设计简介

摘 要

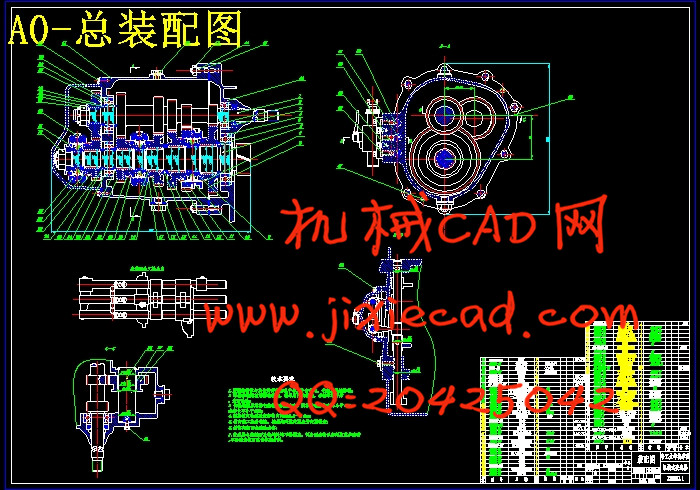

变速器是汽车的核心组成部分,用来改变发动机传到驱动轮上的转矩和转速,将动力有效而经济地传至驱动车轮,以满足汽车的使用要求。变速器是完成传动系任务的重要部件,也是决定整车性能的主要部件之一。变速器的设计水平对汽车的动力性、燃料经济性、换挡操纵的可靠性与轻便性、传动平稳性与效率等都有直接的影响。随着汽车工业的发展,轿车变速器的设计趋势是增大其传递功率与重量之比,并要求其具有更小的尺寸和良好的性能。本设计以一汽大众捷达GTX变速器为基础,在给定发动机输出转矩、转速及最高车速、最大爬坡度等条件下,着重对变速器齿轮的结构参数、轴的结构尺寸等进行设计计算;并对变速器的传动方案和结构形式进行设计;同时对操纵机构和同步器的结构进行设计;从而提高汽车的整体性能。关键词:捷达;变速器;齿轮;设计;结构

ABSTRACT

Transmission is the core components of automobile.Its task is transforming and regulateing the performance of engine. It can be used to change the engine driving wheel on the spread of torque and speed. Transmission is the important part of drivetrain components to complete the tasks. as well as one of the main factor to decide the whole performance of vehicle. The standards of Transmission designing can directly impact the vehicle dynamics, fuel economy, the reliability and portability of shifting , the smoothness and efficiency of Transmiting. Along with the development of the automobile industry,the trend of car transmission designing is to increase its transmission power and decrese its weight,and hope have smaller size and excellent performance. The design based on the FAW-Volkswagen Automotive Company Ltd’JETTA Transmission, In conditions that knowing the engine output torque,speed of engine and maximum speed of vehicles, maximum degree, focus on the designing of transmission gear structural parameters, axis geometry design computation; as well as the transmission and drive program structure design; Meanwhile on the structure of components to manipulation and synchronous design; thereby enhancing the overall performance of cars.Key words: JETTA ;Transmission;Gear ;Design;Structure

目 录

Abstract ·························································Ⅱ

目录····················································Ⅲ

第1章 绪论·····················································1

1.1概述·····················································1

1.1.1汽车变速器的设计要求···································1

1.1.2国内外汽车变速器的发展现状·····························2

1.2设计的内容及方法·········································3

1.3设计的目的及意义·········································4

第2章变速器传动机构与操纵机构的选择与设计················5

2.1变速器传动机构布置方案···································5

2.1.1变速器传动方案分析与选择···························5

2.1.2 倒档布置方案·······································6

2.1.3零部件结构方案分析·····································7

2.2变速器操纵机构布置方案···································9

2.2.1概述····················································9

2.2.2典型的操纵机构及其锁定装置····························10

2.3本章小结················································12

第3章变速器的设计与计算····································13

3.1变速器主要参数的选择····································13

3.1.1档数···················································13

3.1.2传动比范围·············································13

3.1.3变速器各档传动比的确定································14

3.1.4中心距的选择···········································17

3.1.5变速器的外形尺寸······································17

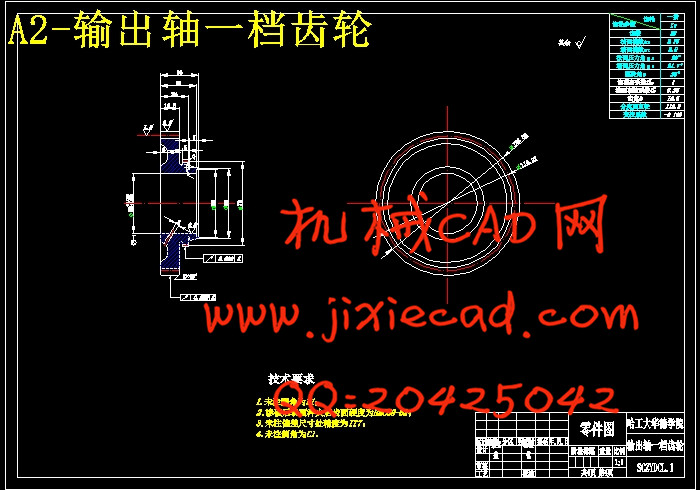

3.1.6齿轮参数的选择········································17

3.1.7各档齿轮齿数的分配及传动比的计算······················19

3.1.8变速器齿轮的变位及齿轮螺旋角的调整····················23

3.2变速器齿轮强度校核······································25

3.2.1齿轮材料的选择原则····································25

3.2.2变速器齿轮弯曲强度校核································25

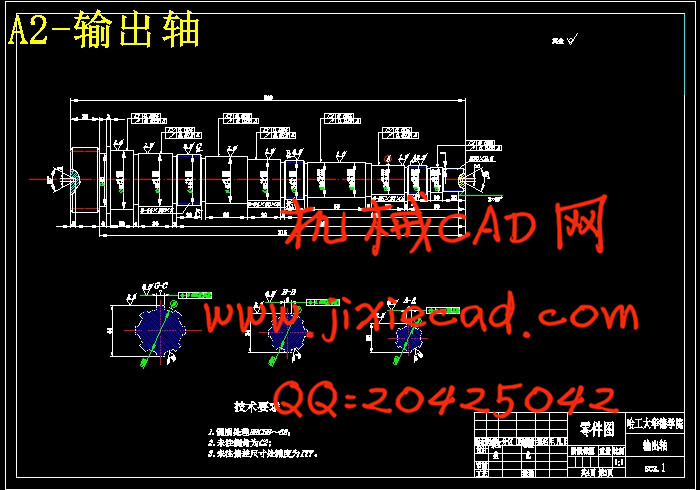

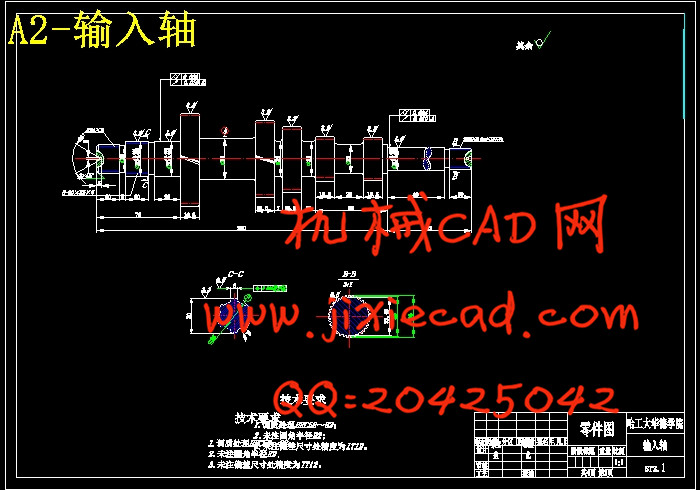

3.3轴的结构和尺寸设计······································30

3.4轴的强度验算············································32

3.4.1轴的刚度计算···········································32

3.4.2轴的强度计算···········································35

3.5轴承选择与寿命计算······································39

3.5.1输入轴轴承的选择与寿命计算····························39

3.5.2输出轴轴承的选择与寿命计算····························42

3.6本章小结················································44

第4章变速器同步器及结构元件设计···························45

4.1同步器设计·············································45

4.1.1同步器的功用及分类································45

4.1.2惯性式同步器······································45

4.1.3锁环式同步器主要尺寸的确定························47

4.1.4主要参数的确定····································48

4.2变速器壳体·············································50

4.3本章小结················································50

结论·····························································51

参考文献························································52

致谢·····························································53