设计简介

摘 要

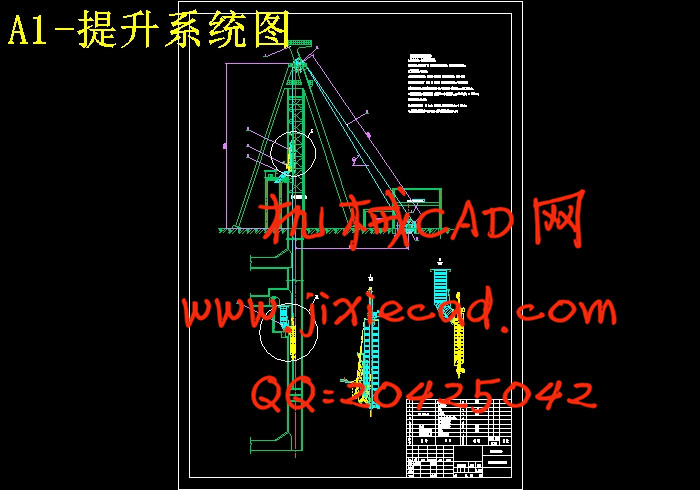

矿井提升设备的任务是沿井筒提升煤炭、矸石、下放材料,升降人员和设备。本设计通过箕斗、钢丝绳、提升机、天轮、井架、电动机等来叙述提升机的设备选型。

在矿井提升中,应根据不同的用途,选用合适的矿井提升设备,扬长避短,充分发挥它们的效能,必须对其结构、性能及选择计算方法予以了解。

为此,必须掌握矿井提升设备的结构、工作原理、性能特点、选择设计、运转理论等方面的知识,以做到选型合理,正确使用与维护,使之安全、可靠、经济地运转。

关键词:提升机;箕斗;钢丝绳;天轮

ABSTRACT

矿井提升设备的任务是沿井筒提升煤炭、矸石、下放材料,升降人员和设备。本设计通过箕斗、钢丝绳、提升机、天轮、井架、电动机等来叙述提升机的设备选型。

在矿井提升中,应根据不同的用途,选用合适的矿井提升设备,扬长避短,充分发挥它们的效能,必须对其结构、性能及选择计算方法予以了解。

为此,必须掌握矿井提升设备的结构、工作原理、性能特点、选择设计、运转理论等方面的知识,以做到选型合理,正确使用与维护,使之安全、可靠、经济地运转。

关键词:提升机;箕斗;钢丝绳;天轮

ABSTRACT

Mine Hoist equipment is raised along the shaft coal,ores,coal,decentralization material,personnel and equipment movements.The selection of the design of vessel,the rope ,elevator,and space launches,Derrick,motors,etc,to describe the Hoist Equipment Selection.

In the mine upgrade,according to the different uses,to choose an appropriate mine hoisting equipment,exceed and give full play to their effectiveness that is structure,performance and choice of method to be understanding.

Therefore,we must master the mine hoisting equipment structure,working principles,characteristics,select the design,operation theory of knowledge.Selection reasonable to do,the proper use and maintenance to make it safe,reliable and economic operation.

Keywords:hoist;skip;rope

目 录

第一章 前言 1In the mine upgrade,according to the different uses,to choose an appropriate mine hoisting equipment,exceed and give full play to their effectiveness that is structure,performance and choice of method to be understanding.

Therefore,we must master the mine hoisting equipment structure,working principles,characteristics,select the design,operation theory of knowledge.Selection reasonable to do,the proper use and maintenance to make it safe,reliable and economic operation.

Keywords:hoist;skip;rope

目 录

第二章 设计原始资料 2

第三章 提升方式的确定 3

第四章 矿井提升设备机械部分的计算与选择 5

4.1 箕斗容量的计算与选择 5

4.1.1 计算合理的提升速度............................................................................5

4.1.2 计算一次循环时间................................................................................5

4.1.3 估算一次提升量....................................................................................5

4.1.4 选择标准箕斗........................................................................................6

4.1.5 计算一次实际提升量............................................................................6

4.1.6 计算一次提升循环时间........................................................................6

4.1.7 计算绞车所需的提升速度....................................................................6

4.2 钢丝绳的计算与选择 6

4.2.1 计算钢丝绳的最大悬垂长度................................................................6

4.2.2 钢丝绳每米重量计算............................................................................7

4.2.3 验算安全系数........................................................................................7

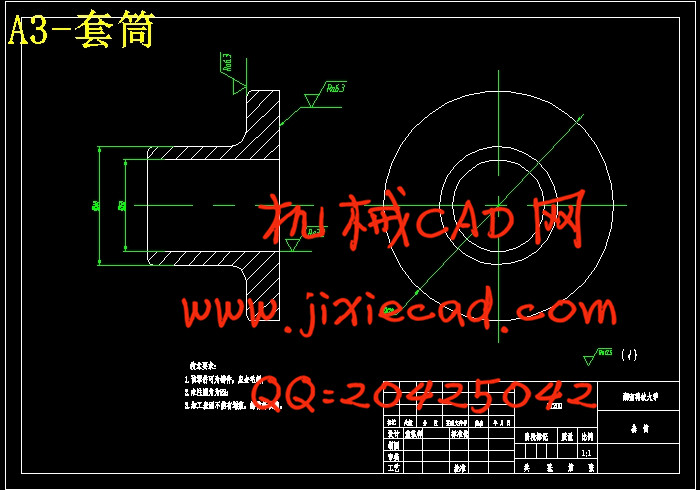

4.3 提升机的计算与选择 8

4.3.1 滚筒直径的选择与计算........................................................................8

4.3.2 计算滚筒宽度........................................................................................8

4.3.3 确定减速器传动比................................................................................9

4.3.4 选用提升机............................................................................................9

4.3.5 校验提升机强度....................................................................................9

4.4 天轮直径的选定 ....10

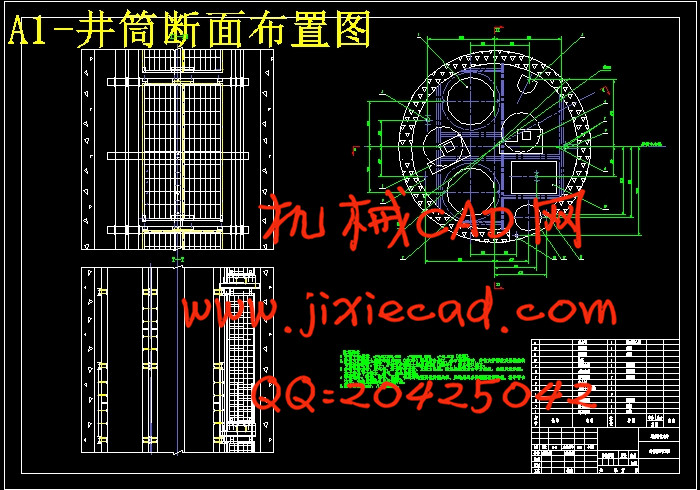

4.5 提升机与井筒相对位置确定 ..10

4.5.1 确定井架高度......................................................................................10

4.5.2 绞筒中心至井筒中心的水平距离......................................................11

4.5.3 计算钢丝绳弦长..................................................................................11

4.5.4 钢丝绳的内、外偏角计算..................................................................11

4.5.5 验算提升机滚筒的下出绳角..............................................................12

4.5.6 提升机与井筒相对位置图..................................................................12

4.6 预选电动机 ..12

4.6.1 估算电动机功率..................................................................................12

4.6.2 计算电动机的转速..............................................................................13

4.6.3 确定提升机实际最大提升速度..........................................................13

4.7 提升系统的变位质量计算 ........14

4.7.1 直线运动部分的变位质量..................................................................14

4.7.2 旋转运动部分的变位质量..................................................................14

4.7.3 总变位质量..........................................................................................14

4.8 主加速度的计算选择 15

4.8.1 初加速度的计算..................................................................................15

4.8.2主加速度的计算...................................................................................15

4.8.3 确定提升减速度..................................................................................16

4.9 六阶段速度图的计算 16

4.9.1 初加速阶段..........................................................................................16

4.9.2 主加速阶段..........................................................................................16

4.9.3 主减速阶段..........................................................................................17

4.9.4 爬行阶段..............................................................................................17

4.9.5 等速阶段..............................................................................................17

4.9.6 抱闸停车时间......................................................................................17

4.9.7 一次提升循环时间..............................................................................17

4.9.8 提升设备生产能力..............................................................................18

4.10 动力学计算 18

4.10.1初加速阶段.........................................................................................18

4.10.2主加速阶段.........................................................................................18

4.10.3等速阶段.............................................................................................19

4.10.4减速阶段.............................................................................................19

4.10.5爬行阶段.............................................................................................19

4.11 电动机功率 .20

4.11.1按电动机允许发热条件验算.............................................................20

4.11.2按正常运行时电动机过负荷能力验算.............................................21

4.11.3按特殊过负荷校验.............................................................................21

4.12 电耗和效率计算 22

4.12.1预算耗电量.........................................................................................22

第五章 提升电控设备的选择 24

5.1 选择高压开关柜 24

5.1.1 选择磁力控制站..................................................................................24

5.1.2 选择高压接触换向器..........................................................................24

5.1.3 选择动力制动装置..............................................................................24

5.2 转子电阻的计算与选择 24

5.2.1 第一预备级电阻的计算......................................................................24

5.2.2 第二预备级电阻的计算......................................................................25

5.2.3 主加速级电阻公比的确定..................................................................25

5.2.4 各级电阻的计算..................................................................................26

5.2.5 计算启动时间和通电持续率..............................................................27

5.2.6 各级电阻启动电流计算......................................................................29

5.2.7 选配电阻箱..........................................................................................29

5.2.8 绘制启动特征曲线..............................................................................31

第六章 控制线路工作原理介绍 34

6.1 电控系统的主要组成部分和作用 34

6.1.1 主回路..................................................................................................34

6.1.2 安全回路..............................................................................................34

6.1.3 测速回路..............................................................................................35

6.1.4 控制回路..............................................................................................35

6.1.5 辅助回路..............................................................................................36

6.2 控制线路中的保护和联锁 .36

6.3 转子电阻的切除控制原则 ....37

第七章 矿井提升机的维护与检修................................................................38

7.1 提升机设备的日常维护..............................................................................38

7.2 提升机设备的定期检查..............................................................................38

7.2.1 日检的基本内容..................................................................................38

7.2.2 周检的基本内容..................................................................................39

7.2.3 月检的基本内容..................................................................................39

7.3 提升机设备的计划维修..............................................................................39

7.3.1 小修的内容..........................................................................................40

7.3.2 中修的内容..........................................................................................40

7.3.3 大修的内容..........................................................................................40

第八章 结论..........................................................................................................42