设计简介

香烟中包包装机—中包传送部分设计

摘 要

当今时代,由于科学技术的迅速发展,企业与企业间的竞争日益加剧,且表现为知识和技术的竞争。故现代企业千方百计的设法提高生产技术,努力实现制造全过程的自动化。制造自动化技术就是研究对制造过程的规划、运作、管理、组织、控制与协调优化等的自动化技术,以使产品制造过程实现高效、优质、低耗、及时和洁净的目标。制造自动化技术代表着先进制造技术的水平,推动了社会的发展。其中高效智能的自动化生产线便是制造自动化技术的重要组成部分。

香烟自动生产线是为实现香烟生产的批量化,且提高生产的机械化、自动化水平而专门设计的。它的产生极大的提高了香烟生产企业制造的自动化水平,提高了企业的生产率;方便了企业对生产过程的规划、运作、管理、组织、控制与协调优化等。

本设计为香烟中包包装机中的一部分,其主要任务是当香烟中包从上一工序——中包远距离水平传送过来后,下落至倾斜放置的弧型转角机构中,中包在弧形轨道实现平滑下落,下落落差为1500MM,并渐进实现中包由水平卧放转90度实现竖直放置,并要求中包在弧形轨道堆积到五包时后面的中包下落应停止,以防止轨道堵塞。此设计的主要功能是实现中包的转角,为后面的工序及中包的打包提供良好的条件。

本设计控制过程较为简单,故采用硬接线,即结构简单,价格低廉,维护方便,抗干扰能力强的继电接触器控制系统来完成。其作用是保证转角机构上的中包堆积量保持在规定的范围内,控制中包有节奏的下落。控制系统对生产和工作可靠性影响很大,因此,要求控制准确、灵敏、可靠、耐用和调整方便。

为了对弧型轨道口的中包堆积量进行适时监控。故采用安装高灵敏度的ENDEVCO型压力传感器。此传感器特点是牢靠,灵敏度高,信噪比高,动态范围宽和线型度好,使用时在三倍满刻度压力下还能得到最高输出信号,而不会因超量程而丢失数据且能在宽温度范围内取得可靠数据。

关键词

自动生产线;香烟中包包装机;电气控制;压力传感器

Mid-package packing machine for cigarette--- make design for a part of mid-package being carried

summary

Now ages, because of science and technical's quick development, the business enterprise turn worse with the competition of the business enterprise increasingly, and the behave of this is knowledge with technical competition.So modern business enterprise tries the exaltation production technique by all ways, working hard to made the automation of the process of whole manufacturing.The manufacturing automation technique is a research to the programming that manufacturing process, operation, management, organize, control and moderate excellent turn the automation technique of etc., to make product manufacturing the process realizes efficiently, superior quality, low consume, on time with undefiled target.The manufacturing automation technique represents the forerunner of the manufacturing the technical level, pushing the social development.The among them efficiently intellective automation production line just makes the technical importance in automation constitutes the part.

Automatic production line of cigarette is in the interest of increases the batch quantity produce, and the mechanization, automation level of the production.The creation of it has biggest improve the automation level of the business enterprise manufacturing,increases the rate of the business enterprise; has made the convenience of the programming which business enterprise for of the production line, operation, management, organize, control and moderate excellent turn etc..

This design is a part of Mid-package machine for cigarette, its main mission is when the Mid-package of cigarette from lastly working procedure ——Mid-package is leave from long-distance,and fall to the arc-shaped compose, and smoothly whereabouts which is about 1500 mm inside the arc-shaped orbit, combine gradually enter realize pack being put by level decubitus turning 90 degrees realizing end up keeping placing, and requesting when inside pack in the arc-shaped orbit piling up five packs ,the following should stop, in order to prevent jam of the orbit.The main function of this design is work to realizes the change of Cape of Mid-package, provide favourable condition for following working procedure and the pack of Mid-package .

This design controls the process more simple, the past adoption is hard to connect the line, namely construction simple, the price is cheap, maintenance convenient, the anti- interference ability is strong to get in touch with after the electricity machine control system to complete.Its function is a whereabouts to guarantee to turn Cape the inside on the organization pack pile up deal keeps within the scope of prescriptive, control inside pack contain rhythm.Control system to produce with work dependable influence very big, therefore, request control accurate, intelligent, dependable, enduring with adjust the convenience.

For piling up to the oscular inside in orbit in type in arc pack the deal proceed to supervise and control in good time.Past the adoption installs the ENDEVCO type pressure of the high and intelligent degree spreads to feel machine.This spreads to feel the machine characteristics is firm and reliable, the intelligent degree is high, SNY is high, the dynamic scope breadth is good with the line type degree, hour in usage is within the scope of the triple is full to engrave a pressure to can still get the tallest exportation signal down, but can't because of super measures distance but throw to lose the data and can in the breadth temperature dependable data in acquisition.

Key Word

Automatic production line; Mid-package machine for cigarette; Electricity control; The pressure spreads to transducer

目 录

插图、表格清单………………………………………………………………………5

第一章概述……………………………………………………………………………8

第二章绪论……………………………………………………………………………9

§2.1自动生产线的结构组成……………………………………………………………………9

§2.2自动生产线设计的基本要求………………………………………………………………9

2.2.1使用性能……………………………………………………………………………………..9

2.2.2技术性能……………………………………………………………………………………..9

2.2.3经济性能……………………………………………………………………………………..9

2.2.4其它………………………………………………………………………………………….10

第三章方案选择……………………………………………………………………11

§3.1已知基本参数条件………………………………………………………………………11

§3.2功能要求……………………………………………………………………………………11

§3.3完美化要求…………………………………………………………………………………11

§3.4方案的比较…………………………………………………………………………………11

3.4.1方案一……………………………………………………………………………………….11

3.4.2方案二……………………………………………………………………………………….14

3.4.3方案三……………………………………………………………………………………….16

3.4.4方案四……………………………………………………………………………………….17

3.4.5各方案简明表……………………………………………………………………………….18

3.4.6方案比较表………………………………………………………………………………….19

3.4.7方案选择…………………………………………………………………………………….20

第四章各部件的设计和标准件的选择……………………………………………..21

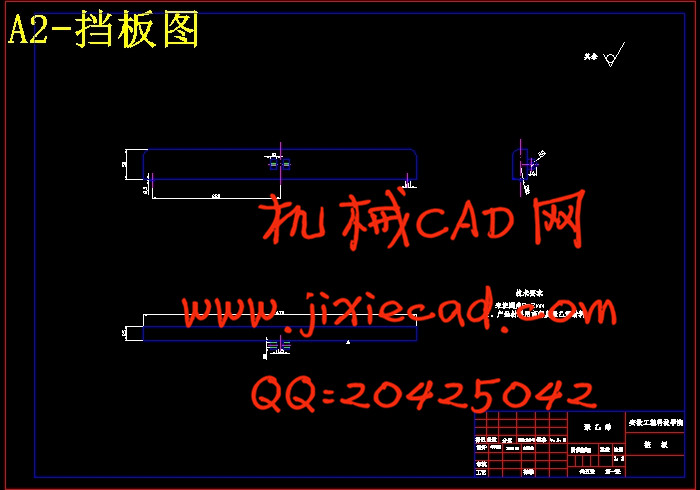

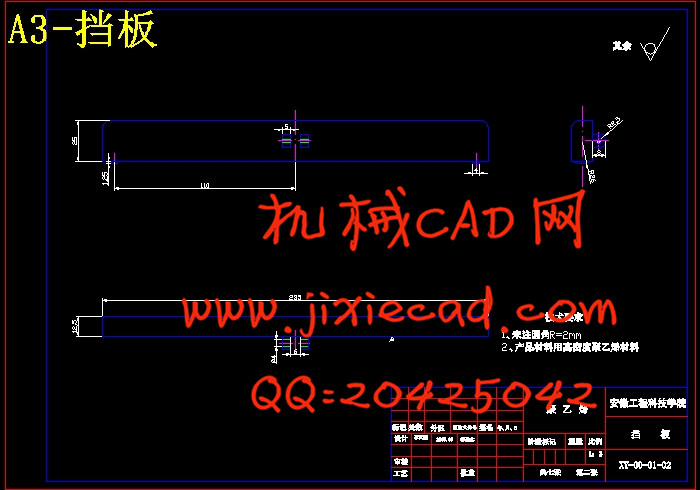

§4.1挡板的设计………………………………………………………………………………..21

4.1.1材料选择……………………………………………………………………………………21

4.1.2挡板机构的外型尺寸及相关说明…………………………………………………………21

4.1.3挡板机构的强度计算………………………………………………………………………22

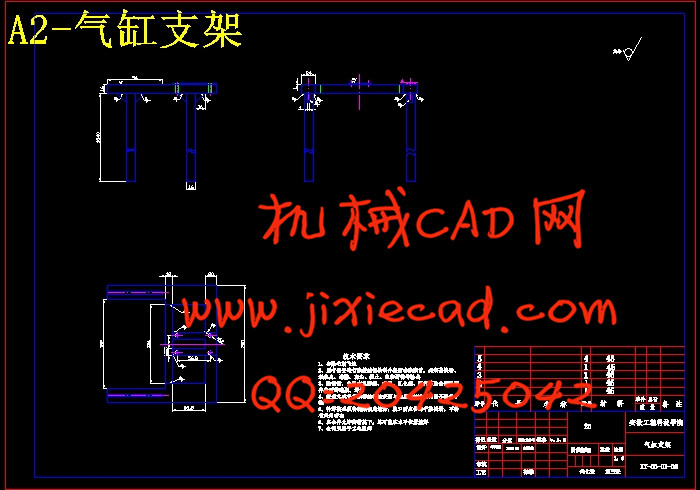

§4.2气缸的选择与计算………………………………………………………………………..23

4.2.1气缸类型的选择……………………………………………………………………………23

4.2.2气缸的安装形式…………………………………………………………………………….24

4.2.3气缸外径计算及其壁厚……………………………………………………………………24

4.2.4活塞杆的设计及其强度设计………………………………………………………………25

4.2.5活塞的设计、计算…………………………………………………………………………26

4.2.6缓冲行程的估算……………………………………………………………………………26

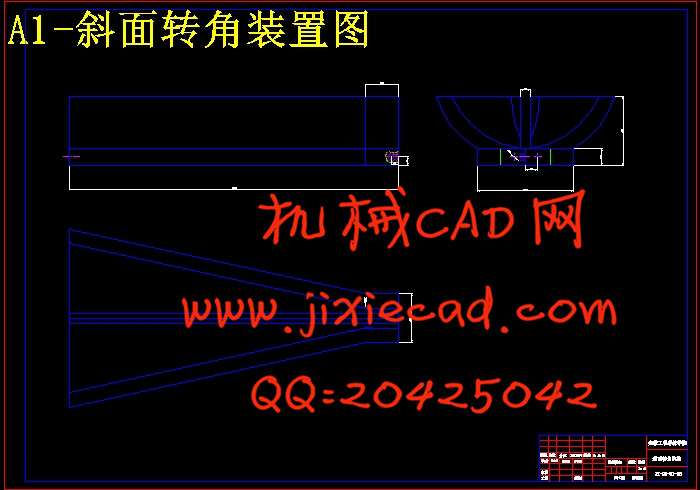

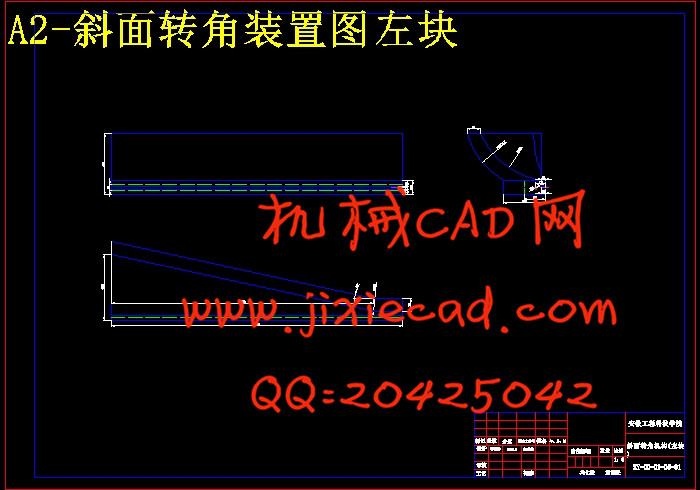

§4.3斜面转角机构设计………………………………………………………………………..26

4.3.1实现功能……………………………………………………………………………………26

4.3.2斜面转角机构材料的选择…………………………………………………………………26

4.3.3斜面转角机构倾斜角度的计算……………………………………………………………27

4.3.4斜面转角机构的外型设计…………………………………………………………………28

4.3.4相关说明…………………………………………………………………………………….29

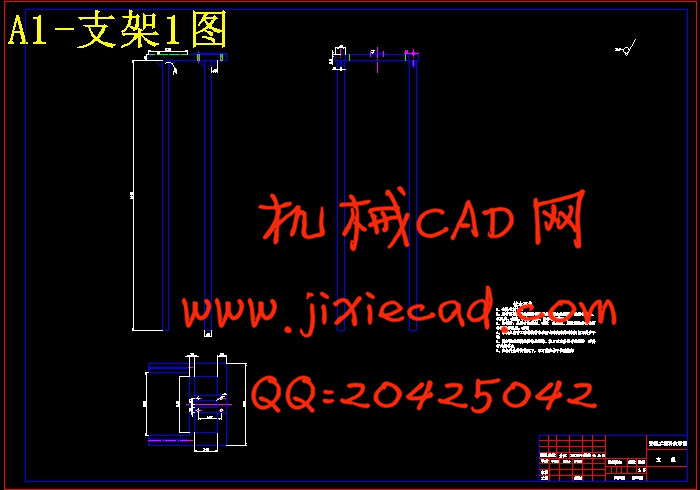

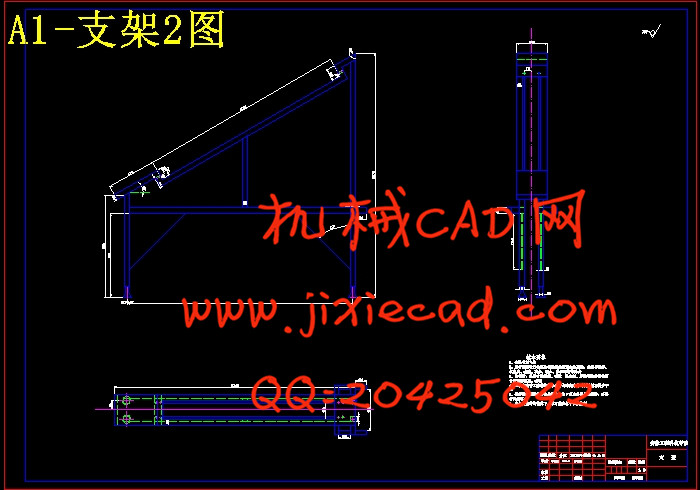

§4.4支架设计…………………………………………………………………………………..29

4.4.1支架应满足的基本条件……………………………………………………………………29

4.4.2注意问题……………………………………………………………………………………29

4.4.3支架材料选择……………………………………………………………………………….30

4.4.4气缸支架的设计及相关尺寸的确定……………………………………………………….30

4.4.5转角机构支架的设计及相关尺寸的确定………………………………………………….31

4.4.6相关说明……………………………………………………………………………………32

4.4.7两支架相关技术要求……………………………………………………………………….33

第五章、传感器的选择……………………………………………………………..34

§5.1概述………………………………………………………………………………………..34

§5.2传感器的选择……………………………………………………………………………..34

§5.3压力传感器的基本结构(如下图)及工作原理………………………………………..34

§5.4ENDEVOC型压力传感器的主要技术参数………………………………………………35

第六章、控制电路的设计……………………………………………………………37

§6.1概述………………………………………………………………………………………...37

§6.2控制方法的选择…………………………………………………………………………...37

§6.3控制电路设计……………………………………………………………………………..38

§6.4控制原理分析…………………………………………………………………………….38

设计展望…………………………………………………………………………………………40

致谢……………………………………………………………………………………………….41

参考文献…………………………………………………………………………………………42

摘 要

当今时代,由于科学技术的迅速发展,企业与企业间的竞争日益加剧,且表现为知识和技术的竞争。故现代企业千方百计的设法提高生产技术,努力实现制造全过程的自动化。制造自动化技术就是研究对制造过程的规划、运作、管理、组织、控制与协调优化等的自动化技术,以使产品制造过程实现高效、优质、低耗、及时和洁净的目标。制造自动化技术代表着先进制造技术的水平,推动了社会的发展。其中高效智能的自动化生产线便是制造自动化技术的重要组成部分。

香烟自动生产线是为实现香烟生产的批量化,且提高生产的机械化、自动化水平而专门设计的。它的产生极大的提高了香烟生产企业制造的自动化水平,提高了企业的生产率;方便了企业对生产过程的规划、运作、管理、组织、控制与协调优化等。

本设计为香烟中包包装机中的一部分,其主要任务是当香烟中包从上一工序——中包远距离水平传送过来后,下落至倾斜放置的弧型转角机构中,中包在弧形轨道实现平滑下落,下落落差为1500MM,并渐进实现中包由水平卧放转90度实现竖直放置,并要求中包在弧形轨道堆积到五包时后面的中包下落应停止,以防止轨道堵塞。此设计的主要功能是实现中包的转角,为后面的工序及中包的打包提供良好的条件。

本设计控制过程较为简单,故采用硬接线,即结构简单,价格低廉,维护方便,抗干扰能力强的继电接触器控制系统来完成。其作用是保证转角机构上的中包堆积量保持在规定的范围内,控制中包有节奏的下落。控制系统对生产和工作可靠性影响很大,因此,要求控制准确、灵敏、可靠、耐用和调整方便。

为了对弧型轨道口的中包堆积量进行适时监控。故采用安装高灵敏度的ENDEVCO型压力传感器。此传感器特点是牢靠,灵敏度高,信噪比高,动态范围宽和线型度好,使用时在三倍满刻度压力下还能得到最高输出信号,而不会因超量程而丢失数据且能在宽温度范围内取得可靠数据。

关键词

自动生产线;香烟中包包装机;电气控制;压力传感器

Mid-package packing machine for cigarette--- make design for a part of mid-package being carried

summary

Now ages, because of science and technical's quick development, the business enterprise turn worse with the competition of the business enterprise increasingly, and the behave of this is knowledge with technical competition.So modern business enterprise tries the exaltation production technique by all ways, working hard to made the automation of the process of whole manufacturing.The manufacturing automation technique is a research to the programming that manufacturing process, operation, management, organize, control and moderate excellent turn the automation technique of etc., to make product manufacturing the process realizes efficiently, superior quality, low consume, on time with undefiled target.The manufacturing automation technique represents the forerunner of the manufacturing the technical level, pushing the social development.The among them efficiently intellective automation production line just makes the technical importance in automation constitutes the part.

Automatic production line of cigarette is in the interest of increases the batch quantity produce, and the mechanization, automation level of the production.The creation of it has biggest improve the automation level of the business enterprise manufacturing,increases the rate of the business enterprise; has made the convenience of the programming which business enterprise for of the production line, operation, management, organize, control and moderate excellent turn etc..

This design is a part of Mid-package machine for cigarette, its main mission is when the Mid-package of cigarette from lastly working procedure ——Mid-package is leave from long-distance,and fall to the arc-shaped compose, and smoothly whereabouts which is about 1500 mm inside the arc-shaped orbit, combine gradually enter realize pack being put by level decubitus turning 90 degrees realizing end up keeping placing, and requesting when inside pack in the arc-shaped orbit piling up five packs ,the following should stop, in order to prevent jam of the orbit.The main function of this design is work to realizes the change of Cape of Mid-package, provide favourable condition for following working procedure and the pack of Mid-package .

This design controls the process more simple, the past adoption is hard to connect the line, namely construction simple, the price is cheap, maintenance convenient, the anti- interference ability is strong to get in touch with after the electricity machine control system to complete.Its function is a whereabouts to guarantee to turn Cape the inside on the organization pack pile up deal keeps within the scope of prescriptive, control inside pack contain rhythm.Control system to produce with work dependable influence very big, therefore, request control accurate, intelligent, dependable, enduring with adjust the convenience.

For piling up to the oscular inside in orbit in type in arc pack the deal proceed to supervise and control in good time.Past the adoption installs the ENDEVCO type pressure of the high and intelligent degree spreads to feel machine.This spreads to feel the machine characteristics is firm and reliable, the intelligent degree is high, SNY is high, the dynamic scope breadth is good with the line type degree, hour in usage is within the scope of the triple is full to engrave a pressure to can still get the tallest exportation signal down, but can't because of super measures distance but throw to lose the data and can in the breadth temperature dependable data in acquisition.

Key Word

Automatic production line; Mid-package machine for cigarette; Electricity control; The pressure spreads to transducer

目 录

插图、表格清单………………………………………………………………………5

第一章概述……………………………………………………………………………8

第二章绪论……………………………………………………………………………9

§2.1自动生产线的结构组成……………………………………………………………………9

§2.2自动生产线设计的基本要求………………………………………………………………9

2.2.1使用性能……………………………………………………………………………………..9

2.2.2技术性能……………………………………………………………………………………..9

2.2.3经济性能……………………………………………………………………………………..9

2.2.4其它………………………………………………………………………………………….10

第三章方案选择……………………………………………………………………11

§3.1已知基本参数条件………………………………………………………………………11

§3.2功能要求……………………………………………………………………………………11

§3.3完美化要求…………………………………………………………………………………11

§3.4方案的比较…………………………………………………………………………………11

3.4.1方案一……………………………………………………………………………………….11

3.4.2方案二……………………………………………………………………………………….14

3.4.3方案三……………………………………………………………………………………….16

3.4.4方案四……………………………………………………………………………………….17

3.4.5各方案简明表……………………………………………………………………………….18

3.4.6方案比较表………………………………………………………………………………….19

3.4.7方案选择…………………………………………………………………………………….20

第四章各部件的设计和标准件的选择……………………………………………..21

§4.1挡板的设计………………………………………………………………………………..21

4.1.1材料选择……………………………………………………………………………………21

4.1.2挡板机构的外型尺寸及相关说明…………………………………………………………21

4.1.3挡板机构的强度计算………………………………………………………………………22

§4.2气缸的选择与计算………………………………………………………………………..23

4.2.1气缸类型的选择……………………………………………………………………………23

4.2.2气缸的安装形式…………………………………………………………………………….24

4.2.3气缸外径计算及其壁厚……………………………………………………………………24

4.2.4活塞杆的设计及其强度设计………………………………………………………………25

4.2.5活塞的设计、计算…………………………………………………………………………26

4.2.6缓冲行程的估算……………………………………………………………………………26

§4.3斜面转角机构设计………………………………………………………………………..26

4.3.1实现功能……………………………………………………………………………………26

4.3.2斜面转角机构材料的选择…………………………………………………………………26

4.3.3斜面转角机构倾斜角度的计算……………………………………………………………27

4.3.4斜面转角机构的外型设计…………………………………………………………………28

4.3.4相关说明…………………………………………………………………………………….29

§4.4支架设计…………………………………………………………………………………..29

4.4.1支架应满足的基本条件……………………………………………………………………29

4.4.2注意问题……………………………………………………………………………………29

4.4.3支架材料选择……………………………………………………………………………….30

4.4.4气缸支架的设计及相关尺寸的确定……………………………………………………….30

4.4.5转角机构支架的设计及相关尺寸的确定………………………………………………….31

4.4.6相关说明……………………………………………………………………………………32

4.4.7两支架相关技术要求……………………………………………………………………….33

第五章、传感器的选择……………………………………………………………..34

§5.1概述………………………………………………………………………………………..34

§5.2传感器的选择……………………………………………………………………………..34

§5.3压力传感器的基本结构(如下图)及工作原理………………………………………..34

§5.4ENDEVOC型压力传感器的主要技术参数………………………………………………35

第六章、控制电路的设计……………………………………………………………37

§6.1概述………………………………………………………………………………………...37

§6.2控制方法的选择…………………………………………………………………………...37

§6.3控制电路设计……………………………………………………………………………..38

§6.4控制原理分析…………………………………………………………………………….38

设计展望…………………………………………………………………………………………40

致谢……………………………………………………………………………………………….41

参考文献…………………………………………………………………………………………42