设计简介

十三辊钢板矫正机压下系统设计

摘 要

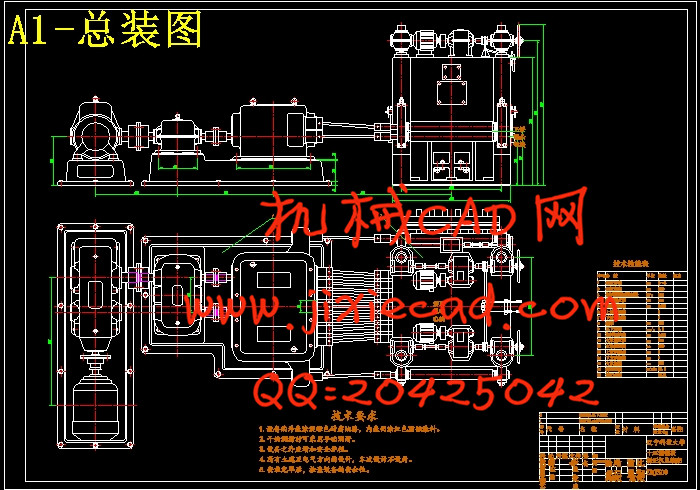

轧钢生产是冶金生产行业中把钢坯轧制成钢材的重要生产环节,具有产量大、品种齐全、生产过程机械化自动化程度高等优点。但是轧件在轧制、冷却和运输过程中,受到不同因素的影响而产生形状缺陷。例如钢轨、型钢和钢管常出现弧形弯曲;某些型钢的面会产生翼缘内并、外扩和扭转;板材和带材容易产生横纵向弯曲、边缘浪形和中间瓢曲以及镰刀弯等。为了消除这些缺陷,矫正技术应运而生。根据本次设计要求,设计了十三辊钢板矫正机压下系统。查阅相关资料,完成绪论及总体方案评述,并对矫正机的压下系统进行设计。主要内容包括:矫正机的结构确定和力能参数计算、主传动电机和压下电动机的选择及校核、选择联轴器和分配减速器、压下螺丝和压下螺母的设计及校核、蜗轮蜗杆的设计及校核、轴承的寿命计算和键的选择及校核。关键词:矫正机;压下系统;力能参数;蜗轮蜗杆

Thirteen roller pressure plate straightening machine system design

Abstract

Production of steel rolling is the billet rolling ChengGangCai in metallurgical industry of the important production link, has a large production, variety complete, high mechanization of production process automation. But the rolled piece in the process of rolling, cooling and transportation, influenced by different factors and produce shape defect. Such as rail, steel and steel pipe often appear arc bending; Some steel surface will produce flange inside and outside, expansion and reverse; Plate and strip are easy to produce transverse buckling, edge wave shape and intermediate ladle and rocker. In order to eliminate these defects, the correction technology emerges as The Times require. According to the design requirements, design the thirteen roller plate straightening machine system under pressure. Refer to related information, complete the introduction and the overall scheme are reviewed, and the system of the straightening machine design. Main content includes: the structure of the straightening machine can determine and force parameters calculation, selection of main drive motor and motor under pressure and checking, selecting coupling and the distribution of reducer, pressure under the screw and nut design and checking, the design of the worm and worm wheel and check, bearing life calculation and selection of key and the check.

Keywords:Straightening machine; Press down system; Can force parameters; Worm gear and worm

目录Production of steel rolling is the billet rolling ChengGangCai in metallurgical industry of the important production link, has a large production, variety complete, high mechanization of production process automation. But the rolled piece in the process of rolling, cooling and transportation, influenced by different factors and produce shape defect. Such as rail, steel and steel pipe often appear arc bending; Some steel surface will produce flange inside and outside, expansion and reverse; Plate and strip are easy to produce transverse buckling, edge wave shape and intermediate ladle and rocker. In order to eliminate these defects, the correction technology emerges as The Times require. According to the design requirements, design the thirteen roller plate straightening machine system under pressure. Refer to related information, complete the introduction and the overall scheme are reviewed, and the system of the straightening machine design. Main content includes: the structure of the straightening machine can determine and force parameters calculation, selection of main drive motor and motor under pressure and checking, selecting coupling and the distribution of reducer, pressure under the screw and nut design and checking, the design of the worm and worm wheel and check, bearing life calculation and selection of key and the check.

Keywords:Straightening machine; Press down system; Can force parameters; Worm gear and worm

1.绪论 1

1.1 课题研究的背景和意义 1

1.2矫正机的发展概况 1

1.3辊式矫正机的工作原理和结构组成 2

1.4辊式矫正机的类型及用途 3

1.5本论文研究内容 3

2.总体方案 4

2.1矫正方案及矫正工艺 4

2.1.1矫正方案 4

2.1.2矫正工艺 4

2.2矫正机结构组成 5

2.2.1机座形式 5

2.2.2主传动机构简介 5

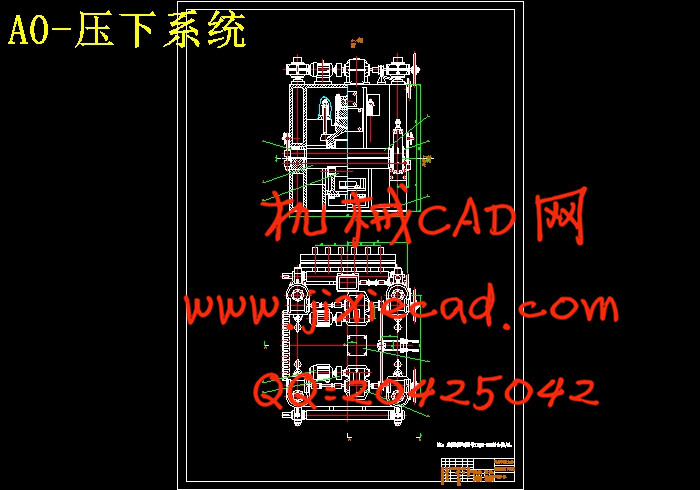

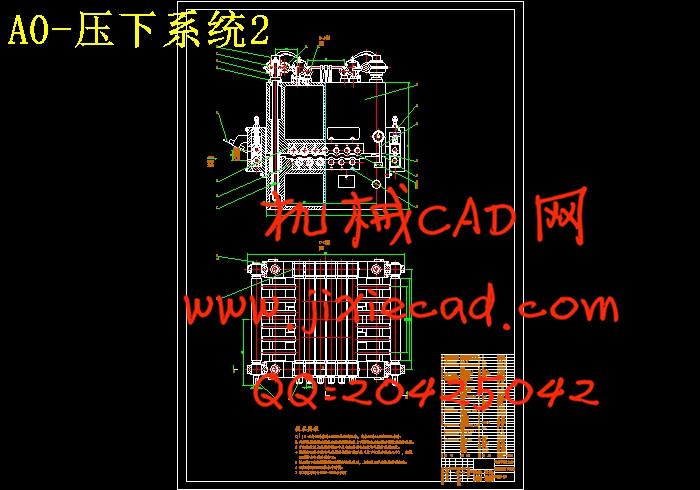

2.2.3压下机构组成和作用 7

2.2.4矫正辊的布置形式 8

3.矫正机结构参数的确定和电机的选择 9

3.1矫正机的结构参数的确定 9

3.1.1辊距和辊径的确定 9

3.1.2矫正辊辊颈直径的确定 11

3.1.3矫正辊传动端的尺寸确定 11

3.2矫正机的力能参数的计算 12

3.2.1作用在矫正辊上的压力(矫正力) 12

3.2.2作用在矫正辊上的矫正扭矩 15

3.3矫正机主电机的选择 16

3.3.1主传动电机功率的确定 16

3.3.2主电机的选择 17

3.3.3主电机过载校核 17

3.4作用在螺丝上的最大矫正力的确定 19

3.5压下电机选择及校核 19

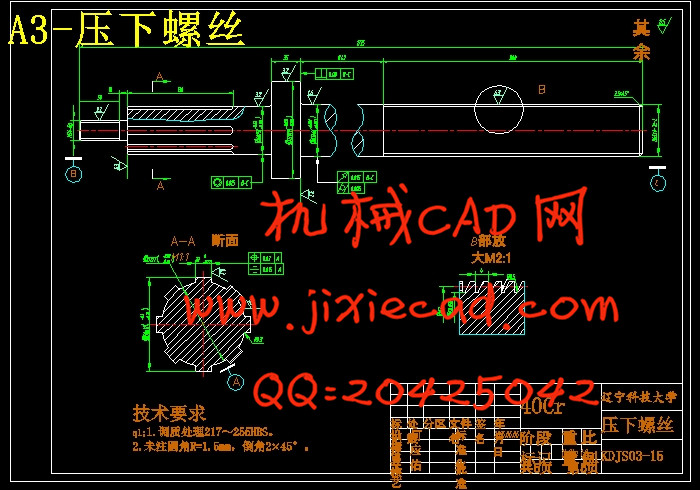

3.5.1压下螺丝的设计 19

3.5.2压下电机功率的计算 21

3.5.3选择压下电机 22

3.5.4电机过载校核 22

4.传动系统设计 24

4.1传动比分配 24

4.2圆柱齿轮减速器的选择 24

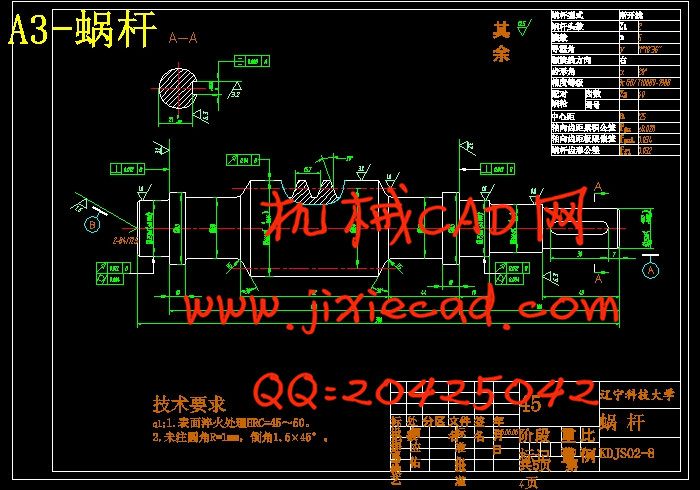

4.3蜗轮蜗杆的设计与校核 24

4.3.1蜗轮蜗杆的设计 24

4.3.2蜗杆的校核 28

4.4蜗杆轴的强度校核 29

5.零、部件的设计与校核 34

5.1压下螺母的设计与校核 34

5.1.1设计压下螺母的高度和外径 34

5.1.2压下螺母的校核 35

5.2圆锥滚子轴承使用寿命计算 36

5.3键的选择及校核 38

5.4联轴器的选择 38

6.润滑方式的选择 40

6.1矫正辊的润滑 40

6.2圆柱齿轮减速机的润滑 40

6.3蜗轮蜗杆的润滑 40

6.4压下螺丝(螺母)的润滑 41

7.设备的可靠性与经济分析 42

7.1设备的可靠性 42

7.2技术经济分析方法 43

7.3设备的经济性分析 44

结 论 46

致 谢 47

参考文献 48