设计简介

DF-300多层纸复合机组裁切部分设计

摘 要

这次设计的目的是设计出一套能够生产高质量防渗漏纸垫的机械设备.这次设计包括各种传动装置的选择与设计计算,还有气缸的计算选择,电动机,减速器的选择.

首先是功率的分配.牵引所需要的功率是由主电机分配而来,切纸所需要的功率由一个调速电机经过减速装置后直接提供.传动方面包括链轮的设计,根据所需要的功率以及转速选择合适的链轮型号以及合适的中心距.在各个传动装置之间合理地分配传动比,既要求严格地完成各种功能要求,包括精度等技术要求,还要在此基础上尽量地减少设计制造的成本.使用气缸控制线压力,可以保持压力的准确,也减少了工人的劳动强度.节省了人力资源,减速器的选用使传动结构大为简化,使设计的机械更轻便.

关键词:比较,传动,气缸,结构

DF-300 Multilayer Laminating Paper Cutting Part Cutting Part Of The Design

Abstract

The aim of the design is to design a machine that can produce high quality paper mat that can defend percolation. The design contains the comparison of the moving device, and the design calculation of the air cylinder, and the choice of the electric motor, decelerating machine.

First,the allotment of the power. The power which lead the paper to move is branches from the main electric motor, at the same time, the power what the cutting part need is from a motor which can change its speed. The moving device contains the design of the chain, according to the power needed and the speed to choose the suitable chains. To allotment the suitable number between different device. The machine should complete various of functions including the accuracy requested, on this foundation, decrease the cost of design and the manufacturing as far as possible. I use two air cylinder to control the pressure between two stalks, and also reduce the worker's labor strength, so save the human resource, I use a Decelerating machine to make the moving structure greatly simplification, making the design of the machine more easy and convenient.

Key words : comparison,moving, air cylinder,structure

目 录

1 绪 论 1

1.1 课题的提出 1

2 方案论证 3

3 调速电机的选用 5

3.1辊刀切纸功率的计算 5

3.2减速器的选择 7

3.3调速电机的选择 9

4链轮的设计 10

4.1连接减速器输出轴与辊刀轴的链轮的设计 10

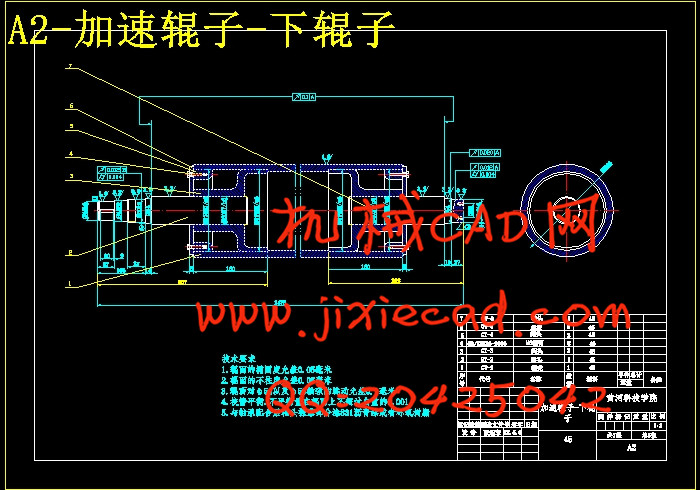

4.2两辊子之间的链轮 15

4.2.1加速辊子功率以及转速的计算 15

4.2.2 同步辊子的选择及功率计算 16

5 同步带轮的选择 21

6辊筒 26

6.1滚筒的设计 26

6.1.1滚筒的结构 26

6.1.2辊筒的机械加工工艺: 26

6.2 滚筒的挠度计算 28

6.3 辊筒轴颈的强度校核 30

6.3.1校核a-a截面 30

6.3.2 校合b-b截面 31

7气缸 32

8 轴 34

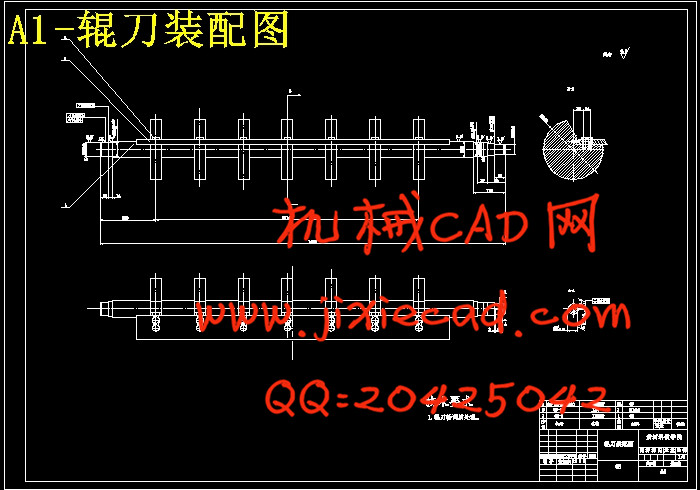

8.1 辊刀轴 34

8.1.1 辊刀轴结构设计 34

8.1.2 辊刀轴的强度校核 34

8.2 轴上键的选择 35

8.3 滚动轴承的选择 36

结 论 38

总 结 39

致 谢 40

参考文献 41

摘 要

这次设计的目的是设计出一套能够生产高质量防渗漏纸垫的机械设备.这次设计包括各种传动装置的选择与设计计算,还有气缸的计算选择,电动机,减速器的选择.

首先是功率的分配.牵引所需要的功率是由主电机分配而来,切纸所需要的功率由一个调速电机经过减速装置后直接提供.传动方面包括链轮的设计,根据所需要的功率以及转速选择合适的链轮型号以及合适的中心距.在各个传动装置之间合理地分配传动比,既要求严格地完成各种功能要求,包括精度等技术要求,还要在此基础上尽量地减少设计制造的成本.使用气缸控制线压力,可以保持压力的准确,也减少了工人的劳动强度.节省了人力资源,减速器的选用使传动结构大为简化,使设计的机械更轻便.

关键词:比较,传动,气缸,结构

DF-300 Multilayer Laminating Paper Cutting Part Cutting Part Of The Design

Abstract

The aim of the design is to design a machine that can produce high quality paper mat that can defend percolation. The design contains the comparison of the moving device, and the design calculation of the air cylinder, and the choice of the electric motor, decelerating machine.

First,the allotment of the power. The power which lead the paper to move is branches from the main electric motor, at the same time, the power what the cutting part need is from a motor which can change its speed. The moving device contains the design of the chain, according to the power needed and the speed to choose the suitable chains. To allotment the suitable number between different device. The machine should complete various of functions including the accuracy requested, on this foundation, decrease the cost of design and the manufacturing as far as possible. I use two air cylinder to control the pressure between two stalks, and also reduce the worker's labor strength, so save the human resource, I use a Decelerating machine to make the moving structure greatly simplification, making the design of the machine more easy and convenient.

Key words : comparison,moving, air cylinder,structure

目 录

1 绪 论 1

1.1 课题的提出 1

2 方案论证 3

3 调速电机的选用 5

3.1辊刀切纸功率的计算 5

3.2减速器的选择 7

3.3调速电机的选择 9

4链轮的设计 10

4.1连接减速器输出轴与辊刀轴的链轮的设计 10

4.2两辊子之间的链轮 15

4.2.1加速辊子功率以及转速的计算 15

4.2.2 同步辊子的选择及功率计算 16

5 同步带轮的选择 21

6辊筒 26

6.1滚筒的设计 26

6.1.1滚筒的结构 26

6.1.2辊筒的机械加工工艺: 26

6.2 滚筒的挠度计算 28

6.3 辊筒轴颈的强度校核 30

6.3.1校核a-a截面 30

6.3.2 校合b-b截面 31

7气缸 32

8 轴 34

8.1 辊刀轴 34

8.1.1 辊刀轴结构设计 34

8.1.2 辊刀轴的强度校核 34

8.2 轴上键的选择 35

8.3 滚动轴承的选择 36

结 论 38

总 结 39

致 谢 40

参考文献 41