设计简介

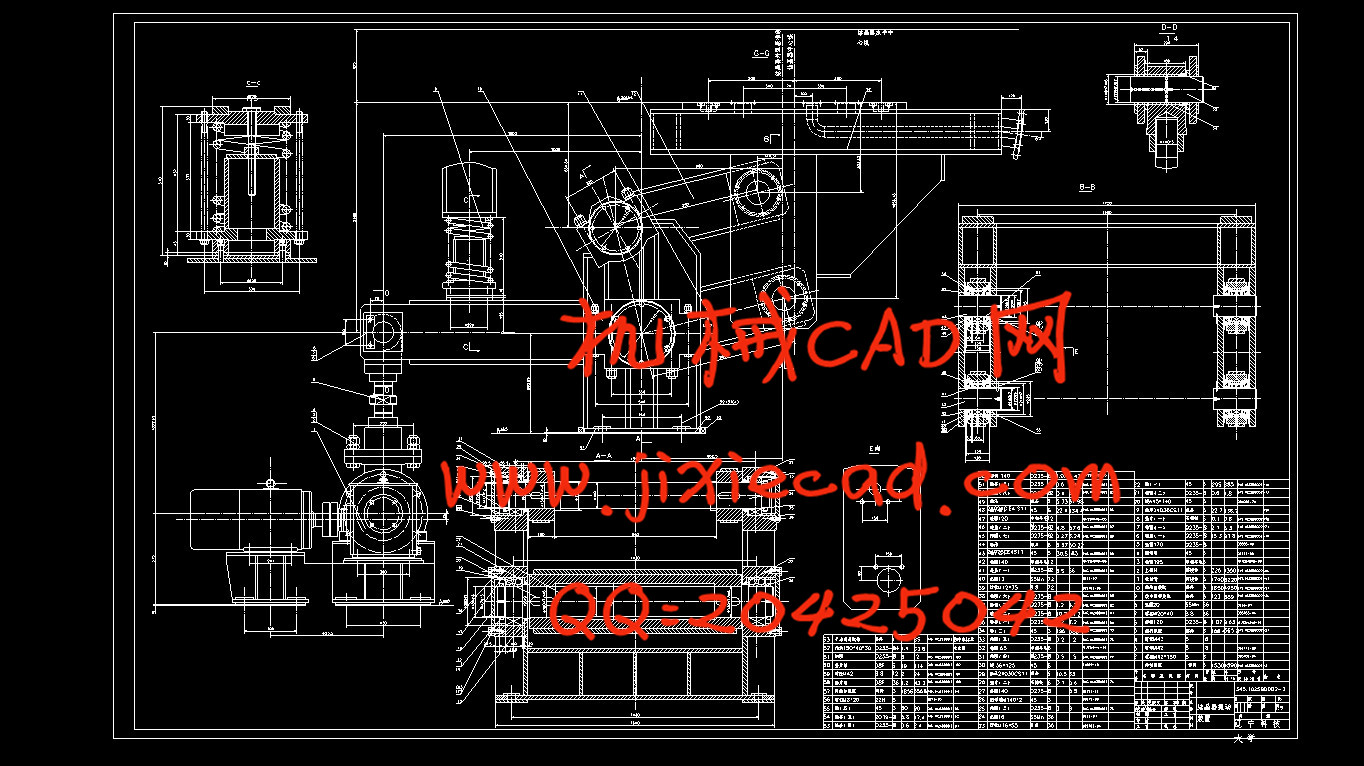

双摇杆式结晶器振动装置的设计

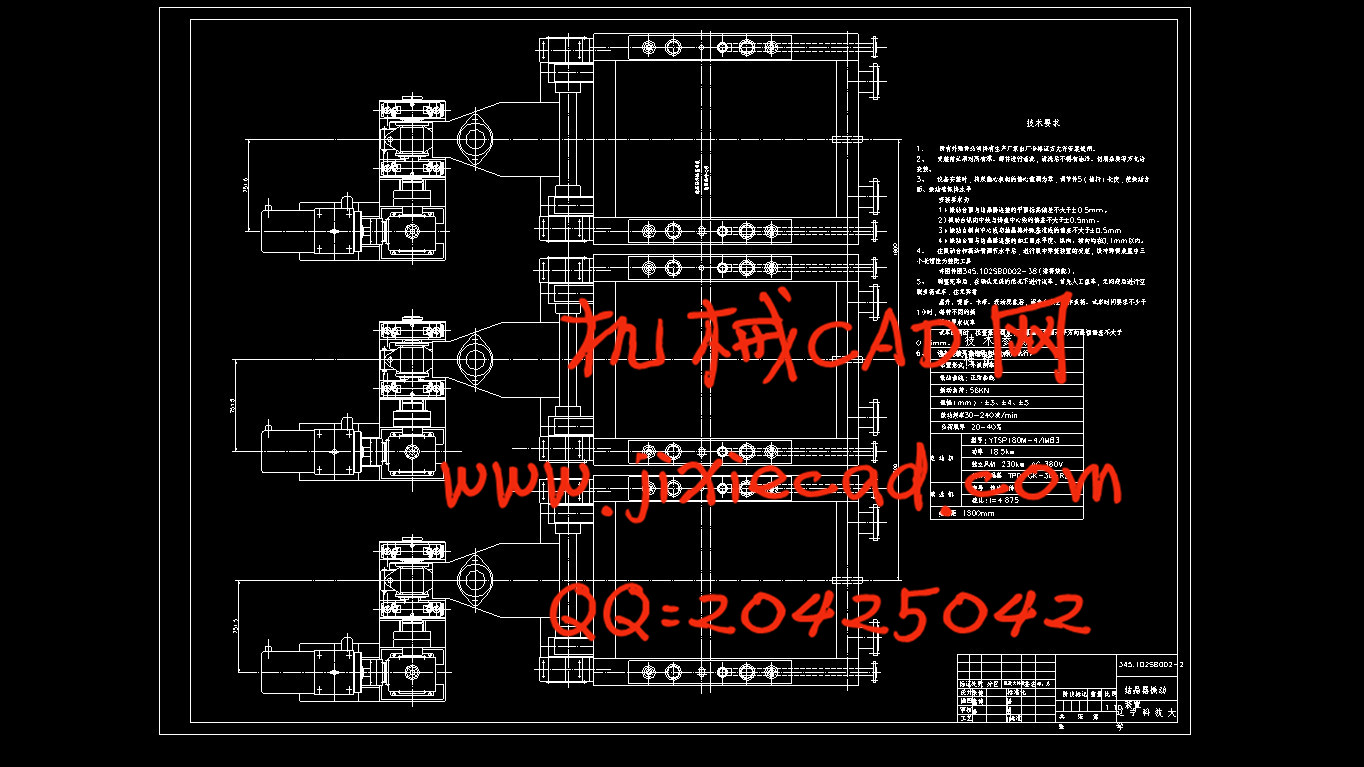

摘要结晶器振动装置是连铸机的重要设备之一,起主要作用是使内壁获得良好的润滑条件,减少摩擦力,防止钢水与内壁的粘结,同时还可以改善铸坯的表面质量。而且发生粘结是,振动能强制脱模,消除粘结。振动机构是使结晶器产生所需的振动,因此任何振动机构都必须满足两个基本条件:第一,使结晶器准确地沿着一定的轨迹振动。第二,使结晶器有一定的振动规律。

本文详细地介绍了结晶器振动方式,并加以比较后,振动变化规律选择正弦振动方式。结晶器振动装置的结构,根据方案讨论提出采用双摇杆式结晶器振动装置。结果表明该振动方式能有效地防止因坯壳的粘结而造成的拉漏等事故,振动机构能准确实现圆弧轨迹,不产生过大的加速度,从而避免了冲击和摆动。此机构的振动参数有利于改善铸坯表面质量,形成表面光滑的铸坯,而且设备的制造,安装和维护方便,并且便于处理事故,使传动系统有足够的安全储备。

关键词:连铸;结晶器;振动装置;正弦

Double rocking lever type crystallizer shake-out equipment design

Abstract

Crystal vibrator is one of important equipment of continuous casting machine, play a major role is to get a good wall lubrication, reduce friction, prevent adhesion of molten steel in the inner wall, while also improving the billets surface quality. And when bonding occurs, the vibration can be forced stripping, erased. Vibration body is needed to mold the vibration generated, so any vibration institution must meet two basic conditions: first, to mold accurately track down some vibration. Second, make sure the laws of the mold according to the vibration.

This article introduced in detail the crystallizer vibration way, after and compares, vibration change rule choice sinusoidal vibration way. The crystallizer shake-out equipment's structure, according to the plan discussion proposed that uses the double rocking lever type crystallizer shake-out equipment design. The result indicated that this vibration way can prevent to pull effectively leaks and so on accidents which creates because of the semifinished product shell's caking, the vibrator unit can realize the circular arc path accurately, does not have the oversized acceleration, thus has avoided the impact and swinging. This organization's vibration parameter is advantageous in the improvement casts the semifinished product surface quality, forms the surface smoothly to cast the semifinished product, moreover equipment's manufacture, the installment and the maintenance are convenient, and is advantageous for the deal with accident, enables the transmission system to have the enough safety margin.

Key words: Continuous casting; Crystallizer; Shake-out equipment; Sine

目 录

摘要 I

Abstract II

1 绪论 1

1.1 选题背景及目的 1

1.2 国内外研究状况 1

1.2.1 50年代工业应用时期 2

1.2.2 60年代稳步发展时期 2

1.2.3 70年代以后的迅猛发展时期 3

1.2.4 80年代连铸完全成熟时期 4

1.3 设计的内容 5

2 总体方案设计选择 7

2.1 结晶器振动装置的技术要求 7

2.2 结晶器振动装置的类型和特点 8

2.2.1 振动方式 8

2.2.2 振动机构 10

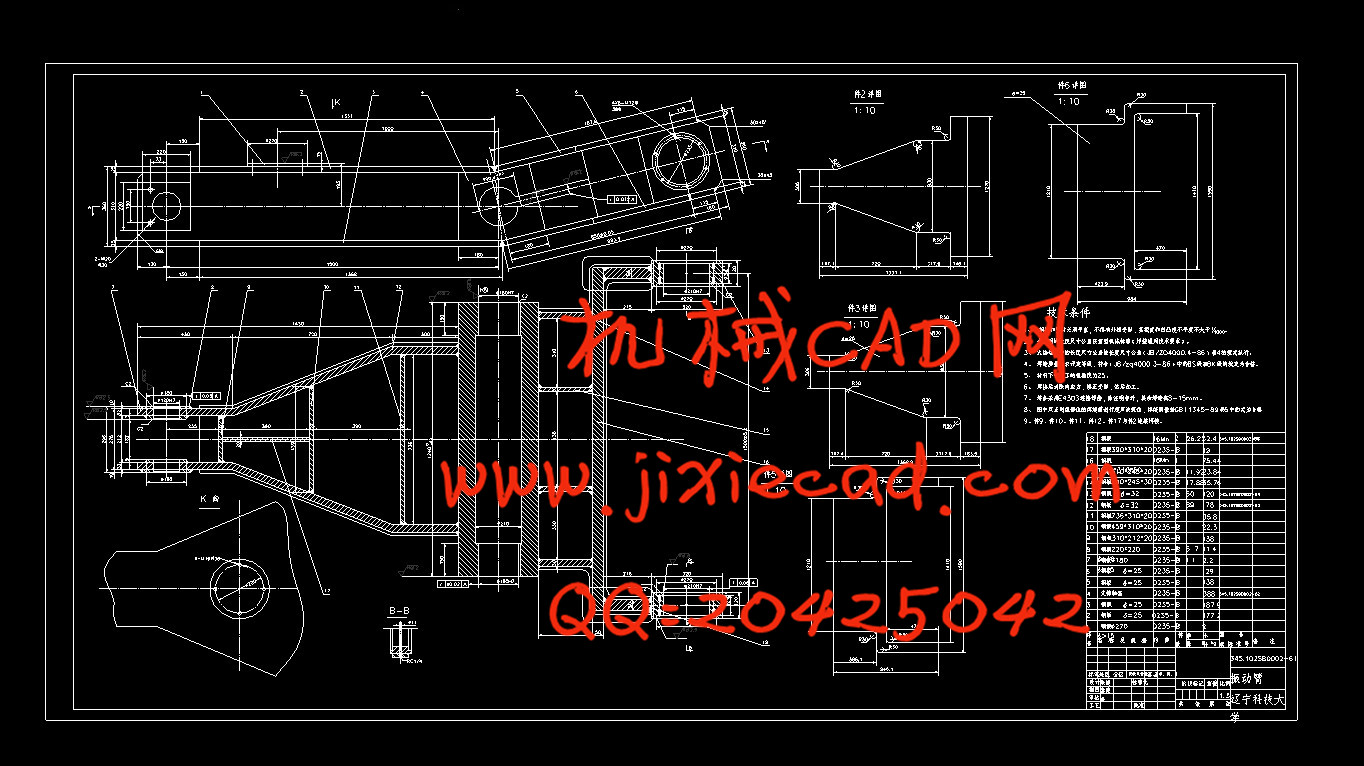

3 技术参数计算 13

3.1 短臂四连杆机构原理 13

3.2 弹簧的设计 16

3.3 振幅的计算 17

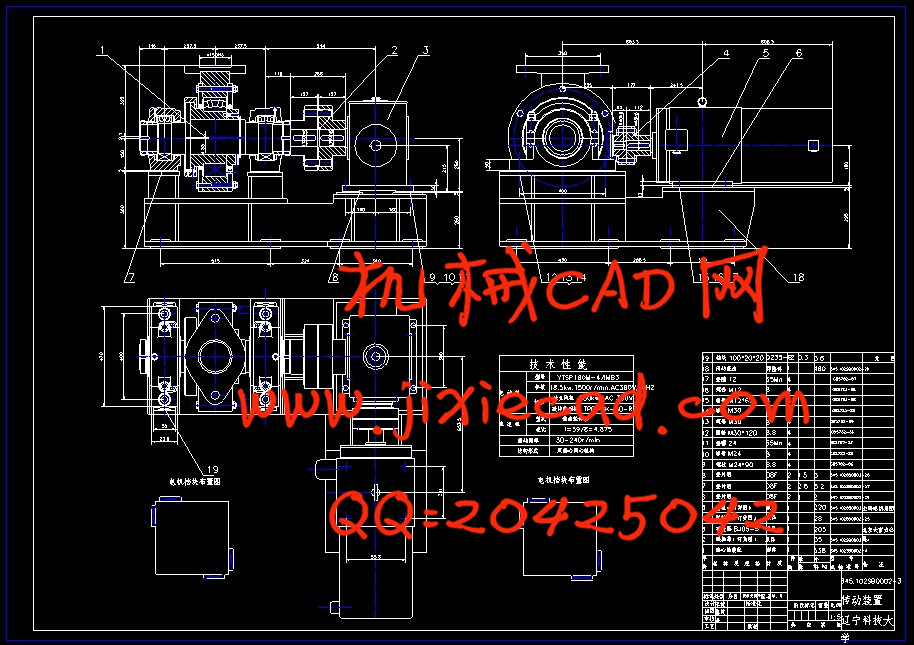

4 主传动装置设计 20

4.1 电机的选择 20

4.2 轴的设计 21

4.3 联轴器的设计 27

4.4 减速器的设计 30

5 零部件的校核 31

5.1 弹簧校核 31

5.2 销轴的校核 33

5.3 电机的校核 35

5.4 轴的校核 36

6 能源消耗与环保分析 40

结束语 41

致谢 42

参考文献 43