设计简介

700水平轧机压下系统的设计

摘要

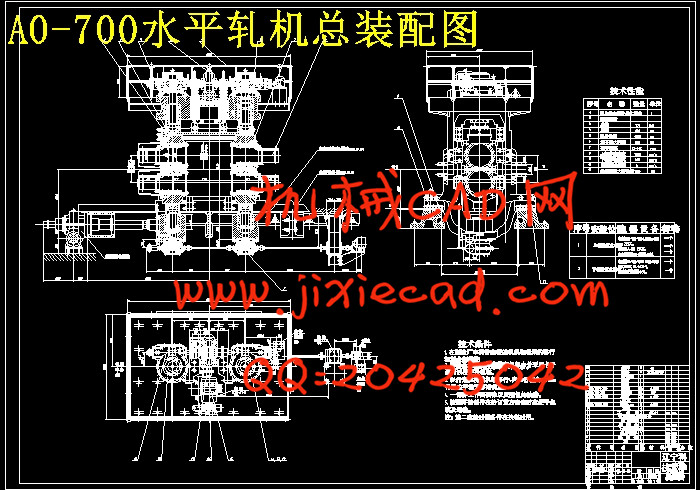

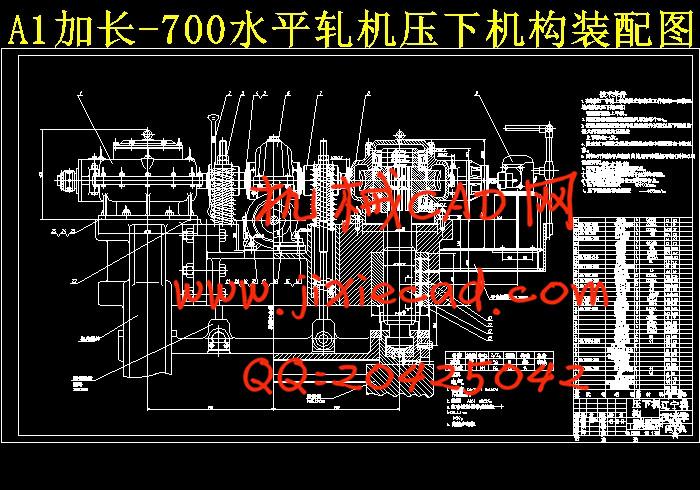

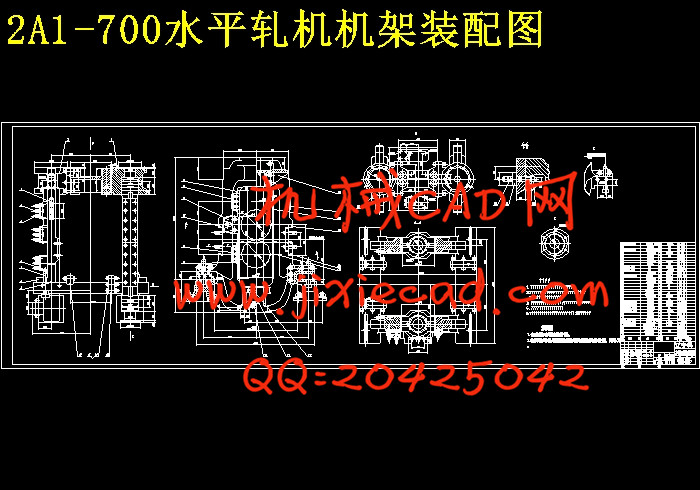

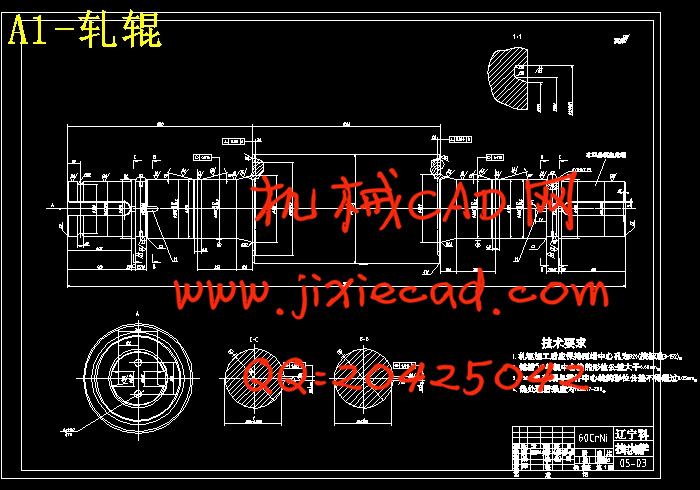

随着近年世界经济的飞速发展,市场对钢铁的需求量也越来越大,对质量的要求也不断的提高。因此,我们对钢坯轧机进行相应的设计,以降低成本,提高效率、产量和质量来满足生产及客户的要求。本篇论文中,首先论述了钢坯轧机的背景与发展状况,以及未来的发展趋势,并根据当前实际情况,考虑经济性和效率性等相关因素,对相关设备做了合理选用。然后对本次设计的700水平轧机的压下系统进行了相应的设计。该轧机用于连铸连轧生产线,生产成品钢坯,采用了双辊驱动、闭式机架,压下装置等机构;压下系统的组成主要包括压下螺丝、压下螺母、压下电机、减速机、联轴器等结构。在设计中,首先,确定压下螺丝的外径、压下螺母的外径及高度。然后,根据压下螺丝的传动力矩求出压下电机的功率。根据压下电机的功率和转数选择压下电机的类型和型号。最后,蜗轮蜗杆的设计及蜗杆轴的强度校核。判断危险截面,并且绘制弯扭矩图。接下的设计内容还有轴承的寿命计算、润滑、环保及经济性分析等内容。

关键词:700水平轧机;压下系统;压下电机;轧辊;减速机

The Design 0f the Pressure System of 700 Horizontal Mill

摘要

随着近年世界经济的飞速发展,市场对钢铁的需求量也越来越大,对质量的要求也不断的提高。因此,我们对钢坯轧机进行相应的设计,以降低成本,提高效率、产量和质量来满足生产及客户的要求。本篇论文中,首先论述了钢坯轧机的背景与发展状况,以及未来的发展趋势,并根据当前实际情况,考虑经济性和效率性等相关因素,对相关设备做了合理选用。然后对本次设计的700水平轧机的压下系统进行了相应的设计。该轧机用于连铸连轧生产线,生产成品钢坯,采用了双辊驱动、闭式机架,压下装置等机构;压下系统的组成主要包括压下螺丝、压下螺母、压下电机、减速机、联轴器等结构。在设计中,首先,确定压下螺丝的外径、压下螺母的外径及高度。然后,根据压下螺丝的传动力矩求出压下电机的功率。根据压下电机的功率和转数选择压下电机的类型和型号。最后,蜗轮蜗杆的设计及蜗杆轴的强度校核。判断危险截面,并且绘制弯扭矩图。接下的设计内容还有轴承的寿命计算、润滑、环保及经济性分析等内容。

关键词:700水平轧机;压下系统;压下电机;轧辊;减速机

The Design 0f the Pressure System of 700 Horizontal Mill

Abstract

With the recent rapid development of the world economy,Market demand for steel has become increasingly, The requirements of quality has been improvement constantly. Therefore, I have relevant design for the steel mill to reduce costs, improve efficiency, productivity and quality to meet production and customer requirements. In this paper, First of all, it discusses the background and development of the steel mill, as well as the future development trend, and in accordance with the current situation, I consider the economy and efficiency and other related factors, to do a reasonable choice for the related equipment. And then have relevant design for pressure system drive of 700 horizontal mill. This mill used for the continuous casting and rolling mill production line, production of finished steel, the use of the twin-roll-driven, closed-rack and pressure system. The pressure system main include screw press、nut press、motor press、reducer and coupling. In the design, first of all, determine the diameter of screw press, nut press the outer diameter and height. Secondly, we can calculate the motor power according to torque transmission of the screw press. Then we may choice the motor power according to the motor power and rotational speed. Finally, Worm gear design and strength check of worm shaft. Determine the risk of cross-section, and draw bending torque map. Content to take over the design was the life of bearings, lubrication, environmental protection and economic analysis, etc.

Key word :700 Horizontal Mill;Pressure system;Motor press;Roll;Reducer

目录

摘要 IWith the recent rapid development of the world economy,Market demand for steel has become increasingly, The requirements of quality has been improvement constantly. Therefore, I have relevant design for the steel mill to reduce costs, improve efficiency, productivity and quality to meet production and customer requirements. In this paper, First of all, it discusses the background and development of the steel mill, as well as the future development trend, and in accordance with the current situation, I consider the economy and efficiency and other related factors, to do a reasonable choice for the related equipment. And then have relevant design for pressure system drive of 700 horizontal mill. This mill used for the continuous casting and rolling mill production line, production of finished steel, the use of the twin-roll-driven, closed-rack and pressure system. The pressure system main include screw press、nut press、motor press、reducer and coupling. In the design, first of all, determine the diameter of screw press, nut press the outer diameter and height. Secondly, we can calculate the motor power according to torque transmission of the screw press. Then we may choice the motor power according to the motor power and rotational speed. Finally, Worm gear design and strength check of worm shaft. Determine the risk of cross-section, and draw bending torque map. Content to take over the design was the life of bearings, lubrication, environmental protection and economic analysis, etc.

Key word :700 Horizontal Mill;Pressure system;Motor press;Roll;Reducer

目录

Abstract II

1绪论 1

1.1设计的选题背景 1

1.2初轧机国内外研究现状及发展趋势 1

1.2.1 初轧机的国内外研究现状及成果 1

1.2.2 初轧机的发展前景和可能的改造方案 2

1.3初轧机的研究内容及方法 3

2.设计方案的确定 4

2.1 压下系统的传动装置 4

2.1.1 压下电动机类型的选择 5

2.1.2 减速器类型的选择 5

2.1.3 联轴器的选择 5

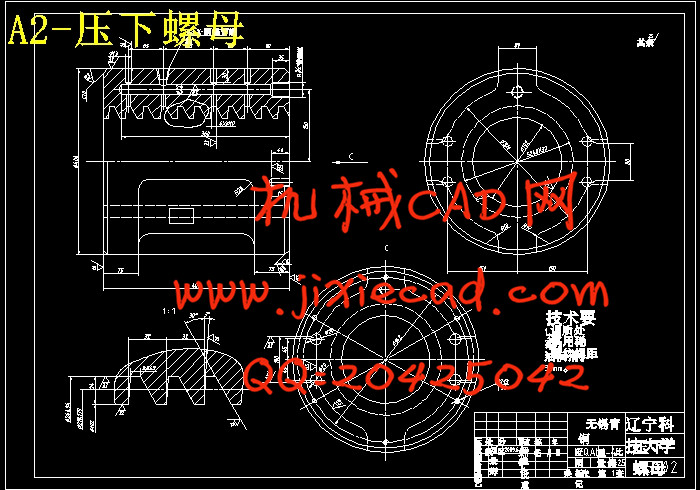

2.2压下螺丝和压下螺母 6

2.2.1 压下螺丝 6

2.2.2 压下螺母的选择 6

3.轧制力能参数的确定 7

3.1 平均单位压力 7

3.2 计算总轧制力 9

3.3 轧制力矩的计算 10

4 压下装置的设计及计算 12

4.1压下螺丝的设计计算 12

4.1.1 压下螺丝螺纹外径的确定 12

4.1.2 压下螺丝的强度校核 12

4.1.3 压下螺丝端部形状的选择 13

4.1.4 压下螺丝传动力矩的计算 13

4.2 压下电机的选择 15

4.2.1 压下电机功率的计算 15

4.2.2 压下电机的选择 16

4.3 压下螺母的结构尺寸设计 16

4.3.1 压下螺母高度H的确定 16

4.3.2 压下螺母的外径D的确定 17

4.3.3 压下螺母材料的选用 18

4.4 蜗轮与蜗杆的设计 18

4.4.1 蜗轮的设计 18

4.4.2 蜗轮的校核 21

4.4.3 热平衡计算 22

5.主要零件的强度校核 24

5.1蜗杆轴的强度校核 24

5.1.1 蜗杆所受载荷的计算 24

5.1.2 蜗杆轴支点受力分析 24

5.1.3 蜗杆轴上力矩的计算 26

5.1.4按弯扭合成校核轴的强度 26

5.1.5 精确校核的疲劳强度 28

5.2 轴承的寿命计算 34

5.2.1 轴承的选择 35

5.2.2 寿命计算 35

5.3 键的强度校核 37

5.3.1 键的选择 37

5.3.2 键联结强度的计算 38

6.润滑方式的选择 39

6.1 蜗轮蜗杆的润滑 39

6.1.1 润滑油的选择 39

6.1.2 润滑油给油方法及油量 39

6.2 轴承的润滑 40

7. 环保与经济性分析 41

7.1 设备的环保性分析 41

7.2 设备的可靠性 41

7.3 设备的经济性分析 43

结束语 45

致谢 46

参考文献 47