设计简介

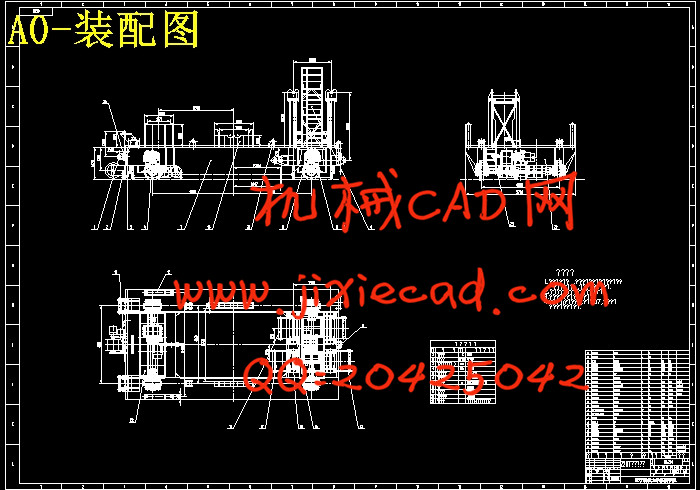

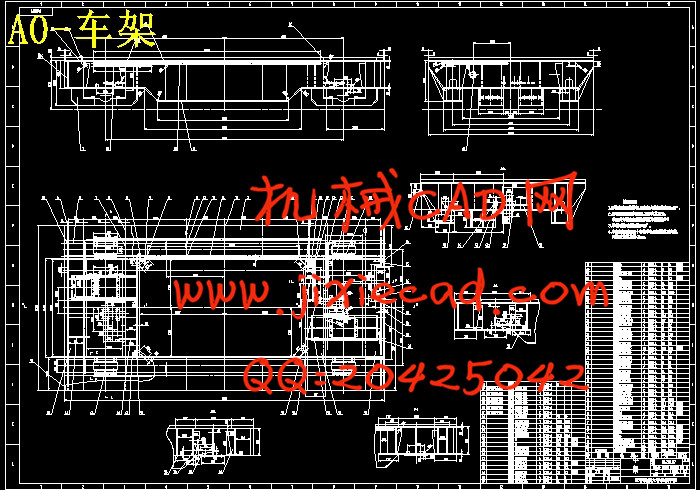

220T过跨车设计

关键词:铁水运输;220T过跨车;行走机构;电动机;立式减速器

摘要

铁水运输是冶金企业关键工艺之一,随着钢铁生产工艺的不断发展,钢铁企业的不断发展壮大,铁水运输方式也在不断发展。铁水罐车是钢铁企业铁水运输的重要工具,目前国内铁水罐车主要有 2种:一种是敞口式铁水车,一种是鱼雷形混铁车( 简称鱼雷罐车 )。采用不同的铁水运输车辆,对于钢铁生产节奏和钢铁质量会产生不同的影响。目前的运输方式能否适应钢铁工业的发展是摆在我们面前十分迫切的课题。本论文是设计220T铁水过跨车,首先分析了铁水车的作用,分类以及发展现状与前景。然后多此课题进行设计,主要是对过跨车的小车走行机构的设计,首先,确定过跨车的主要参数。然后,根据主要参数通过计算选择走行机构的电动机,减速器以及轴承。最后,校核车轮轴、减速器的齿轮,计算轴承的使用寿命,并且对其他的主要零件进行校核。关键词:铁水运输;220T过跨车;行走机构;电动机;立式减速器

The Design of The 220T Hot Metal Cross Car

Key word :Hot metal transport;220T cross car;Walking mechanism;Motor;Vertical reducer

目录

摘要 IAbstract

Molten iron transportation process is one of the key metallurgical enterprises,With the steel production process of continuous developed, iron and steel enterprises has grown in strength and the mode of transport of molten iron has been developed. Hot Metal tankers is an important tool for transport iron and steel enterprises. At present, melted iron mainly have two kinds of tanker: One is the exposure of hot metal type vehicles, the other is the torpedo torpedo-shaped vehicle (referred to Torpedoes Tank). Using different molten iron transport vehicles, for the rhythm of steel production and steel quality will cause different effects. Whether the current mode of transport to adapt to the development of iron and steel industry before us is a very urgent topics. This paper is the design of the design of the 220T hot metal cross car. First, we analyze the role of hot metal cars, classification and the development of the status quo and prospects. Second,design this subject,mainly design the walking mechanism of the hot metal cross car. Firstly, determine the main parameters of the hot metal cross car.Secondly,by calculating the main parameters to choose the motor reducer and bearings of the walking mechanism. Finally, check vehicle axle,the gear of the reducer,calculation the life of the bearings,and check other main parts.Key word :Hot metal transport;220T cross car;Walking mechanism;Motor;Vertical reducer

目录

Abstract II

1.绪论 1

1.1.选题背景及目的 1

1.2.铁水车的种类 1

1.2.1.铁水车的种类及特点 1

1.3.发展趋势 4

2.整体方案评述 5

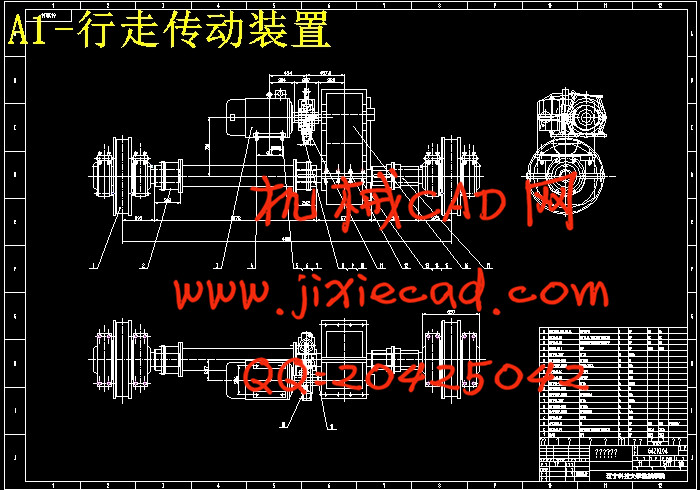

2.1.运行机构的组成和主要型式 5

2.2.运行机构的组成 5

2.2.1.运行机构电动机类型的选择 5

2.2.2.减速器的类型选择 6

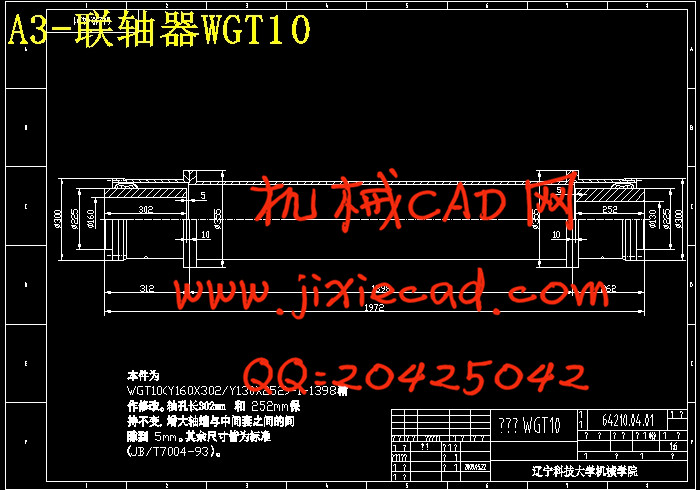

2.2.3.联轴器选择 6

2.2.4.制动器选择 7

2.2.5.轴承的选择 8

3.力能参数确定 9

3.1.设计参数 9

3.2.走行机构的电动机·电机功率 9

3.3.电动机发热校核 10

3.4.电动机过载能力校核 11

3.5.走行机构的减速器及传动比 12

4.主要零件强度计算 13

4.1.

4.1.1.轴的校核 13

4.1.2.精确校核轴的疲劳强度 16

4.1.3.键的校核 22

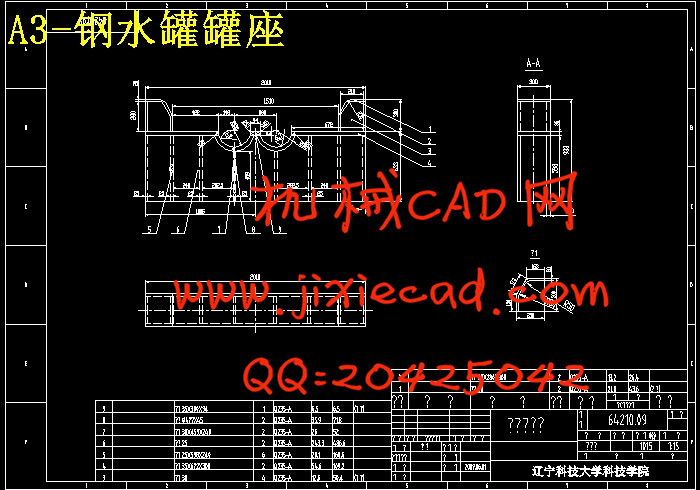

4.1.5.车轮和轨道的选择计算 27

4.2.

4.3.减速器齿轮的校核 28

5传动系统的润滑 32

5.1润滑方法 32

5.2润滑系统的选择原则 32

5.3润滑方式的选择 33

5.3.1减速器的润滑 33

5.3.2轴承的润滑 33

6. 环保与经济性分析 34

6.1.设备的环境保护 34

6.2.设备经济性分析 35

结束语 36

致谢 37

参考文献 38