设计简介

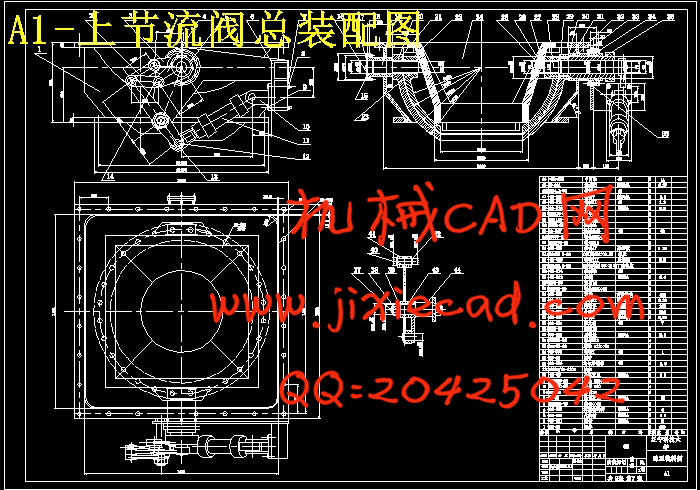

高炉无料钟炉顶上密封阀和

上截料阀的设计

关键词:高炉无料钟、炉顶设备、高炉冶炼、高压操作、密封阀、截料阀

Design for flow-control valve and conseal

valve of Beel-less Blast Furnace Top

is sued to load the stuff to a stove and make furnace chargescatter rationally within the stove, and the equipment must play a part in the furnace tophermetic sealing at the same time. The rapid development of modern industry, technology-led development of the iron and steel metallurgy, traditional furnace top equipment has many shortcomings, such ascomplicated structure, bad capability of preeurization. There are several advantages in this new type equipment ,it has the simpler structure,high drively efficiency,light weight, flexible distributing charg,standout hermeticcapability and so on, and all the characteristics can satisfy the request of extra-highpressure and the mainframe furnace. The key design mainly includes flow control valve and sealed valve and so on. Included the choice of hydraulic pressure cylinder, the basic parameter of the fretsaw machine’s choice and account, important parts of the design and strength check, as well as some standard parts selection and verification, such as bearings, keys, such as hydraulic cylinders. Bell-less top of the equipment simplified the structure to meet the requirements of modern large-scale production blast furnace top for the future development and research provides a new direction.

Key words: blast furnace bell, top equipment, blast furnace smelting, high-pressure operation, flow-control valve and, sealed valve

目 录

摘要 I上截料阀的设计

摘要

高炉是钢铁冶炼的重要设备,高炉炼铁是获得大量生铁的主要手段。高炉冶炼的原理是把氧化铁还原成含有碳硅锰硫磷等杂质的生铁。高炉的炉顶装料设是用来装料入炉并使炉料在炉内合理分布,同时还要起到炉顶密封作用的设备。近代工业的迅速发展,带动钢铁冶金技术的发展,传统的高炉炉顶设备存在着设备复杂、密封性能差等缺点。本文设计的无料钟炉顶装料装置具有设备结构简单、传动效率高、设备重量轻、布料灵活、密封性能好等优点,能够满足现代高炉大型化和超高压操作的要求。而本文主要设计串罐式无料钟炉顶的上密封阀、上截料阀等机构,主要包括主传动方案的设计,基本参数的选择计算,重要零件的设计和强度校核,以及一些标准件的选择和校核,如轴承、键、液压缸等。无料钟炉顶简化了炉顶的设备的结构,满足现代化大生产的要求,对于今后高炉炉顶的发展和研究提供了新方向。关键词:高炉无料钟、炉顶设备、高炉冶炼、高压操作、密封阀、截料阀

Design for flow-control valve and conseal

valve of Beel-less Blast Furnace Top

Abstract

The blastfurnace is an important iron and steel smelting equipment, the blastfurnace production is the main method to obtain a mass of pig irons. The principle of high blast furnace smelting iron oxide is reduced to carbon-containing impurities such as Si-Mn cast iron parathion. The charginge quipment of furnace topis sued to load the stuff to a stove and make furnace chargescatter rationally within the stove, and the equipment must play a part in the furnace tophermetic sealing at the same time. The rapid development of modern industry, technology-led development of the iron and steel metallurgy, traditional furnace top equipment has many shortcomings, such ascomplicated structure, bad capability of preeurization. There are several advantages in this new type equipment ,it has the simpler structure,high drively efficiency,light weight, flexible distributing charg,standout hermeticcapability and so on, and all the characteristics can satisfy the request of extra-highpressure and the mainframe furnace. The key design mainly includes flow control valve and sealed valve and so on. Included the choice of hydraulic pressure cylinder, the basic parameter of the fretsaw machine’s choice and account, important parts of the design and strength check, as well as some standard parts selection and verification, such as bearings, keys, such as hydraulic cylinders. Bell-less top of the equipment simplified the structure to meet the requirements of modern large-scale production blast furnace top for the future development and research provides a new direction.

Key words: blast furnace bell, top equipment, blast furnace smelting, high-pressure operation, flow-control valve and, sealed valve

目 录

Abstract II

1.绪论 1

1.1选题的目的和背景 1

1.1.1选题的目的 1

1.1.2选题的背景 1

1.2高炉炉顶设备发展现状及趋势 2

1.3 无料钟炉顶布料器 2

1.3.1无料钟炉顶的组成和操作流程 2

1.3.2无料钟炉顶发展的方向 3

1.4 其他形式的高炉炉顶装置 4

1.4.1钟式炉顶布料器 4

1.4.2钟阀式炉顶布料器 5

1.5设计目标概述 6

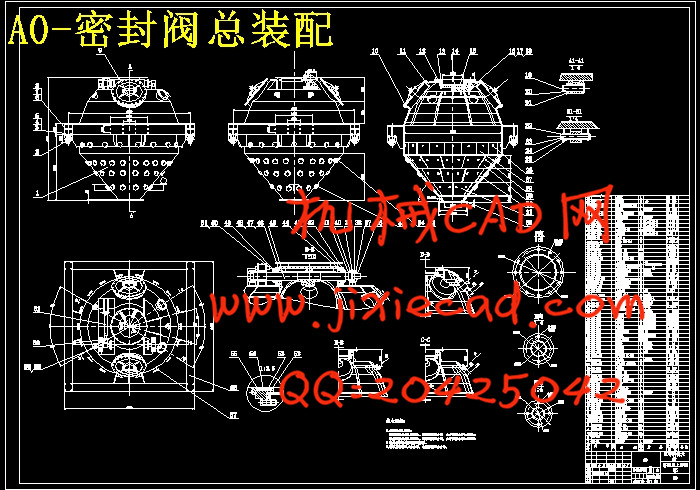

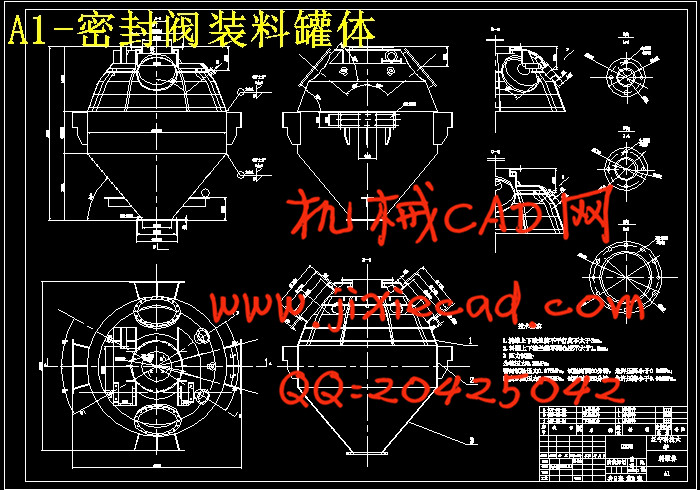

1.5.1 上密封阀 6

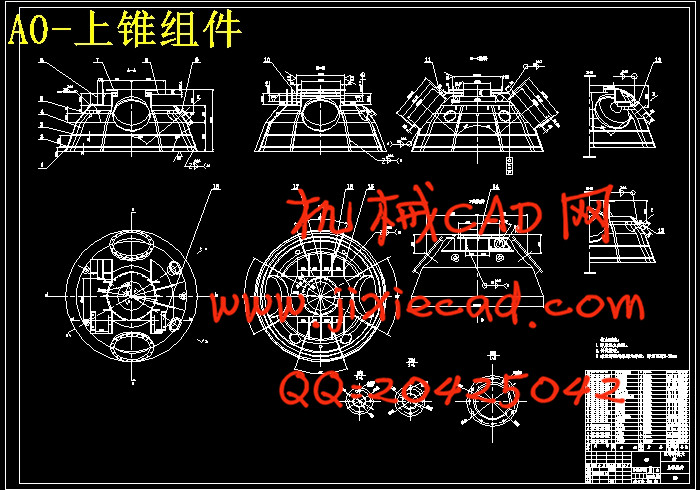

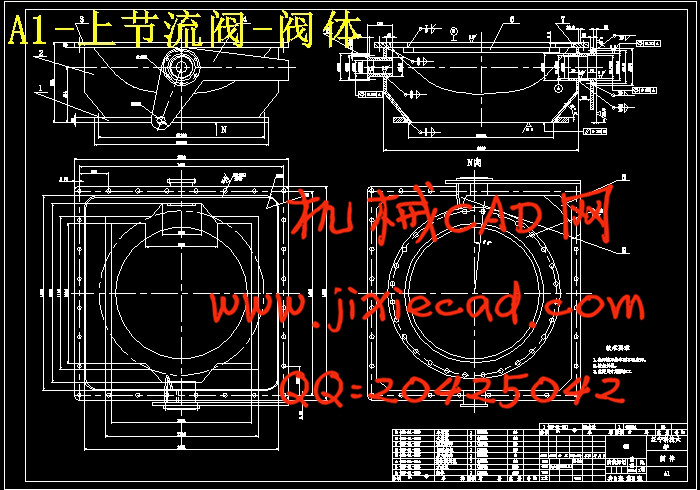

1.5.2上截料阀 7

1.6设计的目的及任务 8

2.无料钟炉顶的总体方案设计 9

2.1串罐式和并罐式的结构与分析比较 9

2.1.1串罐式和并罐式炉顶结构 9

2.1.2串罐式和并罐式的分析比较 11

2.2 设计方案的确定 12

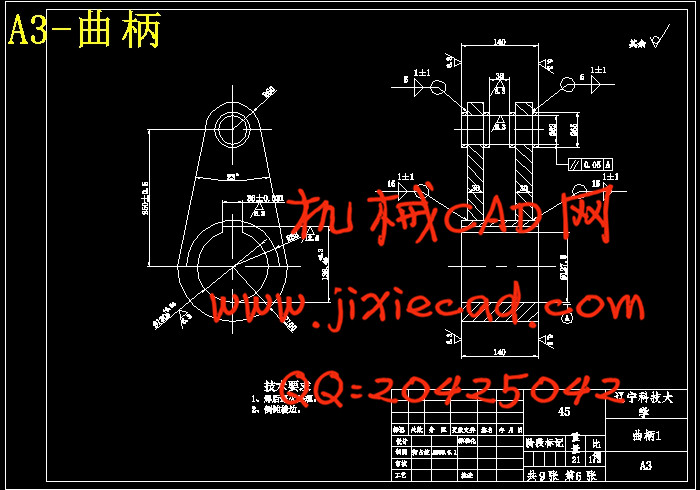

2.2.1 上截料阀的运动分析 12

2.2.2上截料阀传动方案的确定 12

2.2.3上密封阀传动方案的确定 13

2.2.4上密封阀执行和驱动方案的确定 13

3上密封阀的设计计算 15

3.1上截料阀驱动力和行程的计算 15

3.1.1行程的计算 15

3.1.2 驱动力计算 18

3.2液压缸的选择计算 20

3.2.1液压缸型号的选择 20

3.2.2液压缸活塞杆行程的确定 20

3.3 上截料阀花键轴的设计及强度校核 21

3.3.1 花键轴的受力分析 21

3.3.2 花键轴弯矩的计算和弯矩、扭矩图的绘制 22

3.3.3 花键轴的强度校核 24

3.4花键轴套的强度校核 24

3.4.1 花键轴套的受力分析 24

3.4.2 花键轴套弯矩的计算和弯矩、扭矩图的绘制 25

3.4.3 花键轴的强度校核 27

3.5花键的设计和校核 27

3.5.1花键轴上的花键选择和校核 27

3.5.2花键轴套的花键选择和校核 28

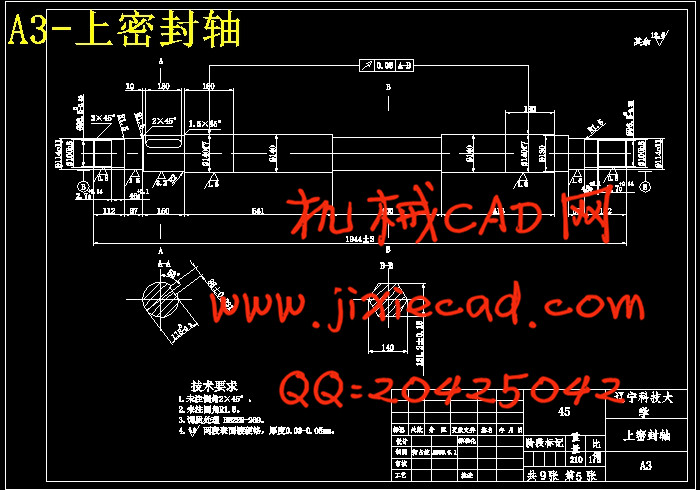

4. 上密封阀的设计计算 29

4.1 上密封阀液压缸的选择 29

4.2上密封轴的设计和强度校核 30

4.2.1上密封轴的受力分析 30

4.2.2上密封轴弯矩的计算和弯矩、扭矩图的绘制 31

4.2.3 上密封轴的强度校核 32

4.3上密封轴的键强度校核 33

4.4上密封轴的轴承校核 34

4.4.1轴承的选择 34

4.4.2验算轴承的寿命 35

5. 润滑方式的确定 37

5.1 润滑的定义和润滑方式种类 37

5.2润滑方式的选择 38

5.2.1上截料阀的润滑方式的选择 38

5.2.2 上密封轴的润滑方式的选择 38

6.经济性分析 39

总 结 41

致 谢 43

参 考 文 献 44