设计简介

基于PLC的皮带运输系统监控设计

摘 要

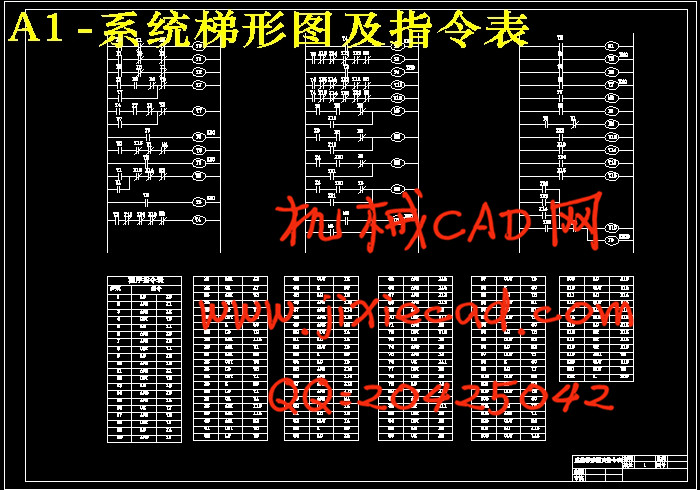

皮带输送机在许多企业中占有很重要的地位,但其控制单元种类繁多,都存在着性能和功能的差异。传统继电器控制的皮带传输机存在电路复杂、可靠性差、故障诊断与排除困难等缺点,为了取得企业的良好的经济效益和社会经济效益,提出了采用实用性强、操作方便的PLC梯形图(LADDER DIAGRAM)编程语言对皮带输送机控制系统进行设计。

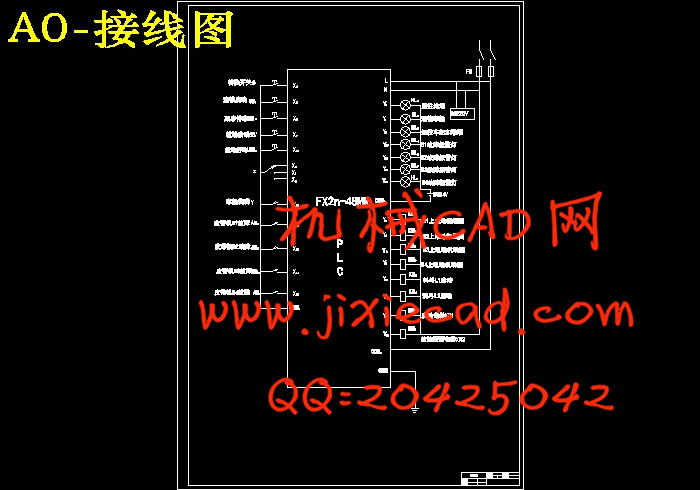

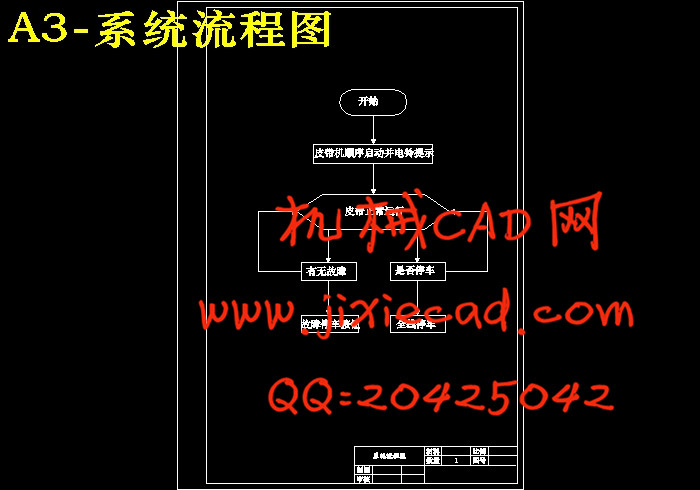

全文采用了三菱公司生产的 FX2n 系列微型可编程控制器在四段皮带输送机控制系统中的应用,给出了PLC控制皮带输送机控制系统的硬件组成和软件设计,其中包括PLC选型、I/O地址分配、I/O端子接线、程序设计和控制原理。该设计大大提高了设备的可靠性,减少了故障率,取得了成功。

关键词:PLC;梯形图;皮带输送机;自动控制;监控系统

ABSTRACT

Transmission belt machines occupy a very important position in many businesses, but its control unit is variety,there is a difference between the performance and functionality. The traditional relay control of the transmission belt has complex circuits exist, poor reliability, fault diagnosis and rule out the difficulties shortcomings, in order to achieve the economic benefits of good corporate and social economic benefits,by using user-friendly,practical,strong PLC ladder (LADDER DIAGRAM) programming language on the belt transmission control system design.

The topic is introduced the apply for Series C Omron PLC in four paragraphs belt transmission system of control,it is given the hardware and software design of the PLC control belt transmission systems,including the PLC Selection,I/O address assignment, I/O terminal wiring,programming and control theory. The design of the equipment improve the reliability of equipment and reduce the failure rate,it has been successful.

Keywords:PLC;Ladder;Transmission belt machine;Automatic control; Supervisory equipment

目 录

摘 要

皮带输送机在许多企业中占有很重要的地位,但其控制单元种类繁多,都存在着性能和功能的差异。传统继电器控制的皮带传输机存在电路复杂、可靠性差、故障诊断与排除困难等缺点,为了取得企业的良好的经济效益和社会经济效益,提出了采用实用性强、操作方便的PLC梯形图(LADDER DIAGRAM)编程语言对皮带输送机控制系统进行设计。

全文采用了三菱公司生产的 FX2n 系列微型可编程控制器在四段皮带输送机控制系统中的应用,给出了PLC控制皮带输送机控制系统的硬件组成和软件设计,其中包括PLC选型、I/O地址分配、I/O端子接线、程序设计和控制原理。该设计大大提高了设备的可靠性,减少了故障率,取得了成功。

关键词:PLC;梯形图;皮带输送机;自动控制;监控系统

ABSTRACT

Transmission belt machines occupy a very important position in many businesses, but its control unit is variety,there is a difference between the performance and functionality. The traditional relay control of the transmission belt has complex circuits exist, poor reliability, fault diagnosis and rule out the difficulties shortcomings, in order to achieve the economic benefits of good corporate and social economic benefits,by using user-friendly,practical,strong PLC ladder (LADDER DIAGRAM) programming language on the belt transmission control system design.

The topic is introduced the apply for Series C Omron PLC in four paragraphs belt transmission system of control,it is given the hardware and software design of the PLC control belt transmission systems,including the PLC Selection,I/O address assignment, I/O terminal wiring,programming and control theory. The design of the equipment improve the reliability of equipment and reduce the failure rate,it has been successful.

Keywords:PLC;Ladder;Transmission belt machine;Automatic control; Supervisory equipment

目 录

摘 要..................................................................................................................................Ⅰ

Abstract................................................................................................................................Ⅱ

第1章 绪 论…….………………………………………………….………………… .1

1.1 研究现状和研究意义…….…………………………………………….……….1

1.1.1国内外皮带运输机的研究现状…….……….………….…………………..11.1.2国内外运皮带运输机的技术的差距…….…….…….…………………...1

1.2 课题的研究目的......................................................................................................3

1.3研究内容..................................................................................................................3

1.4技术路线...................................................................................................................4

第2章PLC控制系统及程序的设计…….………………………….………............6

2.1 PLC的结构及工作原理..........................................................................................6

2.1.1 PLC的结构…….…….……………………………..……………………..6

2.1.2 PLC的工作原理……..…………..………………………………………..8

2.2 系统设计的基本要求...........................................................................................102.3 系统设计的基本步骤............................................................................................11

2.4系统构成.................................................................................................................13

2.5工艺要求.................................................................................................................15

2.6 本章小结................................................................................................................16

第3章 系统设备的选型...............................................................................................163.1可编程控制器的特点…….…………………………………………………….17

3.2本设计采用的 PLC…….………………………………………………..……….17

3.3 电动机………………………………………………………………..……….....17

3.4 皮带运输机…………………………………………………………..………….20

3.5 其他………………………………………………………………………...…….20

3.6本章小结……………………………………………………..……………….…..27

第4 章系统控制方案……………………………………………..…………………...28

4.1控制点的统计与描述…………………………………………………………….28

4.2 程序过程说明…………………………………………………………….……...30

4.3 系统整体运作介绍…………………………………………………..…………...31

4.4 本章小结……………………………………………………………..…...……….33

结论......................................................................................................................................34

参考文献.............................................................................................................................35