设计简介

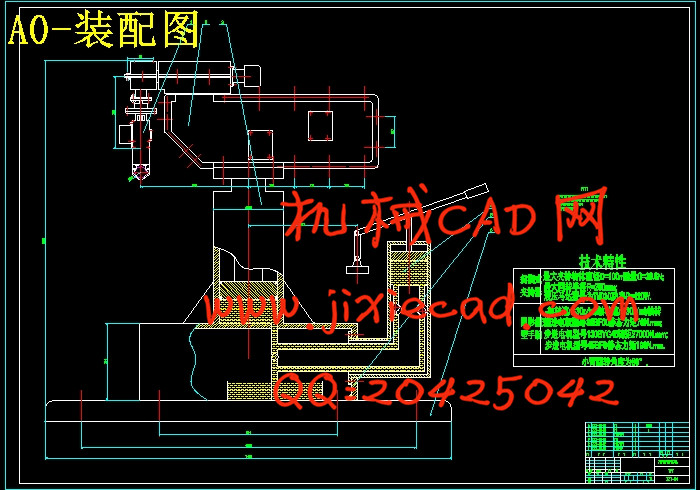

回形偏交型手腕及斜楔式夹持器的设计

摘 要

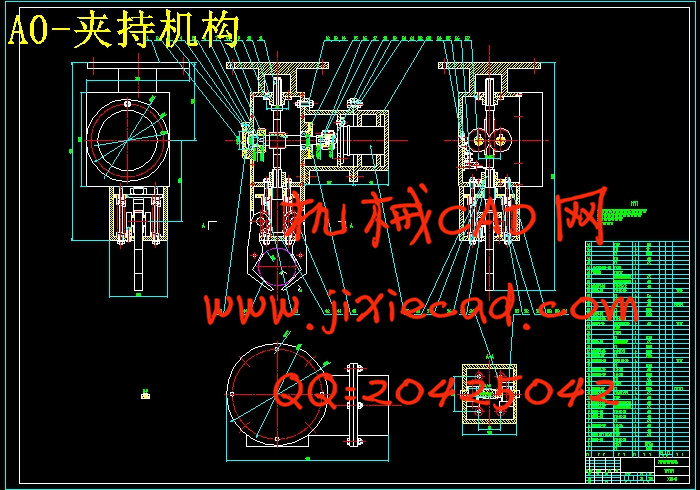

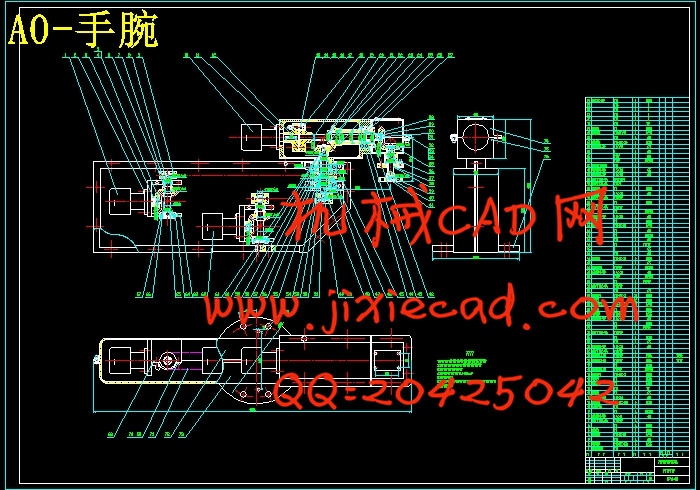

工业机器人自本世纪60年代初问世以来,已有80万余台用于世界各国的自动化生产线上,扮演着灵巧自如、不知疲倦“操作者”的角色,替代生产工人出色的完成极其繁重、复杂、精密或者充满着危险的各种各样的工作。不同用途的工业机器人正在工业生产中起到其它机器无法替代的作用。一般机器人由基座、腰、臂、腕和手五部分组成。腰和臂控制手的空间位置,腕控制手的空间姿态,而手则是实现对操作物体的抓放。本文设计的是回形偏交手腕与斜锲式夹持器,根据设计要求本文制定了一个由液压马达控制夹爪松开、用弹簧夹紧物体的设计方案,对手部和腕部进行了结构设计,同时对其主要零部件进行了选择、设计和计算,内容包括电动机的选择计算,弹簧的设计计算,齿轮、带、轴的设计和校核,最后对设计的可行性进行了经济分析,关键词:手腕;工业机器人;夹持器;操作机

The wrist enjambment eccentric and carves the type screw clamp slanting design

Abstract

Since the beginning of 1960s, more than 800000 industrial robots have been used on automatic production lines of many countries all over the world, playing a role dexterous and as a free “operator” who has no sense of tireness. It can also accomplish various works that are very arduous and complicated or even full of danger instead of workers. The different application of industry robots to industrial production is playing an important role of which other machines are unable to take the place. The common robot basically consists of the waist, the arm, the wrist and the hand. Waist and arm control space position, while wrist controls special attitude, and the hand is used to realize grasping or putting objects. The design of this article is the wrist enjambment eccentric and carves the type screw clamp slanting. According to the design requirements a schematic design has been developed with a hydraulic motor controlling the claws from releasing and using the spring to clamp objects, also it has been carried on the structural design to the hand and wrist, simultaneously conducting the choice, the design and the computation to its main spare parts. The contents including the selection of prime movers, design of springs, design and check of gears, belts, and axes. Finally it is proceeding the economic analysis to the feasibility of design proposal. Conclusions can be drawn through the computational analysis and this design can by and large meet the needs of the design request.

Key words:wrist;Industrial robot;Gripper;End effector

目 录

摘要……………………………………………………………………………………….…Ⅰ

Abstract……………………………………………………………………………………...Ⅱ

1 绪论……………………………………………………………………………….………..1

1.1 选题的背景、目的和意义………………………………………………………….….1

1.2 机器人的发展概况……………………………………………………….…………...1

1.2.1 机器人的定义………………………………………………….………………1

1.2.2 机器人的发展过程………………………………………….…………………2

1.2.3 国内机器人研究状况……………………………………….…………………4

1.2.4 国外机器人的最新发展…………………………………………………….…4

1.2.5 机器人目前研究热点及发展趋势…………………………………….………7

1.3 课题的研究内容与方法…………………………………………………….………...8

2 工作原理及设计方案………………………………………………….……………….9

2.1 斜锲式夹持器工作原理……………………………………………….……………...9

2.2 设计方案……………………………………………………………….……………...9

2.3 可行性分析…………………………………………………………….…………….10

2.3.1 传动方案的选择……………………………………………………….……..10

2.3.2 精定位装置的设计构想………………………………………….…………..10

2.4 机器人回形偏交型手腕的工作原理……………………………………….……….11

3 设计计算………………………………………………………………………………...12

3.1 夹持器的计算…………………………………………………………….………….12

3.1.1 受力分析……………………………………………………….……………..12

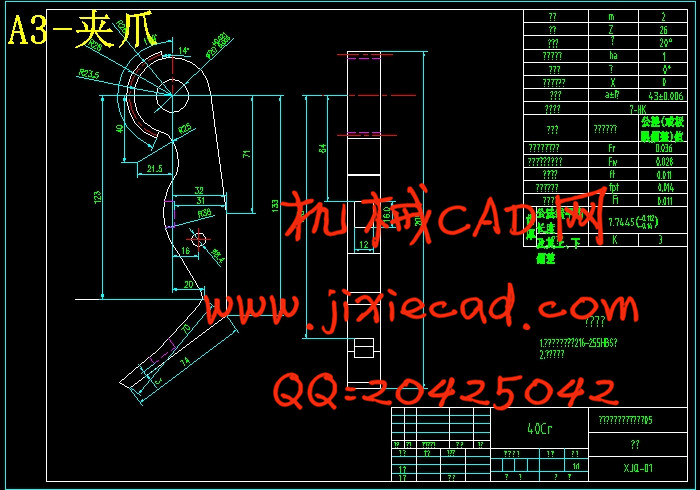

3.1.2 夹爪齿轮的计算……………………………………………….……………..12

3.1.3 圆柱螺旋压缩弹簧的设计计算……………………………….……………..16

3.1.4 液压马达的选择…………………………………………….………………..17

3.1.5 齿轮齿条传动的设计计算…………………………………….……………..18

3.2 腕的计算…………………………………………………………….……………….22

3.2.1 电机的选择………………………………………………….………………..22

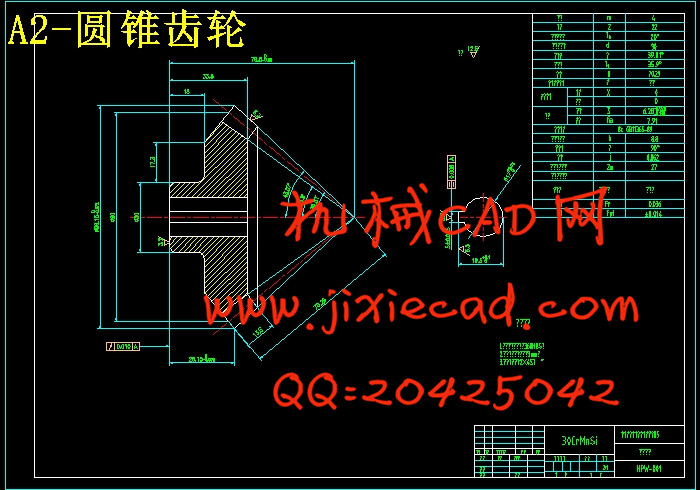

3.2.2 锥齿轮设计………………………………………………….………………..25

3.2.3 同步带和带轮的设计……………………………………….………………..30

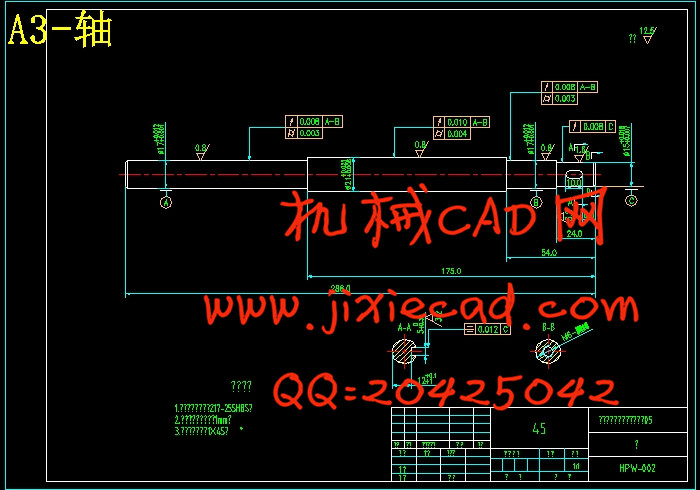

3.2.4 轴的设计及校核………………………………………………….…………..32

4 机械设备的环保、可靠性和经济分析……………………………………………..37

4.1 设备的环保措施……………………………………………………………………..37

4.2 设备的可靠性………………………………………………………………………..37

4.2.1 设备的可靠性定义…………………………………………………………...37

4.2.2 可靠度的计算…………………………………………………………….…..37

4.2.3 设备平均寿命…………………………………………………………….…..37

4.2.4 机械设备的有效度……………………………………………….…………..38

4.3 设备的经济评价………………………………………………………….………….39

4.3.1.投资回收期……………………………………………….…………………...39

4.3.2 盈亏平衡分析……………………………………….………………………..40

4.3.3 设备合理的更新期………………………………….………………………..40

5 结论及存在的问题……………………………………….……………………………42

5.1 结论……………………………….………………………………………………….42

5.2 存在的问题……………………………………………….………………………….42

致谢………………………………………………………………………………………….43

参考文献……………………………………………………………….………………….44

摘 要

工业机器人自本世纪60年代初问世以来,已有80万余台用于世界各国的自动化生产线上,扮演着灵巧自如、不知疲倦“操作者”的角色,替代生产工人出色的完成极其繁重、复杂、精密或者充满着危险的各种各样的工作。不同用途的工业机器人正在工业生产中起到其它机器无法替代的作用。一般机器人由基座、腰、臂、腕和手五部分组成。腰和臂控制手的空间位置,腕控制手的空间姿态,而手则是实现对操作物体的抓放。本文设计的是回形偏交手腕与斜锲式夹持器,根据设计要求本文制定了一个由液压马达控制夹爪松开、用弹簧夹紧物体的设计方案,对手部和腕部进行了结构设计,同时对其主要零部件进行了选择、设计和计算,内容包括电动机的选择计算,弹簧的设计计算,齿轮、带、轴的设计和校核,最后对设计的可行性进行了经济分析,关键词:手腕;工业机器人;夹持器;操作机

The wrist enjambment eccentric and carves the type screw clamp slanting design

Abstract

Since the beginning of 1960s, more than 800000 industrial robots have been used on automatic production lines of many countries all over the world, playing a role dexterous and as a free “operator” who has no sense of tireness. It can also accomplish various works that are very arduous and complicated or even full of danger instead of workers. The different application of industry robots to industrial production is playing an important role of which other machines are unable to take the place. The common robot basically consists of the waist, the arm, the wrist and the hand. Waist and arm control space position, while wrist controls special attitude, and the hand is used to realize grasping or putting objects. The design of this article is the wrist enjambment eccentric and carves the type screw clamp slanting. According to the design requirements a schematic design has been developed with a hydraulic motor controlling the claws from releasing and using the spring to clamp objects, also it has been carried on the structural design to the hand and wrist, simultaneously conducting the choice, the design and the computation to its main spare parts. The contents including the selection of prime movers, design of springs, design and check of gears, belts, and axes. Finally it is proceeding the economic analysis to the feasibility of design proposal. Conclusions can be drawn through the computational analysis and this design can by and large meet the needs of the design request.

Key words:wrist;Industrial robot;Gripper;End effector

目 录

摘要……………………………………………………………………………………….…Ⅰ

Abstract……………………………………………………………………………………...Ⅱ

1 绪论……………………………………………………………………………….………..1

1.1 选题的背景、目的和意义………………………………………………………….….1

1.2 机器人的发展概况……………………………………………………….…………...1

1.2.1 机器人的定义………………………………………………….………………1

1.2.2 机器人的发展过程………………………………………….…………………2

1.2.3 国内机器人研究状况……………………………………….…………………4

1.2.4 国外机器人的最新发展…………………………………………………….…4

1.2.5 机器人目前研究热点及发展趋势…………………………………….………7

1.3 课题的研究内容与方法…………………………………………………….………...8

2 工作原理及设计方案………………………………………………….……………….9

2.1 斜锲式夹持器工作原理……………………………………………….……………...9

2.2 设计方案……………………………………………………………….……………...9

2.3 可行性分析…………………………………………………………….…………….10

2.3.1 传动方案的选择……………………………………………………….……..10

2.3.2 精定位装置的设计构想………………………………………….…………..10

2.4 机器人回形偏交型手腕的工作原理……………………………………….……….11

3 设计计算………………………………………………………………………………...12

3.1 夹持器的计算…………………………………………………………….………….12

3.1.1 受力分析……………………………………………………….……………..12

3.1.2 夹爪齿轮的计算……………………………………………….……………..12

3.1.3 圆柱螺旋压缩弹簧的设计计算……………………………….……………..16

3.1.4 液压马达的选择…………………………………………….………………..17

3.1.5 齿轮齿条传动的设计计算…………………………………….……………..18

3.2 腕的计算…………………………………………………………….……………….22

3.2.1 电机的选择………………………………………………….………………..22

3.2.2 锥齿轮设计………………………………………………….………………..25

3.2.3 同步带和带轮的设计……………………………………….………………..30

3.2.4 轴的设计及校核………………………………………………….…………..32

4 机械设备的环保、可靠性和经济分析……………………………………………..37

4.1 设备的环保措施……………………………………………………………………..37

4.2 设备的可靠性………………………………………………………………………..37

4.2.1 设备的可靠性定义…………………………………………………………...37

4.2.2 可靠度的计算…………………………………………………………….…..37

4.2.3 设备平均寿命…………………………………………………………….…..37

4.2.4 机械设备的有效度……………………………………………….…………..38

4.3 设备的经济评价………………………………………………………….………….39

4.3.1.投资回收期……………………………………………….…………………...39

4.3.2 盈亏平衡分析……………………………………….………………………..40

4.3.3 设备合理的更新期………………………………….………………………..40

5 结论及存在的问题……………………………………….……………………………42

5.1 结论……………………………….………………………………………………….42

5.2 存在的问题……………………………………………….………………………….42

致谢………………………………………………………………………………………….43

参考文献……………………………………………………………….………………….44