设计简介

1800移动式型钢冷锯机设计

关键字:冷锯机;传动;锯切

Design of the 1800 travelling cold saw for shape steel

Keywords: cold saw;transmission; sawing

目 录摘 要

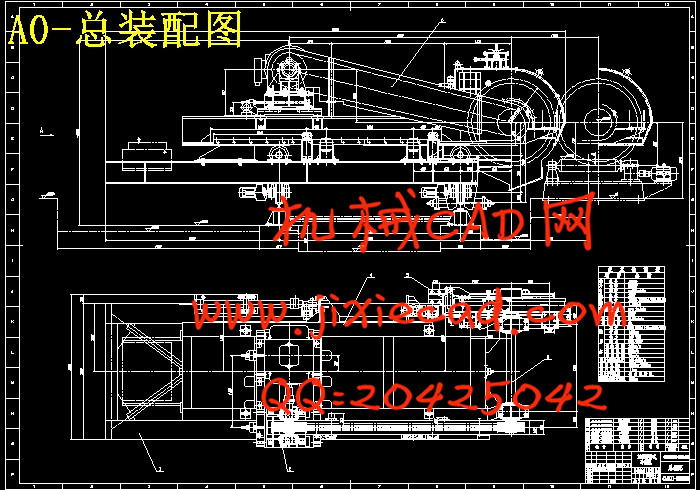

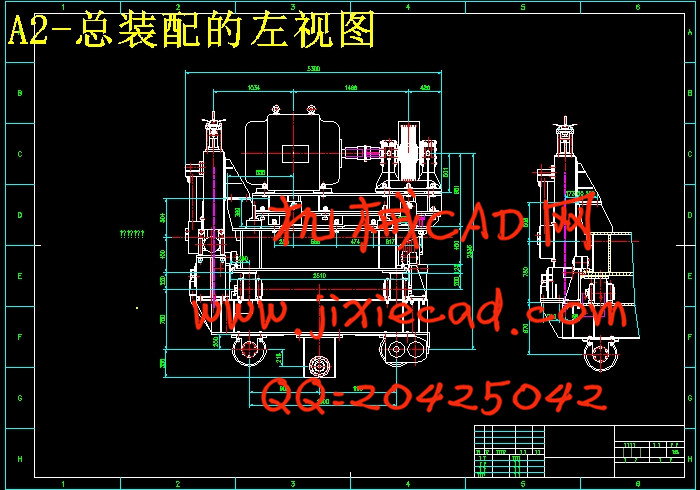

锯机作为一种切割类型的机械设备,它在木工机械、建筑机械、冶金机械等方面得到了广泛的应用。锯机是切割系统中不可缺少的重要组成部分。由于冷锯机在一定程度上提高了锯切断面质量和定尺精度,所以现在的大型和中型型钢轧钢厂多采用冷锯机进行轧件的切头、切尾和定尺锯切。移动式冷锯机的主要结构有三部分:锯片传动机构、锯片送进机构和调整定尺的锯机横移机构。此设备的锯片传动机构是电动机经三角皮带方式传动,这种传动方式可使电动机远离锯切点,减省专门的防护措施。锯片送进机构采用液压传动方式,液压传动可以保证锯片在锯切时能够稳定送进,减少振动。锯机横移机构由电动机直接传动,当设备根据定尺要求移动到规定位置时,用夹轨器将设备固定,然后完成锯切。本文论述了冷锯机设备在国内、外的发展状况,提出了本课题的研究背景以及研究本课题的意义;设计主要是围绕移动冷锯机主轴传动机构、进锯机构、走行机构的分析和设计进行的,通过对各个机构的功率计算,选择合适的电机并进行校核,同时对各个重要零件进行校核,以满足锯切要求。关键字:冷锯机;传动;锯切

Design of the 1800 travelling cold saw for shape steel

Abstract

As a kind of incision equipment, the saw is used comprehensively in the fields of woodwork mechanism, architecture mechanism, metallurgy mechanism and so on. It is the indispensable and important equipment of the incision system. In order to improve the section quality and length accuracy, nowadays, the large and medium rolling mill for shape steel gradually replaces the heat with cold saw machine for the cutting head, tail and length of rolling. There are three main structural parts for the mobile cold saw: the mechanism for saw transmission, the mechanism for saw movement, the mechanism for adjusting length of the rolling. The first part is a motor driven mechanism by means of triangular belt driving, which can keep the motor away from the sawing to reduce the special protective measures. The second part uses hydraulic transmission, which insures the stability and reduce vibration when rolling is sawing. The third part is driven by motor directly. This equipment starts working when it is fixed by rail holder in accordance with the request. In this paper, I introduce the development of the travelling cold saw in domestic and foreign, and tell the research background as well as the significance of studying this subject. This design will focus on the analysis of the spindle drive mechanism, the mechanism for saw movement and the moving mechanism. Through the power calculation of every mechanism, I select the appropriate motor and check it as well as all important parts to meet the requirements.Keywords: cold saw;transmission; sawing

摘要 I

Abstract II

第1章 绪论 1

1.1 毕业设计的选题背景及目的 1

1.1.1 毕业设计的选题背景 1

1.1.2 毕业设计的目的 1

1.2 冷锯机的发展概述 1

1.3 冷锯机的用途及类型 2

1.4 冷锯机的结构 2

1.5 存在的问题 3

1.6 主要设计研究的内容 3

第2章 冷锯机总体方案设计 4

2.1 冷锯机的结构型式及工作过程 4

2.2 冷锯机的基本参数 5

2.3 锯齿形状和锯片材料 7

2.4 锯片结构参数的设计 8

2.5 高速冷锯机锯切功率计算 9

第3章 带传动的设计及锯切力计算 14

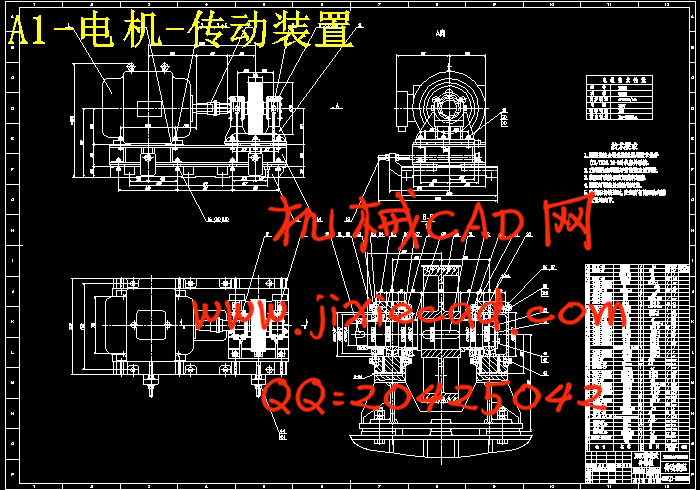

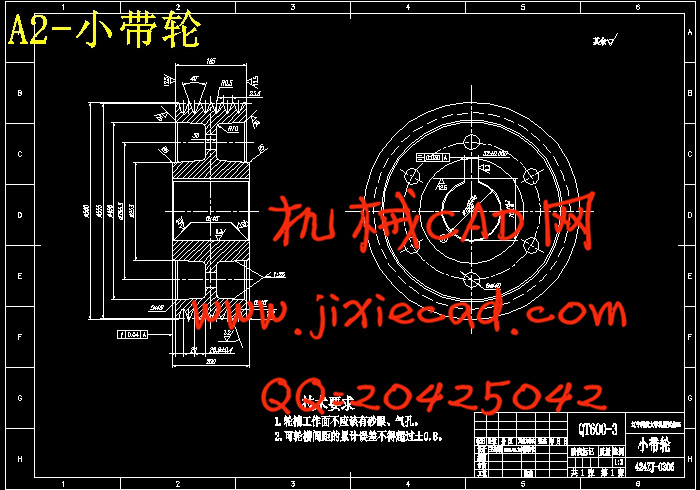

3.1 V带的设计 14

3.2 锯切力的计算 16

第4章 轴的设计和强度校核 20

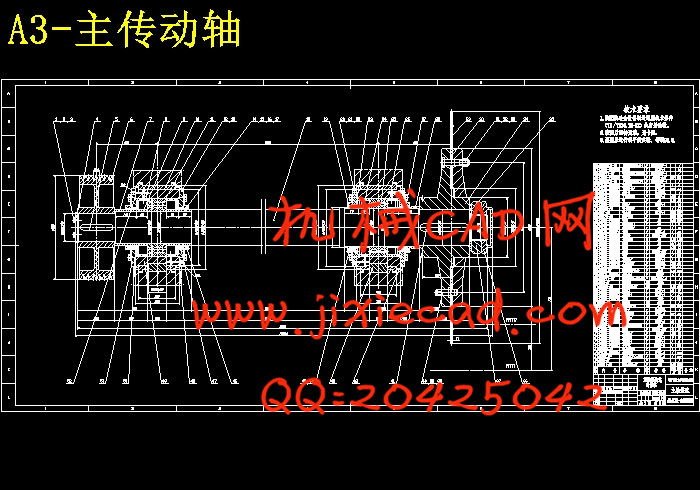

4.1 主传动轴的设计和强度校核 20

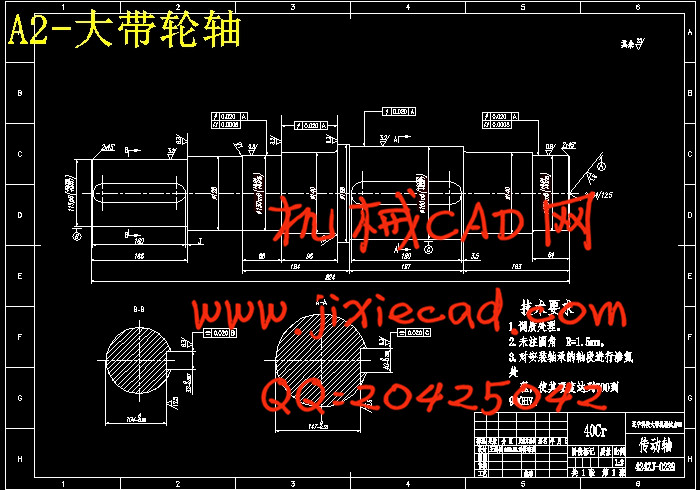

4.2 大带轮轴的强度校核 24

第5章 送锯和走行机构的设计计算 29

5.1 进锯机构的设计计算 29

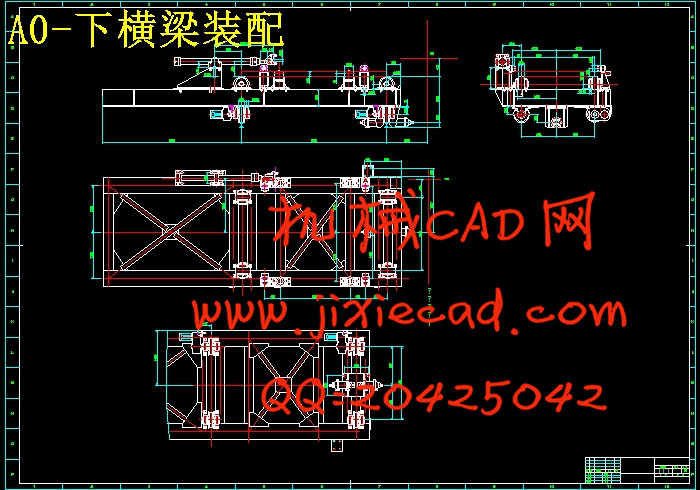

5.2 走行机构的设计计算 30

第6章 联轴器、键、轴承的选择与校核 32

6.1 联轴器的选择和计算 32

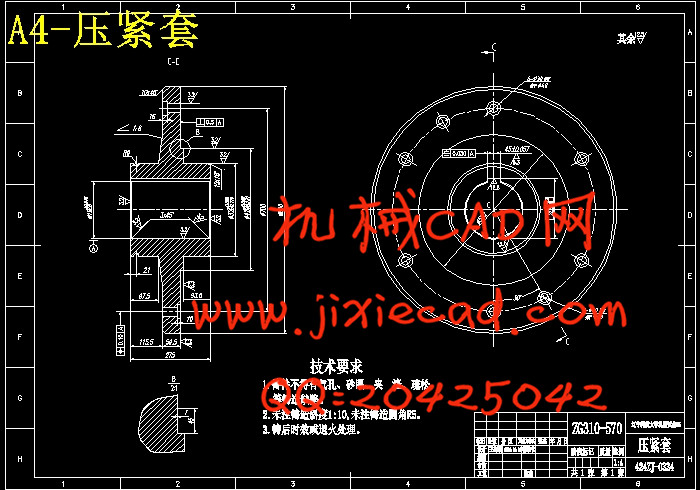

6.2 键的选择和键连接强度计算 32

6.3 轴承的选择与校核 34

6.3.1 主传动轴轴承的选择与校核 34

6.3.2 大带轮轴轴轴承的选择与校核 36

第7章 设备的润滑、密封及维护 38

7.1 设备的润滑 38

7.1.1 润滑的作用 38

7.1.2 润滑的种类 38

7.1.3 润滑方式的选择 39

7.2 设备的密封 39

7.3 设备维护 39

第8章 设备的环保和经济可行性分析 41

8.1 设备的环保 41

8.1.1 冷锯机噪声主要来源 41

8.1.2 噪声控制方案与措施 41

8.2 经济可行性分析 43

总结 45

致谢 46

参考文献 47