设计简介

1780R2粗轧机压下系统设计

摘要

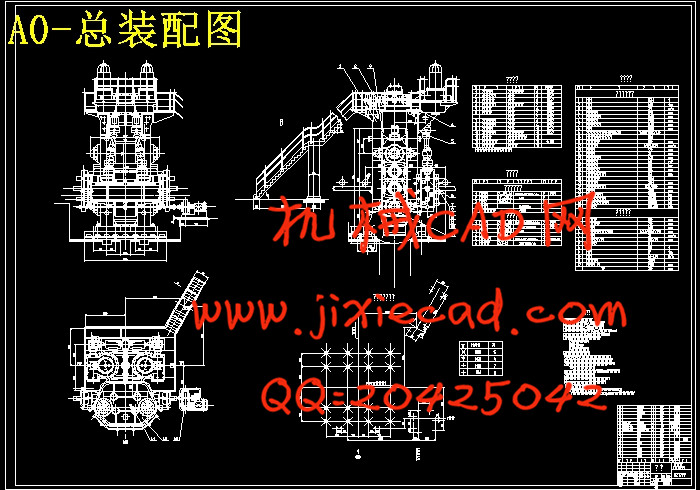

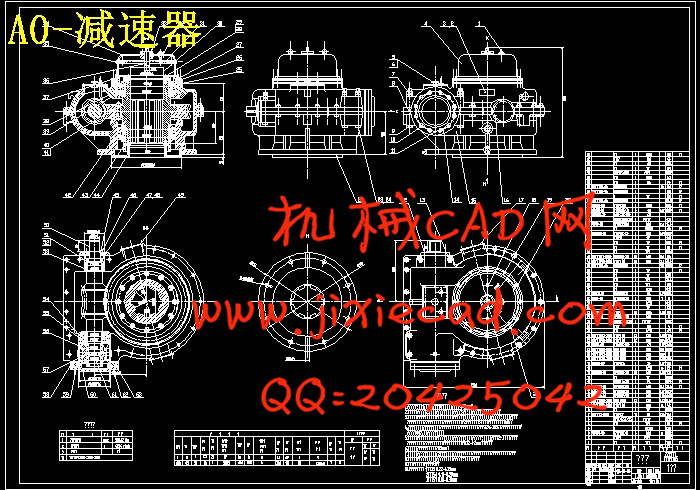

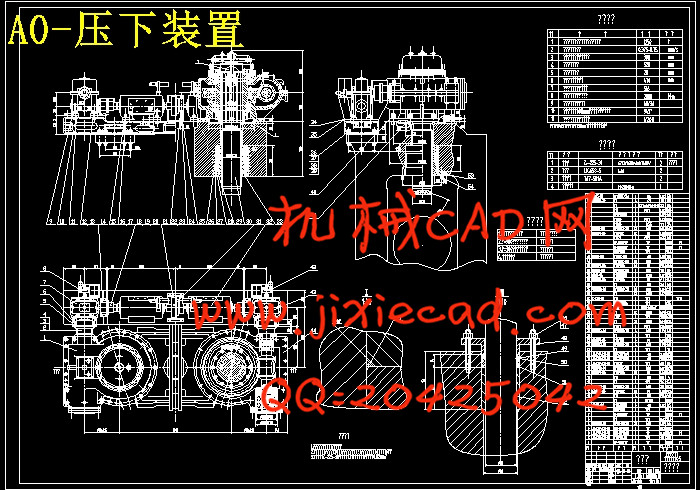

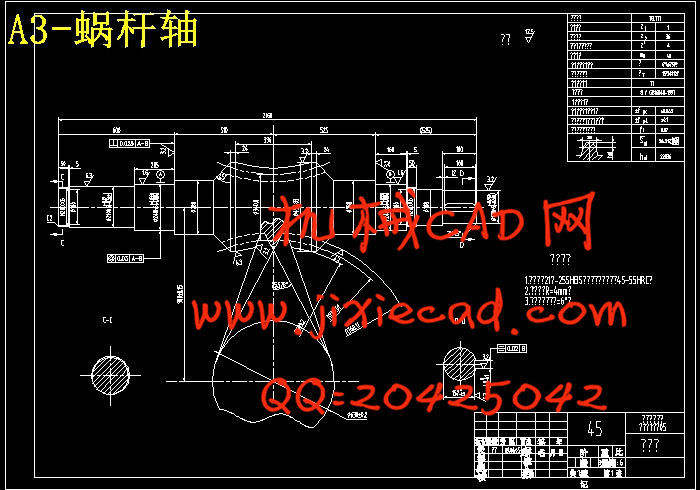

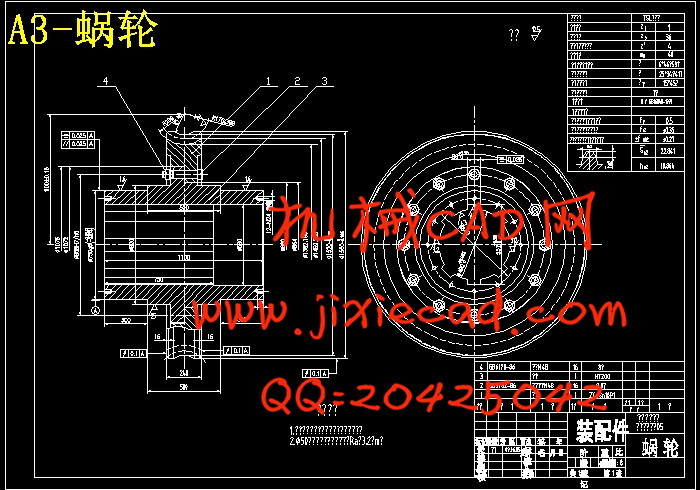

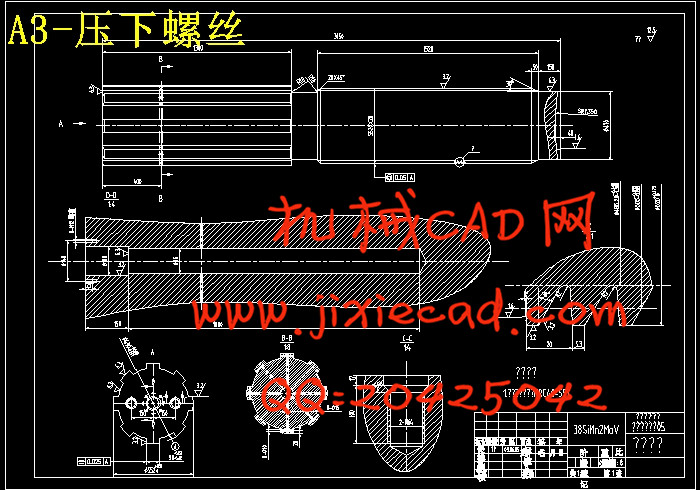

随着钢铁工业的不断发展,轧机作为作为主要的轧钢设备也在不断的更新和发展。1780热带钢连轧机是现代热带钢连轧机的典型代表。其粗轧机采用电动压下系统。结构简单、维护方便、调整范围大、调整迅速。能满足轧制精度的要求。本文对1780R2粗轧机压下系统进行了系统的设计计算,主要介绍了轧钢技术国内外的发展概况和热带钢连轧机的现状及发展趋势,并且系统的分析比较了各种压下系统的优缺点。最终确定了1780R2粗轧机压下系统的最优设计方案。在此基础上,对压下系统进行了设计计算。主要包括压下电机的容量选择、直线环面蜗杆减速器基本尺寸的设计计算、蜗杆轴的强度校核、压下螺丝和螺母的强度校核及轧机机架的强度校核。本文还简要介绍了润滑方式的选择、安装试车规程以及经济性和环保性的分析等。构成了完整的压下系统设计。

关键字:热带钢连轧机;轧钢技术;压下系统;强度校核

The Design of Pressure System of 1780R2 Rude Rolling Mill

Abstract

With the continuous development of the iron and steel industry, mills as the major rolling equipment are also continuously updating and developing. 1780 hot strip rolling mill is a typical of hot strip rolling mill in modern. Its rude rolling mill use of electric pressure system, it has the simple structure, the easy maintenance, large adjustment range and the rapid adjustment. It can meet the accurate requirement of 1780R2 rude rolling mill in the paper, it mainly introduces the rolling technology developments at home and abroad hot strip rolling mill of the status and the development trend, and systematically analysis the advantages and disadvantages of the pressure system. Eventually determine the options of optimal of design system of 1780R2 rude rolling mill. It carried on designing and calculating to the pressure system in this foundation, it including of the options of pressure motor of capacity, the calculation of linear-toroidal worm of reducer basic size, the strength checking of worm axis, the strength checking of adjusting screw and nut and the strength checking of mill housing . Also gave a brief account of the choice of mode lubrication, test order and the analysis of economic and environmental in the paper, and so on. Constituted an integrity of design of pressure system.

Keywords: hot strip rolling mill; rolling technique; pressure system; the strength checking

目录

1.绪 论 1

1.1.轧钢技术国内外发展概况 1

1.2.热带钢连轧机的现状及发展趋势 2

1.3.实习厂情况介绍(主要设备、产品品种、工艺流程、工厂平面布置图) 3

1.4研究内容及设计方法 5

2.方案设计 6

3.设计计算 9

3.1压下电机容量的选择 9

3.1.1被平衡件重量的计算 9

3.1.2 转动压下螺丝静力矩的计算 9

3.1.3 压下电机容量的选择 12

3.2 压下装置传动机构的设计 13

3.2.1 蜗杆传动的设计计算 13

3.2.2蜗杆轴的强度计算(第二级减速器蜗杆轴) 25

3.2.3 压下螺丝螺母的强度计算 31

3.3机架的强度计算 34

3.3.1机架的结构尺寸 34

3.3.2受力及其力矩 35

4.润滑方式的选择 40

5.安装试车规程 41

6.经济性与环保性分析 42

6.1经济性分析 42

6.1.1经济寿命的计算 42

6.1.2经济设备大修期确定 44

6.2环保性分析 47

结束语 49

致谢 50

参考文献 51

摘要

随着钢铁工业的不断发展,轧机作为作为主要的轧钢设备也在不断的更新和发展。1780热带钢连轧机是现代热带钢连轧机的典型代表。其粗轧机采用电动压下系统。结构简单、维护方便、调整范围大、调整迅速。能满足轧制精度的要求。本文对1780R2粗轧机压下系统进行了系统的设计计算,主要介绍了轧钢技术国内外的发展概况和热带钢连轧机的现状及发展趋势,并且系统的分析比较了各种压下系统的优缺点。最终确定了1780R2粗轧机压下系统的最优设计方案。在此基础上,对压下系统进行了设计计算。主要包括压下电机的容量选择、直线环面蜗杆减速器基本尺寸的设计计算、蜗杆轴的强度校核、压下螺丝和螺母的强度校核及轧机机架的强度校核。本文还简要介绍了润滑方式的选择、安装试车规程以及经济性和环保性的分析等。构成了完整的压下系统设计。

关键字:热带钢连轧机;轧钢技术;压下系统;强度校核

The Design of Pressure System of 1780R2 Rude Rolling Mill

Abstract

With the continuous development of the iron and steel industry, mills as the major rolling equipment are also continuously updating and developing. 1780 hot strip rolling mill is a typical of hot strip rolling mill in modern. Its rude rolling mill use of electric pressure system, it has the simple structure, the easy maintenance, large adjustment range and the rapid adjustment. It can meet the accurate requirement of 1780R2 rude rolling mill in the paper, it mainly introduces the rolling technology developments at home and abroad hot strip rolling mill of the status and the development trend, and systematically analysis the advantages and disadvantages of the pressure system. Eventually determine the options of optimal of design system of 1780R2 rude rolling mill. It carried on designing and calculating to the pressure system in this foundation, it including of the options of pressure motor of capacity, the calculation of linear-toroidal worm of reducer basic size, the strength checking of worm axis, the strength checking of adjusting screw and nut and the strength checking of mill housing . Also gave a brief account of the choice of mode lubrication, test order and the analysis of economic and environmental in the paper, and so on. Constituted an integrity of design of pressure system.

Keywords: hot strip rolling mill; rolling technique; pressure system; the strength checking

目录

1.绪 论 1

1.1.轧钢技术国内外发展概况 1

1.2.热带钢连轧机的现状及发展趋势 2

1.3.实习厂情况介绍(主要设备、产品品种、工艺流程、工厂平面布置图) 3

1.4研究内容及设计方法 5

2.方案设计 6

3.设计计算 9

3.1压下电机容量的选择 9

3.1.1被平衡件重量的计算 9

3.1.2 转动压下螺丝静力矩的计算 9

3.1.3 压下电机容量的选择 12

3.2 压下装置传动机构的设计 13

3.2.1 蜗杆传动的设计计算 13

3.2.2蜗杆轴的强度计算(第二级减速器蜗杆轴) 25

3.2.3 压下螺丝螺母的强度计算 31

3.3机架的强度计算 34

3.3.1机架的结构尺寸 34

3.3.2受力及其力矩 35

4.润滑方式的选择 40

5.安装试车规程 41

6.经济性与环保性分析 42

6.1经济性分析 42

6.1.1经济寿命的计算 42

6.1.2经济设备大修期确定 44

6.2环保性分析 47

结束语 49

致谢 50

参考文献 51