设计简介

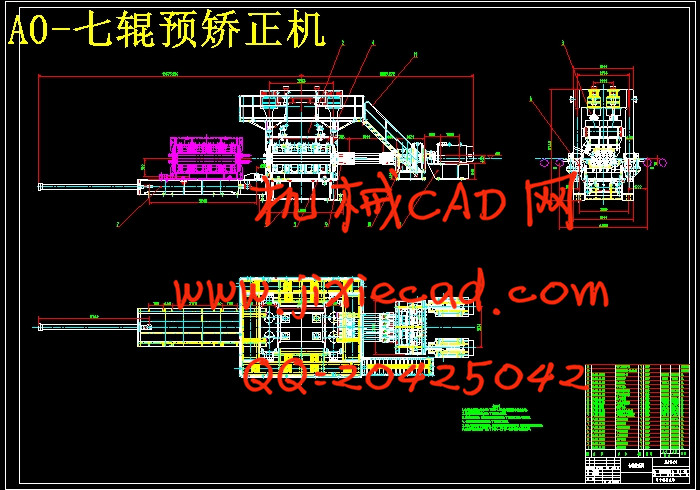

七辊中板预矫正机主传动系统的设计

摘要

随着生产技术的进步和现代化改造的实施,中厚板生产向着高效化、高质量的方向发展,对厚度在4~60 mm的常规产品,各生产单位均采用了线上的多辊矫正设备,为了满足日益提高的板形、板面质量要求,多辊矫正设备得到了进一步的发展。对矫正机进行相应的设计,以降低成本,提高效率、产量和质量来满足生产及客户的要求。本篇论文中,首先论述了矫正机的背景与发展状况,以及未来的发展趋势,并根据当前实际情况,考虑经济性和效率性等相关因素,对相关设备做了合理选用;然后对本次设计的中厚板矫正机进行了方案的选择与论述;其次确定了矫正机相关参数,并通过对矫正力、矫正力矩和主电机功率的计算及工作特点选择矫正机的电机类型和型号;最后,对矫正机的主要零部件(第三个工作辊、工作辊轴承)进行了校核计算。说明书的最后还对润滑的选择和设备的环保、可靠性和经济可行性做了论述。关键词:中板矫正机;主传动系统;矫正辊

The Predistortion Seven Roller Plate Design

Of Main Drive System

Abstract

With the development of technology and the implement of Modernization, production of plate straightening moves towards efficient and high quality direction. For thickness of 4~60mm conventional Products, every production department adopts multi-roll correction equipment. In order to meet the requirements of ever-increasing plate types and quality of boards, the multi-roll correction equipment gets improved. Now we are studying and designing the straightening machine to reduce costs and improve efficiency, output and quality, meeting the requirements of production and our customers.In this thesis. Background, development status and trend of straightening machine were firstly discussed and according to the present situation, considering economy and efficiency-related factors, I select some related equipment reasonably and then this design plate correction machine selection and discussed solutions. Second, determine the correct machine parameters, And through the force of correction, the correction torque and motor power of computing and work characteristics select straightening machine motor types and models. Finally, the main parts of straightening machine (the third work rolls, work roll bearings) were checking calculation. The specification for environmental protection and lubrication equipment selection, reliability and economic feasibility of doing discussed.

Key words: Plate straightening machine;Main drive system;Straightening roller

目录

摘要 IAbstract

With the development of technology and the implement of Modernization, production of plate straightening moves towards efficient and high quality direction. For thickness of 4~60mm conventional Products, every production department adopts multi-roll correction equipment. In order to meet the requirements of ever-increasing plate types and quality of boards, the multi-roll correction equipment gets improved. Now we are studying and designing the straightening machine to reduce costs and improve efficiency, output and quality, meeting the requirements of production and our customers.In this thesis. Background, development status and trend of straightening machine were firstly discussed and according to the present situation, considering economy and efficiency-related factors, I select some related equipment reasonably and then this design plate correction machine selection and discussed solutions. Second, determine the correct machine parameters, And through the force of correction, the correction torque and motor power of computing and work characteristics select straightening machine motor types and models. Finally, the main parts of straightening machine (the third work rolls, work roll bearings) were checking calculation. The specification for environmental protection and lubrication equipment selection, reliability and economic feasibility of doing discussed.

Key words: Plate straightening machine;Main drive system;Straightening roller

目录

Abstract II

1 绪论 1

1.1 课题研究的目的及意义 1

1.2 国内外发展的现状和趋势 1

1.3 矫直机的工作原理 2

1.4 课题研究的内容和方法 3

2 总方案确定 4

2.1 矫正机类型 4

2.1.1 压力矫正机 4

2.1.2 拉伸矫正机 4

2.1.3 拉伸弯曲矫正机 4

2.1.4 管材、棒材矫正机 5

2.1.5 辊式矫正机 5

2.2 矫正方案 6

2.3 主传动系统 6

2.3.1 电机 8

2.3.2 减速器 8

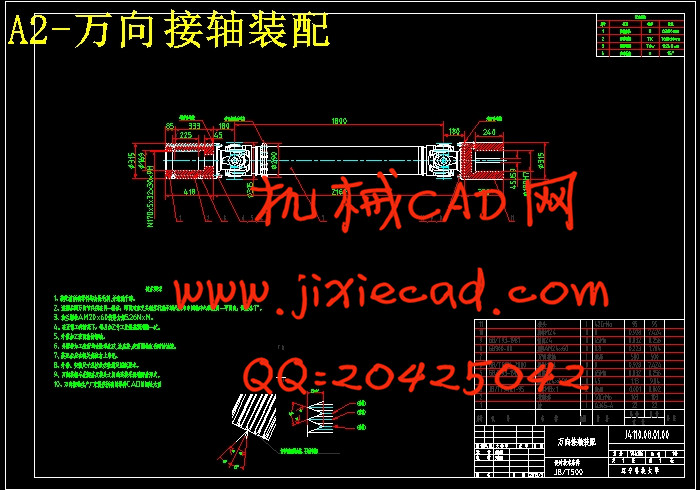

2.3.3 万向接轴 8

2.3.4 联轴器 9

3 矫正机相关参数设计计算 10

3.1 原始数据 10

3.2 矫正机基本参数确定 10

3.2.1 辊距t的确定 10

3.2.2 辊径D的确定11

3.2.3 辊数n确定 11

3.2.4 矫身L的确定 11

3.2.5 矫正速度v的确定 12

3.3 矫正机力能参数的计算 12

3.3.1 矫直力的计算 12

3.3.2 矫直力矩的计算 15

3.4 矫正机主电机的选择 16

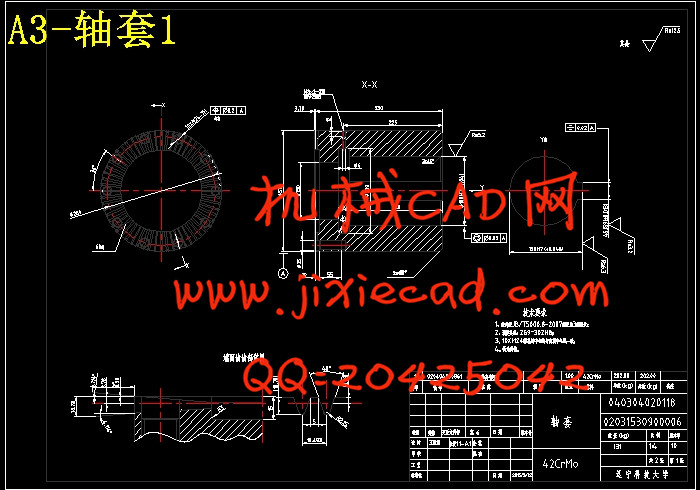

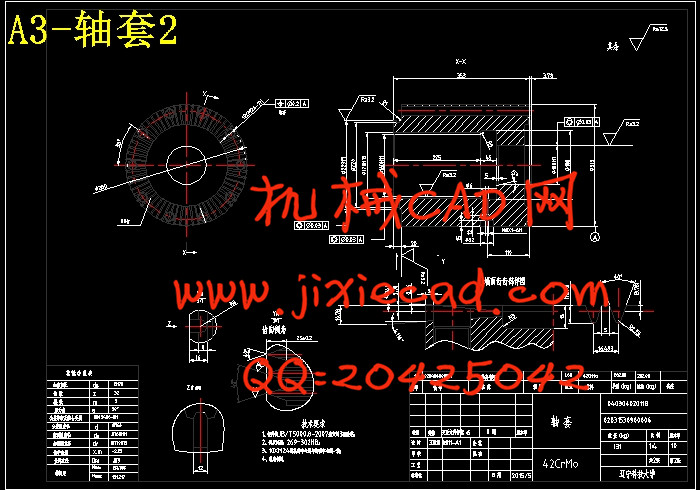

4 主要零部件校核计算 18

4.1 矫直辊的校核计算 18

4.1.1 第三辊压力和矫正力矩的确定 18

4.1.2 第三辊上弯曲力矩和支反力的确定 19

4.1.3 弯曲力矩的计算 20

4.1.4 支反力的计算 23

4.2 矫直辊的强度计算及校核 24

4.3 工作辊轴承的校核 25

5 润滑的选择 27

5.1 辊系的润滑 27

5.2 齿轮减速器中齿轮的润滑 27

6 设备的环保、可靠性和经济可行性分析 29

6.1 设备的环保性分析 29

6.2 设备的可靠性 29

6.3 设备的经济性分析 31

结论 33

致谢 34

参考文献 35