设计简介

双动薄板冲压机液压系统设计

摘 要

随着航天、汽车、轮船等钣金件工业的不断进步,市场对薄板质量的需求越来越高,对薄板的冲压性能也越来越高,不仅要求生产效率的提高,生产质量更要求严格。因此,薄板冲压机对钣金件冲裁、拉伸、成形、弯曲、校正等加工工艺中起到非常重要,同时也能起到提高生产效率和生产质量。

近年来,我国的工程机械取得了蓬勃的发展,其中, 液压传动技术起到了至关重要的作用。而且,随着液压传动技术的快速发展和广泛应用,它已成为下业机械、下程建筑机械等行业小可缺少的重要技术。然而,尽管液压技术在机械能与压力能的转换已取得很大进展,但它在能量损失和传动效率上仍然存在着问题。因为,在液压系统中,随着油液的流动,有相当多的液体能量损失掉,这种能量损失不仅体现在油液流动过程中的内摩擦损失上,还反映在系统的容积损失上,使系统能量利用率降低,传动效率无法提高。高能耗和低效率又使油液发热增加,使性能达不到理想的状况,给液压技术的进一步发展带来障。因此,探索和研究高效液压传动技术,提高其综合性能就成为了液压技术领域研究的重点之一。

关键词:钣金件;工程机械 ;损失;高效

Double action thin steel plate punch press hydraulic system design

Abstract

Along with sheet metal industry's and so on astronautics, automobile, steamboat unceasing progresses, the market is getting higher and higher to the thin steel plate quality's demand, is also getting higher and higher to the thin steel plate ramming performance, not only the request production efficiency's enhancement, the production quality requests strictly. Therefore, the thin steel plate punch press to the sheet metal blanking, the stretch, the forming, curving, processing crafts and so on adjustment gets up is important, simultaneously can also have the enhancement production efficiency and the production quality.

the recent years, our country's engineering machinery has made the vigorous progress, the hydraulic transmission technology played the role which wanted very important. Moreover, along with the hydraulic transmission technology's fast development and the widespread application, it has become the important technology which industry the machinery, professions and so on farewell gift of food construction machinery small may lack. However, although the hydraulic technique has made the very big progress in the mechanical energy and the pressure energy transformation, but it still has the problem in the energy loss and the transmission efficiency. Because, in the hydraulic system, along with the fat liquor flowing, has the quite many liquid energy loss, this kind of energy loss not only manifests in the fat liquor flowing process in the internal friction loss, but also reflected that in system's volumetric loss, causes the system energy use factor to reduce, the transmission efficiency is unable to enhance. Gao Nenghao and the low efficiency cause the fat liquor to give off heat increase, enable the performance not to be able to achieve the ideal condition, brings for hydraulic technique's further development bonds. Therefore, the exploration and the research highly effective hydraulic transmission technology, enhanced its overall performance to become one of hydraulic technique area research key.

目 录

1 绪论 1

1.1 课题提出的背景及目的 1

1.2 液压系统的优点和缺点及发展趋势 2

1.2.1 液压系统的优点 2

1.2.2 液压系统的缺点 2

1.2.3 液压系统发展趋势 2

2 双动薄板冲压机液压系统的参数 5

2.1 动作要求 5

2.2 给定参数 5

3 制定基本方案和绘制液压系统图 7

3.1 制定基本方案 7

3.2 绘制液压系统图 7

3.3 液压系统工作原理 8

4初步确定液压系统参数 9

4.1 液压缸参数的计算与选用 9

4.1.1受力分析 9

4.1.2 初选系统工作压力 13

4.1.3 计算缸的主要结构尺寸 14

4.1.4 计算活塞缸所需流量 16

4.1.5 计算柱塞缸所需流量 17

4.2 液压泵的选择 18

4.2.1 确定液压泵的最大工作压力 18

4.2.2 确定液压泵的的流量 19

4.2.3 选择液压泵的规格 19

4.3 选择电动机 19

4.4 液压阀的选择 20

4.4.1 溢流阀的选择 20

4.4.2 换向阀的选择 21

4.4.3 节流阀的选择 23

4.4.4 单向阀的选择 24

4.5 液压辅助元件的选择及计算 26

4.5.1 蓄能器的设计 26

4.5.2 管道尺寸的计算 27

4.5.3 液压管及管接头的选择 28

4.5.4 过滤器的选择 29

4.5.5 油箱的初步选择 29

4.5.6 压力表的选择 31

4.5.7 过滤器的选择 31

5 性能验算 32

5.1 验算液压系统性能 32

5.1.1管路沿程压力损失 32

5.2 液压系统发热温升计算 33

5.2.1 计算液压系统的发热功率 33

6 液压站的设计 36

6.1 液压站的设计概述 36

6.2 液压站结构设计的注意事项 37

7 环保性、经济性以及安全性分析 38

7.1 环保性分析 38

7.1.1 污染控制 38

7.1.2 泄漏控制 39

7.2 经济性分析 41

7.3 安全性分析 41

结论 43

感谢 44

参考文献 45

摘 要

随着航天、汽车、轮船等钣金件工业的不断进步,市场对薄板质量的需求越来越高,对薄板的冲压性能也越来越高,不仅要求生产效率的提高,生产质量更要求严格。因此,薄板冲压机对钣金件冲裁、拉伸、成形、弯曲、校正等加工工艺中起到非常重要,同时也能起到提高生产效率和生产质量。

近年来,我国的工程机械取得了蓬勃的发展,其中, 液压传动技术起到了至关重要的作用。而且,随着液压传动技术的快速发展和广泛应用,它已成为下业机械、下程建筑机械等行业小可缺少的重要技术。然而,尽管液压技术在机械能与压力能的转换已取得很大进展,但它在能量损失和传动效率上仍然存在着问题。因为,在液压系统中,随着油液的流动,有相当多的液体能量损失掉,这种能量损失不仅体现在油液流动过程中的内摩擦损失上,还反映在系统的容积损失上,使系统能量利用率降低,传动效率无法提高。高能耗和低效率又使油液发热增加,使性能达不到理想的状况,给液压技术的进一步发展带来障。因此,探索和研究高效液压传动技术,提高其综合性能就成为了液压技术领域研究的重点之一。

关键词:钣金件;工程机械 ;损失;高效

Double action thin steel plate punch press hydraulic system design

Abstract

Along with sheet metal industry's and so on astronautics, automobile, steamboat unceasing progresses, the market is getting higher and higher to the thin steel plate quality's demand, is also getting higher and higher to the thin steel plate ramming performance, not only the request production efficiency's enhancement, the production quality requests strictly. Therefore, the thin steel plate punch press to the sheet metal blanking, the stretch, the forming, curving, processing crafts and so on adjustment gets up is important, simultaneously can also have the enhancement production efficiency and the production quality.

the recent years, our country's engineering machinery has made the vigorous progress, the hydraulic transmission technology played the role which wanted very important. Moreover, along with the hydraulic transmission technology's fast development and the widespread application, it has become the important technology which industry the machinery, professions and so on farewell gift of food construction machinery small may lack. However, although the hydraulic technique has made the very big progress in the mechanical energy and the pressure energy transformation, but it still has the problem in the energy loss and the transmission efficiency. Because, in the hydraulic system, along with the fat liquor flowing, has the quite many liquid energy loss, this kind of energy loss not only manifests in the fat liquor flowing process in the internal friction loss, but also reflected that in system's volumetric loss, causes the system energy use factor to reduce, the transmission efficiency is unable to enhance. Gao Nenghao and the low efficiency cause the fat liquor to give off heat increase, enable the performance not to be able to achieve the ideal condition, brings for hydraulic technique's further development bonds. Therefore, the exploration and the research highly effective hydraulic transmission technology, enhanced its overall performance to become one of hydraulic technique area research key.

目 录

1 绪论 1

1.1 课题提出的背景及目的 1

1.2 液压系统的优点和缺点及发展趋势 2

1.2.1 液压系统的优点 2

1.2.2 液压系统的缺点 2

1.2.3 液压系统发展趋势 2

2 双动薄板冲压机液压系统的参数 5

2.1 动作要求 5

2.2 给定参数 5

3 制定基本方案和绘制液压系统图 7

3.1 制定基本方案 7

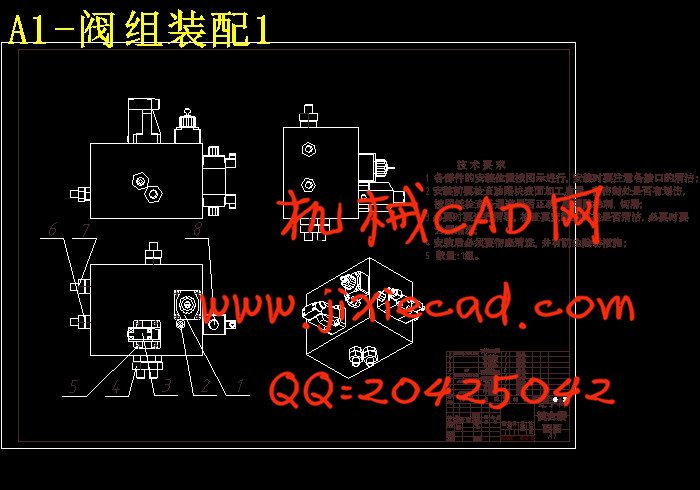

3.2 绘制液压系统图 7

3.3 液压系统工作原理 8

4初步确定液压系统参数 9

4.1 液压缸参数的计算与选用 9

4.1.1受力分析 9

4.1.2 初选系统工作压力 13

4.1.3 计算缸的主要结构尺寸 14

4.1.4 计算活塞缸所需流量 16

4.1.5 计算柱塞缸所需流量 17

4.2 液压泵的选择 18

4.2.1 确定液压泵的最大工作压力 18

4.2.2 确定液压泵的的流量 19

4.2.3 选择液压泵的规格 19

4.3 选择电动机 19

4.4 液压阀的选择 20

4.4.1 溢流阀的选择 20

4.4.2 换向阀的选择 21

4.4.3 节流阀的选择 23

4.4.4 单向阀的选择 24

4.5 液压辅助元件的选择及计算 26

4.5.1 蓄能器的设计 26

4.5.2 管道尺寸的计算 27

4.5.3 液压管及管接头的选择 28

4.5.4 过滤器的选择 29

4.5.5 油箱的初步选择 29

4.5.6 压力表的选择 31

4.5.7 过滤器的选择 31

5 性能验算 32

5.1 验算液压系统性能 32

5.1.1管路沿程压力损失 32

5.2 液压系统发热温升计算 33

5.2.1 计算液压系统的发热功率 33

6 液压站的设计 36

6.1 液压站的设计概述 36

6.2 液压站结构设计的注意事项 37

7 环保性、经济性以及安全性分析 38

7.1 环保性分析 38

7.1.1 污染控制 38

7.1.2 泄漏控制 39

7.2 经济性分析 41

7.3 安全性分析 41

结论 43

感谢 44

参考文献 45