设计简介

摘要

随着精密、超精密技术的发展日益进步,机器及检测仪器等的精度要求越来越高,对气浮垫的制造精度也提出更高的要求。目前,由于气浮垫精密加工技术的研究还不够深入,因此,研究气浮垫的精密制造技术是气浮垫领域函须解决的课题。

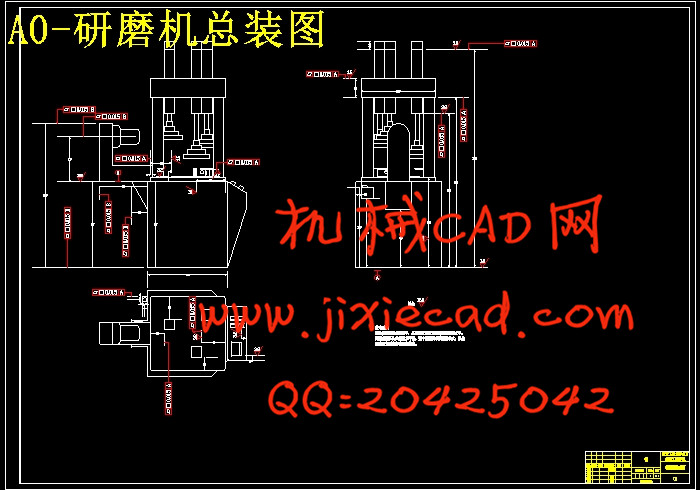

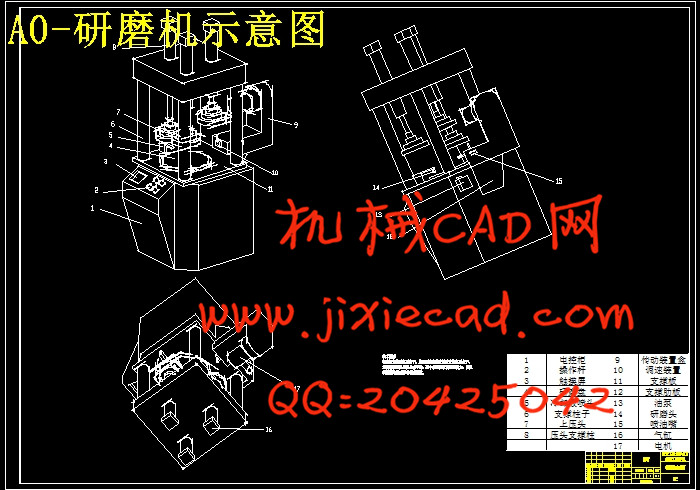

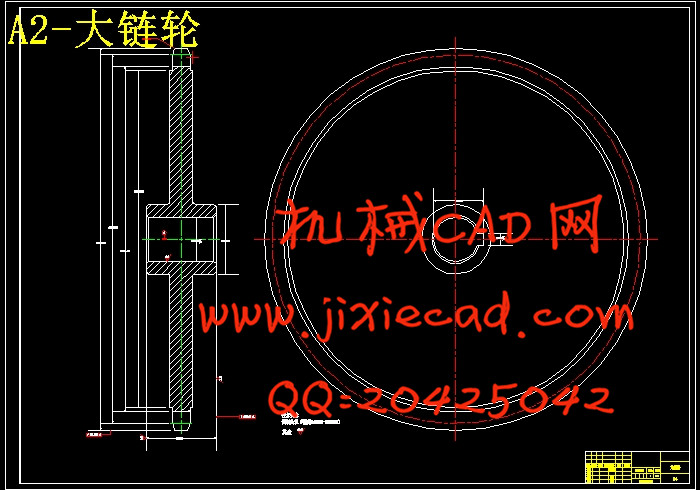

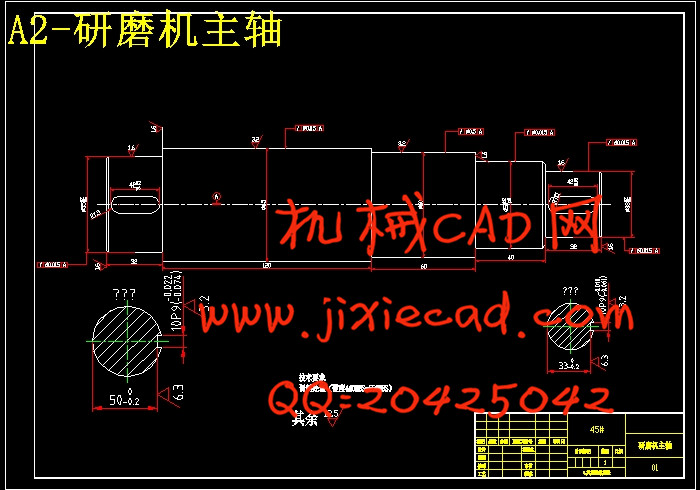

针对研磨抛光过程,本文深入研究了磨料种类、粒度、抛光液溶剂、研抛压力、研抛加工时间等因素对加工表面粗糙度的影响。根据气浮垫研磨设备对研磨工艺的要求,本文设计了一种专门的研磨机,并对研磨机的各个部分进行分析和说明,并对部分零件进行验证和校核。

关键词:气浮垫;研磨;抛光;机械结构

Abstract

With the development of Precision and ultra-Precise technology, the accuracy of the machinery and the detecting instrument become higher, the Production accuracy of cushion needed also more higher. At present, the research about the cushion Precision finishing technology is not enough. So how to enhance the accuracy it is one of needing to resolve problem of the research area of the floatation cushion.

On the surface roughness effects of abrasive type, grain size, polishing liquid solvents, polishing pressure, polishing machining time and so on, are researched in-depth for the process of mechanical polishing. According to gas floating pad grinding equipment requirement for grinding process, this paper designed a kind of special grinding machine, and analyze the various parts of the grinding machine and instructions, and to verify and check parts.

Keywords :Gas floating cushion; Grinding; Polishing; The mechanical structure

随着精密、超精密技术的发展日益进步,机器及检测仪器等的精度要求越来越高,对气浮垫的制造精度也提出更高的要求。目前,由于气浮垫精密加工技术的研究还不够深入,因此,研究气浮垫的精密制造技术是气浮垫领域函须解决的课题。

针对研磨抛光过程,本文深入研究了磨料种类、粒度、抛光液溶剂、研抛压力、研抛加工时间等因素对加工表面粗糙度的影响。根据气浮垫研磨设备对研磨工艺的要求,本文设计了一种专门的研磨机,并对研磨机的各个部分进行分析和说明,并对部分零件进行验证和校核。

关键词:气浮垫;研磨;抛光;机械结构

Abstract

With the development of Precision and ultra-Precise technology, the accuracy of the machinery and the detecting instrument become higher, the Production accuracy of cushion needed also more higher. At present, the research about the cushion Precision finishing technology is not enough. So how to enhance the accuracy it is one of needing to resolve problem of the research area of the floatation cushion.

On the surface roughness effects of abrasive type, grain size, polishing liquid solvents, polishing pressure, polishing machining time and so on, are researched in-depth for the process of mechanical polishing. According to gas floating pad grinding equipment requirement for grinding process, this paper designed a kind of special grinding machine, and analyze the various parts of the grinding machine and instructions, and to verify and check parts.

Keywords :Gas floating cushion; Grinding; Polishing; The mechanical structure