设计简介

摘 要

该设计的题目是关于矿井主排水系统,即煤矿流体机械的选型设计,根据任务书的要求和老师给的资料,查找相关资料了解到,矿井的排水系统设计要严格遵守《矿井安全规程》和《煤矿工业设计规范》所规定的有关条款,保证安全性,经济型的原则,设计合理的排水系统。

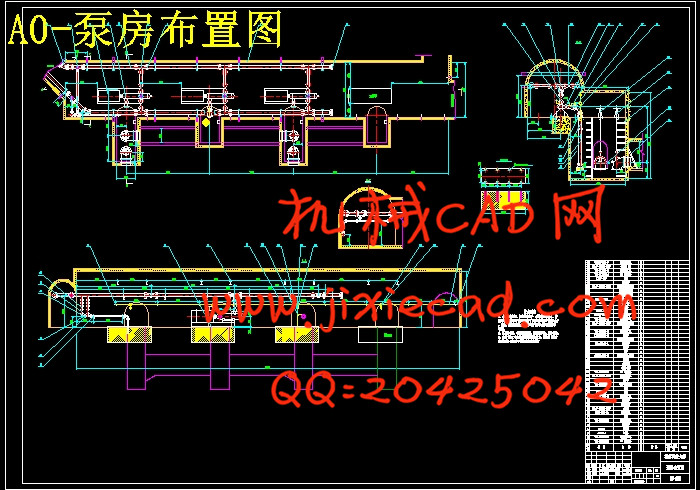

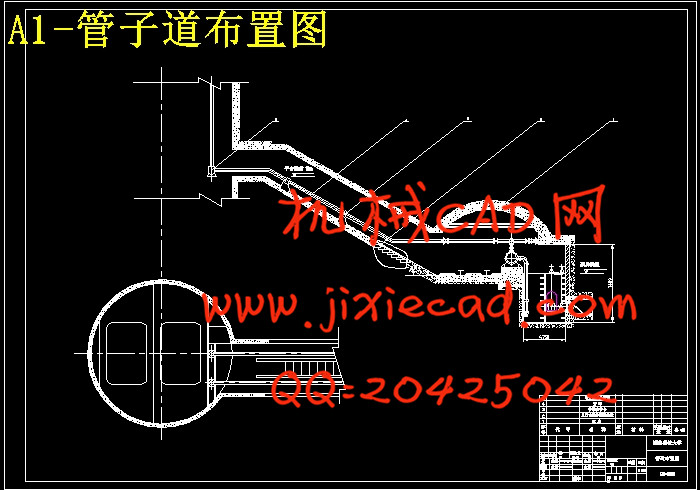

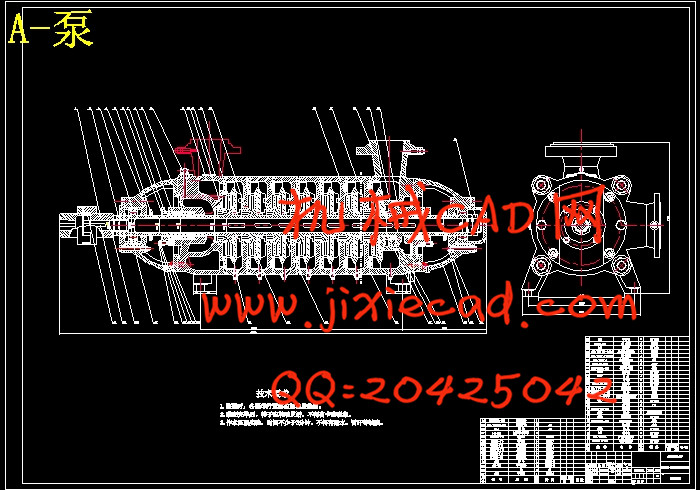

要提前设计出多种方案,然后根据矿井的环境,排水系统的具体要求来选出最合理的方案,包括设备的选型以及相关计算,确定设备工况,进行经济技术分析等等,排除不合理的方案之后确定最终方案。根据任务书的要求,合理设计泵房布置图,管子道图以及水泵结构图。

井下排水系统是矿井系统的四大系统之一,对其设计一定要保持着严格的态度来对待,考虑要周密,必须觉察到很多微小的细节之处,其关系到工人的人身安全,所以对其设计过程要反复检查,提高可行性与安全性。

关 键 词: 矿井涌水; 水泵; 工况点; 设备布置;

ABSTRACT

The graduation design topic is about the mine main drainage system. That is to say , The coal mine in the selection of fluid machinery design.according to the specification and the raw data which is given by teacher.Through to check related information, we learn that the mine drainage system design must strictly abide by the relevant provisions stipulated in the “coal mine safety regulations" and the coal industry design specification ". To ensure the safety, the principle of economy, the rational design of the drainage system.

To advance design multiple solutions and according to the environment of coal mine, drainage system specific requirements to select the most reasonable scheme, including equipment selection and calculation, to determine the status of the equipment, the economic and technical analysis, and so on, unreasonable to exclude determine the final plan. According to the requirements of the task, the reasonable design of pump room layout, pipe pump diagram and structure diagram.

Underground drainage system is one of the four major systems of mine system, the design must maintain a strict attitude to treat, consider to be careful must be aware of the many small details of the Department, its relationship to the worker's personal safety, so the design process must be repeated to check the, improve the feasibility and safety.

Keywords: Mine water; water pump; operating point; equipment layout;

目 录

第一章 前 言该设计的题目是关于矿井主排水系统,即煤矿流体机械的选型设计,根据任务书的要求和老师给的资料,查找相关资料了解到,矿井的排水系统设计要严格遵守《矿井安全规程》和《煤矿工业设计规范》所规定的有关条款,保证安全性,经济型的原则,设计合理的排水系统。

要提前设计出多种方案,然后根据矿井的环境,排水系统的具体要求来选出最合理的方案,包括设备的选型以及相关计算,确定设备工况,进行经济技术分析等等,排除不合理的方案之后确定最终方案。根据任务书的要求,合理设计泵房布置图,管子道图以及水泵结构图。

井下排水系统是矿井系统的四大系统之一,对其设计一定要保持着严格的态度来对待,考虑要周密,必须觉察到很多微小的细节之处,其关系到工人的人身安全,所以对其设计过程要反复检查,提高可行性与安全性。

关 键 词: 矿井涌水; 水泵; 工况点; 设备布置;

ABSTRACT

The graduation design topic is about the mine main drainage system. That is to say , The coal mine in the selection of fluid machinery design.according to the specification and the raw data which is given by teacher.Through to check related information, we learn that the mine drainage system design must strictly abide by the relevant provisions stipulated in the “coal mine safety regulations" and the coal industry design specification ". To ensure the safety, the principle of economy, the rational design of the drainage system.

To advance design multiple solutions and according to the environment of coal mine, drainage system specific requirements to select the most reasonable scheme, including equipment selection and calculation, to determine the status of the equipment, the economic and technical analysis, and so on, unreasonable to exclude determine the final plan. According to the requirements of the task, the reasonable design of pump room layout, pipe pump diagram and structure diagram.

Underground drainage system is one of the four major systems of mine system, the design must maintain a strict attitude to treat, consider to be careful must be aware of the many small details of the Department, its relationship to the worker's personal safety, so the design process must be repeated to check the, improve the feasibility and safety.

Keywords: Mine water; water pump; operating point; equipment layout;

目 录

1.1 矿井简介

1.2 矿水的来源

1.3 对排水设备的要求

1.4 离心式水泵的分类

1.5 排水方案的选择与确定

第二章 排水设备方案的计算与选择

2.1 水泵应具有的排水能力

2.2 确定水泵必须的扬程

2.3 预选水泵

2.4 校验水泵稳定性规定的条件

2.5 确定泵台数

第三章 排水管路的计算与选择

3.1 确定管路趟数

3.2 泵房内管路设置

3.3 计算管径选择管材

3.4 确定排水管壁厚

3.5 计算管路特性

第四章 工况的确定与排水时间的校验

4.1 确定工况点.

4.2 验算排水时间

第五章 排水系统效率的计算

第六章 电动机的计算与选择

6.1 电动机的选择

6.2 年电耗

第七章 技术经济分析

7.1 计算折旧费

7.2 年运转费用

第八章 确定泵房、水仓和管子道尺寸

8.1 估算泵房尺寸

8.2 基础尺寸

8.3 泵房尺寸

8.4 水仓、水房及吸水井的尺寸

8.5 吸水井尺寸

8.6 水仓

8.7 起重梁

8.8 管子道和管子间

第九章 分析离心泵的结构特点

9.1 离心泵的装置及工作原理

9.2 离心泵的工作原理

9.3 离心泵的气蚀

9.4 离心泵的分类

9.5 离心泵型号及结构

9.6 离心泵的主要零部件

第十章 结论

参 考 文 献

致 谢