设计简介

摘 要

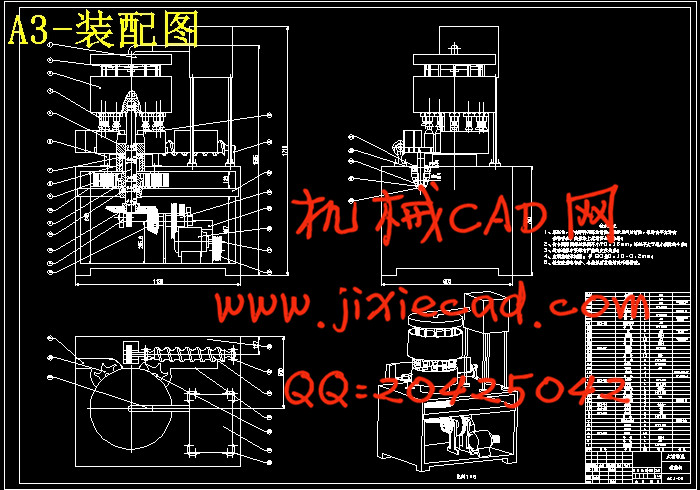

在科学技术日益发展的今天,灌装行业越来越受到人们的关注。灌装行业的发展直接影响到液体灌装的精度,精准的灌装量不仅体现了灌装机械的发展水平,也是对消费者权益的一种保护。本次设计的灌装机主要适应用矿泉水、果汁以及纯净水等无气液体的灌装,它具有操作简单、成本低廉及可批量生产等特点,可适用于一些中小企业的灌装生产。它的主要机构有一下几个:供料装置、供瓶装置、托瓶机构、瓶高调节装置以及灌装阀,此外,它的正常运转还需要靠传动系统的带动。它基本的设计方案是:灌装整体布局是呈立式、旋转型,由洗瓶器出来的瓶子通过传送带传送给供瓶装置,由它分瓶、送瓶给托瓶机构;灌装机的液箱内安装有灌装阀,阀头的喇叭口对准了每一个待灌瓶,液箱内的液体由供料装置供给,液体经供料装置供到液箱中,再通过灌装阀流入每一个空瓶内;待瓶灌满后,再由供瓶装置的星形拨轮拨到传送带然后传送出,运送到下一个工序。

本文从灌装机的基本理论、基本工作原理、基本工作结构以及传动部分的设计上作了阐述,并利用UG软件绘制三维图,从而更直观的反应整体效果。

关键词:灌装机;灌装阀;星形拨轮;传动装置;

Abstract

Today, with the development of science and technology , the filling industry has been paid more and more attention. The development of filling industry directly affects the accuracy of liquid filling ,the filling precision not only reflects the development level of the filling machine, but also is a kind of protection of the rights and interests of consumers.The design of the filling machine is mainly adapted to use for mineral water, fruit juice and water without liquid filling of gas.It has the advantages of simple operation, low cost and mass production characteristics .The filling production can be applied to some small and medium-

sized enterprises of filling production. It has some main institutions,such as feeding device, the

bottle supply device, bottle table institutions, the bottle of high regulator device and the filling valve. In addition, its function also needs to be driven by the drive system.The following is its basic design scheme . Its overall mechanism is vertical and rotary. The bottle which comes from washing device conveys through the conveyor belt transmission to the bottle supply device.The device can let the bottle be separated,and then send these bottles to bottle table institutions;The liquid filling valve is installed in the cabinet, and its valve head is admitted to each bottling. The liquid in the liquid box is supplied by feeding device,and then it is delivered through the filling valve to each empty bottle. After the bottle is filled, the installation of the star dial wheel deliver

-ed them to the conveyor belt and then sent to the next working procedure.

This article describes the basic theory, working principle, structure and transmission part of the filling machine. The use of UG software renders 3D visual effects by drawing its 3D graph.

Key words:filling machine; filling valve; star thumbwheel; transmission device

目 录

Abstract IV

目 录 V

1 绪论 1

1.1本课题的设计内容和意义 1

1.2本课题的国内外发展概况 1

1.3本课题应达到的要求 2

2 液体灌装机主体机构的方案设计 3

2.1 灌装机的概述 3

2.1.1 液体灌装机的分类 3

2.1.2 液体灌装机的选择原则 5

2.1.3 灌装的基本方法 5

2.2 灌装机的总体方案 6

2.3 灌装机的供料装置 7

2.4 灌装机的供瓶装置 8

2.4.1 螺旋限位装置 8

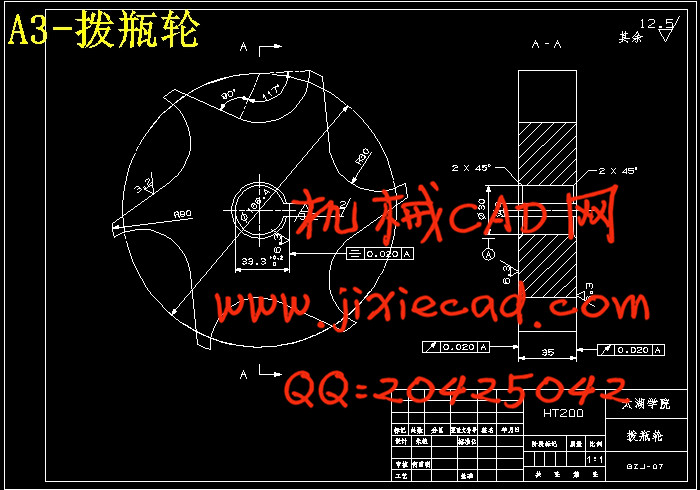

2.4.2 星形拨瓶轮装置 8

2.5 灌装机的托瓶机构 9

2.6 灌装机的灌装阀 10

2.6.1灌装阀的定量方法 10

2.6.2 灌装阀的灌装原理 12

2.6.3 灌装阀的密封 13

3 灌装机传动部分的设计计算 14

3.1 电动机的选择 14

3.2 减速器的选择 15

3.3 带传动的设计 15

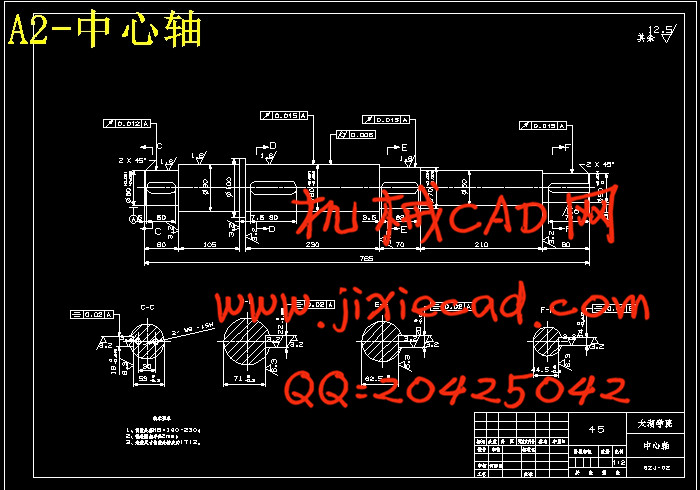

3.4 中心轴的设计 18

3.4.1 中心轴的材料 18

3.4.2 中心轴的安装 19

3.4.3 中心轴的结构尺寸 20

3.4.4 中心轴的计算 21

3.4.5 轴上键的选择 23

3.5 中心轴齿轮的设计 24

3.5.1 齿轮的材料 24

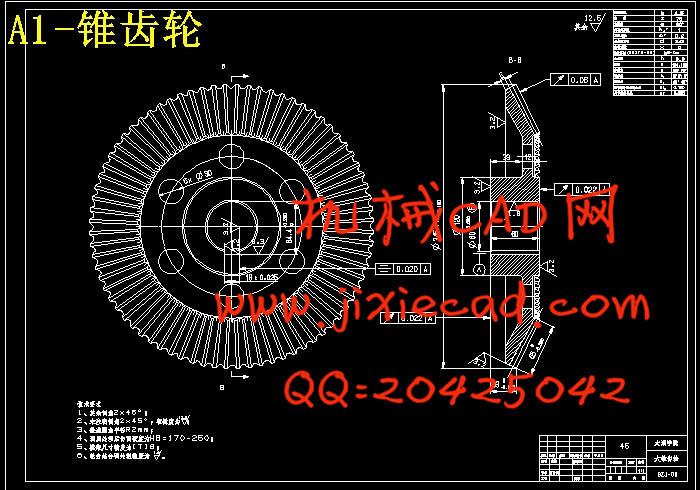

3.5.2 齿轮的计算 25

3.6 锥齿轮的设计计算 30

3.7 本章小结 35

4 灌装机的设备调试与维护 36

4.1设备调试 36

4.2设备维护 36

5 结论与展望 38

5.1结论 38

5.2不足之处及未来展望 38

致 谢 39

参考文献 40