设计简介

摘 要

(一)电机机座钻孔组合机床是大型组合机床,它的配置型式具有固定式液压夹紧的单工位组合机床,这类组合机床夹具和工作台都是固定不动的,动力滑台实现进给运动。滑台上的动力箱实现切削运动,根据工件结构特点,以及精确要求,采用结合面为定值基准面。 在基准面对应的另一圆柱面上,用压块压紧,由于结合面的加工精度较高,以它为基面,完全可以达到要求的加工精度。

(二)几何机床总体设计----三图一卡①“被加工零件工序图”它是组合机床的设计的主要依据,它是制造使用,检修和调整机床的重要技术条件②绘制加工示意图,它是刀具夹具,多轴箱,液压电器装置设计及通用部件选择主要原始资料,它是调整机床,刀具及试车依据。③绘制联系和运动关系及检验机床各部件相对于位置及联系是否满足加工要求,通用部件的选择是否合适,并为进一步开展主轴箱,夹具等专用部件,零件的设计提供依据。④相对生产率计算卡,它用来反映机床的加工过程,完成这一动作所需要的时间,切削用量,机床生产率及机床负荷率。

(三)组合机床主轴箱设计,按专用要求进行设计,由通用零件组成,其主要作用是根据被加工零件的要求,安排各主轴位置并将动力和运动由电机或动力部件传给各主轴,使之得到要求的转速,机床主轴箱选用400*400,用中间传动轴带动主轴传动。

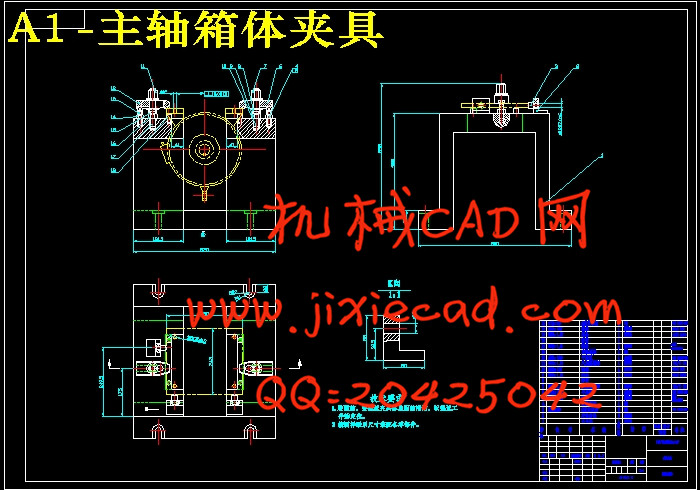

(四)夹具设计

在前述定位基准面选择的前提下,用摆动式压板杠杆夹紧结构,夹紧力经验算可以保证。

关键字:

组合机床 ;动力滑台 ;动力箱 ;主轴箱 ;夹具 ;

This kind of combination machine fitture and working bench are all fixed. Powen-sliding plat makes advam cry mourent. The power box on the power sliding plat from made scatting movement.This comgination and agle in instuit and is comvenient in desxging making and operating .Acording to precision demerd it adopt a datum place fixed in side .It is lined light with après lump on the other lylinder side against the datum palne .Itcan read working prelistion indemard a wording to the datum plane. Bacause of it is high working precision in side besides it has a round hole in high precision in side. It has a threaceling hole on the ohassion.

It can make full use of the strulture charactlst of the work piece. To design two short round cancel in the round hole in the side. To limit three degrees .To design acutside cancel on the bassface the battom. To limit one free degree. To limit three free degree one the deofimtine datum plane.It definet up a ccnrately and it’s fixture power is depene.

(二)To desing the combination machine body-therr draning and one carcl that is ① the working orther draning of the working spares . it’s the major basis of the combination maching body. It’s a important paper in making using excmining and rensing maching .②To draw working schematw. Drawing it’s for design a cutting tool. Assist tool afixture a multiple axle box hydravlive,pressure and a deetric capacity derise and important first hand date of the natirrad. Pants chovced and it’s a rewse machine kinf tool and the mgor basis for the test run.③ To draw the relation dimension drawing the relation dimension drawing is to impress the matual .assembly nelation and the motin redation of the each form spanes of the machine.in order to enamine the relative .Pustion of all the machine spares and if the dimersion nelational .Spares is fix ,in the disigerents of dere loping the main axle box fixtrer’s special purpose pats.④Todesign the machin productirilg planning card .It’swod to report the working process of the machine to finish the need tine the cutting capacity the machine producticity and machine’s rate for the cach activity.

(三)To design the comuination machine main axle box .To design it a cocording to the special cemoncl.It’s made up of the mational pants.As magin use is to arrange the position of all the mational axle box and transrnit the power and the motion to all the main axle by the electrical machinery or the power pants .According to the working demands of the worked pants and make it taget the demand transpont speed.The machine main axle is mode in side 400*400. It’sdraved by the mediwm drive.

(四)To desing the fixture

First to choice the forer word fixed position datum plane.It’s fixed by swing depressor fixtume structure the despower can be assured by checking computations.

Kdyword:

The combination machine ;Powen-sliding plat ;The power box ;The main axle box ;The fixture

目 录

1 组合机床总体设计…………………………………………………………1

1.1 组合机床方案…………………………………………………………1

1.1.1 组合机床的制定方案制定的主要因素…………………………1

1.1.2 分析被加工工件…………………………………………………3

1.1.3 制定本设计的机床方案…………………………………………3

1.2 确定切削用量及选择刀具……………………………………………3

1.2.1 根据工件的材料及加工孔直径确定切削用量…………………3

1.2.2 确定切削力、切削转矩、切削功率及刀具耐用度……………3

1.2.3 刀具的选择………………………………………………………7

1.3 初步确定主轴及传动轴直径…………………………………………7

1.4 三图一卡………………………………………………………………8

1.4.1 被加工零件工序图………………………………………………8

1.4.2 加工示意图………………………………………………………8

1.4.3 机床联系尺寸图…………………………………………………14

1.4.4 组合机床生产率计算卡…………………………………………15

2 多轴箱的设计 ……………………………………………………………20

2.1 多轴箱材料的选择……………………………………………………20

2.2 多轴箱轮廓尺寸的确定………………………………………………20

2.3 轴类零件的选用………………………………………………………20

2.3.1 钻削类主轴………………………………………………………20

2.3.2 传动轴……………………………………………………………21

2.3.3 轴的材料…………………………………………………………21

2.4 齿轮型式的选择………………………………………………………21

2.5 设计计算………………………………………………………………21

2.5.1 绘制多轴箱设计原始依据图……………………………………21

2.5.2 主轴结构型式的选择……………………………………………22

2.5.3 传动系统的设计计算……………………………………………22

2.5.4 多轴箱结构设计…………………………………………………32

2.5.5 主轴的设计………………………………………………………34

2.5.6 手柄轴的设计……………………………………………………40

2.5.7传动轴的设计 ……………………………………………………42

2.5.8 叶片泵轴的设计 …………………………………………………44

2.5.9 动力箱输出轴的设计 ……………………………………………45

2.6 轴的校核 ………………………………………………………………46

2.6.1 求各轴的功率及转矩 ……………………………………………46

2.6.2 主轴的校核 ………………………………………………………47

2.6.3 手柄轴的校核 ……………………………………………………48

2.7 轴承的校核 …………………………………………………………52

2.7.1 主轴上推力球轴承的校核 ………………………………………52

2.7.2 主轴上深沟球轴承的校核 ………………………………………52

3 夹具的设计…………………………………………………………………53

3.1 机床夹具介绍 …………………………………………………………53

3.1.1 夹具的分类 ………………………………………………………53

3.1.2 专用夹具的组成 …………………………………………………53

3.2 夹具的设计……………………………………………………………54

3.2.1 定位装置的设计 …………………………………………………54

3.2.2 夹紧装置的设计 …………………………………………………55

3.2.3 夹紧方案的制定 …………………………………………………55

3.3.4 夹具图 ……………………………………………………………56

结 论 …………………………………………………………………………57

参考文献 ………………………………………………………………………58

致 谢 …………………………………………………………………………59

附录 1 …………………………………………………………………………60

附录 2 …………………………………………………………………………61

(一)电机机座钻孔组合机床是大型组合机床,它的配置型式具有固定式液压夹紧的单工位组合机床,这类组合机床夹具和工作台都是固定不动的,动力滑台实现进给运动。滑台上的动力箱实现切削运动,根据工件结构特点,以及精确要求,采用结合面为定值基准面。 在基准面对应的另一圆柱面上,用压块压紧,由于结合面的加工精度较高,以它为基面,完全可以达到要求的加工精度。

(二)几何机床总体设计----三图一卡①“被加工零件工序图”它是组合机床的设计的主要依据,它是制造使用,检修和调整机床的重要技术条件②绘制加工示意图,它是刀具夹具,多轴箱,液压电器装置设计及通用部件选择主要原始资料,它是调整机床,刀具及试车依据。③绘制联系和运动关系及检验机床各部件相对于位置及联系是否满足加工要求,通用部件的选择是否合适,并为进一步开展主轴箱,夹具等专用部件,零件的设计提供依据。④相对生产率计算卡,它用来反映机床的加工过程,完成这一动作所需要的时间,切削用量,机床生产率及机床负荷率。

(三)组合机床主轴箱设计,按专用要求进行设计,由通用零件组成,其主要作用是根据被加工零件的要求,安排各主轴位置并将动力和运动由电机或动力部件传给各主轴,使之得到要求的转速,机床主轴箱选用400*400,用中间传动轴带动主轴传动。

(四)夹具设计

在前述定位基准面选择的前提下,用摆动式压板杠杆夹紧结构,夹紧力经验算可以保证。

关键字:

组合机床 ;动力滑台 ;动力箱 ;主轴箱 ;夹具 ;

Abstract

(一)Combmtvin drilling machine is a large combination machine it adept a dispose form. The form has a fixed fitture’s single working location combination.This kind of combination machine fitture and working bench are all fixed. Powen-sliding plat makes advam cry mourent. The power box on the power sliding plat from made scatting movement.This comgination and agle in instuit and is comvenient in desxging making and operating .Acording to precision demerd it adopt a datum place fixed in side .It is lined light with après lump on the other lylinder side against the datum palne .Itcan read working prelistion indemard a wording to the datum plane. Bacause of it is high working precision in side besides it has a round hole in high precision in side. It has a threaceling hole on the ohassion.

It can make full use of the strulture charactlst of the work piece. To design two short round cancel in the round hole in the side. To limit three degrees .To design acutside cancel on the bassface the battom. To limit one free degree. To limit three free degree one the deofimtine datum plane.It definet up a ccnrately and it’s fixture power is depene.

(二)To desing the combination machine body-therr draning and one carcl that is ① the working orther draning of the working spares . it’s the major basis of the combination maching body. It’s a important paper in making using excmining and rensing maching .②To draw working schematw. Drawing it’s for design a cutting tool. Assist tool afixture a multiple axle box hydravlive,pressure and a deetric capacity derise and important first hand date of the natirrad. Pants chovced and it’s a rewse machine kinf tool and the mgor basis for the test run.③ To draw the relation dimension drawing the relation dimension drawing is to impress the matual .assembly nelation and the motin redation of the each form spanes of the machine.in order to enamine the relative .Pustion of all the machine spares and if the dimersion nelational .Spares is fix ,in the disigerents of dere loping the main axle box fixtrer’s special purpose pats.④Todesign the machin productirilg planning card .It’swod to report the working process of the machine to finish the need tine the cutting capacity the machine producticity and machine’s rate for the cach activity.

(三)To design the comuination machine main axle box .To design it a cocording to the special cemoncl.It’s made up of the mational pants.As magin use is to arrange the position of all the mational axle box and transrnit the power and the motion to all the main axle by the electrical machinery or the power pants .According to the working demands of the worked pants and make it taget the demand transpont speed.The machine main axle is mode in side 400*400. It’sdraved by the mediwm drive.

(四)To desing the fixture

First to choice the forer word fixed position datum plane.It’s fixed by swing depressor fixtume structure the despower can be assured by checking computations.

Kdyword:

The combination machine ;Powen-sliding plat ;The power box ;The main axle box ;The fixture

目 录

1 组合机床总体设计…………………………………………………………1

1.1 组合机床方案…………………………………………………………1

1.1.1 组合机床的制定方案制定的主要因素…………………………1

1.1.2 分析被加工工件…………………………………………………3

1.1.3 制定本设计的机床方案…………………………………………3

1.2 确定切削用量及选择刀具……………………………………………3

1.2.1 根据工件的材料及加工孔直径确定切削用量…………………3

1.2.2 确定切削力、切削转矩、切削功率及刀具耐用度……………3

1.2.3 刀具的选择………………………………………………………7

1.3 初步确定主轴及传动轴直径…………………………………………7

1.4 三图一卡………………………………………………………………8

1.4.1 被加工零件工序图………………………………………………8

1.4.2 加工示意图………………………………………………………8

1.4.3 机床联系尺寸图…………………………………………………14

1.4.4 组合机床生产率计算卡…………………………………………15

2 多轴箱的设计 ……………………………………………………………20

2.1 多轴箱材料的选择……………………………………………………20

2.2 多轴箱轮廓尺寸的确定………………………………………………20

2.3 轴类零件的选用………………………………………………………20

2.3.1 钻削类主轴………………………………………………………20

2.3.2 传动轴……………………………………………………………21

2.3.3 轴的材料…………………………………………………………21

2.4 齿轮型式的选择………………………………………………………21

2.5 设计计算………………………………………………………………21

2.5.1 绘制多轴箱设计原始依据图……………………………………21

2.5.2 主轴结构型式的选择……………………………………………22

2.5.3 传动系统的设计计算……………………………………………22

2.5.4 多轴箱结构设计…………………………………………………32

2.5.5 主轴的设计………………………………………………………34

2.5.6 手柄轴的设计……………………………………………………40

2.5.7传动轴的设计 ……………………………………………………42

2.5.8 叶片泵轴的设计 …………………………………………………44

2.5.9 动力箱输出轴的设计 ……………………………………………45

2.6 轴的校核 ………………………………………………………………46

2.6.1 求各轴的功率及转矩 ……………………………………………46

2.6.2 主轴的校核 ………………………………………………………47

2.6.3 手柄轴的校核 ……………………………………………………48

2.7 轴承的校核 …………………………………………………………52

2.7.1 主轴上推力球轴承的校核 ………………………………………52

2.7.2 主轴上深沟球轴承的校核 ………………………………………52

3 夹具的设计…………………………………………………………………53

3.1 机床夹具介绍 …………………………………………………………53

3.1.1 夹具的分类 ………………………………………………………53

3.1.2 专用夹具的组成 …………………………………………………53

3.2 夹具的设计……………………………………………………………54

3.2.1 定位装置的设计 …………………………………………………54

3.2.2 夹紧装置的设计 …………………………………………………55

3.2.3 夹紧方案的制定 …………………………………………………55

3.3.4 夹具图 ……………………………………………………………56

结 论 …………………………………………………………………………57

参考文献 ………………………………………………………………………58

致 谢 …………………………………………………………………………59

附录 1 …………………………………………………………………………60

附录 2 …………………………………………………………………………61