设计简介

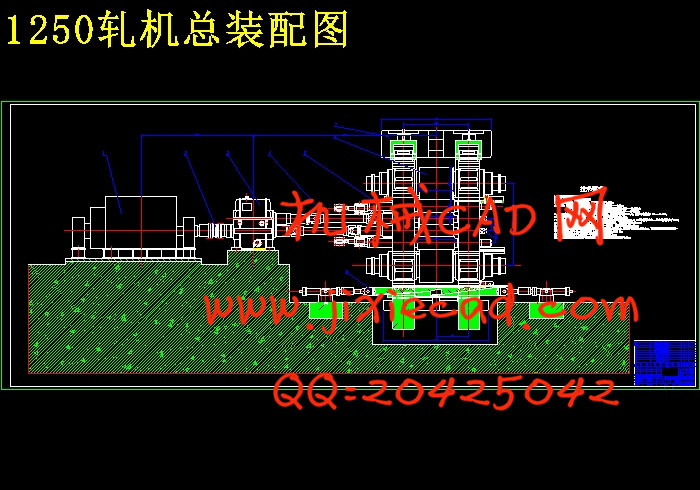

1250HC轧机主传动设计

关键词:轧机;轧辊;主传动系统;电动机;齿轮座

The Design Of The Main Driver Of 1250 HC Mill

Abstract

This design to the hc mill main drive structure. Main drive system of steel rolling is mainly composed of motor,shaft coupling and frame. This design is carried out on the hc mill main drive system design, including motor.coupling and frame, through the calculation of rolling force can parameter and intensity analysis of the parts to complete the design content. So that the use of design to meet requirements and is reasonably practicable. and then rolling force can be calculated parameters,and in accordance with the results calculated to select the motor and check the calculation, while the main components, such as roller, connecting shaft. transmission shaft and tooth strength and wear resistance of the check to ensure that the use of the safety and reliability, the last of the Lubrication Analysis of a simple manner, on the economy is also analyzed.Considering the cost problem, motor with low cost high speed of ac motor. In the process of design, we should consider the practicality manufacturing difficulty. Economic factors and problems encountered in the actual production. Gear stand: used to transfer torque to work roll. the design USES two equal diameter cylidrical herringbone gear in the vertical plane in a row. packed in the sealed enclosure. Coupling: the gear reducer and connecting shaft of a secure connection. The main motor with plum blossom joint shaft coupling in general.

Keywords:rolling mill; roll;The Main Driver;Electric;Roller

目 录

1. 绪论 1

1.1选题背景和目的 1

1.2国内外发展情况 1

1.3课题研究的主要内容 3

2. 总体方案设计 4

2.1轧钢机主传动装置的类型 4

2.1.1 单机座轧钢机 4

2.1.2 多机座轧钢机主传动类型 4

2.2方案对比与选择 4

2.3各零部件类型选择的确定 5

2.3.1 电机 5

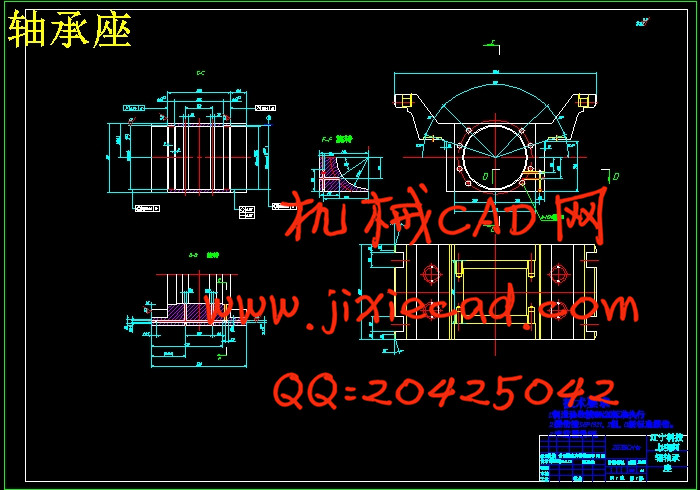

2.3.2 齿轮座 6

2.3.3 联轴器 6

2.4轧辊轴承选择 6

3. 轧制力能参数的计算 7

3.1轧制力的计算 7

3.1.1 设计参数 7

3.1.2 轧辊主要尺寸的选择 7

3.1.3 轧制力的计算 8

3.2轧辊力矩的计算 10

4. 主电机容量选择 14

4.1初选电机 14

4.2主电机力矩 15

4.3电机的校核 16

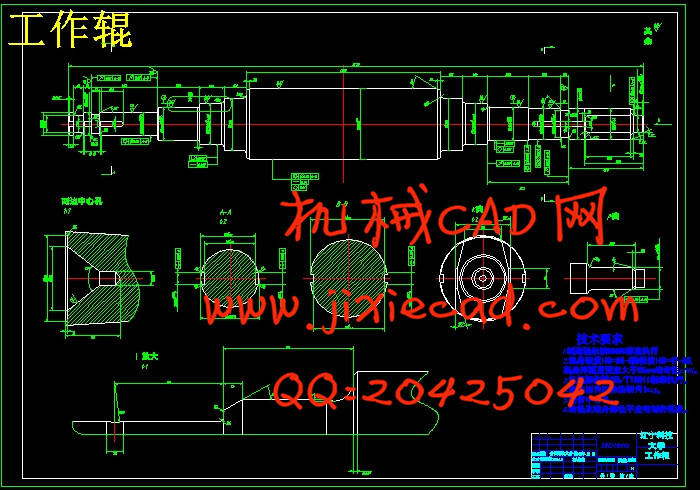

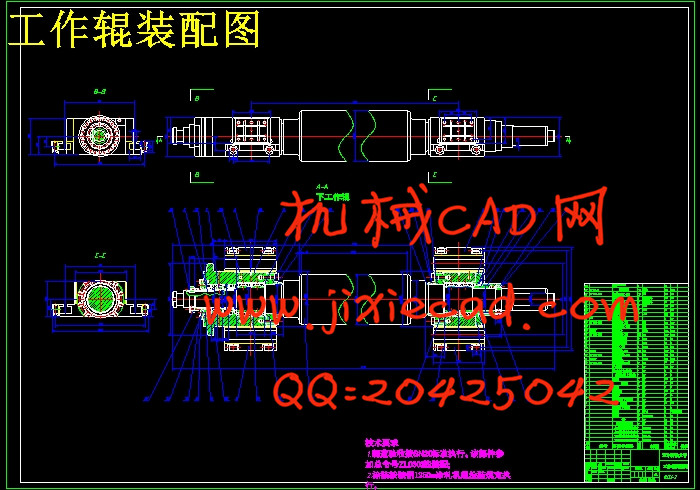

5. 轧辊计算及强度校核 17

5.1工作辊强度校核 18

5.2支承辊强度校核 19

5.3工作辊与支承辊间的接触应力校核 20

5.3.1校核最大正应力 21

5.3.2 校核轧辊内最大切应力 22

5.3.3校核轧辊内最大反复切应力 22

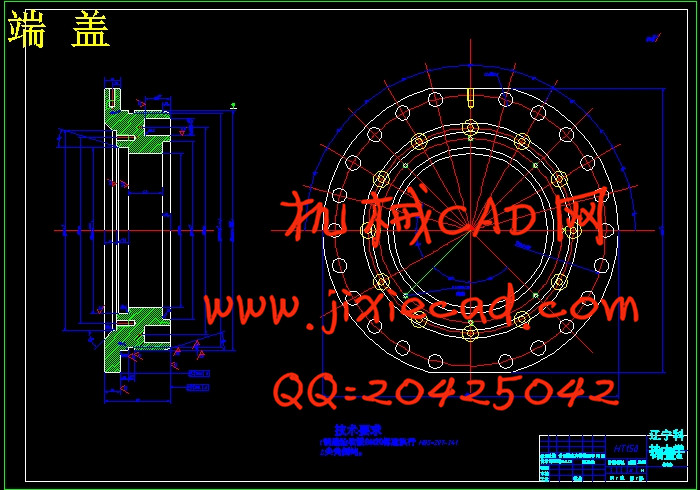

6. 轧辊轴承的选择 23

6.1轴承选择 23

6.2寿命计算 23

7. 齿轮座齿轮的设计与强度计算 25

7.1齿轮座齿轮的确定 25

7.2 按齿面接触强度设计 25

7.3 按齿根弯曲强度设计 28

7.4 几何尺寸计算 30

8. 联接轴的强度计算 31

8.1 开口式扁头的强度计算 31

8.2 叉头的强度计算 33

8.3 轴体强度计算 33

8.4 万向接轴的许用应力 34

9. 润滑方式的选择 35

9.1 润滑方式的类型 35

9.2 轧机常用润滑系统简介 35

9.3 各部分润滑方式的选择 37

10. 环保性及经济分析 38

10.1 设备的环保分析 38

10.2 设备可靠性分析 38

10.3 设备经济性分析 39

结 论 40

致 谢 41

参考文献 42

摘 要

本次设计为hc轧机主传动结构。轧钢机主传动系统主要由电机、齿轮座、联轴器及机架组成。本次设计是对hc轧机进行主传动系统设计,包括电动机、联轴器及机架,通过计算轧制力能参数并进行零件强度校核分析来完成设计内容。使设计方案能够达到使用要求,并且合理可行,然后进行轧制力能参数的计算,并根据算出的结果来选择电动机并进行校核、计算,同时对其中的主要零部件,如轧辊、连接轴、传动轴、等进行强度计算,保证了使用的安全性与可靠性,最后对润滑方式进行了简单分析,对经济性也进行了分析。考虑到造价问题,电动机选用造价低廉的高速交流电动机。在设计的过程中,我们要考虑到实用性、制造的难度、经济因素以及实际生产中所遇到的问题。齿轮机座:用于将转矩传递给工作辊,设计采用两个直径相等的圆柱形人字齿轮在垂直面上排成一排,被装于密闭的箱体内。联轴器:将电机与齿轮座安全连接的连接轴。主联轴器一般采用梅花接轴联轴器。关键词:轧机;轧辊;主传动系统;电动机;齿轮座

The Design Of The Main Driver Of 1250 HC Mill

Abstract

This design to the hc mill main drive structure. Main drive system of steel rolling is mainly composed of motor,shaft coupling and frame. This design is carried out on the hc mill main drive system design, including motor.coupling and frame, through the calculation of rolling force can parameter and intensity analysis of the parts to complete the design content. So that the use of design to meet requirements and is reasonably practicable. and then rolling force can be calculated parameters,and in accordance with the results calculated to select the motor and check the calculation, while the main components, such as roller, connecting shaft. transmission shaft and tooth strength and wear resistance of the check to ensure that the use of the safety and reliability, the last of the Lubrication Analysis of a simple manner, on the economy is also analyzed.Considering the cost problem, motor with low cost high speed of ac motor. In the process of design, we should consider the practicality manufacturing difficulty. Economic factors and problems encountered in the actual production. Gear stand: used to transfer torque to work roll. the design USES two equal diameter cylidrical herringbone gear in the vertical plane in a row. packed in the sealed enclosure. Coupling: the gear reducer and connecting shaft of a secure connection. The main motor with plum blossom joint shaft coupling in general.

Keywords:rolling mill; roll;The Main Driver;Electric;Roller

目 录

1. 绪论 1

1.1选题背景和目的 1

1.2国内外发展情况 1

1.3课题研究的主要内容 3

2. 总体方案设计 4

2.1轧钢机主传动装置的类型 4

2.1.1 单机座轧钢机 4

2.1.2 多机座轧钢机主传动类型 4

2.2方案对比与选择 4

2.3各零部件类型选择的确定 5

2.3.1 电机 5

2.3.2 齿轮座 6

2.3.3 联轴器 6

2.4轧辊轴承选择 6

3. 轧制力能参数的计算 7

3.1轧制力的计算 7

3.1.1 设计参数 7

3.1.2 轧辊主要尺寸的选择 7

3.1.3 轧制力的计算 8

3.2轧辊力矩的计算 10

4. 主电机容量选择 14

4.1初选电机 14

4.2主电机力矩 15

4.3电机的校核 16

5. 轧辊计算及强度校核 17

5.1工作辊强度校核 18

5.2支承辊强度校核 19

5.3工作辊与支承辊间的接触应力校核 20

5.3.1校核最大正应力 21

5.3.2 校核轧辊内最大切应力 22

5.3.3校核轧辊内最大反复切应力 22

6. 轧辊轴承的选择 23

6.1轴承选择 23

6.2寿命计算 23

7. 齿轮座齿轮的设计与强度计算 25

7.1齿轮座齿轮的确定 25

7.2 按齿面接触强度设计 25

7.3 按齿根弯曲强度设计 28

7.4 几何尺寸计算 30

8. 联接轴的强度计算 31

8.1 开口式扁头的强度计算 31

8.2 叉头的强度计算 33

8.3 轴体强度计算 33

8.4 万向接轴的许用应力 34

9. 润滑方式的选择 35

9.1 润滑方式的类型 35

9.2 轧机常用润滑系统简介 35

9.3 各部分润滑方式的选择 37

10. 环保性及经济分析 38

10.1 设备的环保分析 38

10.2 设备可靠性分析 38

10.3 设备经济性分析 39

结 论 40

致 谢 41

参考文献 42