设计简介

摘 要

矿用绞车是煤矿不可缺少的重要设备,是我国煤矿的主要矿山辅助运输设备。但绞车的技术水平和技术性能差异很大,一些产品存在着技术落后,工作效率低,使用寿命短,使用不方便等问题。随着煤矿采煤机械化的发展,这些落后的设备已不能满足现场的需求,甚至影响了煤矿的安全生产和正常生产。

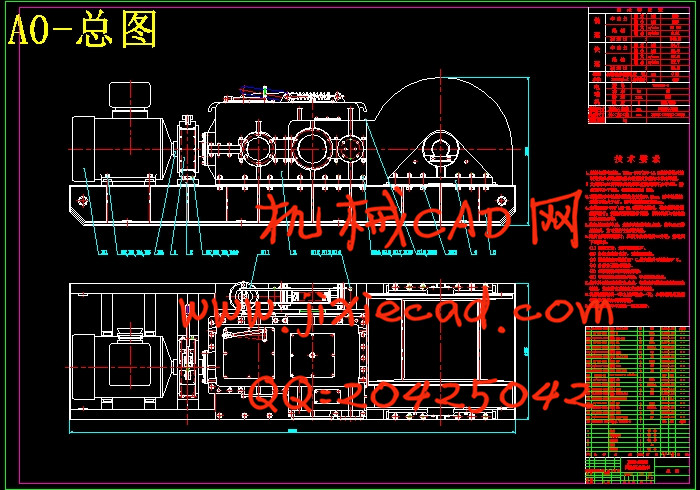

JDHB-380型回柱调度绞车在原SDJ型双速多用绞车的基础上改进发展而来,采用圆锥、圆柱齿轮传动,实现了快、慢两个速度,其慢速可代替回柱绞车和慢速绞车,其快速可代替调度绞车和运输绞车。

在结构特点上,不仅实现了小结构,大拉力的特点,也实现了长条形对称结构特点,适合于煤矿井下狭小的作业空间,操作灵活方便,液动制动闸的安装使绞车实现了标准化。它克服了目前慢速、回柱等系列绞车存在的传动效率低,寿命短,工效低的特点,也克服了调度、运输等系列绞车存在的牵引力小,宽型结构的特点。

关键词: 绞车; 回柱; 调度; 双速

Abstract

Mine winder is the essential equipment in the coal mine. It is the major mine auxiliary haulage in our country. The technical level and performance of the winder have great differences. Some productions exist many problems, such as backward technology, low working efficiency, short service life, inconvenient, and so on. With the development of the mechanization of the coal-mining, these backward equipments have not satisfied the requirement of the in-situ. They affect the safe practice and the normal practice of the coal mine even more.

JDHB-380 drawing-spotting hoist is improved on the base of the SDJ two-speed multi-use winder. It adopts conical and cylindrical gear transmission, brings about immense speed and slow-speed. Its slow-speed can replace that of drawing hoist and slow-speed hoist. Its immense speed can replace that of the spotting hoist and haulage hoist.

In the structural feature, the winder may not only realize the small structure and big drag, but also the extended symmetric structural feature. It is suit for the narrow underground working space. The operation is flexible and convenient. The setting of the hydraulic brake make the winder standard. The winder overcomes the feature of the slow-speed、drawing hoists, such as low drive efficiency, short service life, low working efficiency, but also overcomes the features of the drawing、haulage hoist, such as small traction, wide structure.

Key words: Winder; Drawing; Spotting; Two-speed

目录

1 概 述 - 1 -矿用绞车是煤矿不可缺少的重要设备,是我国煤矿的主要矿山辅助运输设备。但绞车的技术水平和技术性能差异很大,一些产品存在着技术落后,工作效率低,使用寿命短,使用不方便等问题。随着煤矿采煤机械化的发展,这些落后的设备已不能满足现场的需求,甚至影响了煤矿的安全生产和正常生产。

JDHB-380型回柱调度绞车在原SDJ型双速多用绞车的基础上改进发展而来,采用圆锥、圆柱齿轮传动,实现了快、慢两个速度,其慢速可代替回柱绞车和慢速绞车,其快速可代替调度绞车和运输绞车。

在结构特点上,不仅实现了小结构,大拉力的特点,也实现了长条形对称结构特点,适合于煤矿井下狭小的作业空间,操作灵活方便,液动制动闸的安装使绞车实现了标准化。它克服了目前慢速、回柱等系列绞车存在的传动效率低,寿命短,工效低的特点,也克服了调度、运输等系列绞车存在的牵引力小,宽型结构的特点。

关键词: 绞车; 回柱; 调度; 双速

Abstract

Mine winder is the essential equipment in the coal mine. It is the major mine auxiliary haulage in our country. The technical level and performance of the winder have great differences. Some productions exist many problems, such as backward technology, low working efficiency, short service life, inconvenient, and so on. With the development of the mechanization of the coal-mining, these backward equipments have not satisfied the requirement of the in-situ. They affect the safe practice and the normal practice of the coal mine even more.

JDHB-380 drawing-spotting hoist is improved on the base of the SDJ two-speed multi-use winder. It adopts conical and cylindrical gear transmission, brings about immense speed and slow-speed. Its slow-speed can replace that of drawing hoist and slow-speed hoist. Its immense speed can replace that of the spotting hoist and haulage hoist.

In the structural feature, the winder may not only realize the small structure and big drag, but also the extended symmetric structural feature. It is suit for the narrow underground working space. The operation is flexible and convenient. The setting of the hydraulic brake make the winder standard. The winder overcomes the feature of the slow-speed、drawing hoists, such as low drive efficiency, short service life, low working efficiency, but also overcomes the features of the drawing、haulage hoist, such as small traction, wide structure.

Key words: Winder; Drawing; Spotting; Two-speed

目录

1.1 我国绞车的发展历史及趋势 - 1 -

1.2 JDHB回柱调度绞车的组成 - 2 -

1.3 JDHB回柱调度绞车的要特点 - 2 -

2 总体设计 - 3 -

2.1 设计总则 - 3 -

2.2 已知条件 - 3 -

2.3 牵引钢丝绳直径的确定及滚筒直径的确定 - 3 -

2.3.1钢丝绳的选择 - 3 -

2.3.2滚筒参数的确定 - 4 -

2.4 传动系统的确定、运动学计算及电机的选择 - 5 -

2.4.1 传动系统的确定 - 5 -

2.4.2 计算传动效率 - 6 -

2.4.3各级传动比分配及总传动比 - 7 -

2.4.4计算钢丝绳速度 - 8 -

2.4.5确定钢丝绳在卷筒上的拉力及卷筒上的功率 - 9 -

2.4.6选择电机型号 - 10 -

2.4.7验算电机闷车时,钢丝绳在里层的安全系数 - 11 -

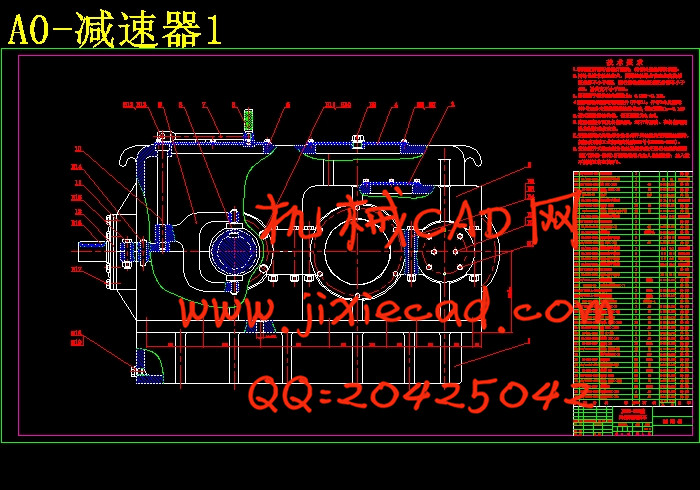

3 齿轮传动的设计计算 - 12 -

3.1 第一级弧齿锥齿轮传动设计计算 - 12 -

3.1.1 基本参数 - 12 -

3.1.2 强度计算 - 12 -

3.2. 第二级齿轮传动的强度校核 - 20 -

3.2.1 基本参数 - 20 -

3.2.2 强度校核 - 20 -

3.3 第三级齿轮传动的强度校核 - 26 -

3.3.1基本参数 - 26 -

3.3.2强度校核 - 26 -

3.4 第四级齿轮传动的强度校核 - 32 -

3.4.1基本参数 - 32 -

3.4.2强度校核 - 32 -

3.5 第五级齿轮传动前级的强度校核 - 38 -

3.5.1基本参数 - 38 -

3.5.2强度校核 - 38 -

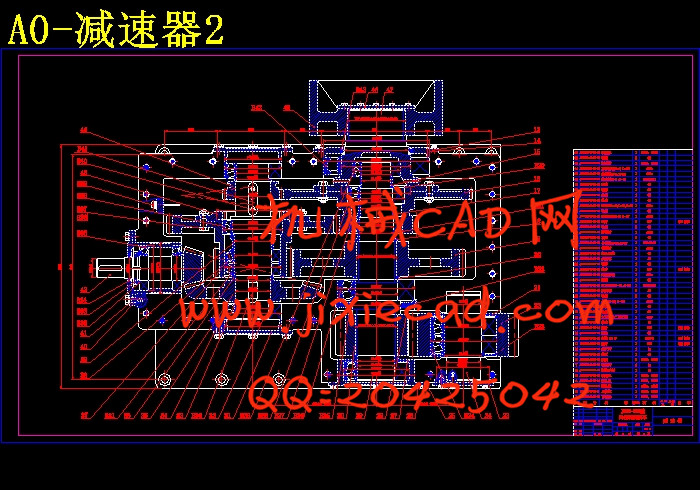

4 锥齿轮轴的设计计算与强度校核 - 44 -

4.1 轴的计算及校核 - 44 -

4.1.1轴的初步设计 - 44 -

4.1.2轴的疲劳强度校核 - 44 -

4.2锥齿轮轴上键的强度验算 - 49 -

4.3锥齿轮轴上轴承的寿命验算 - 49 -

5 二轴的设计计算与强度验算 - 51 -

5.1 轴的设计及校核 - 51 -

5.1.1轴的初步设计 - 51 -

5.1.2轴的疲劳强度校核 - 51 -

5.2二轴上键的强度验算 - 57 -

5.3 二轴上轴承的寿命验算 - 58 -

5.4二轴上滑移齿轮与双联齿轮联接螺栓的强度验算 - 59 -

6 花键轴的设计 - 61 -

6.1 花键轴的设计计算与强度验算 - 61 -

6.1.1轴的初步计算 - 61 -

6.1.2轴的疲劳强度校核 - 61 -

6.2 花键轴上花键的强度验算 - 70 -

6.3 花键轴上轴承的寿命验算 - 71 -

致 谢 - 74 -

参 考 文 献 - 75 -