设计简介

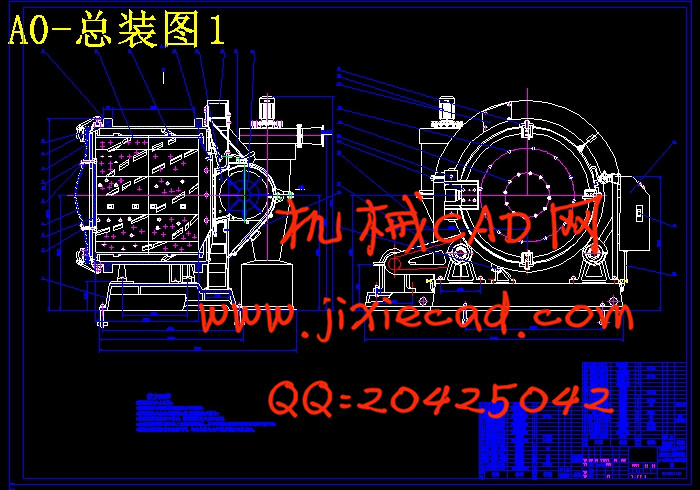

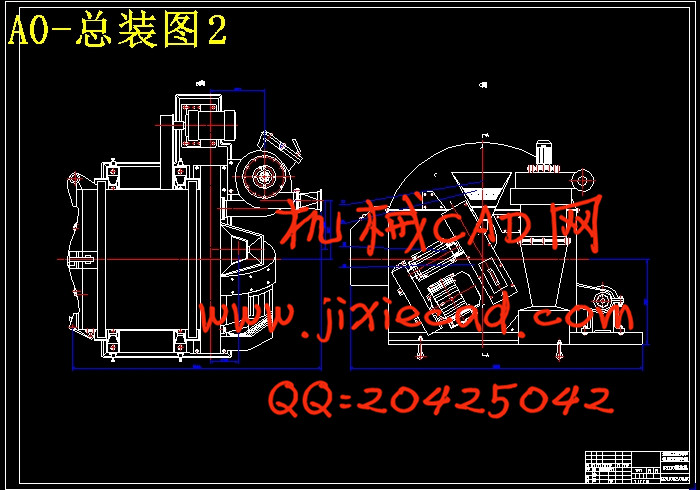

Q3110滚筒式抛丸清理机的设计

(总装、弹丸分离装置及集尘器设计)

摘要: Q3110滚筒式抛丸清理机的工作原理是利用高速回转的叶轮将弹丸抛向滚筒内的铸件,以清除锻件表面的残余型砂或氧化铁皮。

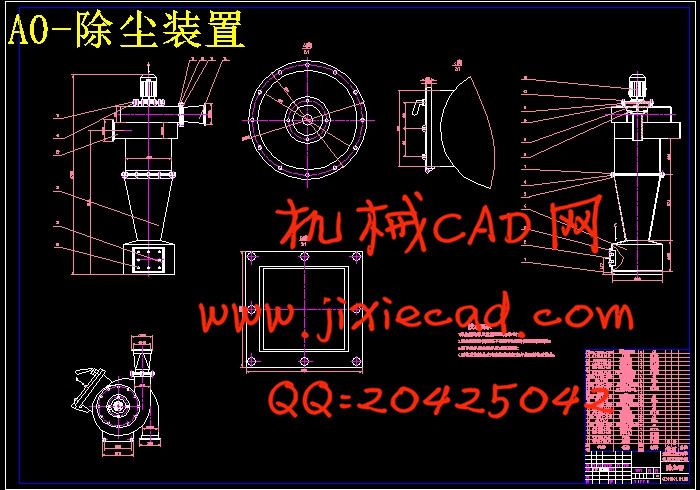

首先,对Q3110清理机的发展前景进行了预测和分析,证明了设计的可行性。其次,对Q3110清理机进行了总体方案的论证和选择。然后对清理机的主要部件除尘器进行了具体的设计和分析。

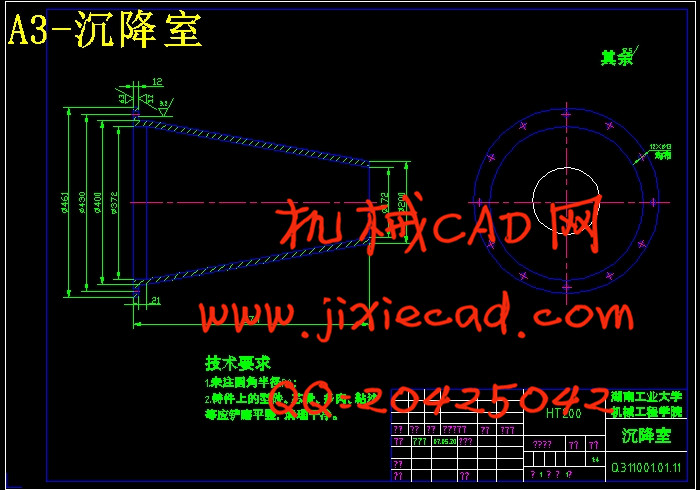

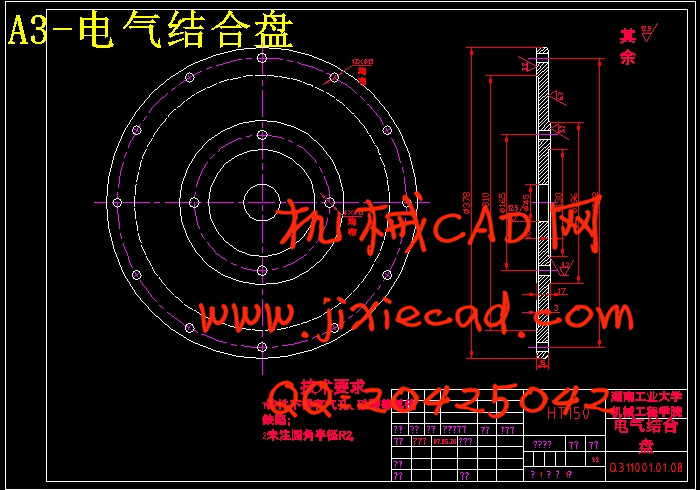

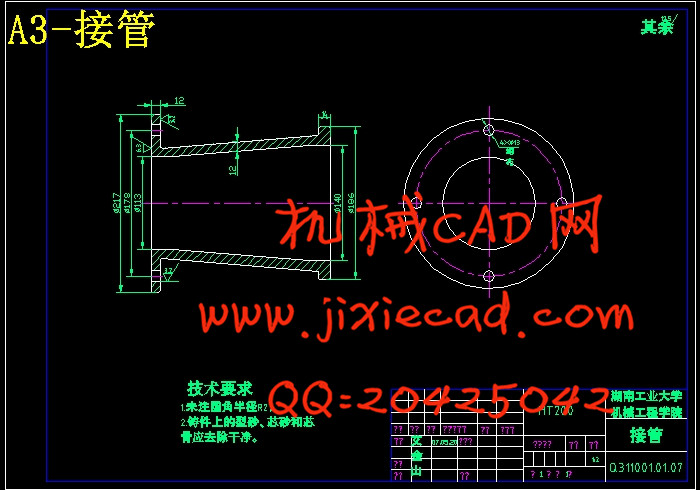

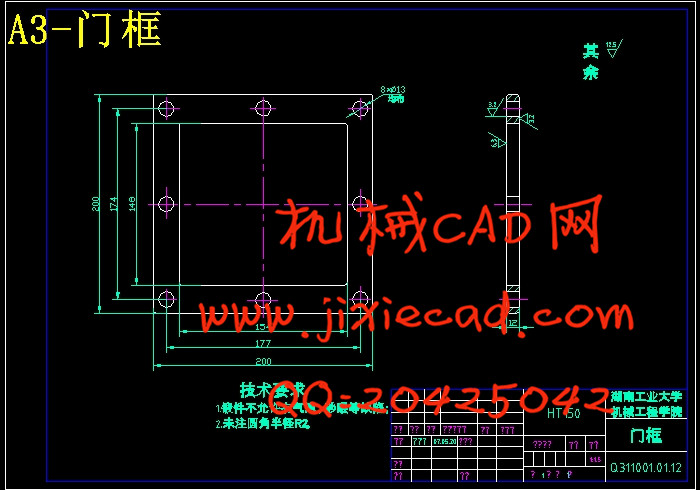

概括地说,利用带轮减速传动和齿轮减速传动带动滚筒和提升斗的回转,从而实现了弹丸的循环使用;另外,运用干式旋风型除尘装置进行尘丸分离工作;弹丸循环装置由滚筒护板与壳体间的螺旋带提升机构及分离筛组成。

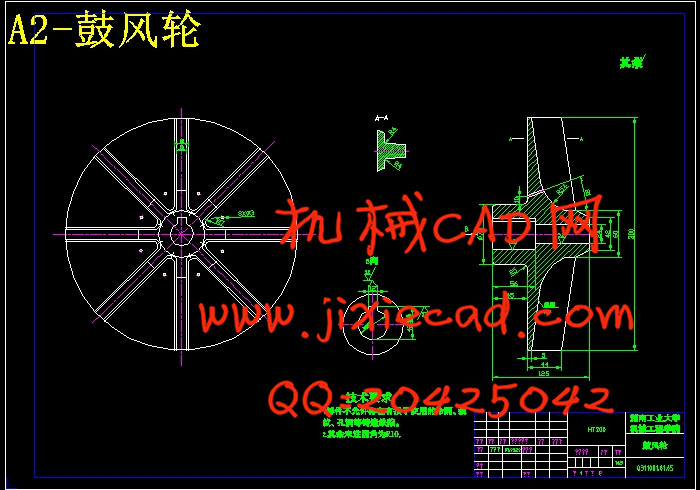

设计的重点是除尘器的分析与计算,包括风机的选择,叶轮的设计计算,叶轮轴的强度校核等。

总体设计主要针对小批量零件的清理工作,具有较好的使用价值和经济效益。

关键词:抛丸机,弹丸,除尘器

The Design of the Q3110 shot Blast cleaning Machine (The Design of the General Fitting、The pill recycling and separate system and the duster)

Abstract: The work principle of the Q3110 shot blast cleaning machine, is that the pill is cased into the casting in roller by the high speed rotation impeller, to clean remnant mounding sands or oxidizing sheet iron on the surface of the casting

Firstly, the development of the Q3110 cleaning machine is anticipated and analyzed and the feasibility of the design is guaranteed.

Secondly, the general design is demonstrated and selected. then one of main parts of the cleaning machine –duster is designed and analyzed。

To sum up, the rotation of the roller and the lifting machine by sprocket-down.. And the circulation use of the pill is realized. The shot motion is realized by gearing down. In addition, the dry rotary duster is used to separate pill from dust. And the pill circulating device is made up of the screw elevator machine and the separating griddle.

The emphases of the design is the analyse and calculation of the duster. It includes the selection and adjustment of the pneumatic conveyer, the design and calculation of the impeller, and the strength adjustment of the impeller.

As a whole, the design aims mainly at the cleaning of the smaller accessory. So the design has preferable value in practice and better benefit in economy.

Keywords: Projectile circulation; Impeller; Dust remover

目录

1 总体设计

1.1抛丸机简介………………………………………………………………… 1

1.2 Q3110型抛丸机的总体布局及主要技术参数及总传动系统图……… …3

1.3抛丸机传动方案论证及其总传动系统图……………………………… …3

1.3.1抛丸机传动方案论证…………………………………………………5

1.3.2总传动系统图…………………………………………………………6

2 主运动设计……………………………………………………………………6

2.1 传动设计……………………………………………………………………6

2.1.1 估算主电动机功率…………………………………………………7

2.2变速方案设计 ………………………………………………………………7

2.2.1电机的转速 ……………………………………………… …….8

……………………………………………… …….8

2.2.2 三角带传动的设计………………………………………… ……10

2.2.3齿轮齿数的确定………………………………………… ………10

2.3 展开图设计…………………………………………………………14

2.3.1 滚筒及摩擦轮设计……………………………………… ……15

3 提升斗的设计分析………………………………………………… ………15

3.1 提升斗设计………………………………………………………… ……15

3.2 粉尘的概念………………………………………………………… ……18

4. 除尘器设计…………………………………………………………… … …18

4 .1离心除尘技术……………………………………………………… ………21

5. 叶轮结构设计………………………………………………………… … …25

6. 卸灰装置……………………………………………………………… ………26

7. 旋风除尘器的计算………………………………………………… ………28

8. 旋风除尘器的注意事项…………………………………………… ………29

9. 旋风除尘器的防磨损措施…………………………………………… ……30

10 箱体设计的有关问题………………………………………………………. 30

11 总 结……………………………………………………………………………30

致谢

参考文献

(总装、弹丸分离装置及集尘器设计)

摘要: Q3110滚筒式抛丸清理机的工作原理是利用高速回转的叶轮将弹丸抛向滚筒内的铸件,以清除锻件表面的残余型砂或氧化铁皮。

首先,对Q3110清理机的发展前景进行了预测和分析,证明了设计的可行性。其次,对Q3110清理机进行了总体方案的论证和选择。然后对清理机的主要部件除尘器进行了具体的设计和分析。

概括地说,利用带轮减速传动和齿轮减速传动带动滚筒和提升斗的回转,从而实现了弹丸的循环使用;另外,运用干式旋风型除尘装置进行尘丸分离工作;弹丸循环装置由滚筒护板与壳体间的螺旋带提升机构及分离筛组成。

设计的重点是除尘器的分析与计算,包括风机的选择,叶轮的设计计算,叶轮轴的强度校核等。

总体设计主要针对小批量零件的清理工作,具有较好的使用价值和经济效益。

关键词:抛丸机,弹丸,除尘器

The Design of the Q3110 shot Blast cleaning Machine (The Design of the General Fitting、The pill recycling and separate system and the duster)

Abstract: The work principle of the Q3110 shot blast cleaning machine, is that the pill is cased into the casting in roller by the high speed rotation impeller, to clean remnant mounding sands or oxidizing sheet iron on the surface of the casting

Firstly, the development of the Q3110 cleaning machine is anticipated and analyzed and the feasibility of the design is guaranteed.

Secondly, the general design is demonstrated and selected. then one of main parts of the cleaning machine –duster is designed and analyzed。

To sum up, the rotation of the roller and the lifting machine by sprocket-down.. And the circulation use of the pill is realized. The shot motion is realized by gearing down. In addition, the dry rotary duster is used to separate pill from dust. And the pill circulating device is made up of the screw elevator machine and the separating griddle.

The emphases of the design is the analyse and calculation of the duster. It includes the selection and adjustment of the pneumatic conveyer, the design and calculation of the impeller, and the strength adjustment of the impeller.

As a whole, the design aims mainly at the cleaning of the smaller accessory. So the design has preferable value in practice and better benefit in economy.

Keywords: Projectile circulation; Impeller; Dust remover

目录

1 总体设计

1.1抛丸机简介………………………………………………………………… 1

1.2 Q3110型抛丸机的总体布局及主要技术参数及总传动系统图……… …3

1.3抛丸机传动方案论证及其总传动系统图……………………………… …3

1.3.1抛丸机传动方案论证…………………………………………………5

1.3.2总传动系统图…………………………………………………………6

2 主运动设计……………………………………………………………………6

2.1 传动设计……………………………………………………………………6

2.1.1 估算主电动机功率…………………………………………………7

2.2变速方案设计 ………………………………………………………………7

2.2.1电机的转速

2.2.2 三角带传动的设计………………………………………… ……10

2.2.3齿轮齿数的确定………………………………………… ………10

2.3 展开图设计…………………………………………………………14

2.3.1 滚筒及摩擦轮设计……………………………………… ……15

3 提升斗的设计分析………………………………………………… ………15

3.1 提升斗设计………………………………………………………… ……15

3.2 粉尘的概念………………………………………………………… ……18

4. 除尘器设计…………………………………………………………… … …18

4 .1离心除尘技术……………………………………………………… ………21

5. 叶轮结构设计………………………………………………………… … …25

6. 卸灰装置……………………………………………………………… ………26

7. 旋风除尘器的计算………………………………………………… ………28

8. 旋风除尘器的注意事项…………………………………………… ………29

9. 旋风除尘器的防磨损措施…………………………………………… ……30

10 箱体设计的有关问题………………………………………………………. 30

11 总 结……………………………………………………………………………30

致谢

参考文献