设计简介

摘 要

21世纪的钟声刚刚响过,和平与发展是当今时间发展的主体,但霸权主义和强权政治仍然存在。国与国之间的竞争更加激烈,随着知识经济和科学技术的迅猛发展,国与国之间综合国力的竞争主要体现在了科学技术的竞争。组合机床的设计、制造和应用水平是一个国家科学技术水平的重大体现。因此,近年来组合机床的设计和制造水平在我国得到了飞速的发展,组合机床的应用在我国得到的广泛的提高。

这篇毕业设计论文主要阐述了多工位孔加工小型组合机床的设计方法。这种组合机床是庞大机床家族中的一种特殊形式。该机床的设计是对大学四年来我们所学各理论知识的应用和深化,也是对我们大学四年来所学知识的检验。这次的毕业设计可以为我们即将毕业参加工作提供丰富的实践操作经验。

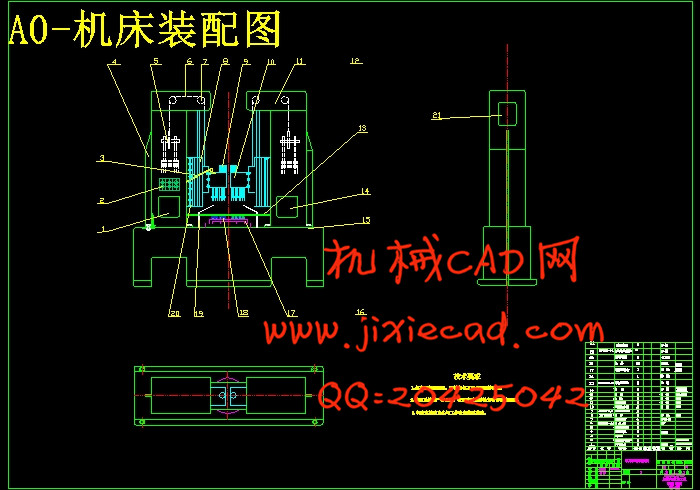

在本次毕业设计中,我主要负责机床整体部分的设计,另外还包括立柱的设计

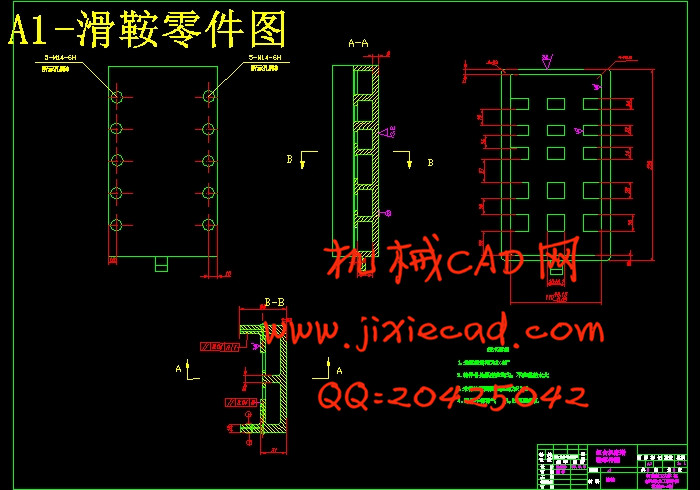

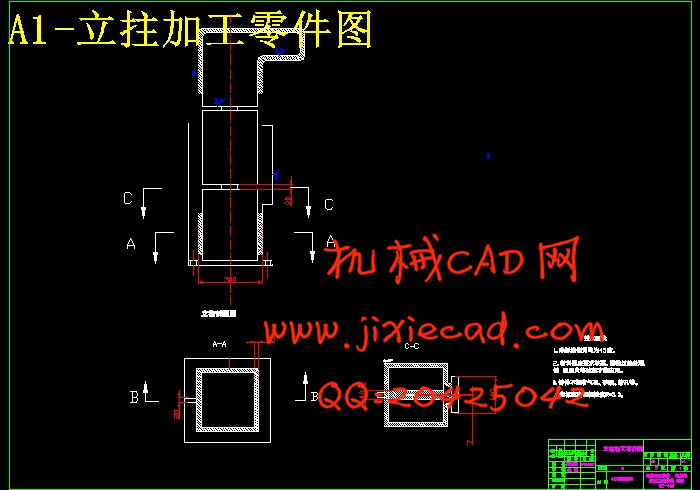

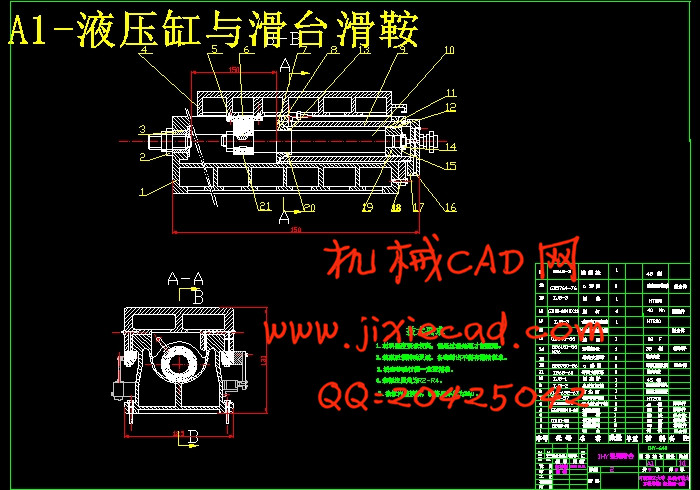

滑台的设计、滑鞍的设计、冷却系统和润滑系统的设计。在该毕业论文中,首先,我介绍了设计机床的目的——机床加工工件的加工工艺和技术要求。其次,阐述了设计机床所需注意的技术要求,机床的联系尺寸和整体样式。随后又详细地说明了机床立柱、滑台和滑鞍设计的具体过程。最后,进一步阐述了机床冷却系统和润滑系统。

近年来,虽然我国机床设计及制造技术有了长足的发展。但与国外相比,在技术上仍然存在较大的差距,尤其是在数控技术和计算机技术在组合机床上的应用方面。因此,要想确保我国科学技术的先进性和综合国力不断增强,就必须加快机床设计技术的发展,尤其加快先进科学技术在机床设计和制造技术的应用。

Abstract

21 centuries of bell just led loudly , the peace and developments are the corpuses of time development nowadays, but the hegemonism and power politicses still exist .The competition between state-to-state is more vigorous, along with the technical fast fierce development of knowledge-based economy and sciences, a competition that synthesizes the national strength main body now technical competition of science .Combine the design, manufacturing and the application levels of the tool machine are a national science techniques levels of important body now .Therefore , combined the design and the manufacturing levels of the tool machine to get the development fly soon in the our country in recent years, the application of the combination tool machine at extensive exaltation that our country get.

This graduation design thesis mainly elaborated that a bore of many works processes the design method of the small scaled combination tool machine .This kind of combination tool machine is a kind of special form within huge tool machine household .The design of that tool machine is to four in the last yearses of university each theories knowledge that we learn of application and turn deeply, also is to our knowledge that four in the last yearses of university learn of examination .This graduation design can soon graduate to attend the work to provide abundant fulfillment operation experience for us.

In this graduation design, I mainly be responsible for the tool machine design of the whole part, still including the design of sign the pillar moreover

The design of the design, cooling system and lubricate system of the design, slippery saddle of the slippery pedestal .In that graduation thesis, first, I introduced the purpose- tool machine of the design tool machine to process the work piece to process the craft and technique requests .The next in order, elaborated the advertent technique request that the design tool machine need, the contact size and whole styles of the tool machine .Explained that the tool machine signs the pillar in detail again later on, slippery pedestal and slippery concrete process that saddle design .End , further elaborated the tool machine cooling system and lubricate the system.

In recent years, although the our country tool machine design and the manufacturing techniques contain substantial development .But compared with the abroad, still exist the bigger margin on the technique, particularly is at count to control the technique and the calculator techniques at combine applied aspect on the tool machine .Therefore , to want to insure the our country forerunner that science is technical and comprehensive national strengths to strengthen continuously, must speed the technical development of the tool machine design, speed the advanced science technique to design and make the technical application in the tool machine particularly.

前 言……………………………………………………6

第一章机床总体方案设计的依据…………… ………8

1 .1概述 …………………………………………………8

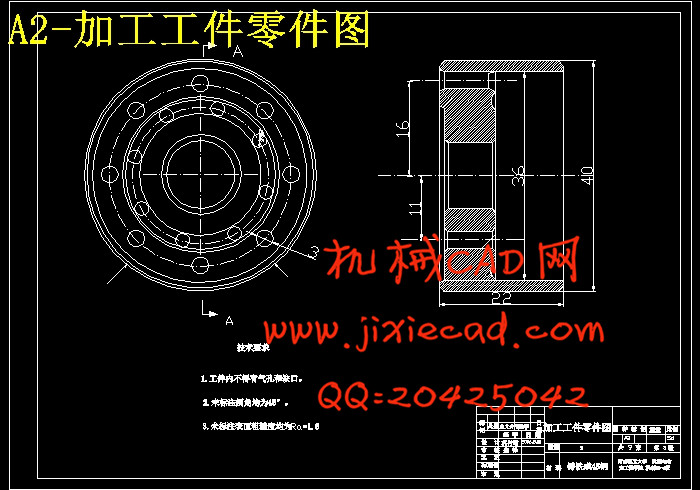

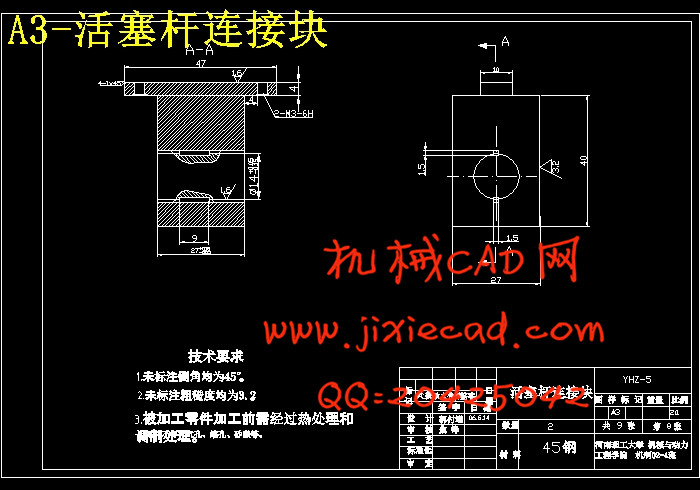

1 .2 设计工件 … ……………………………………..…. ..9

1 .3 本次毕业设计任务 ………………………………11

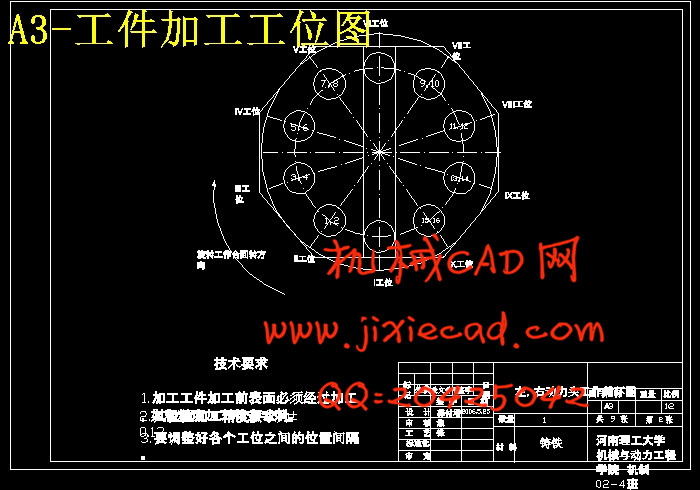

第二章工件的加工工艺分析………………………………………13

2.1 工艺方法对钻床结构和性能的影响………………………13

2.2工件夹具设计对机床加工精度的影响 ……………15

2.3 钻床的运动 ……………………………………24

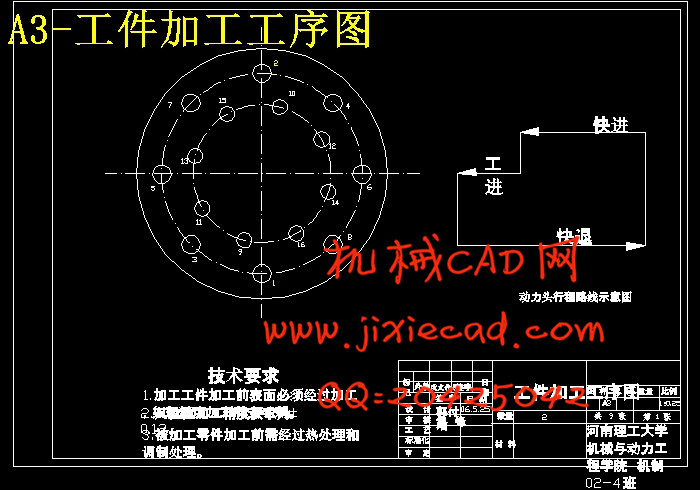

2.4绘制加工示意图 ………………………………………………27

第三章 机床的总体布局……………………………28

3 .1总体布局 ……………………………………………………………28

3 .2 运动的分配 ……………………………………29

3 .3提高加工精度………………………………………………………30

3.4缩小机床占地面积 ………………………………………………30

3.5机床的传动形式……………………………………………………30

3.6 机床的支承形式 …………………………………………………31

3.7 立柱的设计 ………………………………………………………35

3.8机床导轨的设计……………………………………………………41

3.9动力部件的驱动部分——动力滑台………………………43

3 .10 工作台的设计……………………………………………………47

第四章导轨的润滑………………………………………………………49

结束语 …………………………………………………………………………51

致谢………………………………………………………………………………52

参考文献 ……………………………………………………………………53

21世纪的钟声刚刚响过,和平与发展是当今时间发展的主体,但霸权主义和强权政治仍然存在。国与国之间的竞争更加激烈,随着知识经济和科学技术的迅猛发展,国与国之间综合国力的竞争主要体现在了科学技术的竞争。组合机床的设计、制造和应用水平是一个国家科学技术水平的重大体现。因此,近年来组合机床的设计和制造水平在我国得到了飞速的发展,组合机床的应用在我国得到的广泛的提高。

这篇毕业设计论文主要阐述了多工位孔加工小型组合机床的设计方法。这种组合机床是庞大机床家族中的一种特殊形式。该机床的设计是对大学四年来我们所学各理论知识的应用和深化,也是对我们大学四年来所学知识的检验。这次的毕业设计可以为我们即将毕业参加工作提供丰富的实践操作经验。

在本次毕业设计中,我主要负责机床整体部分的设计,另外还包括立柱的设计

滑台的设计、滑鞍的设计、冷却系统和润滑系统的设计。在该毕业论文中,首先,我介绍了设计机床的目的——机床加工工件的加工工艺和技术要求。其次,阐述了设计机床所需注意的技术要求,机床的联系尺寸和整体样式。随后又详细地说明了机床立柱、滑台和滑鞍设计的具体过程。最后,进一步阐述了机床冷却系统和润滑系统。

近年来,虽然我国机床设计及制造技术有了长足的发展。但与国外相比,在技术上仍然存在较大的差距,尤其是在数控技术和计算机技术在组合机床上的应用方面。因此,要想确保我国科学技术的先进性和综合国力不断增强,就必须加快机床设计技术的发展,尤其加快先进科学技术在机床设计和制造技术的应用。

Abstract

21 centuries of bell just led loudly , the peace and developments are the corpuses of time development nowadays, but the hegemonism and power politicses still exist .The competition between state-to-state is more vigorous, along with the technical fast fierce development of knowledge-based economy and sciences, a competition that synthesizes the national strength main body now technical competition of science .Combine the design, manufacturing and the application levels of the tool machine are a national science techniques levels of important body now .Therefore , combined the design and the manufacturing levels of the tool machine to get the development fly soon in the our country in recent years, the application of the combination tool machine at extensive exaltation that our country get.

This graduation design thesis mainly elaborated that a bore of many works processes the design method of the small scaled combination tool machine .This kind of combination tool machine is a kind of special form within huge tool machine household .The design of that tool machine is to four in the last yearses of university each theories knowledge that we learn of application and turn deeply, also is to our knowledge that four in the last yearses of university learn of examination .This graduation design can soon graduate to attend the work to provide abundant fulfillment operation experience for us.

In this graduation design, I mainly be responsible for the tool machine design of the whole part, still including the design of sign the pillar moreover

The design of the design, cooling system and lubricate system of the design, slippery saddle of the slippery pedestal .In that graduation thesis, first, I introduced the purpose- tool machine of the design tool machine to process the work piece to process the craft and technique requests .The next in order, elaborated the advertent technique request that the design tool machine need, the contact size and whole styles of the tool machine .Explained that the tool machine signs the pillar in detail again later on, slippery pedestal and slippery concrete process that saddle design .End , further elaborated the tool machine cooling system and lubricate the system.

In recent years, although the our country tool machine design and the manufacturing techniques contain substantial development .But compared with the abroad, still exist the bigger margin on the technique, particularly is at count to control the technique and the calculator techniques at combine applied aspect on the tool machine .Therefore , to want to insure the our country forerunner that science is technical and comprehensive national strengths to strengthen continuously, must speed the technical development of the tool machine design, speed the advanced science technique to design and make the technical application in the tool machine particularly.

前 言……………………………………………………6

第一章机床总体方案设计的依据…………… ………8

1 .1概述 …………………………………………………8

1 .2 设计工件 … ……………………………………..…. ..9

1 .3 本次毕业设计任务 ………………………………11

第二章工件的加工工艺分析………………………………………13

2.1 工艺方法对钻床结构和性能的影响………………………13

2.2工件夹具设计对机床加工精度的影响 ……………15

2.3 钻床的运动 ……………………………………24

2.4绘制加工示意图 ………………………………………………27

第三章 机床的总体布局……………………………28

3 .1总体布局 ……………………………………………………………28

3 .2 运动的分配 ……………………………………29

3 .3提高加工精度………………………………………………………30

3.4缩小机床占地面积 ………………………………………………30

3.5机床的传动形式……………………………………………………30

3.6 机床的支承形式 …………………………………………………31

3.7 立柱的设计 ………………………………………………………35

3.8机床导轨的设计……………………………………………………41

3.9动力部件的驱动部分——动力滑台………………………43

3 .10 工作台的设计……………………………………………………47

第四章导轨的润滑………………………………………………………49

结束语 …………………………………………………………………………51

致谢………………………………………………………………………………52

参考文献 ……………………………………………………………………53