设计简介

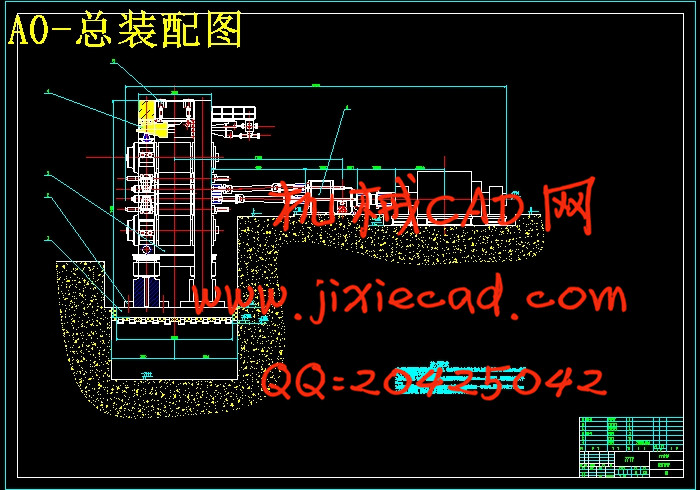

1500六辊冷连轧机主传动系统设计

摘要

随着工业生产的迅猛发展,我国对板带材的需求日益增加,特别是高精度冷轧薄板的生产更是供不应求,本次设计的是1500六辊冷连轧机组主传动系统,设计的该轧机能轧的最小板坯厚度达到了0.3mm,本次设计的主要思路是根据轧件原始尺寸和成品尺寸,确定轧制压下规程,从而计算轧制力和轧制力拒,选择电机,进而确定工作辊、中间辊、支承辊尺寸,并分别进行扭转、接触应力、弯曲强度校核,并对机架、联轴器进行了结构和强度计算,采用了初选结构、校核强度、校核通过则采用,不通过则再选,再校核,直到校核通过为止的基本机械设计方法。这不仅是对所学的理论知识的综合运用,也是考验思维的严谨缜密。

此外,还对设备的安装、试车、经济性分析以及冷轧机的选题背景、发展历史做了简单的介绍,在设计中根据生产实际的要求,选择了不同的设计方案实现主传动,经过比较,确定了最佳方案,对方案中的各重要部件进行结构和性能的校核,力求达到最合理的设计,满足生产的设计要求。

由于该题目是一个全新的课题,所以在设计中遇到了很多的问难,即使尽了最大的努力,得到老师、师傅的很大帮助,也难免有很多错误和考虑不全面的地方,希望大家批评指正。

关键词:1500六辊冷连轧机组,轧制力,轧制力矩,联轴器,机架

1500 six roller cold mill main drive system of the design unit

Abstract

With the rapid development of industrial production, China's plate strip increasing demand, especially in the production of high precision cold-rolled sheet is in short supply, this design is 1,500 units of six roller cold mill main drive system, design of the rolling mill to achieve the minimum slab thickness of 0.3mm, the main idea of the design is based on roll size and finished pieces of original size, determine the rolling down of order in order to estimate the rolling force and rolling force resist, select motor, to determine the work roll, intermediate roller, roller bearing size, and were reversed, contact stress, bending strength checking, and rack, coupling to the structure and strength calculation, using the primary structure, checking the strength, Checking through the use of, does not pass the re-election, re-check until the check through the date of the basic mechanical design. This is not only a theory for the integrated use of knowledge, but also the test of coherent thinking

In addition, the equipment installation, testing, analysis of economic topics, as well as the background of the cold rolling mill, a brief history of the development of the introduction, in the design in accordance with the requirements of the actual production, select a different design options to achieve the main drive, after comparison to determine the best program in the major structural components of the calibration and performance, and strive to achieve the most reasonable design, production to meet the design requirements.

Since the topic is a new subject, encountered in the design of a lot of difficult questions, even the best efforts to be a teacher, master of great help, it is inevitable that many errors and does not consider the local comprehensive, I hope all criticism.

Keywords: 1500 six roller cold rolling unit ;Rolling force ;Rolling moment ;Coupling;Rack

目 录

1、绪论 1

1.1选题背景及目的 1

1.2冷轧机发展 1

1.3板型控制 2

1.4研究内容和研究方法 3

2、传动方案评述与选择 4

2.1方案选择 4

2.2方案评述 4

2.3电机选择 5

2.4.联接轴选择 5

3、力能参数的计算 7

3.1轧制力的计算 7

3.1.1轧制规程 7

3.1.2初选轧辊材料 7

3.1.3轧辊主要参数的确定 7

3.1.4 轧制力的计算 9

3.2轧制力矩的计算 12

3.2.1 轧制力矩的计算 12

3.2.2 反力矩的计算 13

3.2.3 摩擦力矩的计算 14

4、主电机容量的选择 15

4.1初选电机功率 15

4.2轧机主电动机力矩 15

4.3各轧制阶段时间计算 17

4.3电机的校核 19

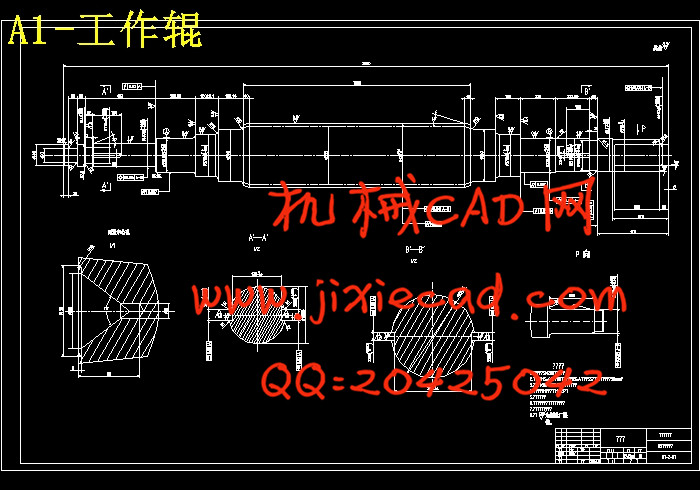

5、轧辊强度校核 20

5.1工作辊强度校核 20

5.2支承辊强度校核 21

5.3工作辊与中间辊间的接触应力校核 22

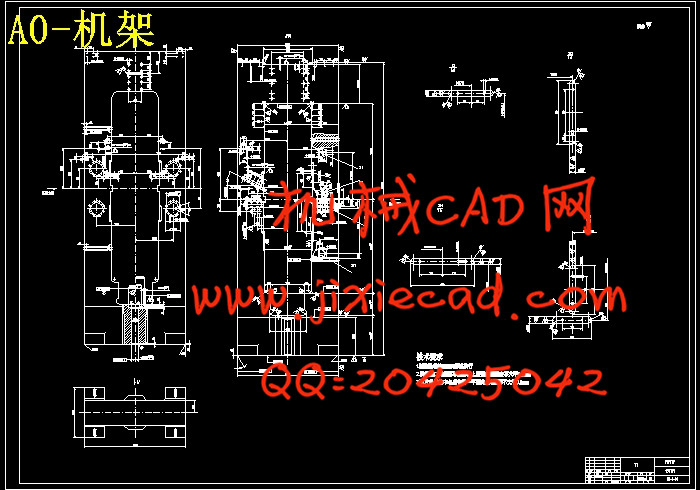

6、机架的设计校核 25

6.1机架结构参数选择 25

6.2机架的强度计算 25

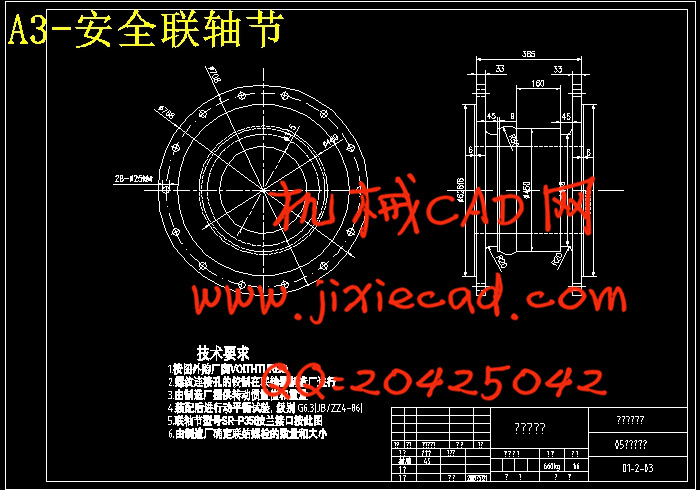

7、联接轴计算 31

7.1 万向接轴的结构尺寸 31

7.2接轴叉头应力计算 31

7.3接轴扁头应力计算 31

7.4接轴轴体的应力计算 32

8、安装、试车规程制定 32

8.1设备的安装 32

8.2设备的试车规程 33

8.2.1试运转前的准备 33

8.2.2试车步骤 34

8.2.3试运转中常见故障分析 35

8.2.4试车后的工作 36

9、设备经济性分析 36

9.1设备的可靠性 36

9.1.1可靠度的计算 36

9.1.2可靠性的计算 37

9.2设备的经济评价 37

9.2.1投资回收期 37

9.3设备的环保措施 38

总结 38

致谢 39

参考文献 40

摘要

随着工业生产的迅猛发展,我国对板带材的需求日益增加,特别是高精度冷轧薄板的生产更是供不应求,本次设计的是1500六辊冷连轧机组主传动系统,设计的该轧机能轧的最小板坯厚度达到了0.3mm,本次设计的主要思路是根据轧件原始尺寸和成品尺寸,确定轧制压下规程,从而计算轧制力和轧制力拒,选择电机,进而确定工作辊、中间辊、支承辊尺寸,并分别进行扭转、接触应力、弯曲强度校核,并对机架、联轴器进行了结构和强度计算,采用了初选结构、校核强度、校核通过则采用,不通过则再选,再校核,直到校核通过为止的基本机械设计方法。这不仅是对所学的理论知识的综合运用,也是考验思维的严谨缜密。

此外,还对设备的安装、试车、经济性分析以及冷轧机的选题背景、发展历史做了简单的介绍,在设计中根据生产实际的要求,选择了不同的设计方案实现主传动,经过比较,确定了最佳方案,对方案中的各重要部件进行结构和性能的校核,力求达到最合理的设计,满足生产的设计要求。

由于该题目是一个全新的课题,所以在设计中遇到了很多的问难,即使尽了最大的努力,得到老师、师傅的很大帮助,也难免有很多错误和考虑不全面的地方,希望大家批评指正。

关键词:1500六辊冷连轧机组,轧制力,轧制力矩,联轴器,机架

1500 six roller cold mill main drive system of the design unit

Abstract

With the rapid development of industrial production, China's plate strip increasing demand, especially in the production of high precision cold-rolled sheet is in short supply, this design is 1,500 units of six roller cold mill main drive system, design of the rolling mill to achieve the minimum slab thickness of 0.3mm, the main idea of the design is based on roll size and finished pieces of original size, determine the rolling down of order in order to estimate the rolling force and rolling force resist, select motor, to determine the work roll, intermediate roller, roller bearing size, and were reversed, contact stress, bending strength checking, and rack, coupling to the structure and strength calculation, using the primary structure, checking the strength, Checking through the use of, does not pass the re-election, re-check until the check through the date of the basic mechanical design. This is not only a theory for the integrated use of knowledge, but also the test of coherent thinking

In addition, the equipment installation, testing, analysis of economic topics, as well as the background of the cold rolling mill, a brief history of the development of the introduction, in the design in accordance with the requirements of the actual production, select a different design options to achieve the main drive, after comparison to determine the best program in the major structural components of the calibration and performance, and strive to achieve the most reasonable design, production to meet the design requirements.

Since the topic is a new subject, encountered in the design of a lot of difficult questions, even the best efforts to be a teacher, master of great help, it is inevitable that many errors and does not consider the local comprehensive, I hope all criticism.

Keywords: 1500 six roller cold rolling unit ;Rolling force ;Rolling moment ;Coupling;Rack

目 录

1、绪论 1

1.1选题背景及目的 1

1.2冷轧机发展 1

1.3板型控制 2

1.4研究内容和研究方法 3

2、传动方案评述与选择 4

2.1方案选择 4

2.2方案评述 4

2.3电机选择 5

2.4.联接轴选择 5

3、力能参数的计算 7

3.1轧制力的计算 7

3.1.1轧制规程 7

3.1.2初选轧辊材料 7

3.1.3轧辊主要参数的确定 7

3.1.4 轧制力的计算 9

3.2轧制力矩的计算 12

3.2.1 轧制力矩的计算 12

3.2.2 反力矩的计算 13

3.2.3 摩擦力矩的计算 14

4、主电机容量的选择 15

4.1初选电机功率 15

4.2轧机主电动机力矩 15

4.3各轧制阶段时间计算 17

4.3电机的校核 19

5、轧辊强度校核 20

5.1工作辊强度校核 20

5.2支承辊强度校核 21

5.3工作辊与中间辊间的接触应力校核 22

6、机架的设计校核 25

6.1机架结构参数选择 25

6.2机架的强度计算 25

7、联接轴计算 31

7.1 万向接轴的结构尺寸 31

7.2接轴叉头应力计算 31

7.3接轴扁头应力计算 31

7.4接轴轴体的应力计算 32

8、安装、试车规程制定 32

8.1设备的安装 32

8.2设备的试车规程 33

8.2.1试运转前的准备 33

8.2.2试车步骤 34

8.2.3试运转中常见故障分析 35

8.2.4试车后的工作 36

9、设备经济性分析 36

9.1设备的可靠性 36

9.1.1可靠度的计算 36

9.1.2可靠性的计算 37

9.2设备的经济评价 37

9.2.1投资回收期 37

9.3设备的环保措施 38

总结 38

致谢 39

参考文献 40