设计简介

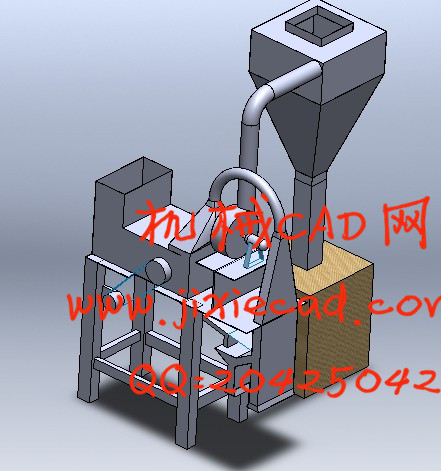

摘 要: 花生仁是由红色外衣和籽仁组成。红衣主要是纤维组织和止血素, 而花生中的油脂、蛋白质等营养素都集中在籽仁中。无论是从花生中提取蛋白粉, 还是提高花生榨制出浓香型花生油的档次, 都需将花生果经剥壳后再去掉花生果仁上的红皮(俗称红衣), 这是制作上述食品及原料加工过程中不可缺少的关键工序之一[1]。为此,我们需要设计与试制一种花生脱红衣机来除去花生红衣为后续的工作做准备。本文通过利用搓擦原理将花生仁上的红衣去除的方法,阐述了通过搓擦的原理可以将花生仁上的红衣有效的脱离下来,并且花生仁的破碎率小[2]。通过实验论证了可以利用两胶带之间的搓擦使花生仁上的红衣有效的脱离下来,可广泛的应用于花生的初加工。

关键词:花生红衣;活动与固定摩擦胶带;搓擦原理;振动筛

Abstract: A peanut kernel is composed by a red skin and a kernel. The skin is mainly made up of fibrous tissues and stypticins, while the kernel mainly contains nutrients like fat and protein. No matter whether the peanuts are used to extract albumen powder or used to enhance the quality of the extracted strong flavor peanut oil, the red one (generally called red skin) covering the kernel should be peeled after the peanut is shelled, which is one of the essential key procedures in making the products and material processing. Therefore, we need to design and trial-produce a peanut red skin huller, in preparation for the subsequent procedures. So, throughout the paper, the designers stated that rubbing principle could be applied in taking off the red skin and expounded how it worked effectively with low broken rate. By experiments, it has been expounded and proved that the red skin can be dropped successfully with the rubbing between the rubber belts, which can be widely applied in the primary processing of peanuts.

Keywords: peanut red skin; movable and fixed rubber belts; rubbing principle; vibrating screen

目 录

1绪论 1

1.1 课题研究的意义 1

1.2 国内外花生红衣脱皮机的发展现状 1

1.3国内外花生红衣脱皮机存在的优缺点 1

1.4花生红衣脱皮机的研制及发展前景 1

1.5预期目标 2

1.6重点研究的关键问题及解决思路 2

1.7工作条件及解决方法 2

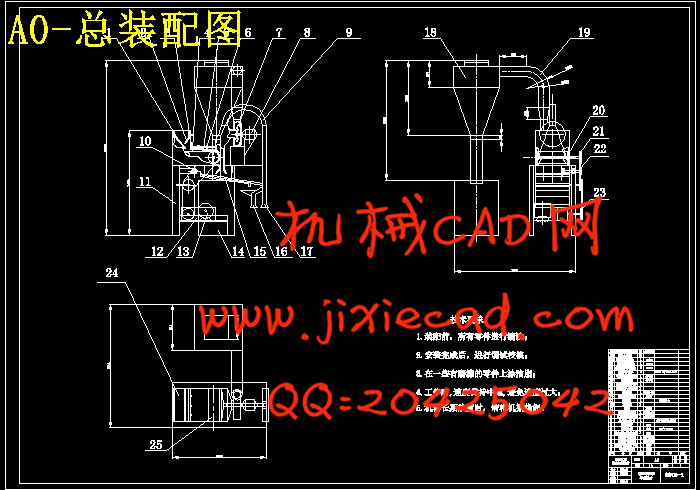

2基本结构、原理及主要技术参数 2

2.1花生红衣脱皮机结构 2

2.2工作原理 4

2.3主要技术参数 5

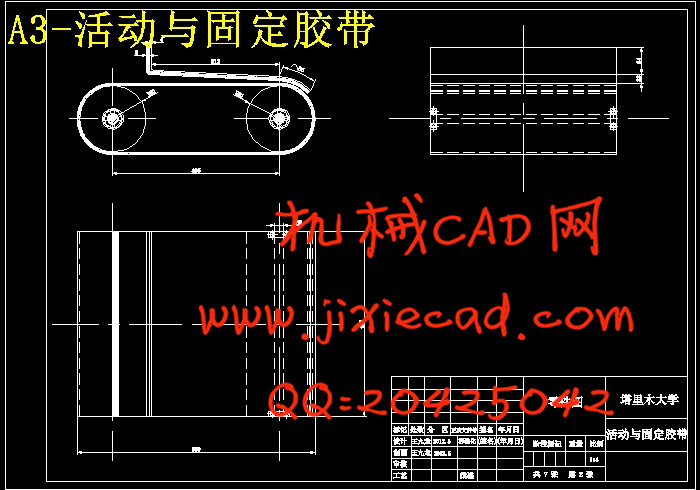

2.4活动摩擦胶带与固定摩擦胶带的结构与分布 5

2.5楔形区大小的确定 5

2.6花生红衣与花生仁分离区物料平均流速 的确定 5

的确定 5

2.7活动摩擦胶带线速度 的确定 6

的确定 6

2.8滚筒转速和振动筛曲柄轴转速的确定 6

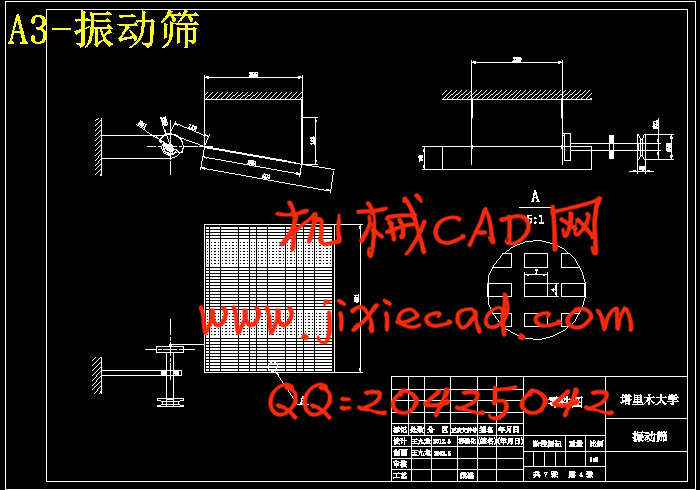

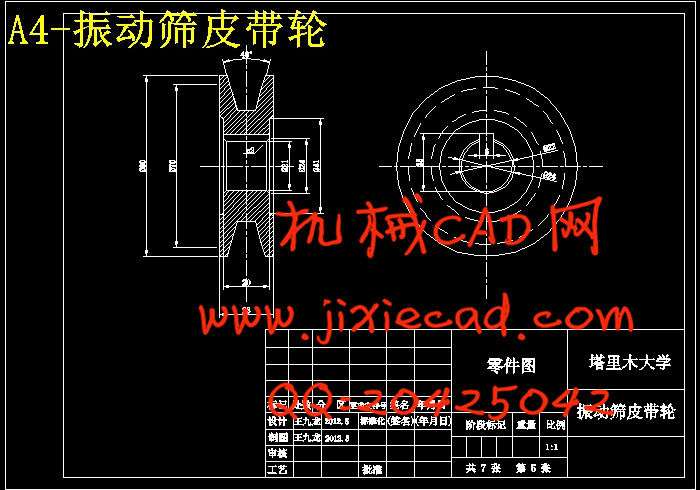

2.9振动筛主要参数的确定 7

2.10筛上物呈现下行体制需要满足的条件 7

2.11风网风量的计算 8

2.12风网风压和风机的确定 9

3电动机、减速箱的选取 10

3.1电动机的确定 10

3.2减速箱的确定 12

4轴和皮带的校核 12

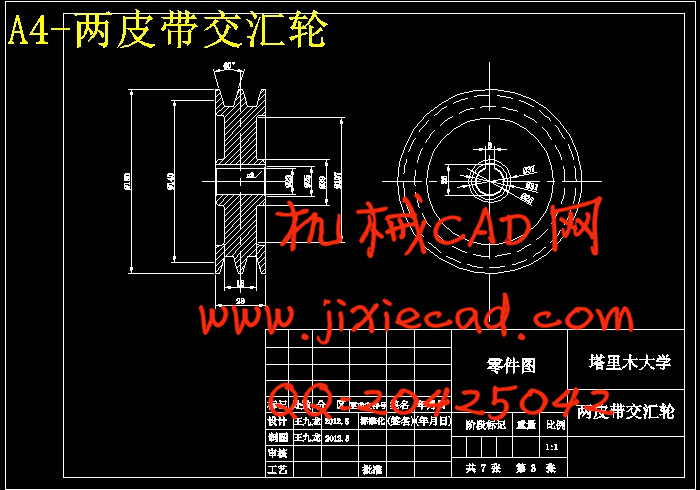

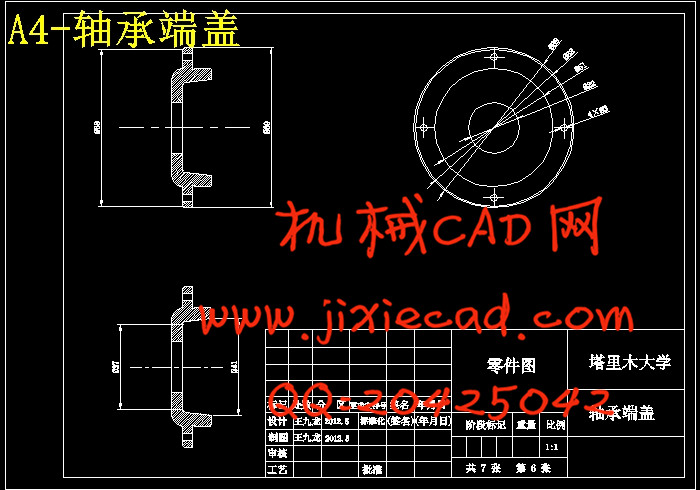

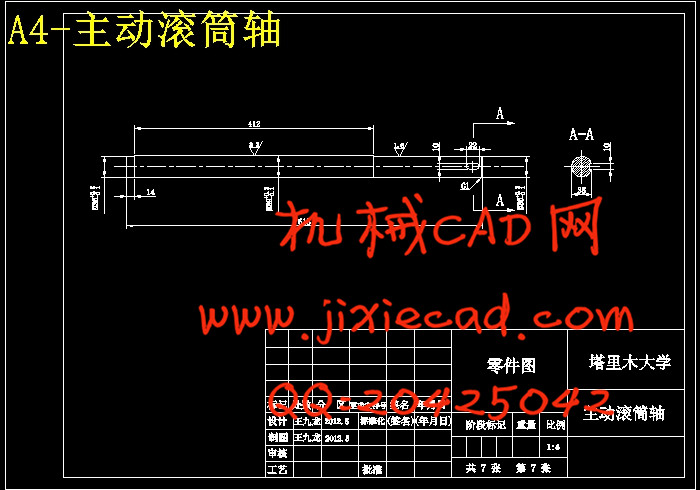

4.1带动活动摩擦胶带转动的滚筒的轴的校核 12

4.2皮带的校核 13

5结论 13

小结 14

致 谢 15

参考文献 16

关键词:花生红衣;活动与固定摩擦胶带;搓擦原理;振动筛

Abstract: A peanut kernel is composed by a red skin and a kernel. The skin is mainly made up of fibrous tissues and stypticins, while the kernel mainly contains nutrients like fat and protein. No matter whether the peanuts are used to extract albumen powder or used to enhance the quality of the extracted strong flavor peanut oil, the red one (generally called red skin) covering the kernel should be peeled after the peanut is shelled, which is one of the essential key procedures in making the products and material processing. Therefore, we need to design and trial-produce a peanut red skin huller, in preparation for the subsequent procedures. So, throughout the paper, the designers stated that rubbing principle could be applied in taking off the red skin and expounded how it worked effectively with low broken rate. By experiments, it has been expounded and proved that the red skin can be dropped successfully with the rubbing between the rubber belts, which can be widely applied in the primary processing of peanuts.

Keywords: peanut red skin; movable and fixed rubber belts; rubbing principle; vibrating screen

目 录

1绪论 1

1.1 课题研究的意义 1

1.2 国内外花生红衣脱皮机的发展现状 1

1.3国内外花生红衣脱皮机存在的优缺点 1

1.4花生红衣脱皮机的研制及发展前景 1

1.5预期目标 2

1.6重点研究的关键问题及解决思路 2

1.7工作条件及解决方法 2

2基本结构、原理及主要技术参数 2

2.1花生红衣脱皮机结构 2

2.2工作原理 4

2.3主要技术参数 5

2.4活动摩擦胶带与固定摩擦胶带的结构与分布 5

2.5楔形区大小的确定 5

2.6花生红衣与花生仁分离区物料平均流速

2.7活动摩擦胶带线速度

2.8滚筒转速和振动筛曲柄轴转速的确定 6

2.9振动筛主要参数的确定 7

2.10筛上物呈现下行体制需要满足的条件 7

2.11风网风量的计算 8

2.12风网风压和风机的确定 9

3电动机、减速箱的选取 10

3.1电动机的确定 10

3.2减速箱的确定 12

4轴和皮带的校核 12

4.1带动活动摩擦胶带转动的滚筒的轴的校核 12

4.2皮带的校核 13

5结论 13

小结 14

致 谢 15

参考文献 16