设计简介

圆弧剪刃滚切式钢板剪切机设计

摘要

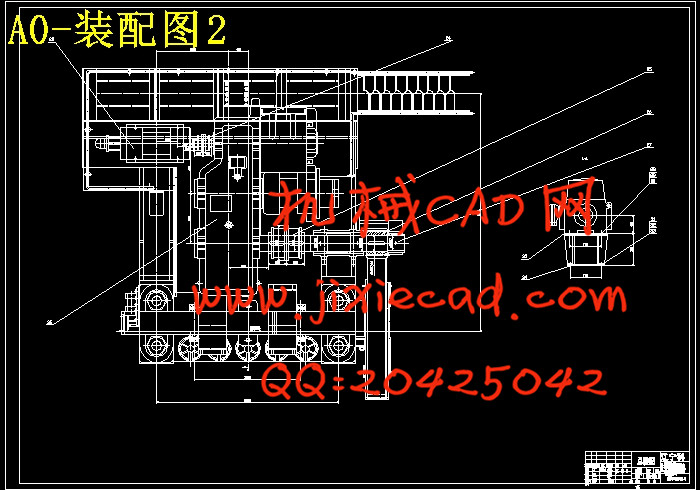

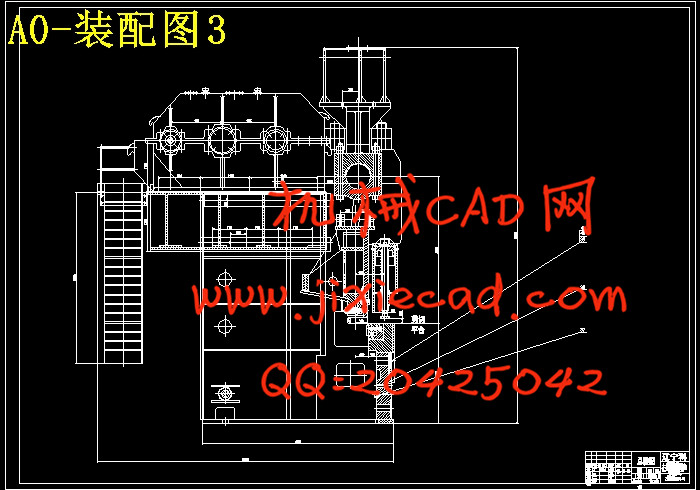

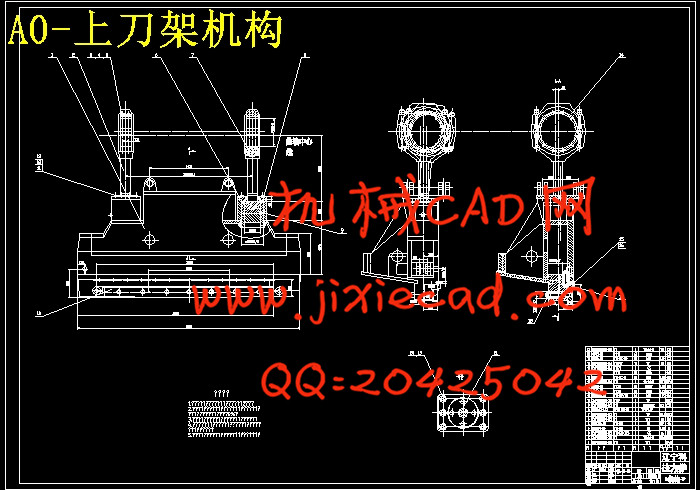

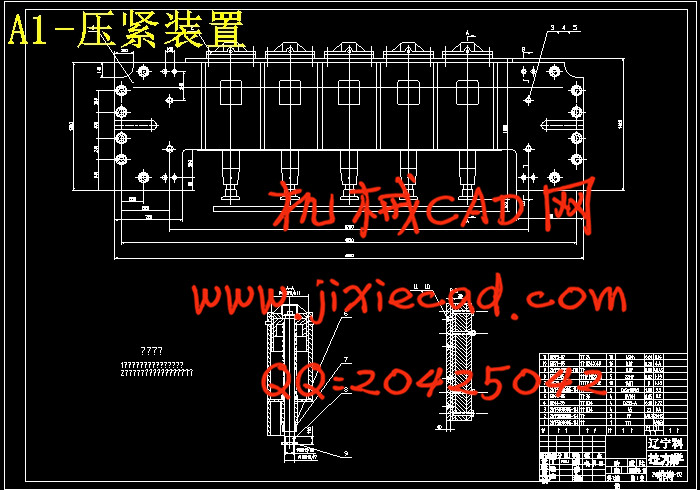

圆弧剪刃滚切式钢板剪切机是一种新式钢板剪切设备,它是中厚钢板精整工序中的重要设备,保证剪切机正常工作队提高板材生产线的产量有重要意义。随着我国中厚钢板年产量的不断增加,现在中厚板轧钢厂对钢板质量、品种、产量的要求也随之提高。圆弧剪刃滚切式钢板剪切机在整个剪切范围内刀片重叠量不变,剪切变形区小,被剪切板材不易弯曲变形,毛刺少,剪切质量高,并且,滚切式剪切机运动的上刀片与被剪板材之间只产生很小的相对运动,刀片磨损较小,特别适合于中厚板的切边、切定尺和纵向部分。本次设计的圆弧剪刃滚切式钢板剪切机用于定尺剪切最大厚度为40mm的钢板,要求剪切机结构合理、工作可靠、剪切质量高。此次设计内容主要是圆弧剪刃滚切式钢板剪切机的设计,设计内容主要包括剪切机总体方案设计、工作原理与基本机构等的确定、滚切剪主要参数的计算、电动机容量选择和减速器的设计、主要零件的设计与校核、润滑方式的选择以及图纸的绘制等。计算得其最大剪切力为8.5MN,剪切次数18次/分,上刀架最大行程162mm,电动机功率355kW,额定转速987r/min。机架采用闭式机架。

关键词:滚切剪;圆弧剪刃;剪切力

The Design of steel plate shearing machine with circular blade and scrolling shear mode

Abstract

The design of steel plate shearing machine with circular blade and scrolling shear mode is a new plate shearing machine, which is the important equipment of medium and heavy plate finishing processes, play an important part in ensuring shearing machines working normally to improve the output of sheet productions. With the increased annual output of medium and heavy plate, the requirements of quality, variety, output of medium and heavy plate rolling mill are much higher than before. The blade of hearing machine with roller blade cutting steel plate is with the same overlap quantity during the whole range of shearing, with small shearing deformation zone, not easy to deform for the sheared plates, with small burrs, high quality of shearing, besides, the blade and sheared plate move only a little on the roller blade cutting steel plate machine, also with small blade wear which is particularly suited to the edge of plate, shearing ruler and vertical parts. The designed shearing machine with roller blade cutting steel plate is used with fixed 40mm shearing plate length, which required the frame of machine to be reasonable, reliable and with high quality of shearing. The design of the main content is circular blade cutting plate shearing machine design, design content mainly includes shear machine overall design, working principle and basic institutions, roll-cut calculation, main parameters of shear capacity motor reducer design, selection and design of the main parts and checking, lubrication and the choice of rendering drawings etc. Calculated the maximum shear stress 8.5MN, shearing time 18 times/min, the biggest distance on the knife rest 162mm, motor power 355KW, rated speed 987r/min. Closed-rack is adopted.

KEY WORDS: rolls cuts, circular blade, shearing stress

目录

1.绪论 1

1.1 选题背景及目的 1

1.2 滚切剪的发展趋势 3

2 设计方案的选择和分析 4

3 滚切剪的设计 6

3.1 滚切剪的工作原理 6

3.2滚切剪的基本机构 7

3.3 剪切理论 11

3.3.1 轧件剪切过程分析 11

3.3.2 金属机械性能对剪切抗力的影响 12

3.4 滚切剪主要参数的计算 12

3.4.1 设计基本要求 12

3.4.2 最大剪切力 13

3.4.3额定剪切力 13

3.4.4 剪切功 14

3.4.5 上剪刃圆弧半径 14

3.4.6 上刀架最大行程 15

3.5 电动机容量的选择 16

3.6 减速器的设计 18

3.7 主要零件的设计与校核 18

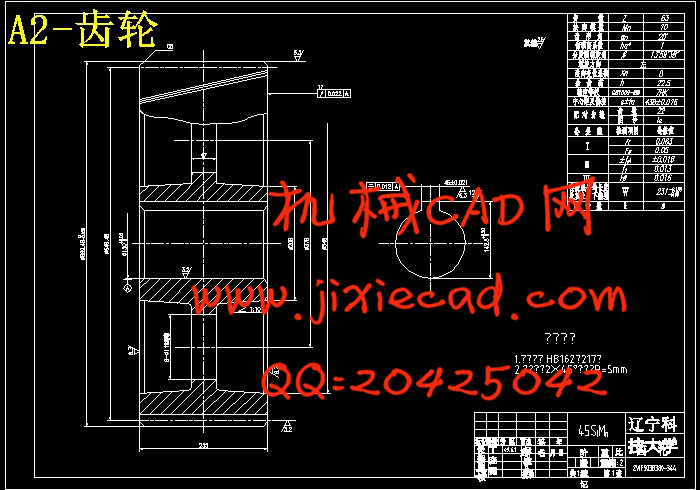

3.7.1齿轮的设计与校核 19

3.7.2 齿轮轴的校核 24

3.7.3 轴承的选择与校核 29

3.7.4 曲轴的设计与校核 30

3.7.5 联轴器的选择与校核 35

3.7.6 键的校核 36

4 影响剪切效率和质量的因素分析 38

4.1 影响剪切效率的因素 38

4.2 影响剪切质量的因素 38

5 润滑方法的选择 39

5.1 润滑的作用 39

5.2 润滑方法 39

5.3 润滑脂的特点和注意事项 40

5.4 添加剂 41

6 设备的环保、可靠性和经济可行性分析 42

6.1 设备的环保性分析 42

6.2 设备的可靠性 42

6.3 设备的经济性分析 44

结论 46

致谢 47

参考文献 48

摘要

圆弧剪刃滚切式钢板剪切机是一种新式钢板剪切设备,它是中厚钢板精整工序中的重要设备,保证剪切机正常工作队提高板材生产线的产量有重要意义。随着我国中厚钢板年产量的不断增加,现在中厚板轧钢厂对钢板质量、品种、产量的要求也随之提高。圆弧剪刃滚切式钢板剪切机在整个剪切范围内刀片重叠量不变,剪切变形区小,被剪切板材不易弯曲变形,毛刺少,剪切质量高,并且,滚切式剪切机运动的上刀片与被剪板材之间只产生很小的相对运动,刀片磨损较小,特别适合于中厚板的切边、切定尺和纵向部分。本次设计的圆弧剪刃滚切式钢板剪切机用于定尺剪切最大厚度为40mm的钢板,要求剪切机结构合理、工作可靠、剪切质量高。此次设计内容主要是圆弧剪刃滚切式钢板剪切机的设计,设计内容主要包括剪切机总体方案设计、工作原理与基本机构等的确定、滚切剪主要参数的计算、电动机容量选择和减速器的设计、主要零件的设计与校核、润滑方式的选择以及图纸的绘制等。计算得其最大剪切力为8.5MN,剪切次数18次/分,上刀架最大行程162mm,电动机功率355kW,额定转速987r/min。机架采用闭式机架。

关键词:滚切剪;圆弧剪刃;剪切力

The Design of steel plate shearing machine with circular blade and scrolling shear mode

Abstract

The design of steel plate shearing machine with circular blade and scrolling shear mode is a new plate shearing machine, which is the important equipment of medium and heavy plate finishing processes, play an important part in ensuring shearing machines working normally to improve the output of sheet productions. With the increased annual output of medium and heavy plate, the requirements of quality, variety, output of medium and heavy plate rolling mill are much higher than before. The blade of hearing machine with roller blade cutting steel plate is with the same overlap quantity during the whole range of shearing, with small shearing deformation zone, not easy to deform for the sheared plates, with small burrs, high quality of shearing, besides, the blade and sheared plate move only a little on the roller blade cutting steel plate machine, also with small blade wear which is particularly suited to the edge of plate, shearing ruler and vertical parts. The designed shearing machine with roller blade cutting steel plate is used with fixed 40mm shearing plate length, which required the frame of machine to be reasonable, reliable and with high quality of shearing. The design of the main content is circular blade cutting plate shearing machine design, design content mainly includes shear machine overall design, working principle and basic institutions, roll-cut calculation, main parameters of shear capacity motor reducer design, selection and design of the main parts and checking, lubrication and the choice of rendering drawings etc. Calculated the maximum shear stress 8.5MN, shearing time 18 times/min, the biggest distance on the knife rest 162mm, motor power 355KW, rated speed 987r/min. Closed-rack is adopted.

KEY WORDS: rolls cuts, circular blade, shearing stress

目录

1.绪论 1

1.1 选题背景及目的 1

1.2 滚切剪的发展趋势 3

2 设计方案的选择和分析 4

3 滚切剪的设计 6

3.1 滚切剪的工作原理 6

3.2滚切剪的基本机构 7

3.3 剪切理论 11

3.3.1 轧件剪切过程分析 11

3.3.2 金属机械性能对剪切抗力的影响 12

3.4 滚切剪主要参数的计算 12

3.4.1 设计基本要求 12

3.4.2 最大剪切力 13

3.4.3额定剪切力 13

3.4.4 剪切功 14

3.4.5 上剪刃圆弧半径 14

3.4.6 上刀架最大行程 15

3.5 电动机容量的选择 16

3.6 减速器的设计 18

3.7 主要零件的设计与校核 18

3.7.1齿轮的设计与校核 19

3.7.2 齿轮轴的校核 24

3.7.3 轴承的选择与校核 29

3.7.4 曲轴的设计与校核 30

3.7.5 联轴器的选择与校核 35

3.7.6 键的校核 36

4 影响剪切效率和质量的因素分析 38

4.1 影响剪切效率的因素 38

4.2 影响剪切质量的因素 38

5 润滑方法的选择 39

5.1 润滑的作用 39

5.2 润滑方法 39

5.3 润滑脂的特点和注意事项 40

5.4 添加剂 41

6 设备的环保、可靠性和经济可行性分析 42

6.1 设备的环保性分析 42

6.2 设备的可靠性 42

6.3 设备的经济性分析 44

结论 46

致谢 47

参考文献 48