设计简介

[摘要]:目前,水力旋流器在油田采出液预分离和含油污水处理中逐步推广应用。水力旋流器具有结构简单紧凑、效 率高、体积及占地面积小等优点。对水力旋流器结构及参数关系进行了分析。通过改进与优选水力旋流器结构,得到旋 流器单体的双入口结构理想型式为反涡线、大小锥段为圆弧过渡形式。同时简要分析了高次曲线与正余切曲线结构的 锥段过渡形式,确定出合理的水力旋流器单体旋流腔长度为65 mm。经过理论研究和对比试验发现,具有结构参数关系 模型的水力旋流器较常规结构的水力旋流器有更高的分离效率。

水力旋流器是利用强离心力场来实现有一定密度差且不互溶物系分离的离心 沉降设备。目前油田在无动力加工环境中的单井作业无法进行机械脱水处理,一 直采用装原油的容器下加煤炭火烧加温、搅拌、沉淀、分解的老方法进行脱水处 理。这种方法不但极易引起火灾,而且原油损耗大、劳动强度髙、工作效率低, 以及对环境造成极大污染。该方法已经不能满足现在油田生产的需要。

水力旋流法是由英国南安普顿大学(Southampton)研究成功的一种具有80 年代先进水平的含油污水处理新方法。因为它结构简单、分离效率高、成本低, 从它问世之日起,就得到了世界各国的重视。现在,旋流分离已作为重力分离的 一项替代技术,成为世界国际油田地面工程中的主体技术和重要装备。

在前期对液-液旋流分离器流量压降特性实验研究的基础上,分析了结构参数、操作参数及物性参数对液- 液旋流分离效率的影响;提出了液-液旋流分离器结构设计的设计方法和设计步骤,认为建立性能优良的旋流器模 型数据库,是选型设计的基础和前提。

[关键词]:水力旋流器;分离效率;入口 ;锥段;溢流管;旋流腔;底流管

[Abstract:] At present, the hydrocyclone in oilfield produced gradually promote the use of liquid separation and oily sewage treatment. Hydrocyclone has the advantages of simple and compact structure, high efficiency, small volume and area etc.. On the relationship between the structure and the parameters of the hydrocyclone are analyzed. Through the improvement and optimization of hydrocyclone, get double entrance structure of ideal type cyclone monomer for the vortex line, size of the taper section is arc transition form. At the same time, a brief analysis of the cone transition form high-order curve and curve structure, reasonable length of single bodied whirl cavity of hydrocyclone has been determined as 65 mm. It has been discovered that through theoretical study and contrast test,the hydrocyclone that possessing relation model of structural parameters hasmore higher separation efficiency than hydrocyclones with conventional structures.

Cyclone separators are used in various kinds of industries to separate materials of different densities. By creating a strong swirl, large centrifugal forces in the process mixture are generated and due to differences in density the materials will separate. At present in petroleum industry, single well cannot proceed mechanical dehydration treatments with not power. It always taken heat up and deposit method to dewatering, such means not only bring fire and crude oil waste large, labor intensity high, and it have badly influence on environment. Now that approach had insatiability oil fields produce demand.

Hydraulic power method was newly oil-water separation method. It was invented by Britain Southampton University in 1980s. For it structure simplicity, separation efficiency high, and cost low. From it appearance, that has been got widely recognition. In the not far future, rotational flow separate will certainly replace gravitational separation technology, became 21 century international oil field primary equipment.

Based on the experiments aiming at studying flowrate and pressure drop performance,geometric parameters, operating parameters and liquid characteristic parameters influence on separate efficiency are analyzed. Optimal structure design method and process of liquid-liquid separate hydrocyclone are brought forward. It's thought that the database of best hydricyclone model is the basic and premises about optimal structure design.

[Keywords]: hydrocyclone; separation efficiency; entrance; conicsection; overflow pipe; whirl cavity; underflow pip

目录

1前言 1

2.选题背景 2

3方案论证 3

3.1油水分离器的主要特点 3

3.2工作原理 4

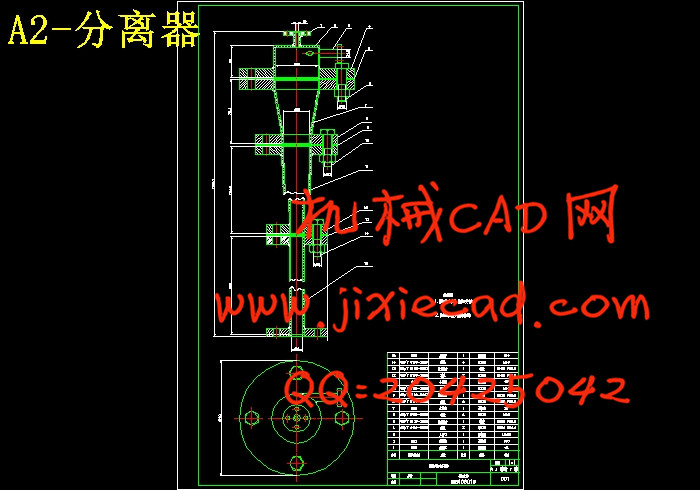

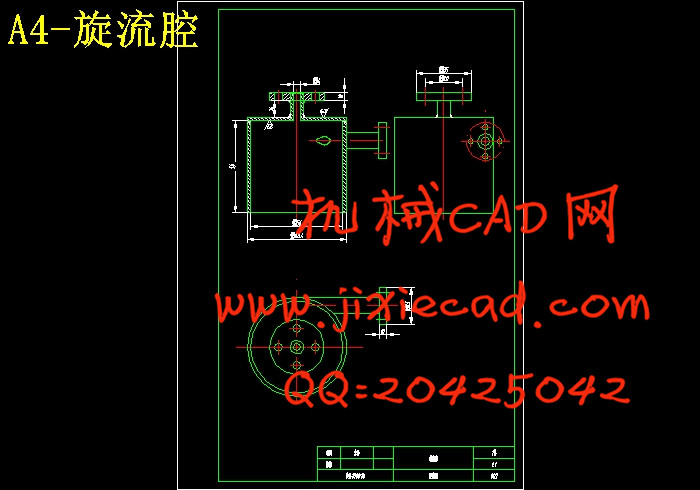

4.旋液式油水分离器结构 6

5.旋液分离器尺寸的计算 7

5.1主直径的选取 7

5.2旋流器其它结构参数的设计 8

5.3溢流口流量和底流口流量的计算 10

6.水力旋流器的制造和安装 11

6.1 水力旋流器在制造上的要求 11

6.2材料选择 12

6.3 常用的制造方法 13

6.4安装 15

7几何参数对水力旋流器性能的影响 15

7.1进料口尺寸 15

7.2旋流器直径 16

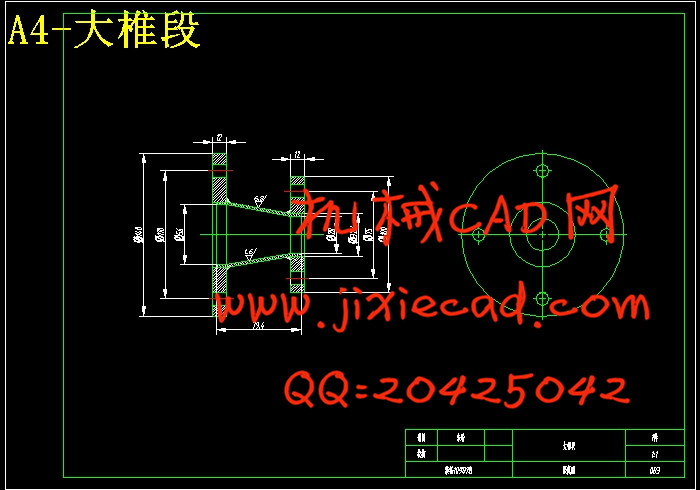

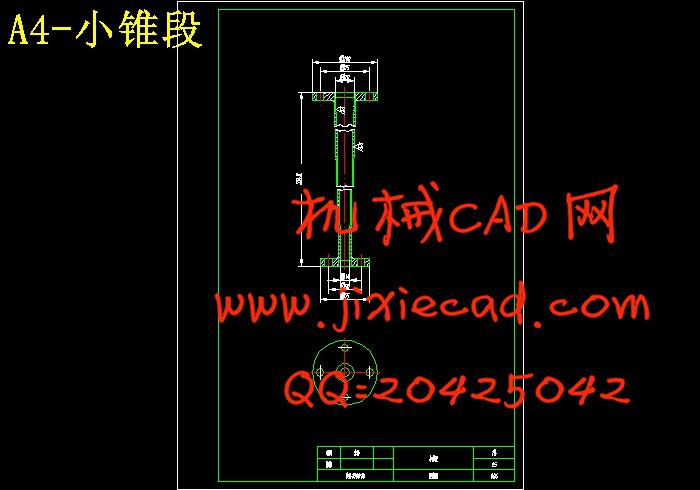

7.3锥角 16

7.4溢流管尺寸 16

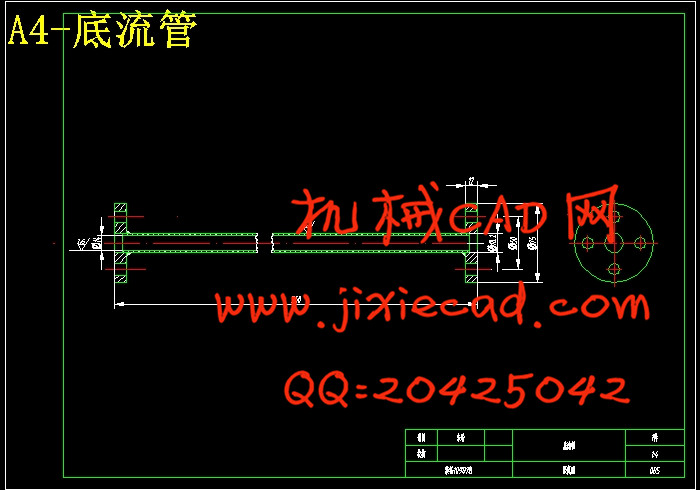

7.5底流口尺寸 16

8操作参数对水力旋流器的影响 16

8.1分离效率与进口流量之间的关系 16

8.2分流比F与分离效率之间的关系 17

8.3分流比与压降比之问的关系 17

9.影响旋流器分离效率的因数 18

9.1旋流器的准数 18

9.2主要影响因素 18

9.2.1 尺寸变量 18

9.2. 2操作变量 20

9.2. 3物性变量 20

致谢 23

水力旋流器是利用强离心力场来实现有一定密度差且不互溶物系分离的离心 沉降设备。目前油田在无动力加工环境中的单井作业无法进行机械脱水处理,一 直采用装原油的容器下加煤炭火烧加温、搅拌、沉淀、分解的老方法进行脱水处 理。这种方法不但极易引起火灾,而且原油损耗大、劳动强度髙、工作效率低, 以及对环境造成极大污染。该方法已经不能满足现在油田生产的需要。

水力旋流法是由英国南安普顿大学(Southampton)研究成功的一种具有80 年代先进水平的含油污水处理新方法。因为它结构简单、分离效率高、成本低, 从它问世之日起,就得到了世界各国的重视。现在,旋流分离已作为重力分离的 一项替代技术,成为世界国际油田地面工程中的主体技术和重要装备。

在前期对液-液旋流分离器流量压降特性实验研究的基础上,分析了结构参数、操作参数及物性参数对液- 液旋流分离效率的影响;提出了液-液旋流分离器结构设计的设计方法和设计步骤,认为建立性能优良的旋流器模 型数据库,是选型设计的基础和前提。

[关键词]:水力旋流器;分离效率;入口 ;锥段;溢流管;旋流腔;底流管

[Abstract:] At present, the hydrocyclone in oilfield produced gradually promote the use of liquid separation and oily sewage treatment. Hydrocyclone has the advantages of simple and compact structure, high efficiency, small volume and area etc.. On the relationship between the structure and the parameters of the hydrocyclone are analyzed. Through the improvement and optimization of hydrocyclone, get double entrance structure of ideal type cyclone monomer for the vortex line, size of the taper section is arc transition form. At the same time, a brief analysis of the cone transition form high-order curve and curve structure, reasonable length of single bodied whirl cavity of hydrocyclone has been determined as 65 mm. It has been discovered that through theoretical study and contrast test,the hydrocyclone that possessing relation model of structural parameters hasmore higher separation efficiency than hydrocyclones with conventional structures.

Cyclone separators are used in various kinds of industries to separate materials of different densities. By creating a strong swirl, large centrifugal forces in the process mixture are generated and due to differences in density the materials will separate. At present in petroleum industry, single well cannot proceed mechanical dehydration treatments with not power. It always taken heat up and deposit method to dewatering, such means not only bring fire and crude oil waste large, labor intensity high, and it have badly influence on environment. Now that approach had insatiability oil fields produce demand.

Hydraulic power method was newly oil-water separation method. It was invented by Britain Southampton University in 1980s. For it structure simplicity, separation efficiency high, and cost low. From it appearance, that has been got widely recognition. In the not far future, rotational flow separate will certainly replace gravitational separation technology, became 21 century international oil field primary equipment.

Based on the experiments aiming at studying flowrate and pressure drop performance,geometric parameters, operating parameters and liquid characteristic parameters influence on separate efficiency are analyzed. Optimal structure design method and process of liquid-liquid separate hydrocyclone are brought forward. It's thought that the database of best hydricyclone model is the basic and premises about optimal structure design.

[Keywords]: hydrocyclone; separation efficiency; entrance; conicsection; overflow pipe; whirl cavity; underflow pip

目录

1前言 1

2.选题背景 2

3方案论证 3

3.1油水分离器的主要特点 3

3.2工作原理 4

4.旋液式油水分离器结构 6

5.旋液分离器尺寸的计算 7

5.1主直径的选取 7

5.2旋流器其它结构参数的设计 8

5.3溢流口流量和底流口流量的计算 10

6.水力旋流器的制造和安装 11

6.1 水力旋流器在制造上的要求 11

6.2材料选择 12

6.3 常用的制造方法 13

6.4安装 15

7几何参数对水力旋流器性能的影响 15

7.1进料口尺寸 15

7.2旋流器直径 16

7.3锥角 16

7.4溢流管尺寸 16

7.5底流口尺寸 16

8操作参数对水力旋流器的影响 16

8.1分离效率与进口流量之间的关系 16

8.2分流比F与分离效率之间的关系 17

8.3分流比与压降比之问的关系 17

9.影响旋流器分离效率的因数 18

9.1旋流器的准数 18

9.2主要影响因素 18

9.2.1 尺寸变量 18

9.2. 2操作变量 20

9.2. 3物性变量 20

致谢 23