设计简介

摘 要

组合机床是以大量的通用部件为基础,配以少量的按被加工零件特殊要求而设计的专用部件,以实现对一种或几种零件按预先确定的工序进行加工的高效机床。它既具有专用机床的结构简单、生产率及自动化程度较高的特点,又具有一定的重新调整能力,以适应工件变化的要求,是当今制造业应用很广的一类机床。

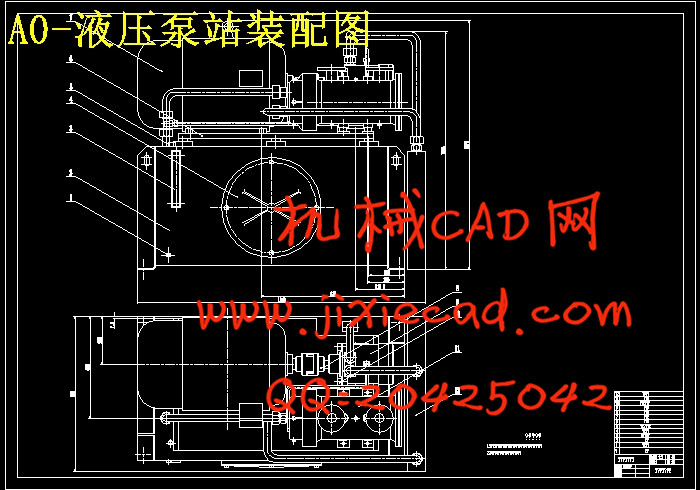

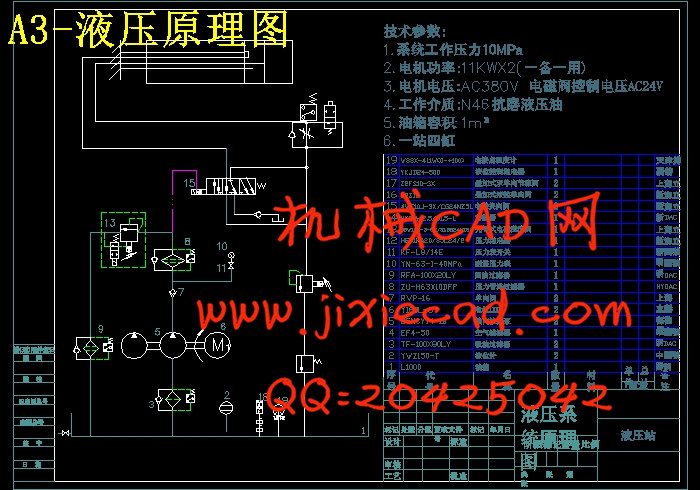

在明确设计目的的基础上,以卧式钻孔组合机床为对象,依据液压系统设计的基本原理,拟出合理的液压系统图,通过系统主要参数的计算确定了液压元件的规格,并对设计的原理图的优缺点做了简单的概括,验算了液压系统的性能。最后对整个设计过程做了总结,对设计过程中出现的问题、设计的液压系统的不足进行了思考并对未来的工作作了展望。

关键词:组合机床、卧式、钻孔、液压系统

Abstract

The modular machine tools is a lot of common parts for the foundation, was supported by a small number of special requirements for the processing parts and components for the design, to achieve one or more of the components of the pre-set process for the efficient processing machine. It has a dedicated machine simple structure, productivity and a higher degree of automation features, but also has a re-adjustment ability to adapt to changing requirements of the work piece.

In the clear on the basis of the design purpose, Using one-side bore modular machine tool as an object According to hydraulic system design basic principle, Formulates the reasonable schematic diagram, Determined the hydraulic pressure part specification through the system main parameter computation, checking the hydraulic system performance. Finally, the entire design process to do a summary of the design process problems, inadequate design of the hydraulic system had been thinking and future work prospects.

Key words:modular machine tool,horizontal type,bore,fluid drive

目 录

第1章 引言 1

1.1 组合机床简介 1

1.2 主要研究内容 4

1.3 本章小结 5

第2章 液压系统设计 6

2.1 设计引言 6

2.2 设计要求 6

2.3 负载与运动分析 6

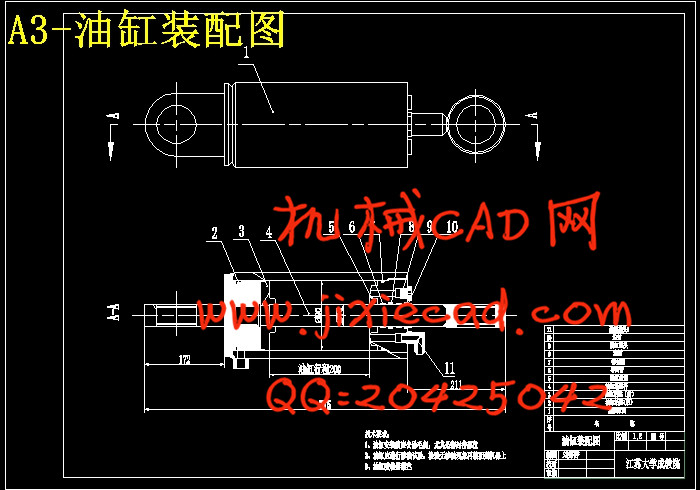

2.4 确定执行元件主要参数 8

2.5 设计液压系统方案和拟定液压系统原理图 11

2.5.1 设计液压系统方案 11

2.5.2 选择基本回路 13

2.5.3选择速度换接回路 14

2.6 计算和选择液压元件 16

2.6.1 液压泵 16

2.6.2 阀类元件及辅助元件 17

2.6.3 油管 18

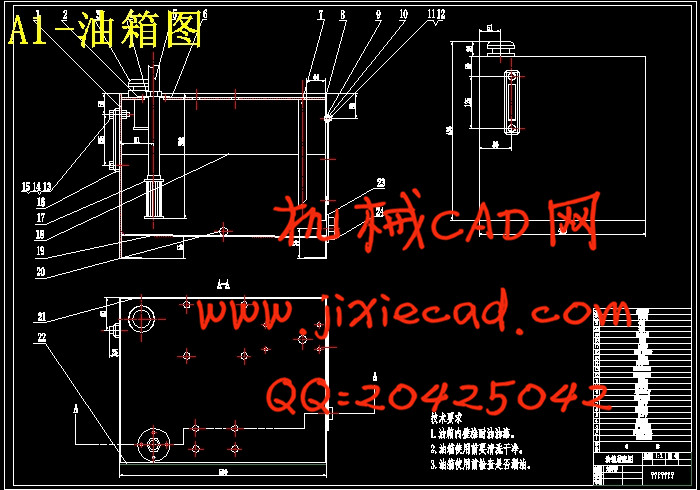

2.6.4 油箱 19

2.7 本章小结 19

第3章 验算液压系统性能 21

3.1 验算系统压力损失 21

3.2 验算系统发热与温升 24

结 论 26

致 谢 27

参考文献 28

组合机床是以大量的通用部件为基础,配以少量的按被加工零件特殊要求而设计的专用部件,以实现对一种或几种零件按预先确定的工序进行加工的高效机床。它既具有专用机床的结构简单、生产率及自动化程度较高的特点,又具有一定的重新调整能力,以适应工件变化的要求,是当今制造业应用很广的一类机床。

在明确设计目的的基础上,以卧式钻孔组合机床为对象,依据液压系统设计的基本原理,拟出合理的液压系统图,通过系统主要参数的计算确定了液压元件的规格,并对设计的原理图的优缺点做了简单的概括,验算了液压系统的性能。最后对整个设计过程做了总结,对设计过程中出现的问题、设计的液压系统的不足进行了思考并对未来的工作作了展望。

关键词:组合机床、卧式、钻孔、液压系统

Abstract

The modular machine tools is a lot of common parts for the foundation, was supported by a small number of special requirements for the processing parts and components for the design, to achieve one or more of the components of the pre-set process for the efficient processing machine. It has a dedicated machine simple structure, productivity and a higher degree of automation features, but also has a re-adjustment ability to adapt to changing requirements of the work piece.

In the clear on the basis of the design purpose, Using one-side bore modular machine tool as an object According to hydraulic system design basic principle, Formulates the reasonable schematic diagram, Determined the hydraulic pressure part specification through the system main parameter computation, checking the hydraulic system performance. Finally, the entire design process to do a summary of the design process problems, inadequate design of the hydraulic system had been thinking and future work prospects.

Key words:modular machine tool,horizontal type,bore,fluid drive

目 录

第1章 引言 1

1.1 组合机床简介 1

1.2 主要研究内容 4

1.3 本章小结 5

第2章 液压系统设计 6

2.1 设计引言 6

2.2 设计要求 6

2.3 负载与运动分析 6

2.4 确定执行元件主要参数 8

2.5 设计液压系统方案和拟定液压系统原理图 11

2.5.1 设计液压系统方案 11

2.5.2 选择基本回路 13

2.5.3选择速度换接回路 14

2.6 计算和选择液压元件 16

2.6.1 液压泵 16

2.6.2 阀类元件及辅助元件 17

2.6.3 油管 18

2.6.4 油箱 19

2.7 本章小结 19

第3章 验算液压系统性能 21

3.1 验算系统压力损失 21

3.2 验算系统发热与温升 24

结 论 26

致 谢 27

参考文献 28