设计简介

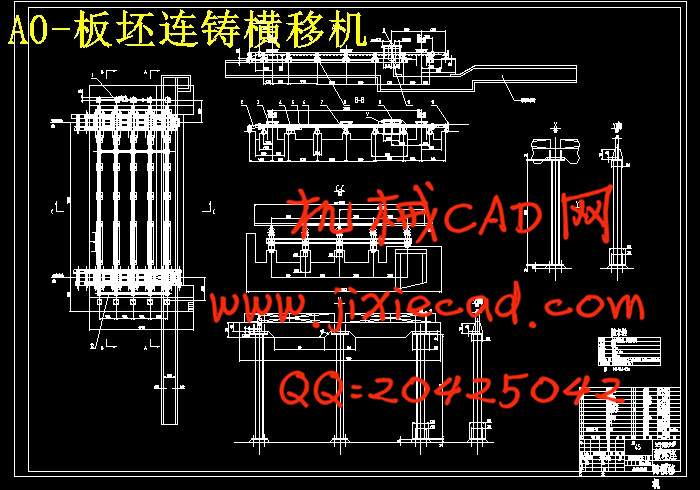

板坯连铸横移机设计

摘要

连续铸钢的出现和发展,大大地缩短了工艺流程,极大地简化了轧钢生产的工艺系统,与传统的模铸坯-初轧开坯相比、省去了脱模、整模、均热初轧和连轧开坯等一系列工序和对应的设备。这不仅明显降低了能耗,并且大大节省了设备投资和生产投资。

鞍钢集团公司炼钢厂的连铸技术已达到国内外先进水平,连铸的特点是将高温钢水连续不断的浇注成具有一定断面形状和一定尺寸规格的铸坯,并具有了提高综合成材率、降低能耗、产品的均一性好、质量高、易于实现机械化自动化等显著特点。但是随着事成竞争的逐渐激烈,板坯连铸机的优化与改良就成了提高板坯质量、占领市场的重要环节。因此,本人通过大量的实地调研、现场学习、仔细询问观看,对连铸机相关设备(板坯横移机)的结构与性能有了一个深入的认识。并运用自己所学的知识,从动力学、机械原理、经济学等诸多方面对连铸机中的板坯横移机进行设计,使其更加适用于新市场的形势。

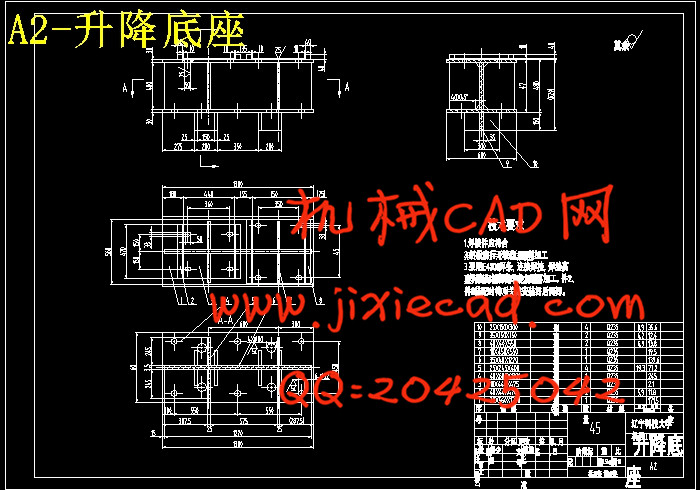

本设计还对板坯横移机的传动系统的各参数进行了设计计算,同时也对主要部件进行了强度分析与校核,对其中的一部分零部件进行了改进。

关键词:连铸,改良,板坯质量,板坯横移机

摘要

连续铸钢的出现和发展,大大地缩短了工艺流程,极大地简化了轧钢生产的工艺系统,与传统的模铸坯-初轧开坯相比、省去了脱模、整模、均热初轧和连轧开坯等一系列工序和对应的设备。这不仅明显降低了能耗,并且大大节省了设备投资和生产投资。

鞍钢集团公司炼钢厂的连铸技术已达到国内外先进水平,连铸的特点是将高温钢水连续不断的浇注成具有一定断面形状和一定尺寸规格的铸坯,并具有了提高综合成材率、降低能耗、产品的均一性好、质量高、易于实现机械化自动化等显著特点。但是随着事成竞争的逐渐激烈,板坯连铸机的优化与改良就成了提高板坯质量、占领市场的重要环节。因此,本人通过大量的实地调研、现场学习、仔细询问观看,对连铸机相关设备(板坯横移机)的结构与性能有了一个深入的认识。并运用自己所学的知识,从动力学、机械原理、经济学等诸多方面对连铸机中的板坯横移机进行设计,使其更加适用于新市场的形势。

本设计还对板坯横移机的传动系统的各参数进行了设计计算,同时也对主要部件进行了强度分析与校核,对其中的一部分零部件进行了改进。

关键词:连铸,改良,板坯质量,板坯横移机

Slab continuous casting and transverse moving design

Abstracts

The emergence and development of continuous casting steel greatly shortened process, greatly simplifies the system of steel rolling production process, from the traditional mold casting - blooming sufficiently compared, eliminating the demoulding, at the beginning of the whole mold, soaking rolling and rolling breakdown and a series of process and the corresponding equipment. This not only significantly reduces the energy consumption, and greatly saves equipment investment and production.

Anshan iron and steel (group) corporation steel continuous casting technology has reached the advanced level at home and abroad, the characteristics of the continuous casting is the high temperature molten steel continuous casting into a certain section shape and a certain size of slab, and with the increase yield, reduce energy consumption, product uniformity good, high quality and easy to implement and other significant characteristics of mechanization automation. Into the increasingly fierce competition, but as a matter of slab continuous casting machine optimization and improvement has become an important link in improve the quality of the slab, occupy the market. Therefore, I through a lot of field investigation, field study, ask to watch carefully, for continuous casting machine related equipment (slab structure and properties of horizontal moving) have an in-depth understanding of. And use their learned knowledge, from many aspects, such as dynamics, mechanical principles, economics to design of the slab continuous caster horizontal moving, to make it more suitable for new market situation.

This design also the parameters of the transmission system of slab transverse moving has carried on the design and calculation, but also on the main components of strength analysis and check, on the part of parts was improved.

Keywords: continuous casting, improved, the quality of the slab, the slab transverse moving

Abstracts

The emergence and development of continuous casting steel greatly shortened process, greatly simplifies the system of steel rolling production process, from the traditional mold casting - blooming sufficiently compared, eliminating the demoulding, at the beginning of the whole mold, soaking rolling and rolling breakdown and a series of process and the corresponding equipment. This not only significantly reduces the energy consumption, and greatly saves equipment investment and production.

Anshan iron and steel (group) corporation steel continuous casting technology has reached the advanced level at home and abroad, the characteristics of the continuous casting is the high temperature molten steel continuous casting into a certain section shape and a certain size of slab, and with the increase yield, reduce energy consumption, product uniformity good, high quality and easy to implement and other significant characteristics of mechanization automation. Into the increasingly fierce competition, but as a matter of slab continuous casting machine optimization and improvement has become an important link in improve the quality of the slab, occupy the market. Therefore, I through a lot of field investigation, field study, ask to watch carefully, for continuous casting machine related equipment (slab structure and properties of horizontal moving) have an in-depth understanding of. And use their learned knowledge, from many aspects, such as dynamics, mechanical principles, economics to design of the slab continuous caster horizontal moving, to make it more suitable for new market situation.

This design also the parameters of the transmission system of slab transverse moving has carried on the design and calculation, but also on the main components of strength analysis and check, on the part of parts was improved.

Keywords: continuous casting, improved, the quality of the slab, the slab transverse moving

目 录

1.绪论 1

1.1连铸发展历史简介 1

1.2连铸及连铸机简介 2

1.2.1连铸机的组成 2

1.2.2连铸工艺概述 2

1.2板坯连铸工艺流程图 3

1.3连铸技术的优越特性 4

1.4鞍钢连铸技术的概况 5

1.5设计对象 6

2、设计方案评述 7

2.1传动方案评述 7

2.2三环减速器评述及其传动的原理与布置形式 7

2.2.1三环减速器的特点 8

2.2.2三环减速器的不足 9

2.2.3板坯横移机的性能参数 9

3、传动装置的设计计算 11

3.1电动机的计算 11

3.2减速机的选择 12

3.3确定传动比 13

3.3.1传动装置的运动和动力参数的选择和计算 13

4、主要零件的强度计算 14

4.1三环传动齿轮副的强度计算特点 14

4.2齿轮的传动校核计算 15

4.21齿轮的材料及性能参数 15

4.2.2考虑弹性啮合效应的齿轮弯曲疲劳强度的计算 15

4.23弯曲疲劳许用应力的确定 18

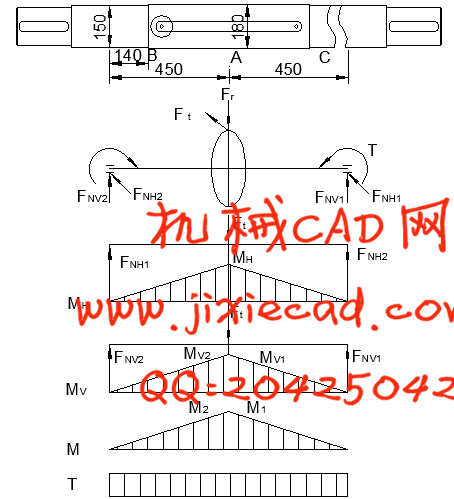

4.3轴强度的校核计算 20

4.3.1减速器中输出轴的校核计算 20

4.32与减速器中输出轴相连的轴(二)校核计算 23

4.4轴承的选择和寿命计算 29

5、钢丝绳的设计及计算 32

5.1钢丝绳的作用 32

5.2钢丝绳的设计 32

5.3钢丝绳的选取 32

6、电机与减速器之间联轴器的选择 34

7、润滑与密封的说明 35

7.1设备润滑的说明 35

7.2设备密封的说明 35

8、我国钢铁工业的污染现状与应对措施 37

8.1我国钢铁工业环境污染状况分析 37

8.2对于钢铁工业污染的应对措施 38

8.2.1我国钢铁工业应对环境问题所采取的主要措施 38

8.2.2推行循环经济。建立钢铁工业的循环链 38

8.2.3加快产业调整转变生产方式和加快淘汰落后企业步伐 39

8.2.4加强钢铁王业环境保护技术支撑措施,积极推进钢铁工业清洁生产技术建立和完善钢铁工业环保技术支撑体系。 39

结论 41

参考文献 42