设计简介

摘 要

车架工作状态比较复杂,无法用简单的数学方法对其进行准确的分析计算,而采用有限元方法可以对车架的静动态特性进行较为准确的分析,从而使车架设计从经验设计进入到科学设计阶段。

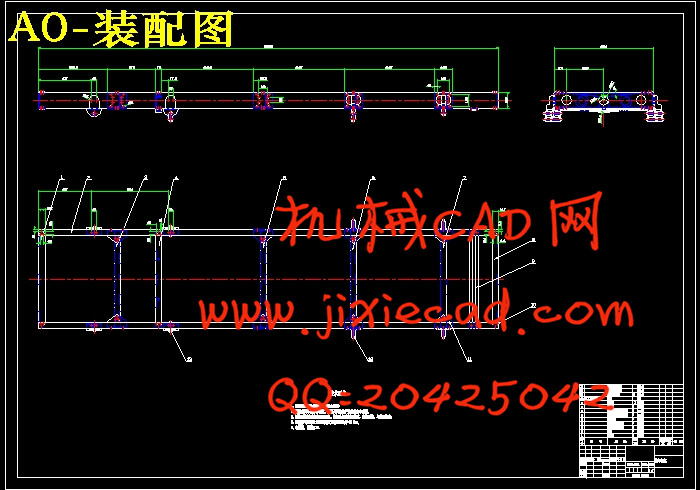

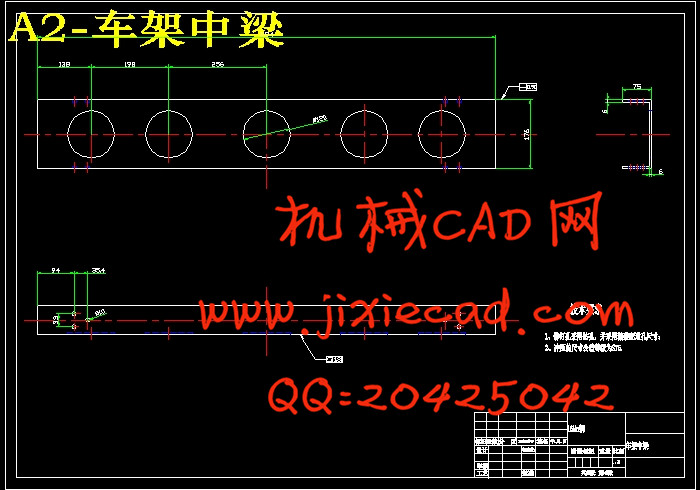

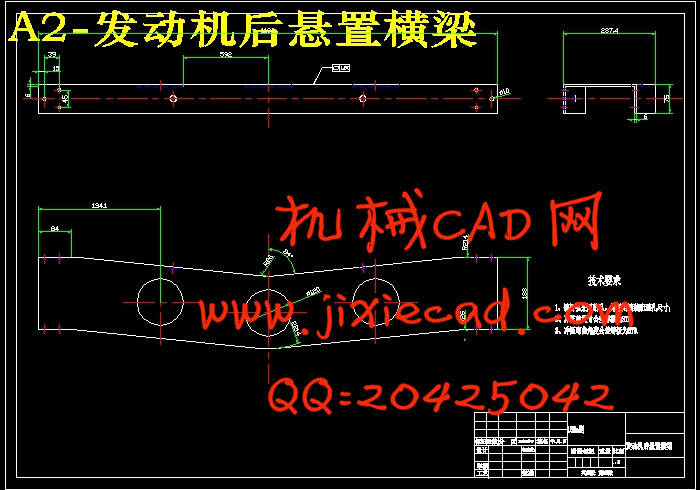

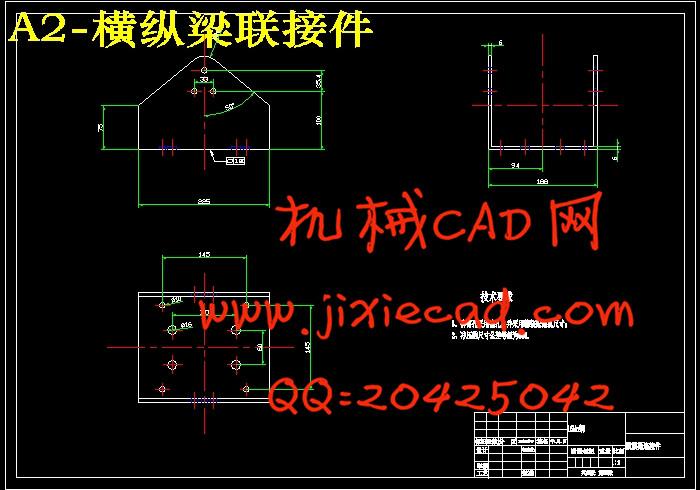

首先确定轻型货车的总体布置形式,在此基础上选择各总成的相关参数。然后初选车架横、纵梁的尺寸参数,运用材料力学对车架进行强度与刚度校核。经过优化完成对车架的结构设计。

其次,运用Pro/E软件建立车架三维模型。在满足结构力学特征的前提下,对车架结构进行了保留主要承载横梁的简化。

最后,使用有限元分析软件ANSYS 12.0从弯曲和扭转两大方向对车架进行强度、刚度分析。结合车架工作实际,对其进行了满载、前侧偏载、单侧偏载和单侧扭转、双侧扭转等工况的分析及对比,保证了车架结构满足实际使用要求。

关键词:车架;Pro/E;ANSYS;强度;刚度

ABSTRACT

In addition, the work condition of carrier car is extremely bad, and stress condition is also complex, it is unable to use simple mathematical method for accurate analysis of the calculation, and the finite element method can be used to analyze the static and dynamic performance of the frame more accurately, so that the design of frame will go from the experience design into the scientific design stage.

Firstly, the overall layout of LGV is determined, on this basis, selected parameters of every assembly. Then beams and stringers’ dimensions of the frame are selected, the strength and stiffness on the frame are checked by Mechanics of Materials. After all, the frame is designed after feedback.

Secondly, the 3D model is created used Pro/E. In faithful of the structure’s mechanical characteristics, it is necessary to simplify the geometry.

Finally, on two directions of the bending and the reverse to analyze the strength and stiffness on the frame used ANSYS 12.0. With the frame’s actual work characteristics, the frame is analyzed under the full, the front side of the partial load, the unilateral partial load and the unilateral reverse, the reverse sides conditions, guarantee the frame structure meet the mechanical requirements.

Key words:Frame; Pro/E; ANASYS ; Strength; Stiffne

目 录车架工作状态比较复杂,无法用简单的数学方法对其进行准确的分析计算,而采用有限元方法可以对车架的静动态特性进行较为准确的分析,从而使车架设计从经验设计进入到科学设计阶段。

首先确定轻型货车的总体布置形式,在此基础上选择各总成的相关参数。然后初选车架横、纵梁的尺寸参数,运用材料力学对车架进行强度与刚度校核。经过优化完成对车架的结构设计。

其次,运用Pro/E软件建立车架三维模型。在满足结构力学特征的前提下,对车架结构进行了保留主要承载横梁的简化。

最后,使用有限元分析软件ANSYS 12.0从弯曲和扭转两大方向对车架进行强度、刚度分析。结合车架工作实际,对其进行了满载、前侧偏载、单侧偏载和单侧扭转、双侧扭转等工况的分析及对比,保证了车架结构满足实际使用要求。

关键词:车架;Pro/E;ANSYS;强度;刚度

ABSTRACT

In addition, the work condition of carrier car is extremely bad, and stress condition is also complex, it is unable to use simple mathematical method for accurate analysis of the calculation, and the finite element method can be used to analyze the static and dynamic performance of the frame more accurately, so that the design of frame will go from the experience design into the scientific design stage.

Firstly, the overall layout of LGV is determined, on this basis, selected parameters of every assembly. Then beams and stringers’ dimensions of the frame are selected, the strength and stiffness on the frame are checked by Mechanics of Materials. After all, the frame is designed after feedback.

Secondly, the 3D model is created used Pro/E. In faithful of the structure’s mechanical characteristics, it is necessary to simplify the geometry.

Finally, on two directions of the bending and the reverse to analyze the strength and stiffness on the frame used ANSYS 12.0. With the frame’s actual work characteristics, the frame is analyzed under the full, the front side of the partial load, the unilateral partial load and the unilateral reverse, the reverse sides conditions, guarantee the frame structure meet the mechanical requirements.

Key words:Frame; Pro/E; ANASYS ; Strength; Stiffne

摘要 I

Abstract II

第 1 章 绪论 1

1.1 研究的目的和意义 1

1.2 研究背景 3

1.3 车架有限元法国内外研究现状 4

1.4 主要设计内容 6

第 2 章 车架结构方案的选择 7

2.1 车架的设计要求 7

2.2 车架的结构型式 7

2.3 横梁、纵梁及其联接型式 11

2.4 车架的制造工艺 12

2.5 本章小结 13

第 3 章 车架的结构设计 14

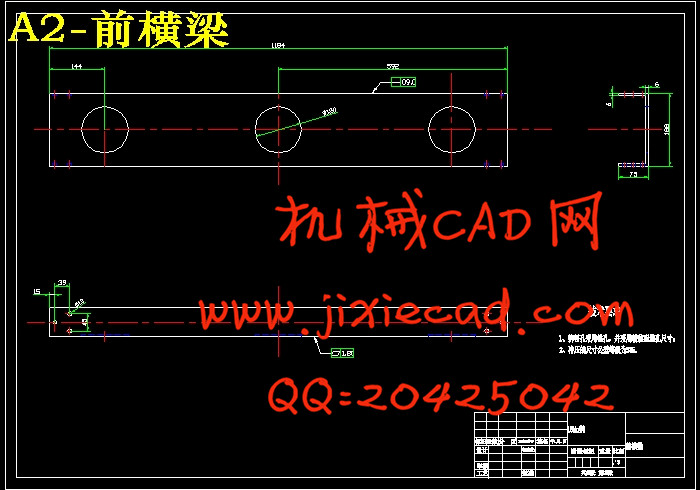

3.1 车架横、纵梁设计 14

3.2 车架的弯矩及弯曲应力计算 15

3.3 车架的挠度计算 18

3.4 纵梁钢板弹簧跨度计算 19

3.5 本章小结 20

第 4 章 车架三维模型的建立 21

4.1 Pro/E软件介绍 21

4.2 三维模型的建立 22

4.3 本章小结 25

第 5 章 车架静态有限元分析 26

5.1 有限元概述 26

5.2 ANSYS Workbench 12.0概述 30

5.3 车架有限元模型的建立 32

5.4 车架弯曲工况分析 34

5.4.1 满载工况分析 34

5.4.2 前侧偏载工况分析 35

5.4.3 单侧偏载工况分析 36

5.5 局部分析 37

5.6 车架扭转工况分析 38

5.6.1 单侧扭转工况分析 38

5.6.2 双侧扭转工况分析 40

5.7 各工况分析结果总结 41

5.8 本章小结 41

结论 42

参考文献 43

致谢 44