设计简介

1700立辊轧机主传动系统设计

摘要

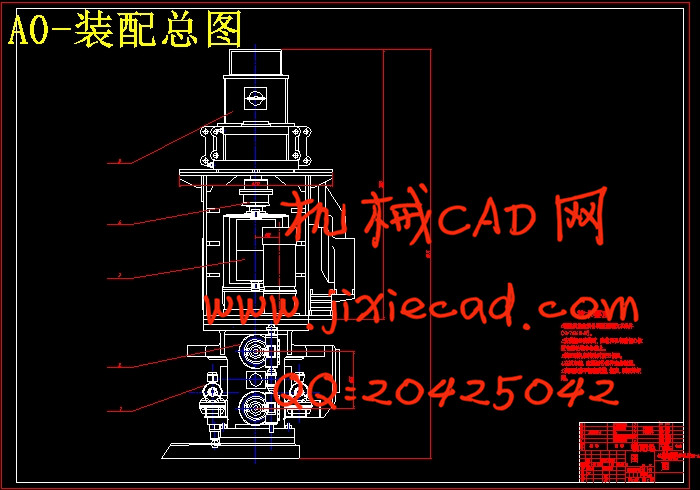

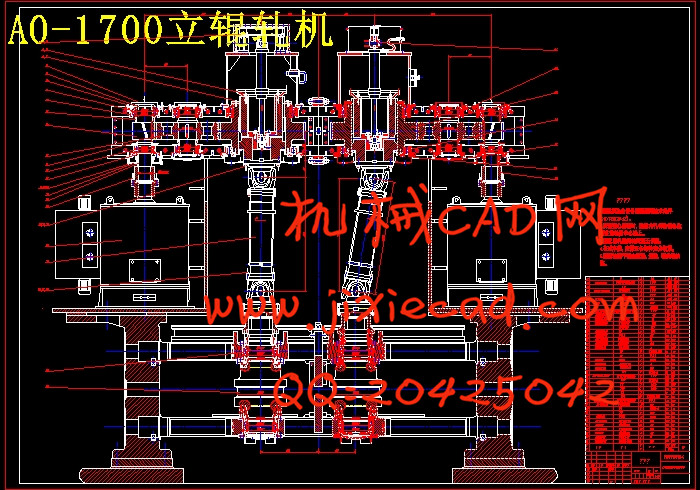

立辊轧机曾经一度被人们所忽视,然而随着近年来轧钢技术的不断进步,各种新方法的应用,立辊轧机相对于以往有了很大的改进,它在轧钢生产中使用越来越广泛,尤其是在热轧薄板带钢生产中的破鳞、控制板坯宽度等方面更是必不可少的轧钢设备。本次设计的主要目的是对立辊轧机的主传动系统进行了解和研究,并对主要部件进行设计和校核计算,最终设计绘制出立辊轧机主传动系统的总装配图。在查阅文献和相关资料的同时,通过到鞍山钢铁集团公司热轧带钢厂1700及1780生产线进行参观实习,使我对立辊轧机有了深入的了解和认识。本次设计主要包括阐述立辊轧机的发展、结构、作用和主传动方案等,并重点对立辊轧机主传动系统中涉及的各个零部件进行了设计计算。主要包括轧机结构参数计算、力能参数计算、主电机选择、减速箱中齿轮传动设计、轧辊设计与校核、轧辊轴承寿命计算等相关内容。

关键词:立辊轧机;主传动系统;力能参数计算;零部件设计与校核

The Design of Edger Mill Main’s Driving System

Abstract

The Edger mill were once ignored by many people,however,they have a very great improvement which compared to the past as the technique of rolling steel progressing incessantly and the application of kinds of new methods in recent years. They have been used more and more extensively in production of rolling steel. They are more essential rolling steel equipment especially in such aspects as breaking scale, controlling the width of the panel in hot-rolled sheet metal and belted steel production. The main purpose of the design is to have a further understanding to the Edger mill’s main driving system and to have a check and calculation to the main parts,and eventually to design the assembly drawing of the Edger mill’s main driving system. While consulting a large number of documents and referring to relevant knowledge, and through visiting the 1700 and 1780 rolling steel production lines in Hot Rolling mill of An Shan’s Iron and Steel Company,I have a great improvement in rising to perceptual knowledge from rational knowledge.The design mainly includes the development, the structure and functions of the Edger mill and the scheme of the Edger mill’s main driving system. At the same time I have checked and calculated all parts related to the main driving system which insists of mill structural parameters, force and energy parameters, the main motor choice, speed gear box design, Design and Verification roller, roller bearings and other related content.

Keyword: the Edger mill; the main Driving system; force and energy parameters calculated; parts design and verification

目录

1 绪论 1摘要

立辊轧机曾经一度被人们所忽视,然而随着近年来轧钢技术的不断进步,各种新方法的应用,立辊轧机相对于以往有了很大的改进,它在轧钢生产中使用越来越广泛,尤其是在热轧薄板带钢生产中的破鳞、控制板坯宽度等方面更是必不可少的轧钢设备。本次设计的主要目的是对立辊轧机的主传动系统进行了解和研究,并对主要部件进行设计和校核计算,最终设计绘制出立辊轧机主传动系统的总装配图。在查阅文献和相关资料的同时,通过到鞍山钢铁集团公司热轧带钢厂1700及1780生产线进行参观实习,使我对立辊轧机有了深入的了解和认识。本次设计主要包括阐述立辊轧机的发展、结构、作用和主传动方案等,并重点对立辊轧机主传动系统中涉及的各个零部件进行了设计计算。主要包括轧机结构参数计算、力能参数计算、主电机选择、减速箱中齿轮传动设计、轧辊设计与校核、轧辊轴承寿命计算等相关内容。

关键词:立辊轧机;主传动系统;力能参数计算;零部件设计与校核

The Design of Edger Mill Main’s Driving System

Abstract

The Edger mill were once ignored by many people,however,they have a very great improvement which compared to the past as the technique of rolling steel progressing incessantly and the application of kinds of new methods in recent years. They have been used more and more extensively in production of rolling steel. They are more essential rolling steel equipment especially in such aspects as breaking scale, controlling the width of the panel in hot-rolled sheet metal and belted steel production. The main purpose of the design is to have a further understanding to the Edger mill’s main driving system and to have a check and calculation to the main parts,and eventually to design the assembly drawing of the Edger mill’s main driving system. While consulting a large number of documents and referring to relevant knowledge, and through visiting the 1700 and 1780 rolling steel production lines in Hot Rolling mill of An Shan’s Iron and Steel Company,I have a great improvement in rising to perceptual knowledge from rational knowledge.The design mainly includes the development, the structure and functions of the Edger mill and the scheme of the Edger mill’s main driving system. At the same time I have checked and calculated all parts related to the main driving system which insists of mill structural parameters, force and energy parameters, the main motor choice, speed gear box design, Design and Verification roller, roller bearings and other related content.

Keyword: the Edger mill; the main Driving system; force and energy parameters calculated; parts design and verification

目录

1.1选题的背景及目的 1

1.1.1选题背景 1

1.1.2选题的目的 1

1.2立辊轧机的国内外发展过程1

1.3立辊轧机的用途和特点 3

1.3.1立辊轧机的用途 3

1.3.2 立辊轧机的特点 3

1.4 课题的研究内容及研究方法 3

1.4.1课题的研究内容 3

1.4.2课题的研究方法 3

2 总体方案的确定 4

2.1 立辊轧机的结构组成 4

2.2传动形式的选择 4

2.3电机的选择 6

2.4 联轴器 7

2.5减速器 7

2.6 万向接轴 8

2.7 轧辊系统 8

2.8 轧辊轴承 9

3 立辊轧机相关参数的计算 10

3.1 立辊轧机结构参数计算 10

3.2 立辊轧机力能参数计算 11

3.2.1 平均单位应力

3.2.2 立辊轧机轧制力及力矩计算 12

3.3 轧机主电动机的确定 13

3.3.1 初选主电机 13

3.3.2 轧机主电动机力矩计算 14

3.3.3 电机过载校核 15

4 主要零部件的校核计算 16

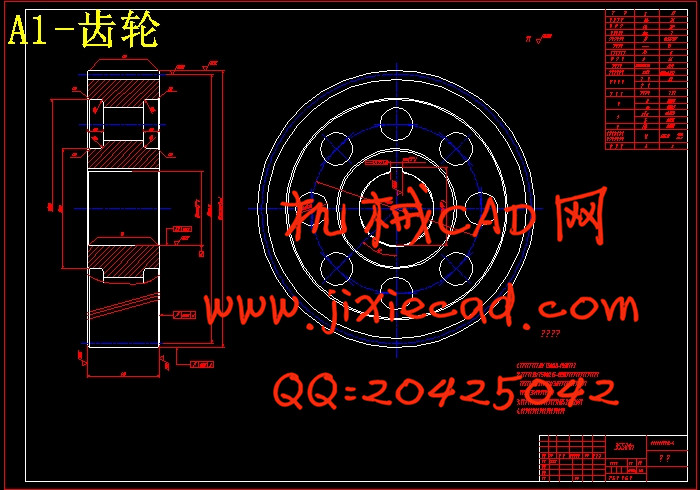

4.1减速机的设计与校核计算 16

4.1.1.确定传动方案、精度等级、材料及齿数 16

4.1.2.按齿面接触强度设计 16

4.1.3.按齿根弯曲强度校核设计 18

4.1.4.齿轮几何尺寸计算 20

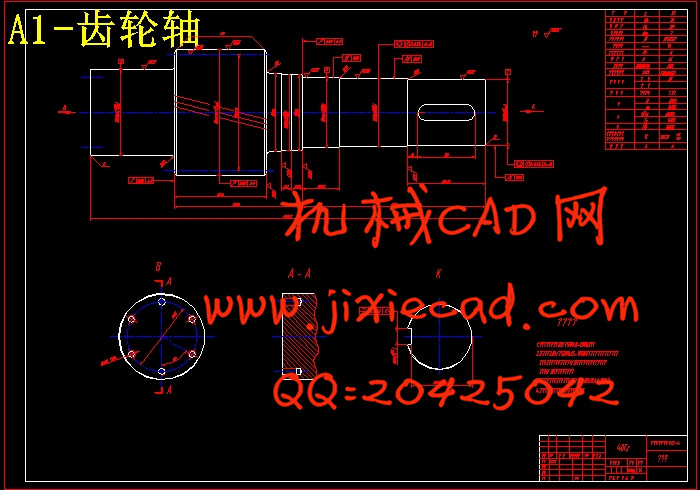

4.2齿轮轴的校核计算 16

4.2.1齿轮轴上载荷计算 21

4.2.2按弯扭合成应力校核轴的强度 21

4.2.3精确校核轴的疲劳强度 24

4.3轴承寿命验算 27

4.3.1轴承所受载荷计算 27

4.3.2验算轴承寿命 29

4.4轧辊校核计算 30

4.4.1轧辊基本参数 30

4.4.2轧辊校核 30

4.5轧辊轴承寿命计算 34

4.5.1 轧辊轴承当量动载荷 34

4.5.2 轧辊轴承寿命计算 35

5 设备的润滑 36

5.1 轧钢机械的润滑 36

5.2 润滑的方法 36

5.3 润滑的功能 36

5.4 润滑油的选择原则 36

5.5 1700立辊轧机设备润滑方法 37

6 设备的环保性和可靠性分析 38

6.1 设备的环保性分析 38

6.2 设备的可靠性 38

结束语 40

致谢 41

参考文献 42