设计简介

中文摘要

本文是关于双面卧式攻丝机床设计的说明。此机床要求:在两个面同时进行自动攻丝。

本文主要内容包括设计的必要性分析;通过对设计的机床的功能分解与功能合成,以及对方案的设计从而提出新的加工方案。通过对定位方式的选择和对工件工艺性的分析,以及对零件工序图、加工示意图、机床联系尺寸图和功率计算卡这“三卡一图”的分析,提出对组合机床的总体设计方案。文中对组合机床的通用部件及专用部件的选择都做了较为详细的说明。由于要实现自动化,所以对液压传动系统和单片机的电气控制系统的设计显得尤为重要,本文也对此做了阐明,并编写了程序。另外,本文还对设计做了小结。

关键词 组合机床,攻丝,单片机。

Abstract

This text is concerning two-lyings offend the silk combination machine bed design of say. The design request of this machine bed is: proceed at the same time in two the auto offend the silk.

The main contents in this text includes the necessity analysis of the design; The function that pass the machine to design to bed resolves to synthesize with function, and the design of the other party case from but put forward to process the project newly. Pass to the choiceof the fixed method with to work an analysis for craft analysis, and to spare parts work preface diagram, processing sketch map, machine bed contact size diagram with power calculation stucking “three figures and one card”, put forword to the total design project of the combination machine bed. The text inside all did to the in general use parts of the combination bed and the choice of the appropriation parts than for expatiation. Because of realizing automation, so press to spread to move the system to the liquid to control with the electricity of SCM the design of the system seems to be particularly for importance, this text also makes to clarify to this, writing the procedure. Moreover, this text returns to this time designed to make the sub-footing.

Key phrase Combination machine bed, offend the silk,SCM.

目 录

1 绪论 1

2 设计任务书 2

2.1 产品用途和使用范围 2

2.2 关于机床的主要加工功能和系统组成的建议 2

2.3 关于总体布局的建议 3

2.4 主要技术指标和相关重要参数 4

2.5 主要工作原理 4

2.6 国内外的现状和发展趋势 4

2.7 国内外同类产品对比 6

2.8 跟题目有关的专利情况 6

2.9 关于采用新技术、新结构、新材料、新工艺的建议 8

2.10 拟采用的技术路线 8

3 组合机床的总体设计 9

3.1 组合机床的配置形式 9

3.2 机床加工示意图 12

3.3 机床的联系尺寸 12

4 组合机床通用部件及其选用 14

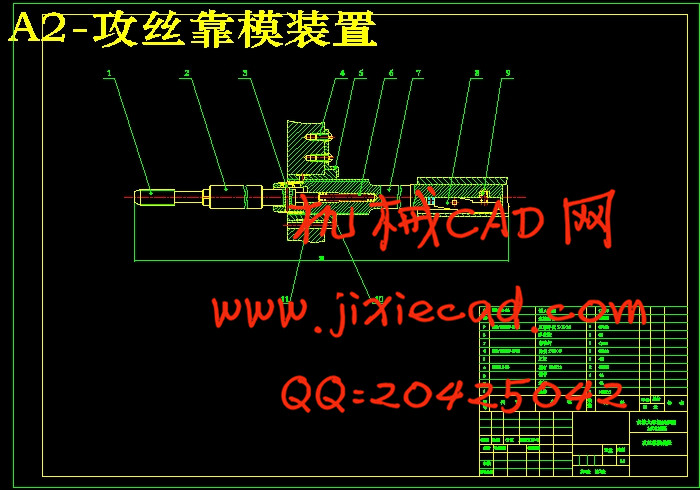

4.1 攻丝靠模装置和攻丝卡头 14

4.2 攻丝装置及攻丝靠模头 15

4.3 主轴箱的设计 16

5 进给机构的设计 20

6 电气部分设计 21

6.1 整个机床的动作顺序 21

6.2 电器原理图 21

总 结 24

致 谢 25

参考文献 26

本文是关于双面卧式攻丝机床设计的说明。此机床要求:在两个面同时进行自动攻丝。

本文主要内容包括设计的必要性分析;通过对设计的机床的功能分解与功能合成,以及对方案的设计从而提出新的加工方案。通过对定位方式的选择和对工件工艺性的分析,以及对零件工序图、加工示意图、机床联系尺寸图和功率计算卡这“三卡一图”的分析,提出对组合机床的总体设计方案。文中对组合机床的通用部件及专用部件的选择都做了较为详细的说明。由于要实现自动化,所以对液压传动系统和单片机的电气控制系统的设计显得尤为重要,本文也对此做了阐明,并编写了程序。另外,本文还对设计做了小结。

关键词 组合机床,攻丝,单片机。

Abstract

This text is concerning two-lyings offend the silk combination machine bed design of say. The design request of this machine bed is: proceed at the same time in two the auto offend the silk.

The main contents in this text includes the necessity analysis of the design; The function that pass the machine to design to bed resolves to synthesize with function, and the design of the other party case from but put forward to process the project newly. Pass to the choiceof the fixed method with to work an analysis for craft analysis, and to spare parts work preface diagram, processing sketch map, machine bed contact size diagram with power calculation stucking “three figures and one card”, put forword to the total design project of the combination machine bed. The text inside all did to the in general use parts of the combination bed and the choice of the appropriation parts than for expatiation. Because of realizing automation, so press to spread to move the system to the liquid to control with the electricity of SCM the design of the system seems to be particularly for importance, this text also makes to clarify to this, writing the procedure. Moreover, this text returns to this time designed to make the sub-footing.

Key phrase Combination machine bed, offend the silk,SCM.

目 录

1 绪论 1

2 设计任务书 2

2.1 产品用途和使用范围 2

2.2 关于机床的主要加工功能和系统组成的建议 2

2.3 关于总体布局的建议 3

2.4 主要技术指标和相关重要参数 4

2.5 主要工作原理 4

2.6 国内外的现状和发展趋势 4

2.7 国内外同类产品对比 6

2.8 跟题目有关的专利情况 6

2.9 关于采用新技术、新结构、新材料、新工艺的建议 8

2.10 拟采用的技术路线 8

3 组合机床的总体设计 9

3.1 组合机床的配置形式 9

3.2 机床加工示意图 12

3.3 机床的联系尺寸 12

4 组合机床通用部件及其选用 14

4.1 攻丝靠模装置和攻丝卡头 14

4.2 攻丝装置及攻丝靠模头 15

4.3 主轴箱的设计 16

5 进给机构的设计 20

6 电气部分设计 21

6.1 整个机床的动作顺序 21

6.2 电器原理图 21

总 结 24

致 谢 25

参考文献 26