Air compressor ( referred to as the compressor) is a method used to increase the gas pressure of compressed gas or gas transportation machinery. Air compressor is widely used, almost throughout the industry and agriculture, national defence, science and technology, civil and other fields. Air compressor safety protection for coal mine enterprise's production is very important. Programmable controller ( PLC ) will be the traditional relay control technology, computer control technology and communication technology com., designed specifically for industrial control and design.

The design of coal mine gas storage tank as the control object, the system is mainly composed of 3 air compressors,1 frequency converters, PLC and linear remote pressure sensor and so on.PLC and linear remote pressure sensor and so on. PLC and linear remote pressure sensor and so on. The PLC, inverter, air compressor and pressure sensor composed of closed-loop feedback control system. The supply pressure constant. PLC according to the control of the air compressors operating state ( such as frequency operation, frequency operation, stop ), thereby controlling the compressor running numbers, in a wide range of control of gas pressure regulator control; inverter internal PID converter for variable frequency motor speed regulation, on a smaller scale control of gas pressure. Air compressor motor speed regulation with frequency conversion technology, the use of frequency converter speed control for air compressor.

Key words: Air compressor; Programmable Logic Controller ( PLC ) control system; Frequency converter; PID regulator; Pressure sensor

目录

摘要 Ⅰ

Abstract Ⅱ

第1章 绪论 1

1.1 空气压缩机的发展与现状 1

1.2本课题研究的目的与意义 1

1.3设计内容 2

第2章 变频恒压供气系统方案的设计 4

2.1变频恒压供气方法的设计 4

2.2控制系统的工作原理 4

2.2.1空压机变频调速要求 6

2.2.2空压机切换工作过程 6

2.3本章小结 7

第3章 控制系统的硬件设计 8

3.1 控制系统的要求及分析 8

3.2控制系统I/O配置 8

3.3 PLC系统的硬件选型设计 9

3.3.1 PLC的产生和发展 9

3.3.2 PLC的基本结构 10

3.3.3 PLC的基本工作原理 10

3.3.4 PLC的主要特点 12

3.3.5 PLC的选型 13

3.3.6 变频器的选择 13

3.3.7 传感器的选择 14

3.4 PLC电气控制系统原理图 14

3.4.1 主电气原理图 14

3.4.2 控制电气原理图 14

3.4.3 PLC外围控制电气接线图 16

3.5 本章小结 18

第4章 控制系统软件设计 19

4.1软件设计分析 19

4.2 梯形图程序设计 19

4.3 系统流程图 19

4.4 本章小结 19

结论 24

参考文献 25

致谢 27