设计简介

摘 要

随着现代科技的发展,机械制造业面临着高速度、高精度的新的挑战,高速进给系统成为高速高精度工具磨床的关键环节之一。由于进给系统刚度低、惯量大,难以获得高进给速度和高加速度,为了提高高速高精度工具磨床的定位精度和传动精度,除了正确设计、选择进给系统部件,精确计算其强度、稳定性、和驱动力矩外,还要对进给系统的刚度进行合理设计,减少因刚度引起的失动量,以确保加工定位精度。

进给系统是数控装置和机床机械传动部件间的联系环节,是工具磨床的重要组成部分。它包含机械、电子、电机(早期产品还包含液压)等各个部件,并涉及到强点与弱点的控制,是一个比较复杂的控制系统。锯片刀具工具磨床的性能很大程度上取决于进给伺服系统的,因此研究和开发高性能的伺服进给系统,是锯片刀具工具磨床的设计成败的关键之一。本文对锯片刀具工具磨床的进给系统进行了详细分析和计算设计,对其伺服电机也进行了选择和计算,对进给系统的精度和刚度进行了验算,保证了可靠性。

关键词:锯片刀具工具磨床 进给系统 数控

Abstract

With the development of modern technology, machinofacture industry new challenge of high speed and high-precision, high speed becomes one of the key links in tool grinder of high-precision. Due to the feeding system with low steel grade, high inertia, it’s difficult to get high-feeding and accelerated speed. in order to enhance positioning and spreading precision of high speed and precision tool grinder, except the exact designing, selecting components of feeding system, calculating its strength, stability and drive moment precisely, also the reasonable design to the strength of feeding system, reducing lose momentum caused by strength, to ensure the positioning precise during processing.

Feeding system is the connection between the components of numerical control device and tool mechanical device, also the important parts of tool grinder. It’s a complex control system, which contains the component parts of machinery, electron, dynamo (the previous one contains hydraumatic), referring to the control of strengthens and weakness. The property of tool grinder’s saw bit highly depends on feeding servo system, so researching and developing high property feeding servo system, is the key to success or failure of tool grinder’s saw bit design .This text analyses in detail and designs calculation to the tool grinder’s saw bit, also chooses and calculates to the servo motor, makes checking computations to the precise and strength to feeding system, ensures reliability.

Key words: tool grinders saw bit feeding system numerical control

目 录

摘 要 I

Abstract II

第一章 概 述 1

1.1 锯片刀具工具磨床的简介 1

1.2 锯片刀具工具磨床的工作原理与种类 1

1.3 锯片刀具工具磨床进给系统的深入研究 1

1.3.1 传动系统的选择 2

1.3.2 研究方向和内容 5

1.4 设计方法实现及预期目标 6

1.4.1 滚珠丝杠螺母副 6

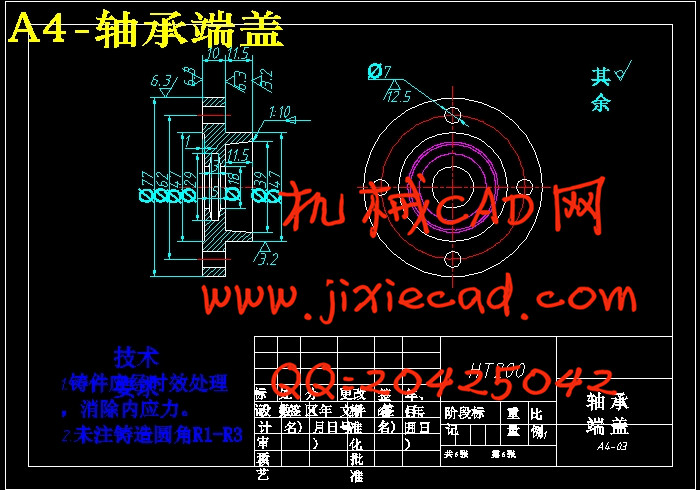

1.4.2 丝杠中常用的滚动轴承 7

1.4.3 滚珠丝杠螺母副的支撑形式 8

1.5 交流伺服电机的选择 9

1.6 进给精度的保证 11

1.7 直线滚动导轨副的选择 11

第二章 锯片刀具工具磨床进给系统的整体设计 12

2.1 工作负载的分析 12

2.2 进给系统主要技术参数 12

2.3 伺服进给系统设计 12

2.3.1 确定滚珠丝杆导程 12

12

2.3.2 滚珠丝杆副载荷及转速计算 12

2.3.3 确定预期额定动载荷 13

2.3.4 按精度要求确定允许的滚珠丝杆最小螺纹底径 13

13

2.3.5 确定滚珠丝杠副规格代号 14

2.3.6 确定预紧滚珠丝杠副预紧力 14

14

2.3.7 计算行程补偿值C和预拉伸力F。 14

2.3.8 确定滚珠丝杠副支承用轴承规格型号 15

2.3.9 滚珠丝杠副工作图设计 15

2.3.10 电机的选择 15

2.3.11 传动系统刚度计算 16

2.3.12 传动系统刚度验算及滚珠丝杠副的精度选择 17

2.3.13 联轴器的选择 18

2.3.14 滚动导轨的选择 18

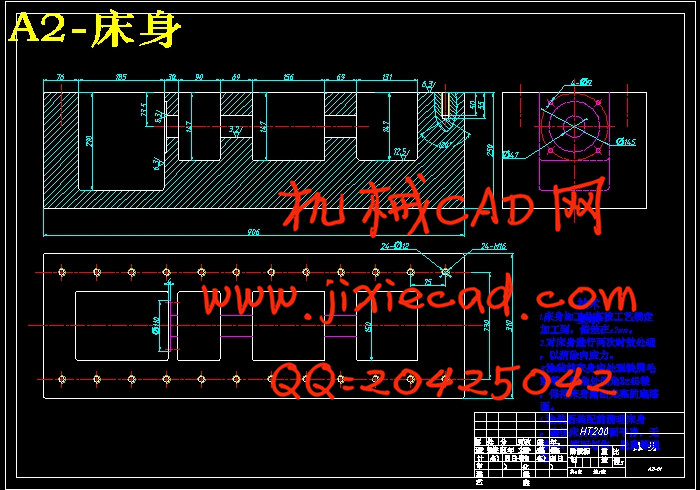

第三章 锯片刀具工具磨床的支承大件结构设计 20

3.1 锯片刀具工具磨床结构材料 20

3.2 锯片刀具工具磨床机床整体布局的设计 22

结束语 23

参考文献 24

随着现代科技的发展,机械制造业面临着高速度、高精度的新的挑战,高速进给系统成为高速高精度工具磨床的关键环节之一。由于进给系统刚度低、惯量大,难以获得高进给速度和高加速度,为了提高高速高精度工具磨床的定位精度和传动精度,除了正确设计、选择进给系统部件,精确计算其强度、稳定性、和驱动力矩外,还要对进给系统的刚度进行合理设计,减少因刚度引起的失动量,以确保加工定位精度。

进给系统是数控装置和机床机械传动部件间的联系环节,是工具磨床的重要组成部分。它包含机械、电子、电机(早期产品还包含液压)等各个部件,并涉及到强点与弱点的控制,是一个比较复杂的控制系统。锯片刀具工具磨床的性能很大程度上取决于进给伺服系统的,因此研究和开发高性能的伺服进给系统,是锯片刀具工具磨床的设计成败的关键之一。本文对锯片刀具工具磨床的进给系统进行了详细分析和计算设计,对其伺服电机也进行了选择和计算,对进给系统的精度和刚度进行了验算,保证了可靠性。

关键词:锯片刀具工具磨床 进给系统 数控

Abstract

With the development of modern technology, machinofacture industry new challenge of high speed and high-precision, high speed becomes one of the key links in tool grinder of high-precision. Due to the feeding system with low steel grade, high inertia, it’s difficult to get high-feeding and accelerated speed. in order to enhance positioning and spreading precision of high speed and precision tool grinder, except the exact designing, selecting components of feeding system, calculating its strength, stability and drive moment precisely, also the reasonable design to the strength of feeding system, reducing lose momentum caused by strength, to ensure the positioning precise during processing.

Feeding system is the connection between the components of numerical control device and tool mechanical device, also the important parts of tool grinder. It’s a complex control system, which contains the component parts of machinery, electron, dynamo (the previous one contains hydraumatic), referring to the control of strengthens and weakness. The property of tool grinder’s saw bit highly depends on feeding servo system, so researching and developing high property feeding servo system, is the key to success or failure of tool grinder’s saw bit design .This text analyses in detail and designs calculation to the tool grinder’s saw bit, also chooses and calculates to the servo motor, makes checking computations to the precise and strength to feeding system, ensures reliability.

Key words: tool grinders saw bit feeding system numerical control

目 录

摘 要 I

Abstract II

第一章 概 述 1

1.1 锯片刀具工具磨床的简介 1

1.2 锯片刀具工具磨床的工作原理与种类 1

1.3 锯片刀具工具磨床进给系统的深入研究 1

1.3.1 传动系统的选择 2

1.3.2 研究方向和内容 5

1.4 设计方法实现及预期目标 6

1.4.1 滚珠丝杠螺母副 6

1.4.2 丝杠中常用的滚动轴承 7

1.4.3 滚珠丝杠螺母副的支撑形式 8

1.5 交流伺服电机的选择 9

1.6 进给精度的保证 11

1.7 直线滚动导轨副的选择 11

第二章 锯片刀具工具磨床进给系统的整体设计 12

2.1 工作负载的分析 12

2.2 进给系统主要技术参数 12

2.3 伺服进给系统设计 12

2.3.1 确定滚珠丝杆导程

2.3.2 滚珠丝杆副载荷及转速计算 12

2.3.3 确定预期额定动载荷 13

2.3.4 按精度要求确定允许的滚珠丝杆最小螺纹底径

2.3.5 确定滚珠丝杠副规格代号 14

2.3.6 确定预紧滚珠丝杠副预紧力

2.3.7 计算行程补偿值C和预拉伸力F。 14

2.3.8 确定滚珠丝杠副支承用轴承规格型号 15

2.3.9 滚珠丝杠副工作图设计 15

2.3.10 电机的选择 15

2.3.11 传动系统刚度计算 16

2.3.12 传动系统刚度验算及滚珠丝杠副的精度选择 17

2.3.13 联轴器的选择 18

2.3.14 滚动导轨的选择 18

第三章 锯片刀具工具磨床的支承大件结构设计 20

3.1 锯片刀具工具磨床结构材料 20

3.2 锯片刀具工具磨床机床整体布局的设计 22

结束语 23

参考文献 24