设计简介

2150滚筒式切头飞剪机设计

摘要

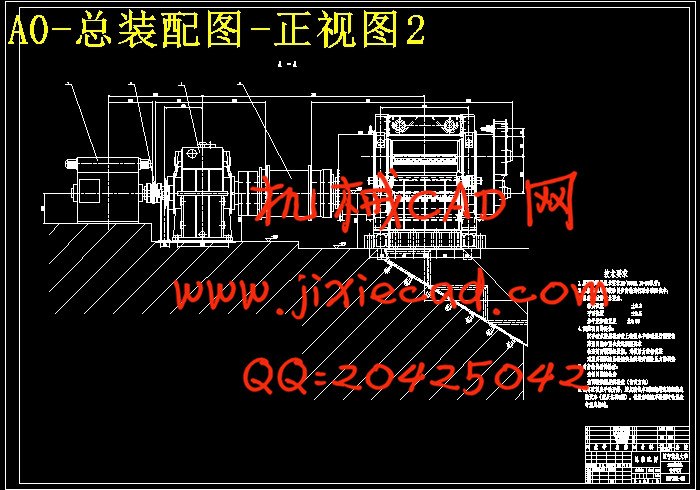

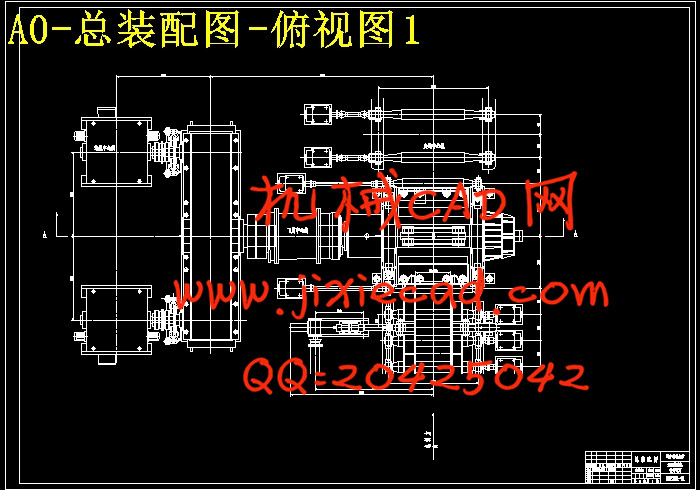

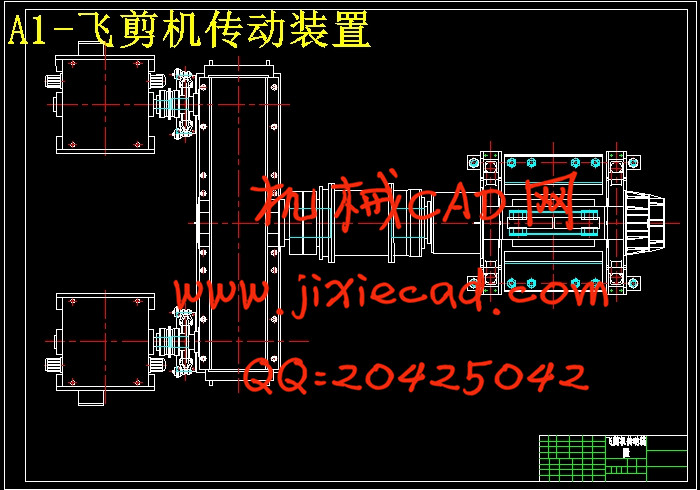

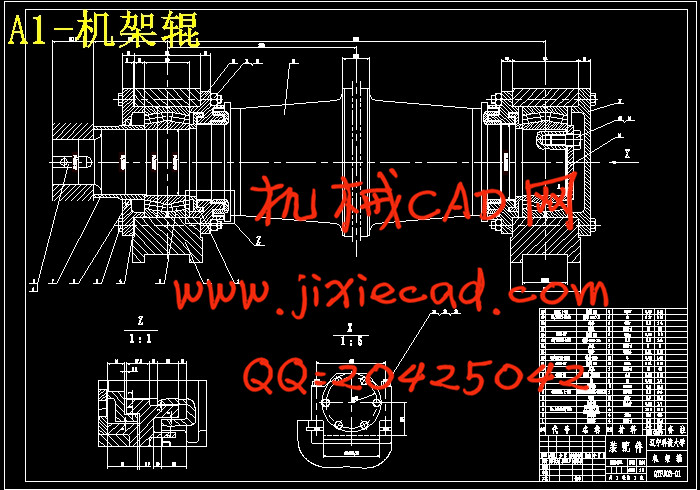

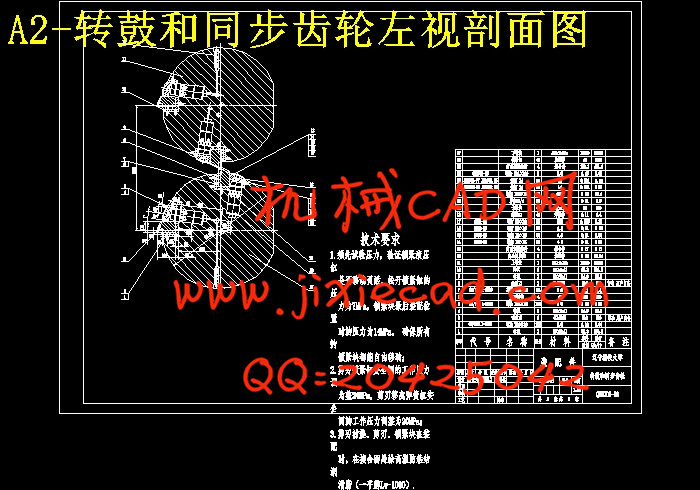

切头飞剪机是热连轧生产线上的单体设备,它的用途是切头、切尾,出现卡钢事故时,将轧件剪断,处理卡钢事故。有时也可切定尺,检查轧件的质量。本设计是2150滚筒式切头飞剪,主要用于切头和切尾,采用双电机驱动,剪切机构的传动方式是转鼓式,上下转鼓同步转动,减少了动力矩,提高了剪切质量。在该设计中,主要进行剪切力的计算,选择主电机的容量,进行转鼓轴、齿轮的设计计算,进行剪切机构刀片的设计,剪切侧间隙调整装置的设计,对飞剪机进行润滑方法的选择,试车和控制要求,采用环保措施,保证可靠性经济性好,具有显著的经济效益。2150切头飞剪是热连轧厂常用的剪切设备。

关键词:飞剪机;滚筒式;切头;切尾

Design of the 2150 Drum Type Crop Shear

Abstract

Crop shear is the monomer equipment on the hot rolling production line,which is used to cut head and tail of rolling. When the steel can not travel as usual ,it can be used to cut the stock and to avoid an accident. Sometimes, it's also used to cutting stock into desired sectional lengths and to check the quality of the rolled piece. This design is the design of the 2150 drum type crop shear, which is drived by two motor. It is an object of this designto reduce remarkably the power consumption in flyingshears of the instant character by eliminating acceleration and deceleration of the shear drums for each shearing operation and improve the section quality. In this design, it is important to calculate shear stress ,select main motor ,design and calculate drum axis and gears. In this paper, I also give the design of shear blade and adjusting device for the gap between the upper and lower shear drums. Besides, selection of lubrication and testing and control requirements are also necessary. In order to get significant economic benefits, we must take environmental measures when producing. Nowadays, the 2150 drum type crop shear is used in continuous hot-strip mills generally.

Key words: Flying shear ;Drum type;Cutting head ;Cutting tail

目 录

1绪 论 1

1.1课题选择的背景和目的 1

1.2飞剪机国内外发展现状 2

1.3飞剪机的现状 3

1.3.1飞剪机在车间布置和作用 3

1.3.2飞剪机的类型和特点 4

1.3.3飞剪机研究的内容和方法 5

2方案的选择与评述 6

2.1方案选择 6

2.2方案评述 6

3电机的选择 8

3.1剪切力的计算 8

3.2剪切机的扭矩计算 8

3.3转股稳定运转转速 10

3.4电机型式及电机容量的选择 10

4主要零件的强度计算 12

4.1减速机的计算 12

4.1.1减速机的传动比分配 12

4.1.2减速机齿轮设计 13

4.1.3下转鼓轴的设计计算 20

4.2剪刃的设计 26

4.2.1材料的选择 26

4.2.2剪刃的结构设计 26

4.3转股轴承的选择及校核 26

4.4侧隙调整机构的设计 28

4.5 联轴器的选择与校核 30

4.5.1联轴器的分类 30

4.5.2联轴器的选择 30

4.5.3联轴器的强度计算 31

5润滑方法的选择 32

5.1减速机润滑方法及润滑油的选择 32

5.2飞剪机的润滑 32

6试车方法和对控制的要求 34

6.1试车要求 34

6.2对控制系统的要求 34

7设备可靠性与经济评价 35

7.1机械设备的有效度 35

7.2投资回收期 35

结 论 37

致 谢 38

参考文献 39

摘要

切头飞剪机是热连轧生产线上的单体设备,它的用途是切头、切尾,出现卡钢事故时,将轧件剪断,处理卡钢事故。有时也可切定尺,检查轧件的质量。本设计是2150滚筒式切头飞剪,主要用于切头和切尾,采用双电机驱动,剪切机构的传动方式是转鼓式,上下转鼓同步转动,减少了动力矩,提高了剪切质量。在该设计中,主要进行剪切力的计算,选择主电机的容量,进行转鼓轴、齿轮的设计计算,进行剪切机构刀片的设计,剪切侧间隙调整装置的设计,对飞剪机进行润滑方法的选择,试车和控制要求,采用环保措施,保证可靠性经济性好,具有显著的经济效益。2150切头飞剪是热连轧厂常用的剪切设备。

关键词:飞剪机;滚筒式;切头;切尾

Design of the 2150 Drum Type Crop Shear

Abstract

Crop shear is the monomer equipment on the hot rolling production line,which is used to cut head and tail of rolling. When the steel can not travel as usual ,it can be used to cut the stock and to avoid an accident. Sometimes, it's also used to cutting stock into desired sectional lengths and to check the quality of the rolled piece. This design is the design of the 2150 drum type crop shear, which is drived by two motor. It is an object of this designto reduce remarkably the power consumption in flyingshears of the instant character by eliminating acceleration and deceleration of the shear drums for each shearing operation and improve the section quality. In this design, it is important to calculate shear stress ,select main motor ,design and calculate drum axis and gears. In this paper, I also give the design of shear blade and adjusting device for the gap between the upper and lower shear drums. Besides, selection of lubrication and testing and control requirements are also necessary. In order to get significant economic benefits, we must take environmental measures when producing. Nowadays, the 2150 drum type crop shear is used in continuous hot-strip mills generally.

Key words: Flying shear ;Drum type;Cutting head ;Cutting tail

目 录

1绪 论 1

1.1课题选择的背景和目的 1

1.2飞剪机国内外发展现状 2

1.3飞剪机的现状 3

1.3.1飞剪机在车间布置和作用 3

1.3.2飞剪机的类型和特点 4

1.3.3飞剪机研究的内容和方法 5

2方案的选择与评述 6

2.1方案选择 6

2.2方案评述 6

3电机的选择 8

3.1剪切力的计算 8

3.2剪切机的扭矩计算 8

3.3转股稳定运转转速 10

3.4电机型式及电机容量的选择 10

4主要零件的强度计算 12

4.1减速机的计算 12

4.1.1减速机的传动比分配 12

4.1.2减速机齿轮设计 13

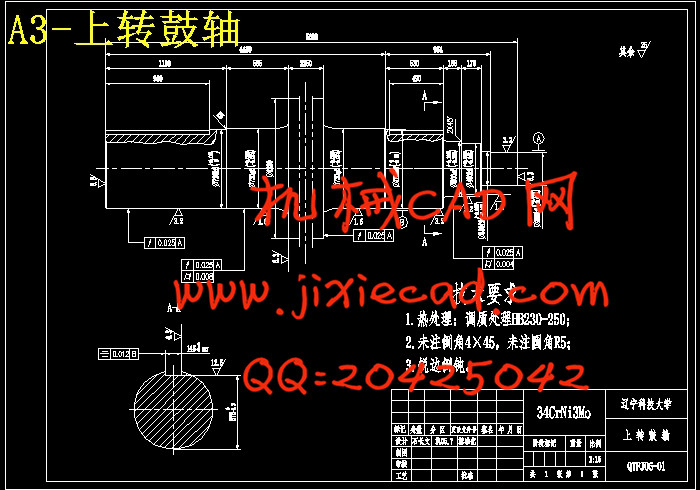

4.1.3下转鼓轴的设计计算 20

4.2剪刃的设计 26

4.2.1材料的选择 26

4.2.2剪刃的结构设计 26

4.3转股轴承的选择及校核 26

4.4侧隙调整机构的设计 28

4.5 联轴器的选择与校核 30

4.5.1联轴器的分类 30

4.5.2联轴器的选择 30

4.5.3联轴器的强度计算 31

5润滑方法的选择 32

5.1减速机润滑方法及润滑油的选择 32

5.2飞剪机的润滑 32

6试车方法和对控制的要求 34

6.1试车要求 34

6.2对控制系统的要求 34

7设备可靠性与经济评价 35

7.1机械设备的有效度 35

7.2投资回收期 35

结 论 37

致 谢 38

参考文献 39