设计简介

摘要

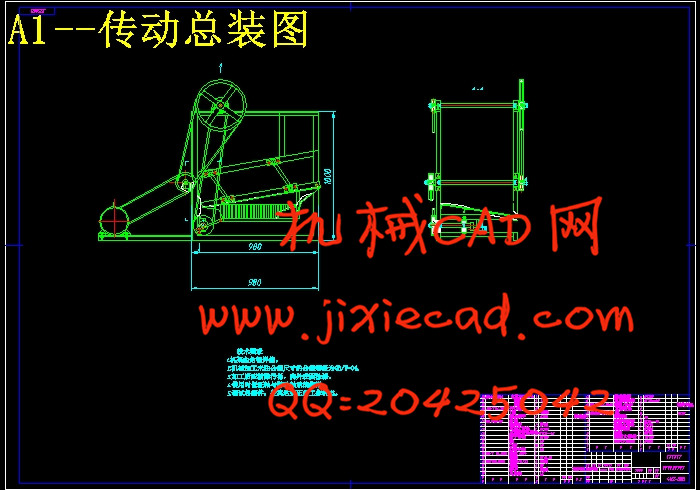

主要是对花生摘果机传动部分设计,由电机的选择,传动比分配以及V带设计计算和轴系零件的计算校核等组成。该机用于花生收获后带蔓直接摘果,可在田间地头灵活移动使用,工作效率高。该机采用全喂入、圆柱滚筒机构摘果,具有摘净率高、破碎率低、清选干净、工作效率高、整机结构合理、场地间移动方便等优点。

关键词 : 花生摘果机 传动 计算

Abstract

Mainly on the peanut picking machine transmission part of the design, the choice of motor, transmission ratio distribution as well as the V with the design calculation and the calculation of shafting components composition. The machine for peanut harvesting with cranberry direct picking, in field edge of a field mobile and flexible use, high work efficiency. The machine adopts full feeding, cylindrical roller mechanism to pick fruit, with removable net rate is high, the low rate of broken, cleaning, clean, high work efficiency, it has the advantages of reasonable structure, convenient venue between mobile.

Key words: peanut picking machine ;transmission ;calculation

目录

摘要 I主要是对花生摘果机传动部分设计,由电机的选择,传动比分配以及V带设计计算和轴系零件的计算校核等组成。该机用于花生收获后带蔓直接摘果,可在田间地头灵活移动使用,工作效率高。该机采用全喂入、圆柱滚筒机构摘果,具有摘净率高、破碎率低、清选干净、工作效率高、整机结构合理、场地间移动方便等优点。

关键词 : 花生摘果机 传动 计算

Abstract

Mainly on the peanut picking machine transmission part of the design, the choice of motor, transmission ratio distribution as well as the V with the design calculation and the calculation of shafting components composition. The machine for peanut harvesting with cranberry direct picking, in field edge of a field mobile and flexible use, high work efficiency. The machine adopts full feeding, cylindrical roller mechanism to pick fruit, with removable net rate is high, the low rate of broken, cleaning, clean, high work efficiency, it has the advantages of reasonable structure, convenient venue between mobile.

Key words: peanut picking machine ;transmission ;calculation

目录

Abstract II

1 绪论 1

1.1 花生的简介 1

1.2 我国花生摘果机现状 1

1.3花生摘果机的类型与特点 2

1.4 花生摘果机工作原理 3

2 机械传动系统总体设计 4

2.1 传动方案的拟定: 4

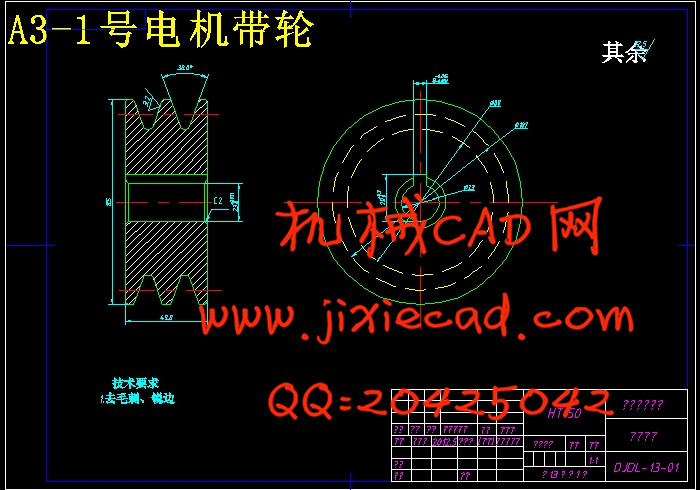

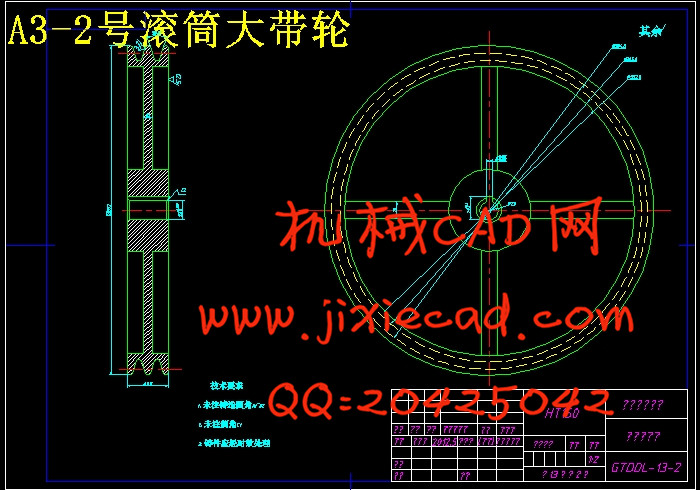

2.2 电动机的选择 5

2.3 风扇的设计 5

3传动装置运动和动力参数的计算 6

3.1 传动比分配 6

3.2 各轴的转速计算 6

3.3 各轴输入功率计算 6

3.4 各轴输入扭矩计算 6

4.V带的设计 7

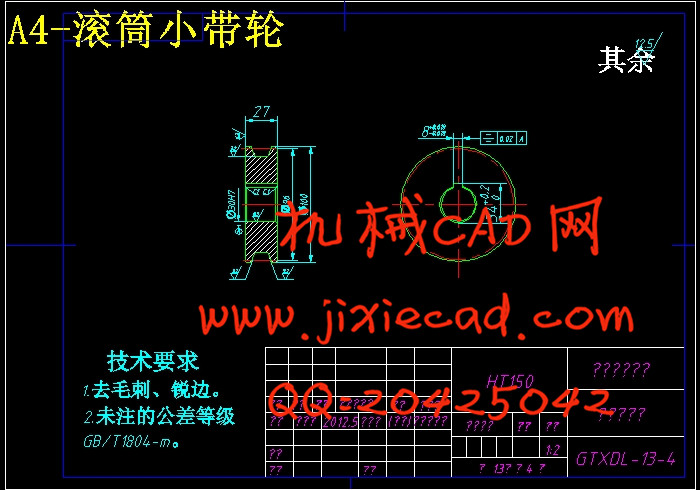

4.1 V1带传动的设计计算 7

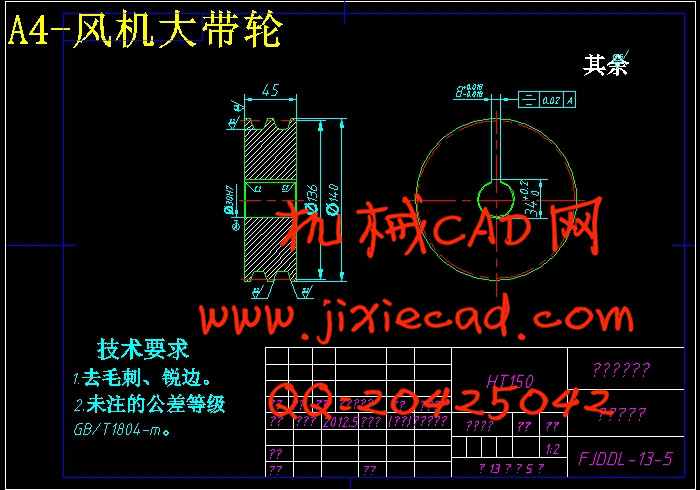

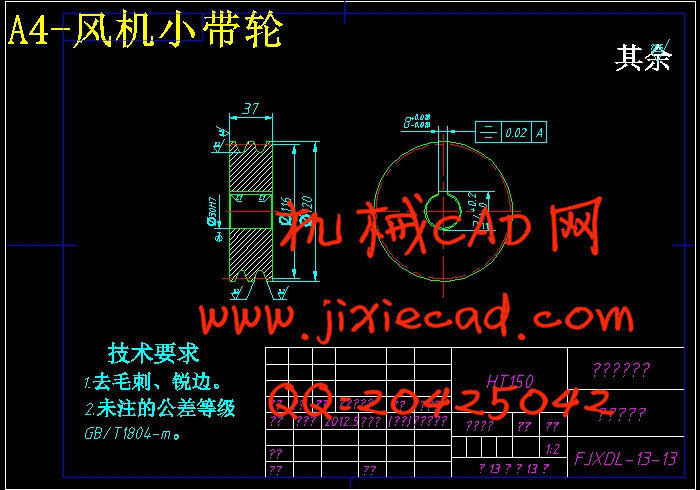

4.2 V2带传动的设计 9

4.3 V3带传动的设计计算 12

5 轴系零件的设计计算 15

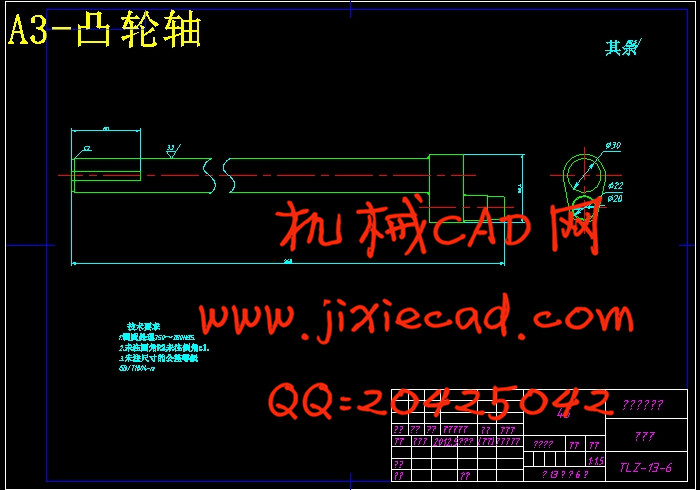

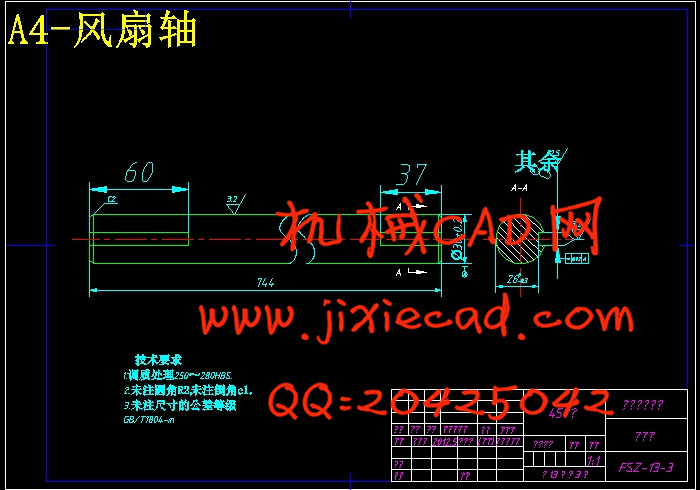

5.1 风扇轴设计校核 15

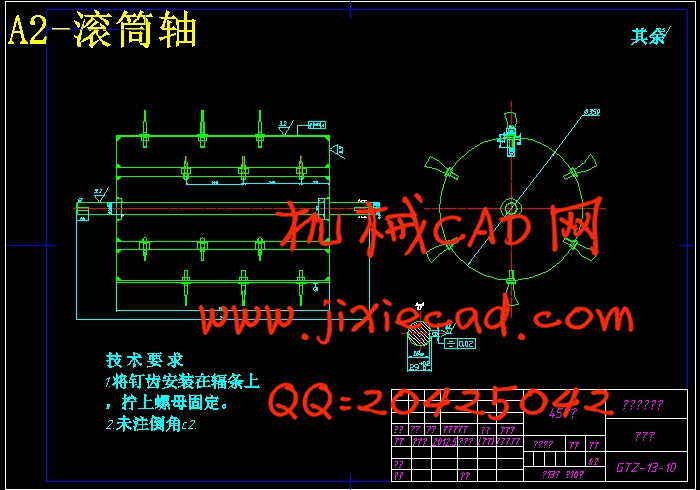

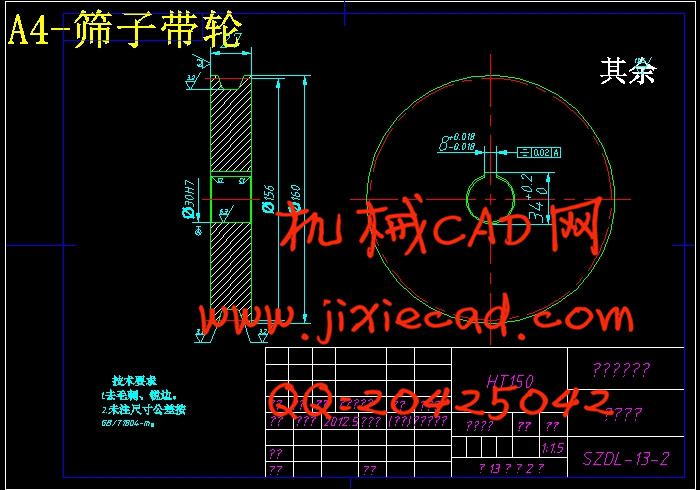

5.2 滚筒轴的设计与校核 18

5.3 III轴的设计与校核 19

5.4 轴上键连接的选择及校核 20

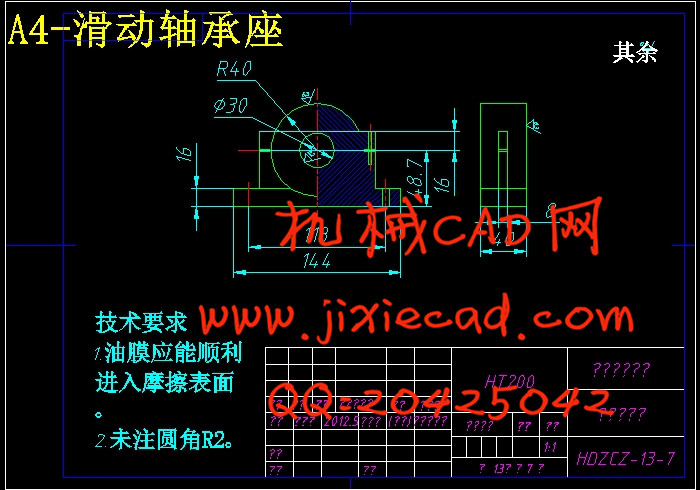

5.5 轴承座、端盖的结构设计 20

6 机架的结构设计 21

参考文献 22

设计小结 23