设计简介

摘要

随着食品工业的发展,以及市场需求的变化,近年来我国的磨粉机层出不穷。专用的食品加工用的磨粉机从无到有、从少到多有了长足的发展。现今市场上有专用加工一种农作物的磨粉机,也有可加工多种农作物的磨粉机。各种各样的磨粉机,从大型的到小型的,名目繁多。磨粉机的工作原理也不一样,有的是用刀片切削的方式进行粉碎,也有的用磨盘进行磨碎,也有的先用一机构进行切碎再进行磨粉。经过我的现场的了解和对市场上各种磨粉机的探究,市场上的磨粉机主要是大型商用磨粉机和超小型磨粉机,没有一种是中型磨粉机。这对需要中小型磨粉机的用户来说,没有合适的产品供其选择。在这里我针对这种情况,设计了一款中型磨粉机,非常适合小型加工厂的使用。可磨多种谷物,如大米、麦子等。

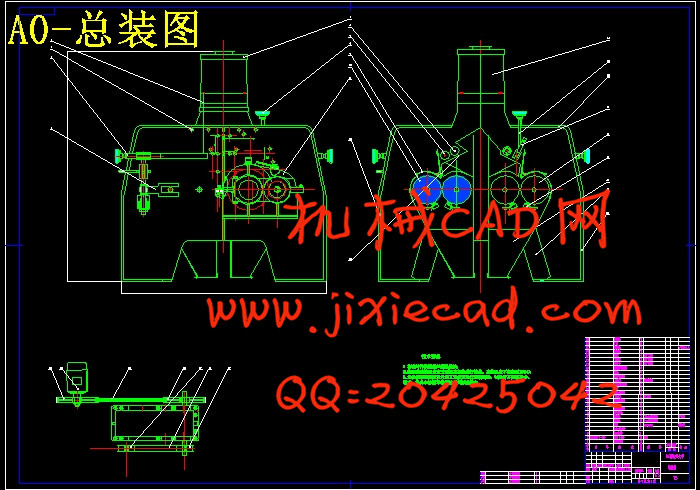

我所设计的磨粉机的工作原理是利用一对平置等径不等速相向旋转的齿辊(或光辊),以剪切、挤压、研磨(或挤压和研磨)的方法将物料粉碎。本机的工作效率高,既适合小型面粉厂又适合家庭。

本设计利用Auto CAD软件绘制相关的图纸。本设计的主要特点在于所设计的机构简单,实用性强,便于加工。其所用的材料便宜,所以本机的制造成本很低。本设计所设计的磨粉机具有成本低,效率高的特点。

关键词:磨粉机、辊式、谷物

Abstract

Along with the development of food industry, and the change of market demand, in recent years China's grinding machine are endless. Special food processing with a mill from scratch, from a limited amount has developed rapidly. On the market today to have special processing a crop of grinding machine, also have a variety of crops can be processed the grinding machine. All kinds of grinding machine, from large to small, various kinds. The working principle of grinding machine is different also, have a plenty of with a blade cutting way pieces, and also some micropipette grinding with on, also some use first a mechanism to cut up grinding. After my site to the understanding of the market and the mill of the inquiry, in the market grinding machine Lord if large commercial grinding machine and mini mill, no one is medium mill. The need to small and medium mill of users, not suitable products for their choice. Here I in this kind of situation, designed a medium-sized grinding machine, very suitable for the use of small processing plant. Can whet a variety of grains, such as rice, wheat, etc.

I designed by grinding machine working principle is to use a pair of flat buy such as track not constant speed at the rotation teeth roll (or light roller) to shear, extrusion, grinding (or extrusion and grinding) methods will material crushing. This machine is of high working efficiency, and is suitable for both small flour factories and suitable for home.

This design using Auto CAD software rendering the relevant drawings. This design is the main characteristics of the design of simple structure, practical strong, facilitate processing. It used materials cheap, so the machine manufacturing cost is very low. The design of the milling machine has the design cost is low, the efficiency high characteristic.

Key words: mill, roller type, grain

目录随着食品工业的发展,以及市场需求的变化,近年来我国的磨粉机层出不穷。专用的食品加工用的磨粉机从无到有、从少到多有了长足的发展。现今市场上有专用加工一种农作物的磨粉机,也有可加工多种农作物的磨粉机。各种各样的磨粉机,从大型的到小型的,名目繁多。磨粉机的工作原理也不一样,有的是用刀片切削的方式进行粉碎,也有的用磨盘进行磨碎,也有的先用一机构进行切碎再进行磨粉。经过我的现场的了解和对市场上各种磨粉机的探究,市场上的磨粉机主要是大型商用磨粉机和超小型磨粉机,没有一种是中型磨粉机。这对需要中小型磨粉机的用户来说,没有合适的产品供其选择。在这里我针对这种情况,设计了一款中型磨粉机,非常适合小型加工厂的使用。可磨多种谷物,如大米、麦子等。

我所设计的磨粉机的工作原理是利用一对平置等径不等速相向旋转的齿辊(或光辊),以剪切、挤压、研磨(或挤压和研磨)的方法将物料粉碎。本机的工作效率高,既适合小型面粉厂又适合家庭。

本设计利用Auto CAD软件绘制相关的图纸。本设计的主要特点在于所设计的机构简单,实用性强,便于加工。其所用的材料便宜,所以本机的制造成本很低。本设计所设计的磨粉机具有成本低,效率高的特点。

关键词:磨粉机、辊式、谷物

Abstract

Along with the development of food industry, and the change of market demand, in recent years China's grinding machine are endless. Special food processing with a mill from scratch, from a limited amount has developed rapidly. On the market today to have special processing a crop of grinding machine, also have a variety of crops can be processed the grinding machine. All kinds of grinding machine, from large to small, various kinds. The working principle of grinding machine is different also, have a plenty of with a blade cutting way pieces, and also some micropipette grinding with on, also some use first a mechanism to cut up grinding. After my site to the understanding of the market and the mill of the inquiry, in the market grinding machine Lord if large commercial grinding machine and mini mill, no one is medium mill. The need to small and medium mill of users, not suitable products for their choice. Here I in this kind of situation, designed a medium-sized grinding machine, very suitable for the use of small processing plant. Can whet a variety of grains, such as rice, wheat, etc.

I designed by grinding machine working principle is to use a pair of flat buy such as track not constant speed at the rotation teeth roll (or light roller) to shear, extrusion, grinding (or extrusion and grinding) methods will material crushing. This machine is of high working efficiency, and is suitable for both small flour factories and suitable for home.

This design using Auto CAD software rendering the relevant drawings. This design is the main characteristics of the design of simple structure, practical strong, facilitate processing. It used materials cheap, so the machine manufacturing cost is very low. The design of the milling machine has the design cost is low, the efficiency high characteristic.

Key words: mill, roller type, grain

1 绪论 1

1.1 引言 1

1.2 适用范围及特点 1

2 设计方案的确定和关键技术的解决方法 2

2.1 总体结构与主要工作部分 2

2.1.1 机架 2

2.1.2 外形 2

2.1.3 与机架有关的部分 2

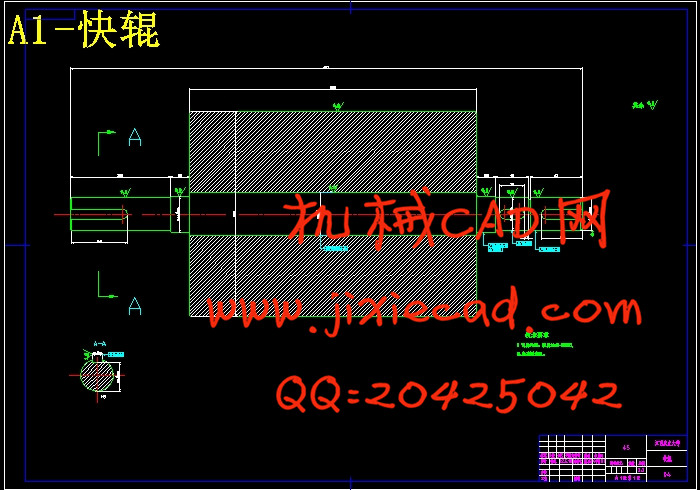

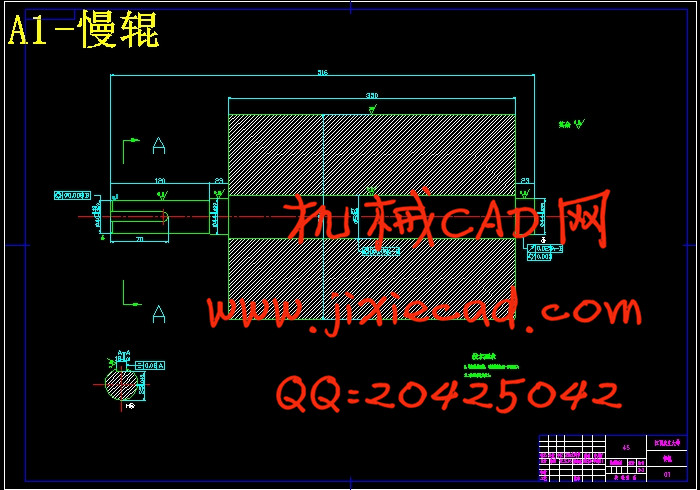

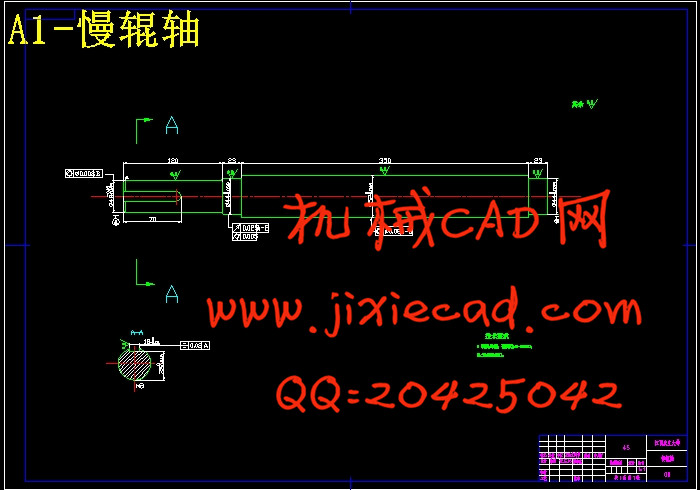

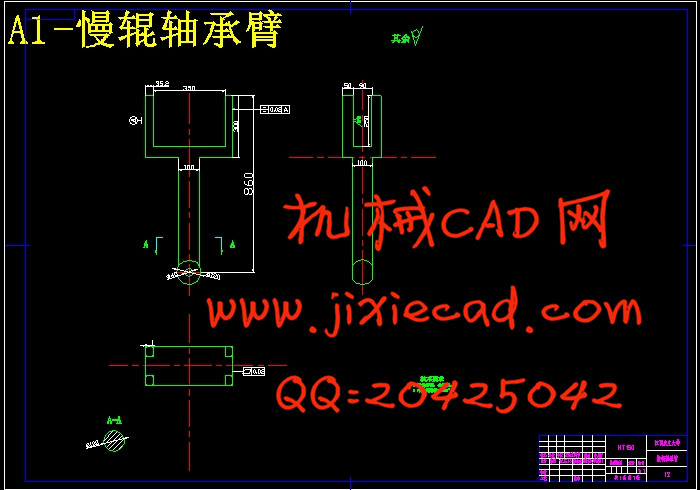

2.1.4 磨辊及其支承、清理与调平 3

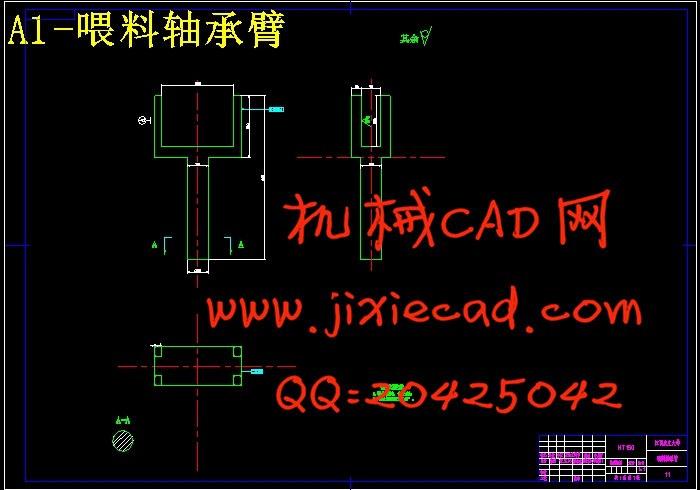

2.1.5 喂料辊及其有关尺寸参数的确定 4

2.2 传动系统 6

2.2.1 快辊拖动 6

2.2.2 辊间传动 7

2.2.3 喂料辊传动 8

2.2.4 传动示意图 8

2.3 控制系统 9

2.3.1 传感机构 9

2.3.2 喂料调节机构 10

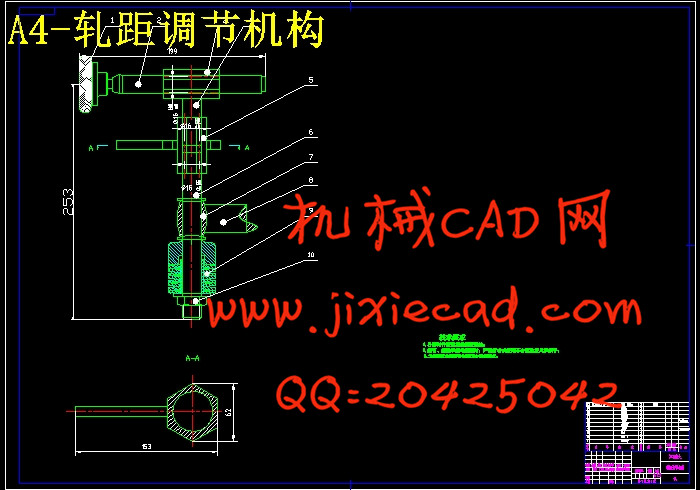

2.3.3 离合轧——轧调机构 11

2.3.4 过载冲击问题 12

2.4 卸料方式 13

2.5 棘轮微调问题 13

2.6 磨辊的生产率 13

3 本机工作原理与操作方法 14

3.1 工作原理 14

3.2 操作方法 14

4 本机的结构特点与先进性 15

5 本机的特征 16

6 计算部分 17

6.1 动力计算、选配电机 17

6.2 传动设计 17

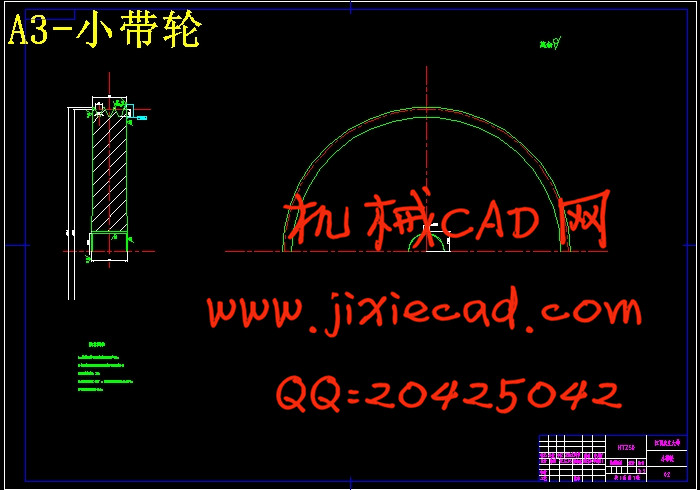

6.2.1 三角带传动设计 17

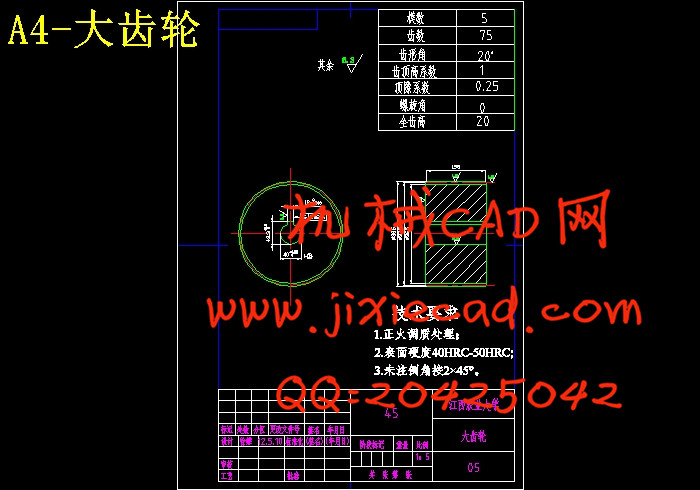

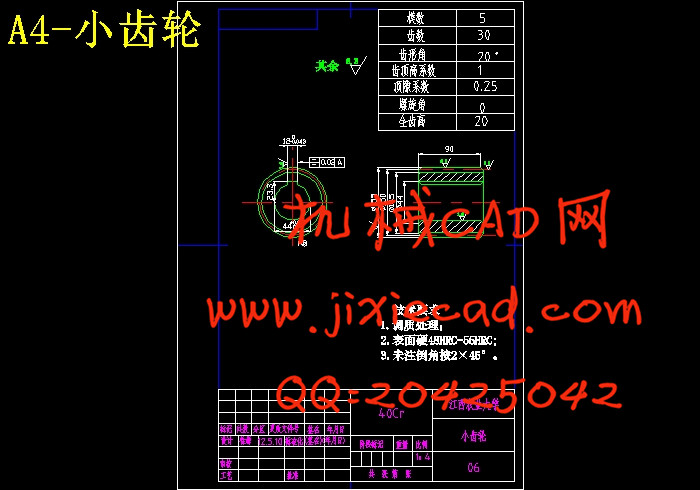

6.2.2 齿轮减速箱部分的设计 19

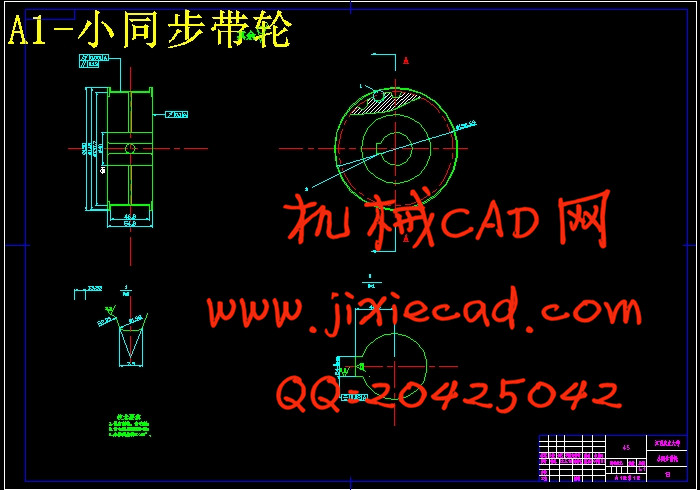

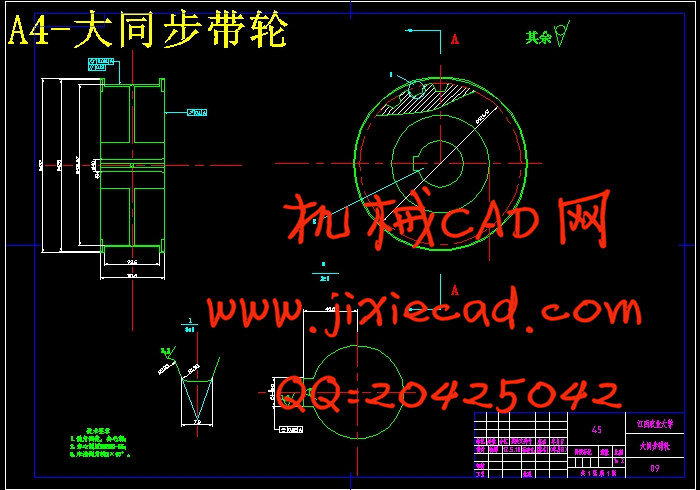

6.2.3 同步带传动设计 23

6.3 磨辊受力分析 24

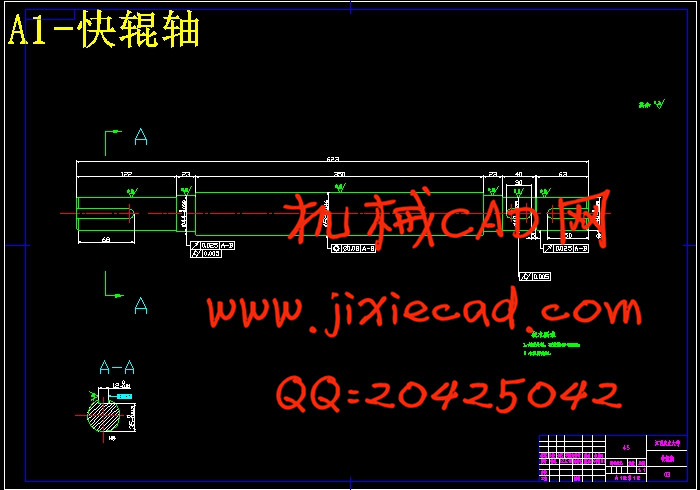

6.3.1 磨辊轴的结构设计 24

6.3.2 磨辊受力分析 24

6.4 磨辊轴的校核 27

6.5 轴承的选用与校核 30

6.6 关于传感机构的计算 31

6.7 喂料调节机构的计算 32

6.8 离合轧——轧调机构的计算 35

参考文献 39

致谢 40