设计简介

摘 要

我们的课题来源于指导老师对地方制砖设备的考察,根据砖厂经营者对目前设备成本高、能耗大、占地广、消耗大量人力物力的不满等诸多弊端而提出的具有经济性的优化设计,结合蜂窝煤机与目前市场常用挤压式制砖机的工作原理进行分析,研发的一种新型制砖设备。

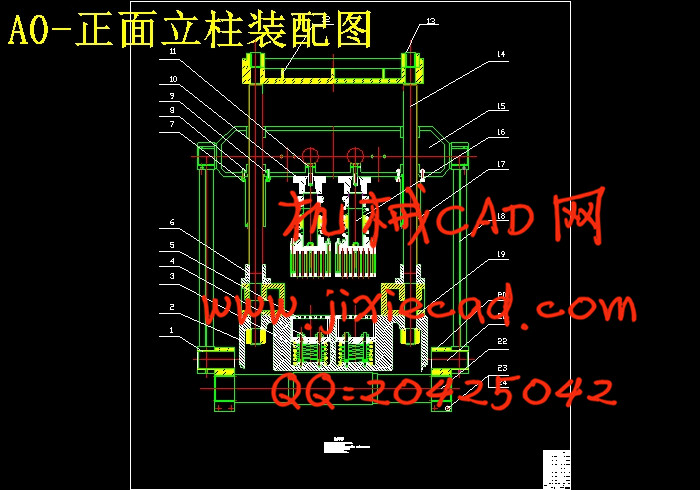

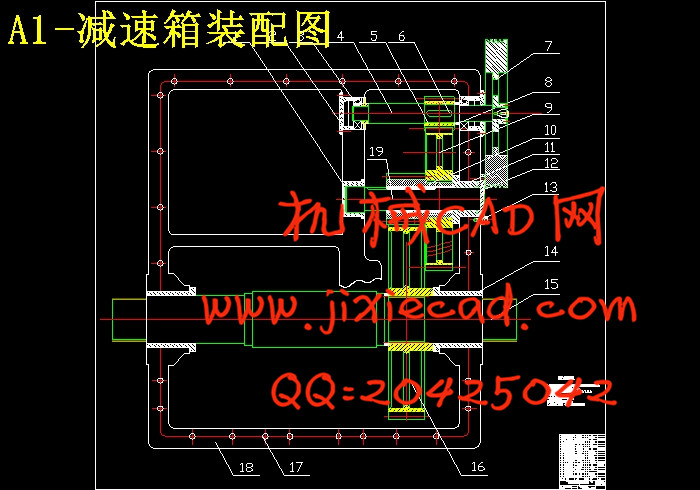

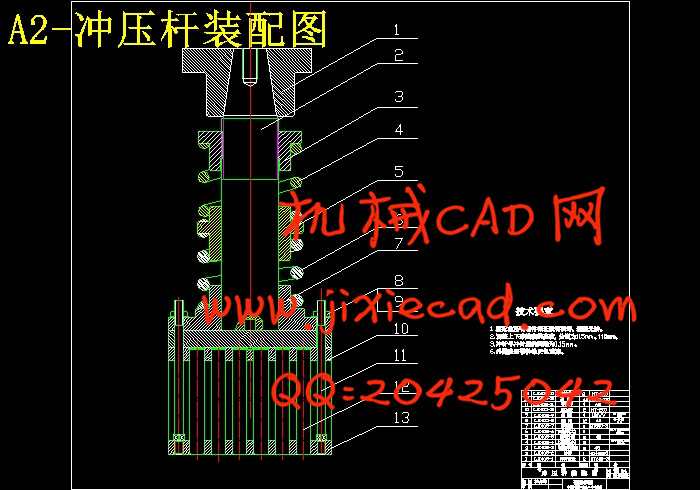

本方案中采用曲轴传动压砖、液压脱模,并应用行程开关控制液压部分,使机械能有序协作以达到预期目的,大大地简化了传统砖机的复杂结构,降低了制造和使用成本,提高了生产效率。

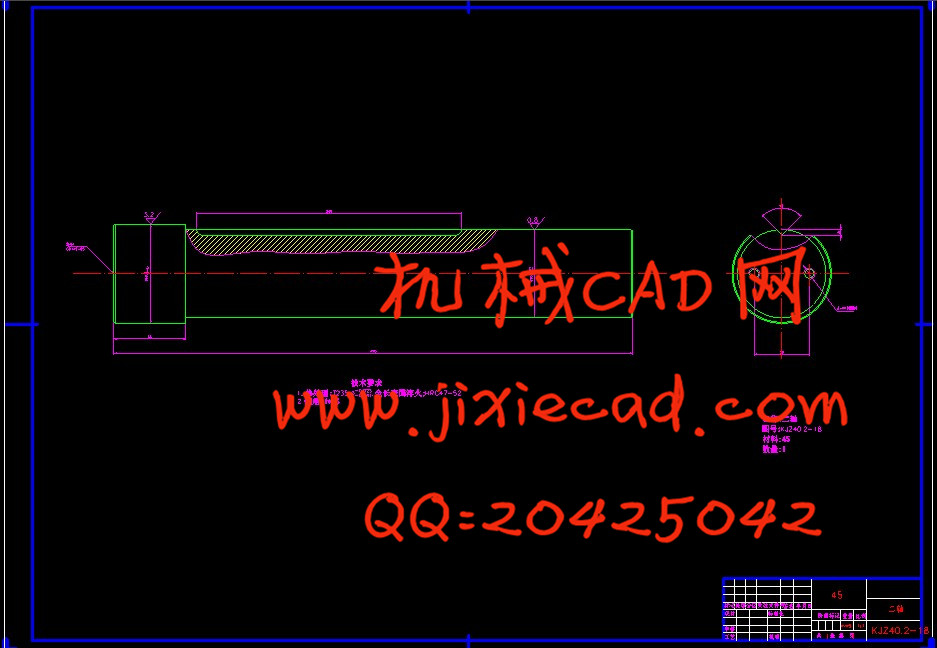

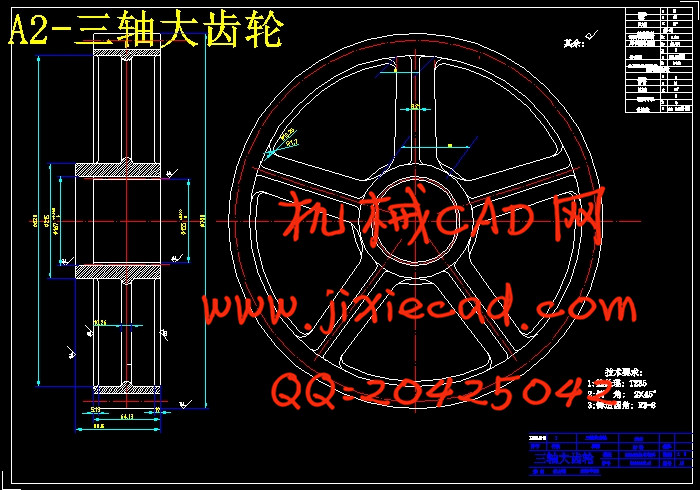

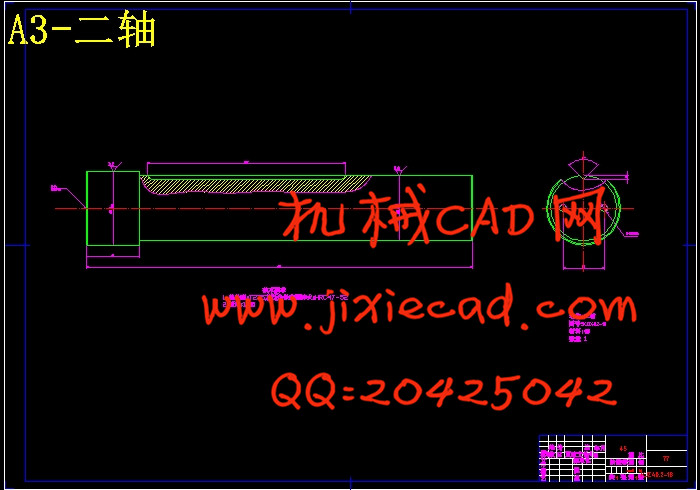

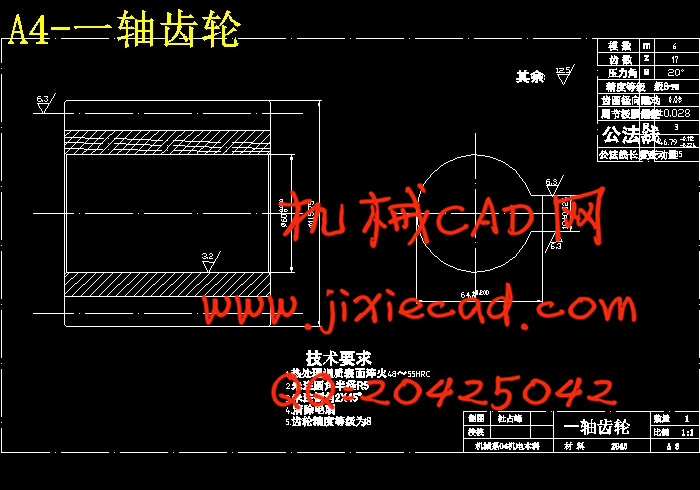

制砖机的设计涉及面广,机械设计、机械制造、公差、液压传动等学科,简约而不简单。我们已经仔细校核机械中齿轮、轴等部件,确保其强度等满足生产要求,在地方企业和老师的指导下做出详细的零部件及装配图,委托地方企业做出样机,结果符合设计要求。

关键词: 挤压式制砖机;曲轴;液压脱模。

Abstract

My subject comes from our instructor’ inspection of a local bricking equipment, according to the brick factory operators’discontents of the current high cost of equipment, energy consumption, covering space, consume a large amount of lob and material resources, and many other shortcomings, I have issued the economy Optimized design combined with the working principles of briquette machine and brick equipment of squeezeing found commonly in current market for analysis to research and development of a new type of brick equipment.

The programme I take advantage of crankshaft drive for pressuring bricks and hydraulic Stripping ,and use triping switch to control hydraulic making sure the mechanical cooperation is in an orderly manner to achieve the desired objectives. The design greatly simplifies the traditional brick’s complex structure and reduces the cost of manufacture and working, and improves the efficiency of production.

The design of brick involves many areas, mechanical design, machine engneering, tolerance, hydraulic transmission, and other disciplines, more than simplicity.I have carefully checked gears, shafts and other components conncerned with the machine, to ensure that their strength to meet production requirement .Under the guidance of local enterprises and teacher I have completed detailed parts and assembly, the prototype have made by local enterprise, the result meet the design requirements .

Key words: brick-extrusion machine;crankshaft; hydraulic stripping.

我们的课题来源于指导老师对地方制砖设备的考察,根据砖厂经营者对目前设备成本高、能耗大、占地广、消耗大量人力物力的不满等诸多弊端而提出的具有经济性的优化设计,结合蜂窝煤机与目前市场常用挤压式制砖机的工作原理进行分析,研发的一种新型制砖设备。

本方案中采用曲轴传动压砖、液压脱模,并应用行程开关控制液压部分,使机械能有序协作以达到预期目的,大大地简化了传统砖机的复杂结构,降低了制造和使用成本,提高了生产效率。

制砖机的设计涉及面广,机械设计、机械制造、公差、液压传动等学科,简约而不简单。我们已经仔细校核机械中齿轮、轴等部件,确保其强度等满足生产要求,在地方企业和老师的指导下做出详细的零部件及装配图,委托地方企业做出样机,结果符合设计要求。

关键词: 挤压式制砖机;曲轴;液压脱模。

Abstract

My subject comes from our instructor’ inspection of a local bricking equipment, according to the brick factory operators’discontents of the current high cost of equipment, energy consumption, covering space, consume a large amount of lob and material resources, and many other shortcomings, I have issued the economy Optimized design combined with the working principles of briquette machine and brick equipment of squeezeing found commonly in current market for analysis to research and development of a new type of brick equipment.

The programme I take advantage of crankshaft drive for pressuring bricks and hydraulic Stripping ,and use triping switch to control hydraulic making sure the mechanical cooperation is in an orderly manner to achieve the desired objectives. The design greatly simplifies the traditional brick’s complex structure and reduces the cost of manufacture and working, and improves the efficiency of production.

The design of brick involves many areas, mechanical design, machine engneering, tolerance, hydraulic transmission, and other disciplines, more than simplicity.I have carefully checked gears, shafts and other components conncerned with the machine, to ensure that their strength to meet production requirement .Under the guidance of local enterprises and teacher I have completed detailed parts and assembly, the prototype have made by local enterprise, the result meet the design requirements .

Key words: brick-extrusion machine;crankshaft; hydraulic stripping.