设计简介

摘要: 工业自动化技术在近年来发展十分迅猛,当前工业自动化三大支柱技术之一的PLC技术以其很高的可靠性和抗干扰能力受到广泛的欢迎,在各行各业的技术改造过程中被大量地应用。然而,单机控制往往因为点数的限制,无法实现对于较复杂的系统的控制。

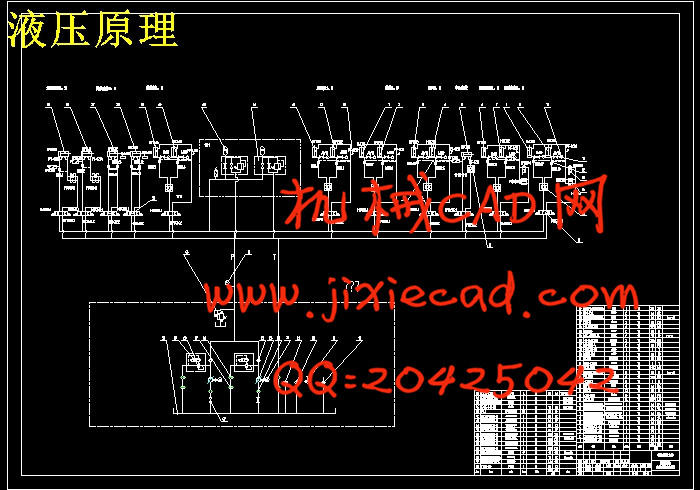

表面处理工程领域是当前一个倍受关注的领域,作为一个新兴的边缘学科领域,有着蓬勃的生机,这一工程领域内的喷码生产则是一项非常传统的产业,生产率低下生产技术水平不高的现实迫切需要对其加以技术改造。本文就如何提高喷码生产领域的自动化水平,运用PLC技术在生产线上实现控制。论文首先分析了喷码打标行业的生产状况,比较了几种常用的控制策略的优缺点,确定具体的控制方案,接着分析并设计了系统的控制流程,再就设备级的控制进行深入的研究,在硬件和软件两个层面上的控制进行了设计,最后对于系统的可靠性进行了设计。针对钢坯生产线,运用PLC控制气动回路,再控制喷头进行定位喷码;在操作上选用步进电机来精确定位和调速。

关键词: PLC; 钢坯喷码; 控制; 气动; 步进电机

Abstract:Industry automation technology develops very fast in recent years, as one of the three support technologies in industry automation, PLC is greatly welcomed with its very high reliability and anti-interence ability, and applied largely in the technology reformation process of all walks of industries.However, the single machine control usually can't carry out for the control of more complicated system because of the restriction of point.

The surface treatment engineering realm is paid close attention at present, as a new frontier subject realm it has booming source of vitality, however, in this engineering realm ,marking production is a very traditional industry, the reality of low production rate and low production technology level need urgently technology reformation. This paper analyses how to raise marking automation level of producing the realm, and use PLC technology to control in the production line. The thesis analyzed marking on the production condition of profession first, compared with the merit and shortcoming of a few control strategies in common use, gave concrete control project, analyzed and designed the structure of the controlling process, also carried on a thorough research for the control of equipments class, designed two levels’s control with production line of hardware and software, finally designed the credibility of the system. Face to the production line ,it uses PLC technology to control the pneumatic loop ,then it controls the marking head to mark on the exact location that we need and choose the stepping motor to find the exact location and change the speed .

Keywords: PLC; marking on the billet ; control,; pneumatic; stepping motor

目 录

摘要------------------------------------------------------------------------1

英文摘要-----------------------------------------------------------------------1

1 绪论-------------------------------------------------------------------------2

1.1 项目研究的背景-------------------------------------------------------------2

1.1.1 国外打标机的发展-----------------------------------------------------2

1.1.2 我国打号机的发展现状------------------------------------------------4

1.2 钢坯打标机在炼钢生产中的作用----------------------------------------------5

1.3 课题的提出及意义-----------------------------------------------------------5

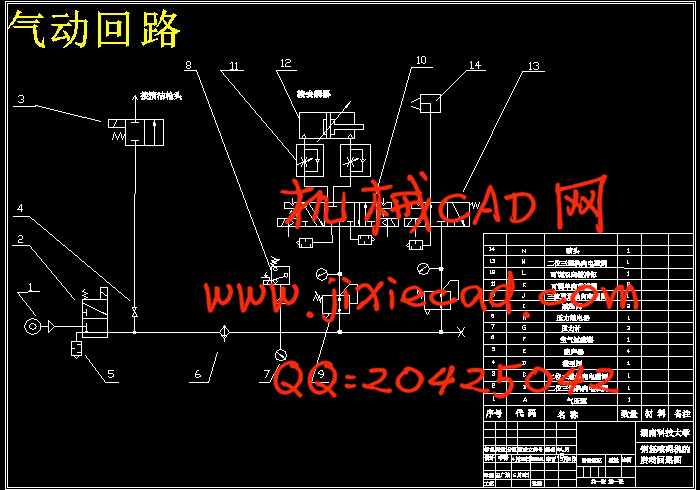

2 气动回路设计-------------------------------------------------------6

2.1 气动回路设计-----------------------------------------------------------------6

2.1.1气动回路的设计思路--------------------------------------------------6

2.1.2 气动回路图的设计----------------------------------------------------6

2.2 气动回路图各元件型号选择及其性能分析----------------------------------------7

3 硬件系统设计--------------------------------------------------------13

3.1 PLC型号选择及其性能分析--------------------------------------------------13

3.1.1 可编程控制器的应用和发展-----------------------------------------------13

3.1.2 PLC的工作原理及其性能分析--------------------------------------------- 17

3.2 PLC中CPU的选择----------------------------------------------------------- 18

3.3 电机的选择及其分析-----------------------------------------------------19

3.3.1 步进电机的选用及分析-------------------------------------------------19

3.3.2三相异步电动机的选用及分析---------------------------------------------- 20

3.4 传感器型号选择及其性能分析-------------------------------------------------- 22

3.4.1 激光测距传感器------------------------------------------------------ 22

3.4.2 透射式电涡流测厚传感器---------------------------------------------- 22

4 软件设计部分-----------------------------------------------------25

4.1 各运行部分之间距离与延时时间的设定--------------------------------------25

4.1.1 各零件距离设定----------------------------------------------------25

4.1.2 各运行速度设定----------------------------------------------------25

4.1.3 其他值的计算------------------------------------------------------25

4.2 PLC控制系统流程的设计--------------------------------------------------26

4.2.1 系统描述----------------------------------------------------------26

4.2.2 PLC控制系统------------------------------------------------------27

4.2.3 PLC控制系统的扩展配置-------------------------------------------27

4.2.4 程序主流程-------------------------------------------------------28

4.3 PLC的I/O地址分配-----------------------------------------------------31

4.4 设计PLC的外部接线图---------------------------------------------------31

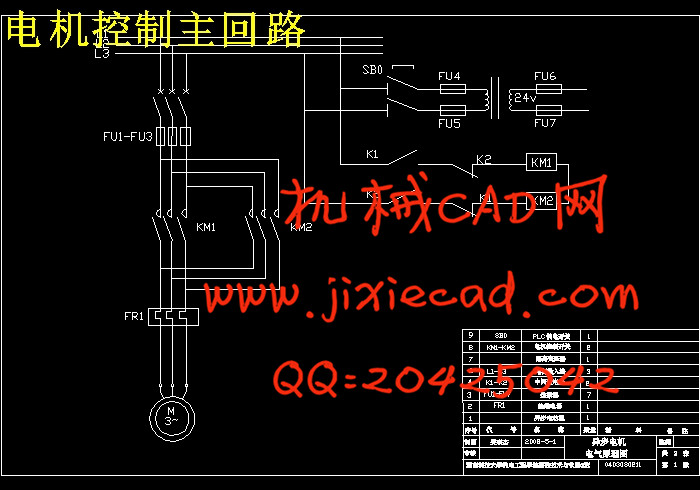

4.5 电机控制电路主回路-----------------------------------------------------32

4.6 设计梯形图程序------------------------------------------------------------33

4.6.1 编写梯形图的软件介绍------------------------------------------------33

4.6.2 用PLC对步进电机的控制方式描述-------------------------------------34

4.6.3 采用多段管线PTO输出控制步进电机-----------------------------------37

4.6.4 PLC的抗干扰措施----------------------------------------------------46

5 研究工作的总结----------------------------------------------------47

6 致谢--------------------------------------------------------------48

7 参考文献----------------------------------------------------------49

表面处理工程领域是当前一个倍受关注的领域,作为一个新兴的边缘学科领域,有着蓬勃的生机,这一工程领域内的喷码生产则是一项非常传统的产业,生产率低下生产技术水平不高的现实迫切需要对其加以技术改造。本文就如何提高喷码生产领域的自动化水平,运用PLC技术在生产线上实现控制。论文首先分析了喷码打标行业的生产状况,比较了几种常用的控制策略的优缺点,确定具体的控制方案,接着分析并设计了系统的控制流程,再就设备级的控制进行深入的研究,在硬件和软件两个层面上的控制进行了设计,最后对于系统的可靠性进行了设计。针对钢坯生产线,运用PLC控制气动回路,再控制喷头进行定位喷码;在操作上选用步进电机来精确定位和调速。

关键词: PLC; 钢坯喷码; 控制; 气动; 步进电机

Abstract:Industry automation technology develops very fast in recent years, as one of the three support technologies in industry automation, PLC is greatly welcomed with its very high reliability and anti-interence ability, and applied largely in the technology reformation process of all walks of industries.However, the single machine control usually can't carry out for the control of more complicated system because of the restriction of point.

The surface treatment engineering realm is paid close attention at present, as a new frontier subject realm it has booming source of vitality, however, in this engineering realm ,marking production is a very traditional industry, the reality of low production rate and low production technology level need urgently technology reformation. This paper analyses how to raise marking automation level of producing the realm, and use PLC technology to control in the production line. The thesis analyzed marking on the production condition of profession first, compared with the merit and shortcoming of a few control strategies in common use, gave concrete control project, analyzed and designed the structure of the controlling process, also carried on a thorough research for the control of equipments class, designed two levels’s control with production line of hardware and software, finally designed the credibility of the system. Face to the production line ,it uses PLC technology to control the pneumatic loop ,then it controls the marking head to mark on the exact location that we need and choose the stepping motor to find the exact location and change the speed .

Keywords: PLC; marking on the billet ; control,; pneumatic; stepping motor

目 录

摘要------------------------------------------------------------------------1

英文摘要-----------------------------------------------------------------------1

1 绪论-------------------------------------------------------------------------2

1.1 项目研究的背景-------------------------------------------------------------2

1.1.1 国外打标机的发展-----------------------------------------------------2

1.1.2 我国打号机的发展现状------------------------------------------------4

1.2 钢坯打标机在炼钢生产中的作用----------------------------------------------5

1.3 课题的提出及意义-----------------------------------------------------------5

2 气动回路设计-------------------------------------------------------6

2.1 气动回路设计-----------------------------------------------------------------6

2.1.1气动回路的设计思路--------------------------------------------------6

2.1.2 气动回路图的设计----------------------------------------------------6

2.2 气动回路图各元件型号选择及其性能分析----------------------------------------7

3 硬件系统设计--------------------------------------------------------13

3.1 PLC型号选择及其性能分析--------------------------------------------------13

3.1.1 可编程控制器的应用和发展-----------------------------------------------13

3.1.2 PLC的工作原理及其性能分析--------------------------------------------- 17

3.2 PLC中CPU的选择----------------------------------------------------------- 18

3.3 电机的选择及其分析-----------------------------------------------------19

3.3.1 步进电机的选用及分析-------------------------------------------------19

3.3.2三相异步电动机的选用及分析---------------------------------------------- 20

3.4 传感器型号选择及其性能分析-------------------------------------------------- 22

3.4.1 激光测距传感器------------------------------------------------------ 22

3.4.2 透射式电涡流测厚传感器---------------------------------------------- 22

4 软件设计部分-----------------------------------------------------25

4.1 各运行部分之间距离与延时时间的设定--------------------------------------25

4.1.1 各零件距离设定----------------------------------------------------25

4.1.2 各运行速度设定----------------------------------------------------25

4.1.3 其他值的计算------------------------------------------------------25

4.2 PLC控制系统流程的设计--------------------------------------------------26

4.2.1 系统描述----------------------------------------------------------26

4.2.2 PLC控制系统------------------------------------------------------27

4.2.3 PLC控制系统的扩展配置-------------------------------------------27

4.2.4 程序主流程-------------------------------------------------------28

4.3 PLC的I/O地址分配-----------------------------------------------------31

4.4 设计PLC的外部接线图---------------------------------------------------31

4.5 电机控制电路主回路-----------------------------------------------------32

4.6 设计梯形图程序------------------------------------------------------------33

4.6.1 编写梯形图的软件介绍------------------------------------------------33

4.6.2 用PLC对步进电机的控制方式描述-------------------------------------34

4.6.3 采用多段管线PTO输出控制步进电机-----------------------------------37

4.6.4 PLC的抗干扰措施----------------------------------------------------46

5 研究工作的总结----------------------------------------------------47

6 致谢--------------------------------------------------------------48

7 参考文献----------------------------------------------------------49