设计简介

【摘要】旋流分离器,是一种利用离心沉降原理将非均相混合物中具有不同密度的相分离的机械分离设备。在具有密度差的混合物以一定的方式及速度从入口进入旋流分离器后,在离心力场的作用下,密度大的相被甩向四周,并顺着壁面向下运动,作为底流排出;密度小的相向中间迁移,并向上运动,最后作为溢流排出。这样就达到了分离的目的。旋流分离技术可用于液液分离、气液分离、固液分离、气固分离等。本文设计的旋流器用于石油钻井中钻井液的气液分离。在工作原理的基础上,进行了气液分离器的结构设计,包括,总体结构、脱气结构、内部旋流器结构、外筒体结构以及分离器外部结构。根据相关数据对进口管、排气排液管、侧开口、以及相对应的法兰进行设计选取。并且进行了筒体和封头壁厚的计算,估算了分离器的质量,支座的负荷估算及选用,人孔的选用及补强,对外壳体进行了有限元的分析,说明了分离器的安装顺序。

【关键词】钻井液 旋流分离器 气液分离器 设计

【Abstract】Cyclone separator is a kind of mechanical separation equipment which use centrifugal sedimentation principle to separator the heterogeneous mixture with different density of phase separation.The mixture having a density difference in a certain way and speed from the inlet into the cyclone separator, under the action of the centrifugal force field, the dense phase is thrown around and downwardly along the wall, as a bottom flow discharge; density opposite the middle of a small migration of upward movement, and finally as an overflow discharge.This achieves the purpose of separation.Cyclone separation technology can be used for liquid-liquid separation, gas-liquid separation, solid-liquid separation and gas-solid separation and so on.In this paper,design of the cyclone separator is used in oil drilling in the drilling fluid of gas and liquid separation.Based on the principle of work, carried out the structural design of the gas-liquid separator,Including, overall structure, degassing structure, the internal structure of the cyclone separator , the separator outer cylinder structure, and external structure. According tothe relevant data of inlet tube, exhaust drainage pipe, side opening, and the corresponding flange design selection. And has carried on the cylinder head and the calculation of wall thickness, estimating the quality of the separator, bearing load calculations and selection,manhole selection and reinforcement,external shell finite element analysis was conducted, illustrates the installation sequence of separator.

【Key words】oil drilling ,Cyclone separator, gas-liquid separator,design

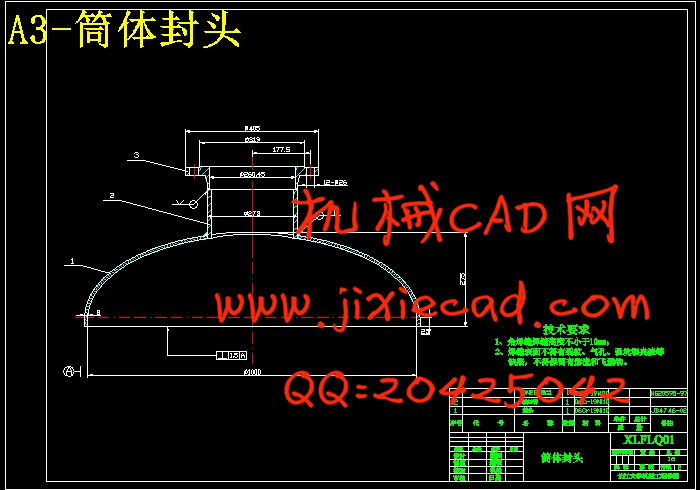

4.3旋流器筒体封头壁厚计算 22

4.4人孔 23

4.4.1人孔选择 23

4.4.2人孔补强 24

4.5支座 24

4.5.1分离器的总质量 24

4.5.2支座的选用及安装要求 26

5 分离器的安装 26

5.1 焊接 26

5.2安装顺序 27

6 壳体的有限元分析 28

7 总结 32

参考文献 34

致谢 36

【关键词】钻井液 旋流分离器 气液分离器 设计

【Abstract】Cyclone separator is a kind of mechanical separation equipment which use centrifugal sedimentation principle to separator the heterogeneous mixture with different density of phase separation.The mixture having a density difference in a certain way and speed from the inlet into the cyclone separator, under the action of the centrifugal force field, the dense phase is thrown around and downwardly along the wall, as a bottom flow discharge; density opposite the middle of a small migration of upward movement, and finally as an overflow discharge.This achieves the purpose of separation.Cyclone separation technology can be used for liquid-liquid separation, gas-liquid separation, solid-liquid separation and gas-solid separation and so on.In this paper,design of the cyclone separator is used in oil drilling in the drilling fluid of gas and liquid separation.Based on the principle of work, carried out the structural design of the gas-liquid separator,Including, overall structure, degassing structure, the internal structure of the cyclone separator , the separator outer cylinder structure, and external structure. According tothe relevant data of inlet tube, exhaust drainage pipe, side opening, and the corresponding flange design selection. And has carried on the cylinder head and the calculation of wall thickness, estimating the quality of the separator, bearing load calculations and selection,manhole selection and reinforcement,external shell finite element analysis was conducted, illustrates the installation sequence of separator.

【Key words】oil drilling ,Cyclone separator, gas-liquid separator,design

中文摘要...............................................................Ⅵ

外文摘要...............................................................Ⅶ

1 绪论 5

1.1 选择旋流式液气分离器的意义 5

1.2 国内外现状和发展趋势 5

1.2.1国外现状和发展趋势 5

1.2.2国内现状和发展趋势 7

2 方案论证 7

2.1 旋流式液气分离方案的可行性 7

2.2旋流式分离器的结构及工作原理 7

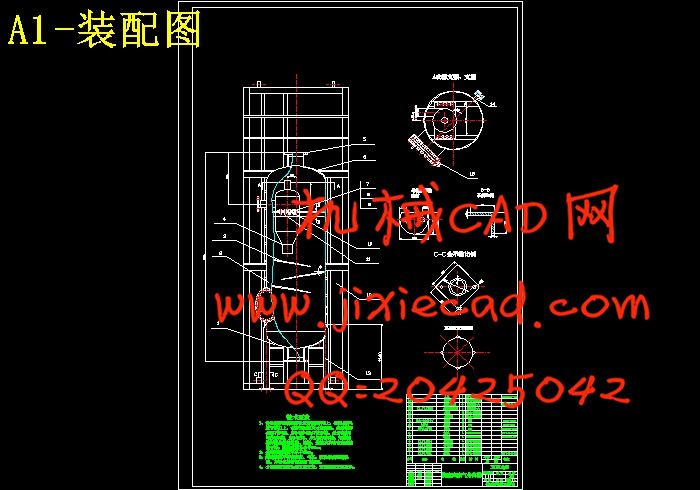

3 分离器的总体设计 9

3.1旋流器的直径和长度的计算 9

3.2分离器结构设计 11

3.2.1分离器总体结构设计 11

3.2.2脱气结构 13

3.2.3钻井液进口的尺寸 13

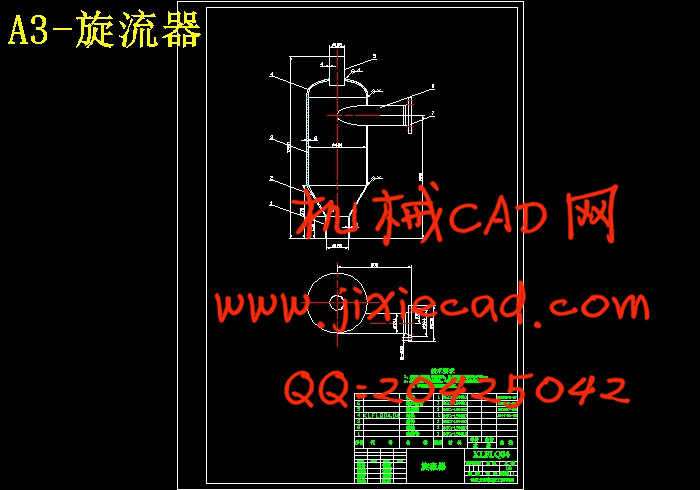

3.2.4旋流器的结构设计 13

3.2.5外筒体的设计 15

3.2.6接口管设计 16

3.2.7外部结构 19

4、主要零部件的设计及校核计算 20

4.1筒体和封头的壁厚计算 20

4.2外容器筒体、封头壁厚计算 20外文摘要...............................................................Ⅶ

1 绪论 5

1.1 选择旋流式液气分离器的意义 5

1.2 国内外现状和发展趋势 5

1.2.1国外现状和发展趋势 5

1.2.2国内现状和发展趋势 7

2 方案论证 7

2.1 旋流式液气分离方案的可行性 7

2.2旋流式分离器的结构及工作原理 7

3 分离器的总体设计 9

3.1旋流器的直径和长度的计算 9

3.2分离器结构设计 11

3.2.1分离器总体结构设计 11

3.2.2脱气结构 13

3.2.3钻井液进口的尺寸 13

3.2.4旋流器的结构设计 13

3.2.5外筒体的设计 15

3.2.6接口管设计 16

3.2.7外部结构 19

4、主要零部件的设计及校核计算 20

4.1筒体和封头的壁厚计算 20

4.3旋流器筒体封头壁厚计算 22

4.4人孔 23

4.4.1人孔选择 23

4.4.2人孔补强 24

4.5支座 24

4.5.1分离器的总质量 24

4.5.2支座的选用及安装要求 26

5 分离器的安装 26

5.1 焊接 26

5.2安装顺序 27

6 壳体的有限元分析 28

7 总结 32

参考文献 34

致谢 36