设计简介

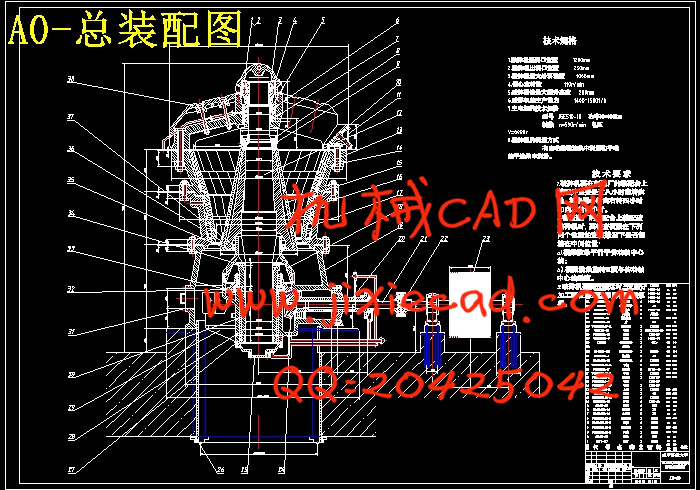

PX1200/250旋回破碎机设计

摘 要

新中国成立以来,随着采矿业的发展,选矿机械经历了从无到有、从小到大、从单个品种和规格到多个品种和规格的发展过程,各种选矿机械产品已经形成了系列,现在生产的各种形式和规格的破碎机、磨矿机和选矿机械,基本上能满足国民经济建设的需求,同时,在液压破碎机、反击式破碎机、离心选矿机等新产品的研制和新技术的应用方面都取得了一定的成就,但是,根据我国矿藏资源的特点(贫矿多、共生矿物多),选别的机械品种还不能完全满足新的选矿工艺的需要,特别需要发展一些适于对难选物的选别机械。旋回破碎机是利用破碎锥在壳体内腔中的旋回运动,对物料产生挤压和弯曲作用,粗碎各种硬度的矿石或岩石的大型破碎机械,装有破碎锥的主轴的上端支承在横梁中部的衬套内,其下端则置于轴套的偏心套中,轴套转动时,破碎锥绕机器中心线作偏心旋回运动,他的破碎动作是连续的,故工作效率高于颚式破碎机,旋回破碎机的工作是连续的,它与其他破碎机相比其优点是生产能力大,工作平稳,破碎单位重量矿石的耗量少,产品粒度比较均匀。

关键词:旋回破碎机;破碎;破碎锥

The design of PX1200/250 gyratory crusher

Abstract

Since new China had been established ,along with the mining industry development , the dressing machinery experienced has grown out of nothing, form infancy to maturity , from the single variety and the specification to many varieties and the specification developing process. Each kind of dressing mechanical product have already formed the series .Now each kind of pattern and specification breaker,the ore mail and classification machinery, basically can satisfy the need of the national economy construction, meanwhile, in the hydraulic pressure breaker, the counter-attack type breaker ,the centrifugal concentrator and so on, the new product development and the new technical application aspect have yielded the certain result. However, according to our country mineral resource characteristic(The lean ore are many associated mineral are many), classifies the machinery the variety not to be able completely to satisfy the new dressing craft the need ,particularly needs to develop some to be suitable for the difficult electing classification machinery.The gyratory crusher is the curing function, thick garrulous each kind of degree of hardness orator rock large-scale broken machinery which is loaded with the broken awl the main axle upper extreme supporting in the crossbeam bushing, its lower extremity sets to the axle sleeve center. When the axle sleeve rotates, the broken awl circles in the machine the core to make the biased cycle movement its broken movement is continuously carries on, hence the working efficiency is higher than the jaw type breaker. The gyratory crusher broken work is continual, it compares with other breakers, its merit is the high productivity , work steady, few crushing unit weight ore consumption quantity,and the uniform distribution equispaced product granularity .

Key words: The Gyratory crusher;Break;Cone

目 录

1 绪论 1

1.1 研究的目的和意义 1

1.2 国内外碎磨设备的简介 3

1.3 旋回破碎机的发展趋势 4

2 总体方案设计 5

2.1 旋回破碎机的类型 5

2.2 旋回破碎机的工作原理 5

2.3 旋回破碎机的构造 5

3 旋回破碎机的结构参数和工作参数的选择和计算 9

3.1 结构参数的选择和计算 9

3.1.1 给矿口尺寸与排矿口尺寸 9

3.1.2 啮角α 9

3.1.3 破碎锥的摆动行程s 10

3.1.4 基本结构尺寸的确定 10

3.2 工作参数的选择与计算 11

3.2.1 破碎锥的摆动次数n(偏心轴套的转数) 11

3.2.2 生产率 12

3.2.3 电动机功率N 12

3.3 破碎力 13

3.4 受力分析 16

4 电动机的选择及轴的计算 18

4.1 电动机的选择及传动比的分配 18

4.1.1 电动机的选择 18

4.1.2 传动比的分配 18

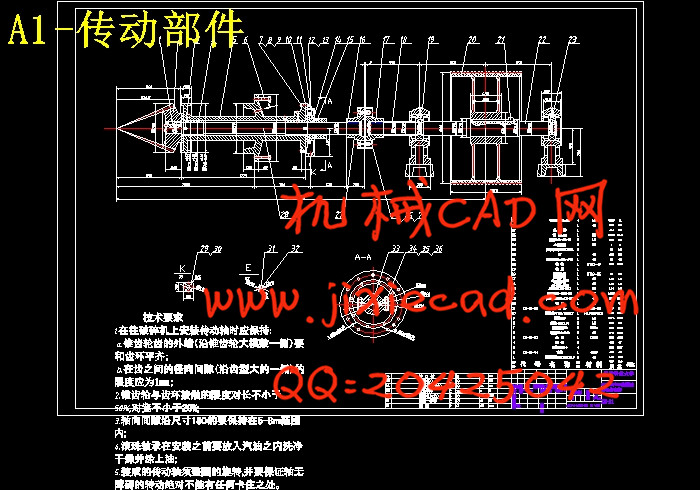

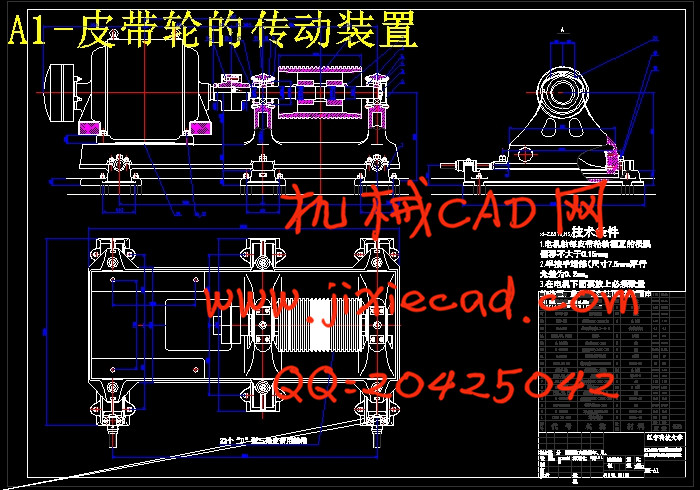

4.2 传动装置的选择与设计 18

4.2.1 转矩的计算 18

4.2.2 V带的传动设计计算 19

4.3 传动齿轮零件的设计计算 22

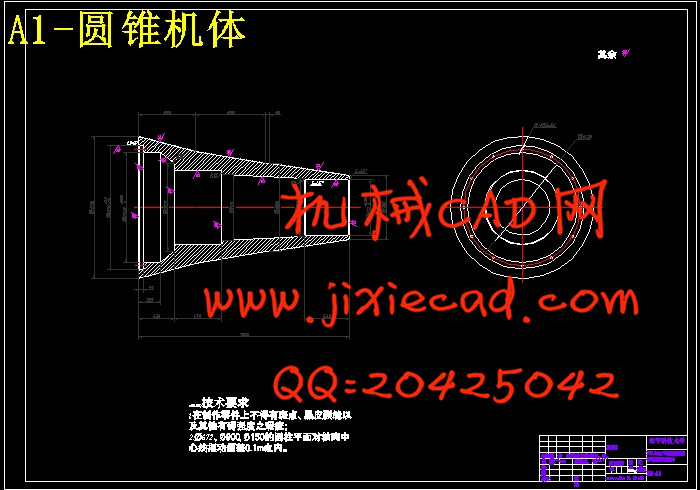

4.3.1 锥齿轮的计算 22

4.3.2 锥齿轮的校核 25

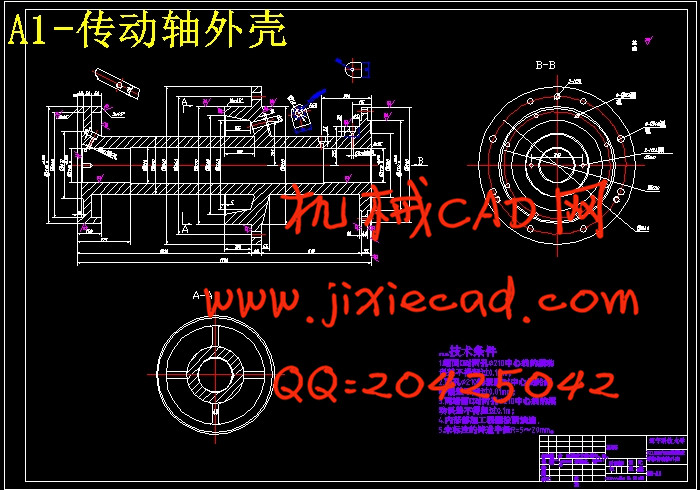

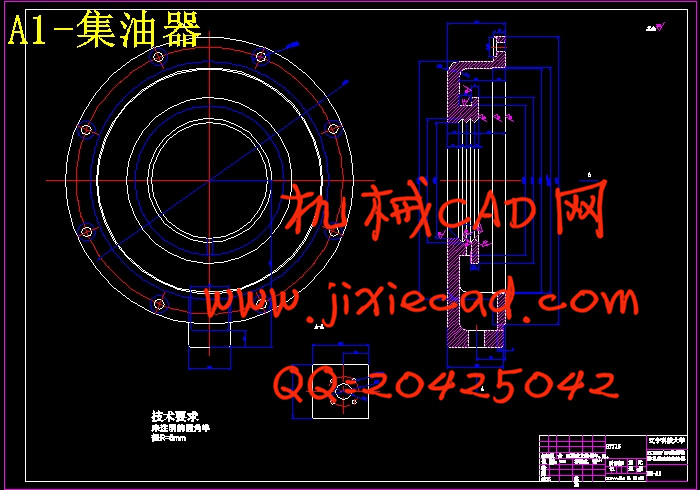

4.4 传动轴的设计计算 27

4.5 滚动轴承的选择和寿命验算 30

4.6 键的强度校核 31

4.6.1 传动轴上键的强度计算 31

4.6.2 主轴上键的强度计算 31

5 PX1200/250旋回破碎机的环保、可靠性与经济性分析 33

5.1 设备的环保措施 33

5.2 设备的可靠性 33

5.2.1 可靠性的计算 33

5.2.2 机械设备的有效度 34

5.3 设备的经济评价 34

5.3.1 投资回收期 34

5.3.2 盈亏平衡分析 35

5.3.3 设备合理的更新期 36

结 论 38

致 谢 39

参考文献 40

摘 要

新中国成立以来,随着采矿业的发展,选矿机械经历了从无到有、从小到大、从单个品种和规格到多个品种和规格的发展过程,各种选矿机械产品已经形成了系列,现在生产的各种形式和规格的破碎机、磨矿机和选矿机械,基本上能满足国民经济建设的需求,同时,在液压破碎机、反击式破碎机、离心选矿机等新产品的研制和新技术的应用方面都取得了一定的成就,但是,根据我国矿藏资源的特点(贫矿多、共生矿物多),选别的机械品种还不能完全满足新的选矿工艺的需要,特别需要发展一些适于对难选物的选别机械。旋回破碎机是利用破碎锥在壳体内腔中的旋回运动,对物料产生挤压和弯曲作用,粗碎各种硬度的矿石或岩石的大型破碎机械,装有破碎锥的主轴的上端支承在横梁中部的衬套内,其下端则置于轴套的偏心套中,轴套转动时,破碎锥绕机器中心线作偏心旋回运动,他的破碎动作是连续的,故工作效率高于颚式破碎机,旋回破碎机的工作是连续的,它与其他破碎机相比其优点是生产能力大,工作平稳,破碎单位重量矿石的耗量少,产品粒度比较均匀。

关键词:旋回破碎机;破碎;破碎锥

The design of PX1200/250 gyratory crusher

Abstract

Since new China had been established ,along with the mining industry development , the dressing machinery experienced has grown out of nothing, form infancy to maturity , from the single variety and the specification to many varieties and the specification developing process. Each kind of dressing mechanical product have already formed the series .Now each kind of pattern and specification breaker,the ore mail and classification machinery, basically can satisfy the need of the national economy construction, meanwhile, in the hydraulic pressure breaker, the counter-attack type breaker ,the centrifugal concentrator and so on, the new product development and the new technical application aspect have yielded the certain result. However, according to our country mineral resource characteristic(The lean ore are many associated mineral are many), classifies the machinery the variety not to be able completely to satisfy the new dressing craft the need ,particularly needs to develop some to be suitable for the difficult electing classification machinery.The gyratory crusher is the curing function, thick garrulous each kind of degree of hardness orator rock large-scale broken machinery which is loaded with the broken awl the main axle upper extreme supporting in the crossbeam bushing, its lower extremity sets to the axle sleeve center. When the axle sleeve rotates, the broken awl circles in the machine the core to make the biased cycle movement its broken movement is continuously carries on, hence the working efficiency is higher than the jaw type breaker. The gyratory crusher broken work is continual, it compares with other breakers, its merit is the high productivity , work steady, few crushing unit weight ore consumption quantity,and the uniform distribution equispaced product granularity .

Key words: The Gyratory crusher;Break;Cone

目 录

1 绪论 1

1.1 研究的目的和意义 1

1.2 国内外碎磨设备的简介 3

1.3 旋回破碎机的发展趋势 4

2 总体方案设计 5

2.1 旋回破碎机的类型 5

2.2 旋回破碎机的工作原理 5

2.3 旋回破碎机的构造 5

3 旋回破碎机的结构参数和工作参数的选择和计算 9

3.1 结构参数的选择和计算 9

3.1.1 给矿口尺寸与排矿口尺寸 9

3.1.2 啮角α 9

3.1.3 破碎锥的摆动行程s 10

3.1.4 基本结构尺寸的确定 10

3.2 工作参数的选择与计算 11

3.2.1 破碎锥的摆动次数n(偏心轴套的转数) 11

3.2.2 生产率 12

3.2.3 电动机功率N 12

3.3 破碎力 13

3.4 受力分析 16

4 电动机的选择及轴的计算 18

4.1 电动机的选择及传动比的分配 18

4.1.1 电动机的选择 18

4.1.2 传动比的分配 18

4.2 传动装置的选择与设计 18

4.2.1 转矩的计算 18

4.2.2 V带的传动设计计算 19

4.3 传动齿轮零件的设计计算 22

4.3.1 锥齿轮的计算 22

4.3.2 锥齿轮的校核 25

4.4 传动轴的设计计算 27

4.5 滚动轴承的选择和寿命验算 30

4.6 键的强度校核 31

4.6.1 传动轴上键的强度计算 31

4.6.2 主轴上键的强度计算 31

5 PX1200/250旋回破碎机的环保、可靠性与经济性分析 33

5.1 设备的环保措施 33

5.2 设备的可靠性 33

5.2.1 可靠性的计算 33

5.2.2 机械设备的有效度 34

5.3 设备的经济评价 34

5.3.1 投资回收期 34

5.3.2 盈亏平衡分析 35

5.3.3 设备合理的更新期 36

结 论 38

致 谢 39

参考文献 40